A large-diameter pile self-reaction force detection device convenient for concrete pouring

A detection device and a large-diameter technology, which is applied in basic structure testing, construction, and basic structure engineering, etc., can solve problems such as uncompacted concrete pouring, and achieve the effects of convenient pouring, accurate bearing capacity detection, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

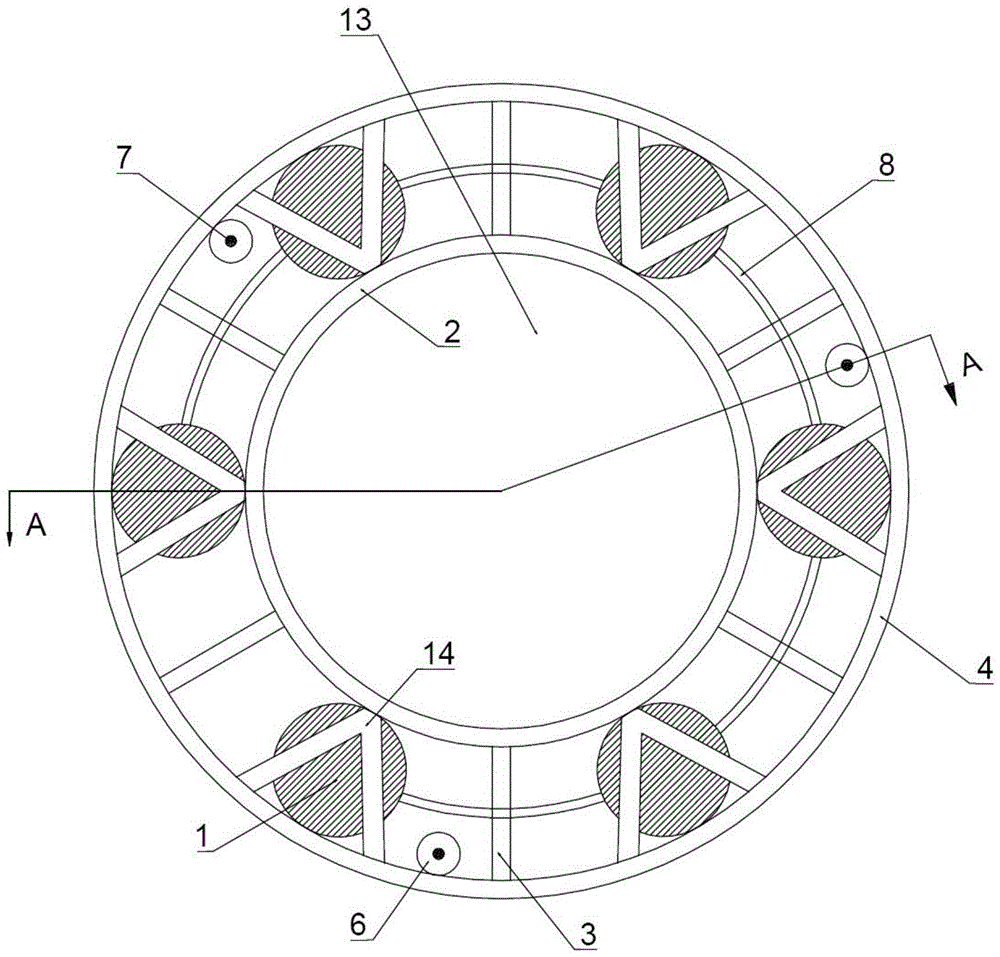

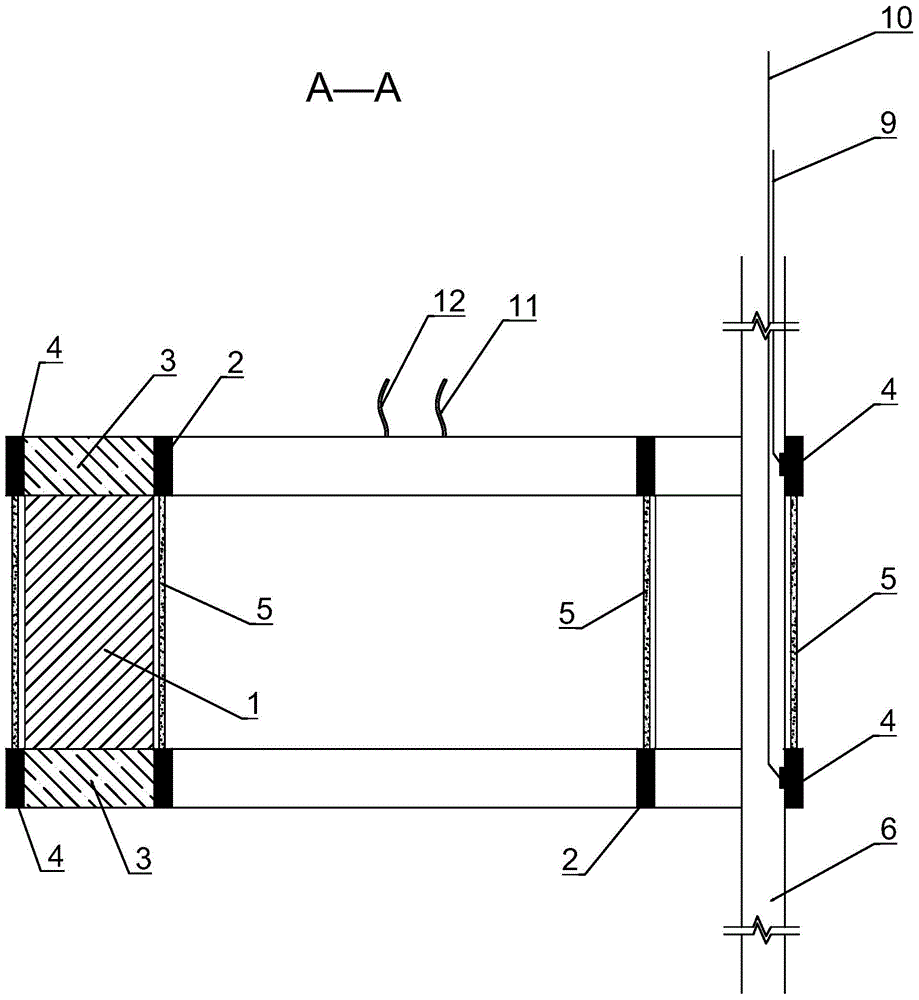

[0022] The specific embodiment of the present invention will be described in further detail below in conjunction with the drawings, wherein the same symbols in all the drawings represent the same or similar components, and the drawings in the description are in simplified form and are only for understanding the specific structure of the present invention. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

[0023] like figure 1 , figure 2 As shown, a large-diameter pile self-reflexive force detection device that is convenient for concrete pouring includes an upper steel frame and a lower steel frame, and several jacks 1 are fixedly arranged between the upper steel frame and the lower steel frame, and the upper steel frame The same as the lower steel skeleton structure, both are annular structures, and the center is a circular through hole 13. The ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com