Bearing capacity detection equipment adaptive to heavy truck transmission shafts with different diameter specifications

A technology for testing equipment and transmission shafts, which is applied in the testing of mechanical parts, the testing of machine/structural parts, and measuring devices, etc. Guaranteed effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

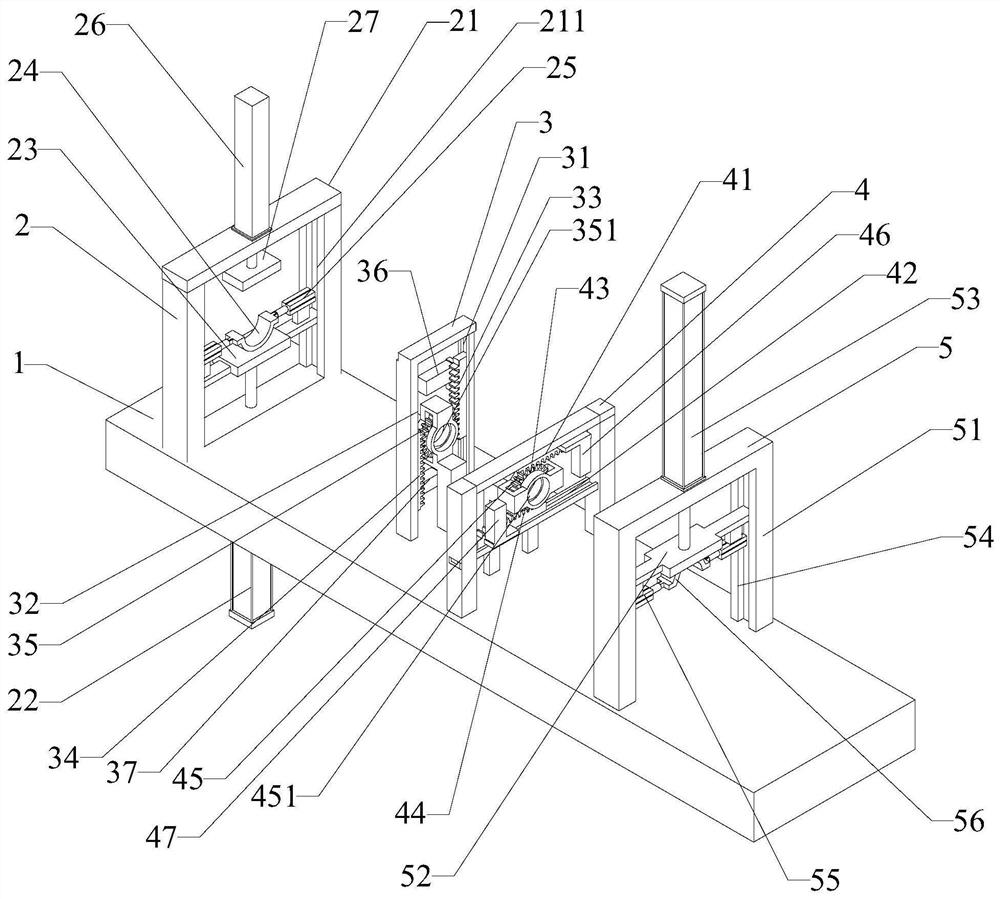

[0035] A bearing capacity testing device adapted to heavy truck transmission shafts of different diameters, including a frame 1, a first centering and positioning device 2, a second centering and positioning device 3, a third centering and positioning device 4, and a pressure applying device 5 ; The first centering and positioning device 2, the second centering and positioning device 3, the third centering and positioning device 4 and the pressing device 5 are sequentially arranged in a line and connected to the frame 1; the first centering and positioning device 2 includes a first support 21, a first hydraulic cylinder 22, a first sliding seat 23, a first flexible arc pad 24, a first adjustment cylinder 25, a second hydraulic cylinder 26 and a pressure plate 27; the first support 21 is provided with The first vertical slide rail 211, the first sliding seat 23 is slidably connected with the first vertical slide rail 211, the first hydraulic cylinder 22 is vertically fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com