Bearing capacity detection device of heavy truck transmission shaft

A detection device and transmission shaft technology, which is applied in the field of hoisting fixtures, can solve the problems of large man-hours for transmission shafts, bending and fracture of transmission shafts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

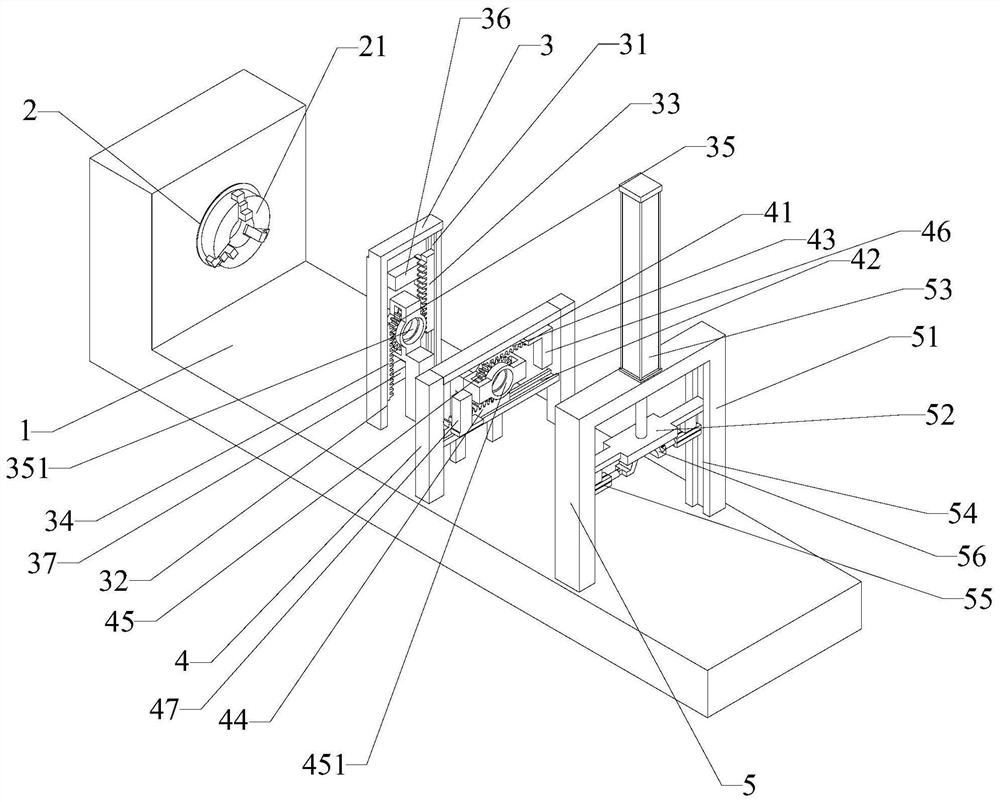

[0036] A bearing capacity detection device for a heavy truck transmission shaft, comprising a frame 1, a first centering and positioning device 2, a second centering and positioning device 3, a third centering and positioning device 4 and a pressure applying device 5; The centering and positioning device 2, the second centering and positioning device 3, the third centering and positioning device 4 and the pressure applying device 5 are sequentially arranged in a line and connected to the frame 1; the first centering and positioning device 2 is a three-jaw chuck 21. The second centering and positioning device 3 includes a first vertical guide rail 31, a second vertical guide rail 32, a first rack 33, a second rack 34, a first gear 35, a first clamping block 36, a first Two clamping blocks 37 and the first driving device; the first rack 33 is slidably connected to the first vertical guide rail 31, the second rack 34 is slidably connected to the second vertical guide rail 32, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com