Safety ladder assembly on ship

A ladder frame and safety technology, applied in the direction of ladders, buildings, building structures, etc., can solve the problems of large space occupation, low safety performance, and inability to fully ensure the phenomenon of vibrating slides, so as to reduce the occupied space and improve safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

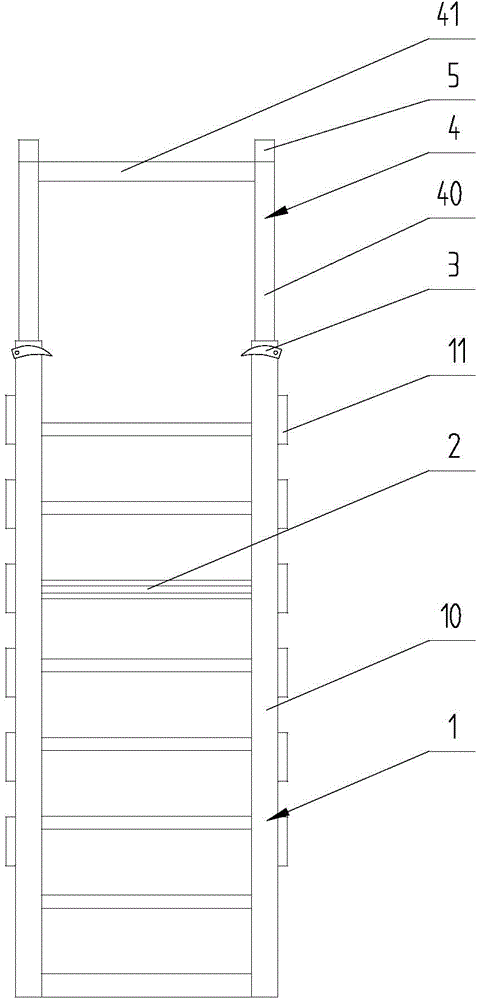

[0010] See figure 1 , the present invention includes a ladder frame 1 and an inclined ladder 2, the top of the ladder frame 1 is connected to a telescopic frame 4, and the top of the telescopic frame 4 is fixedly connected to a hook 5. The telescopic frame 4 includes vertical rods 40 and crossbeams 41 connected between the vertical rods 40, the vertical rods 40 on both sides are sleeved in the two side rods 10 of the ladder frame 1, and are fastened by means of the pull button 3; in order to improve safety, the ladder frame A plurality of rubber sleeves 11 are affixed on the side bar of 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com