Device and method for testing high-temperature fatigue performance of micro-components under combined stress

A fatigue performance testing, composite stress technology, applied in the direction of using stable bending force to test material strength, using stable tension/pressure to test material strength, etc., can solve problems such as the test content of a single load mode, to improve service Reliability and stability, compact structure, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

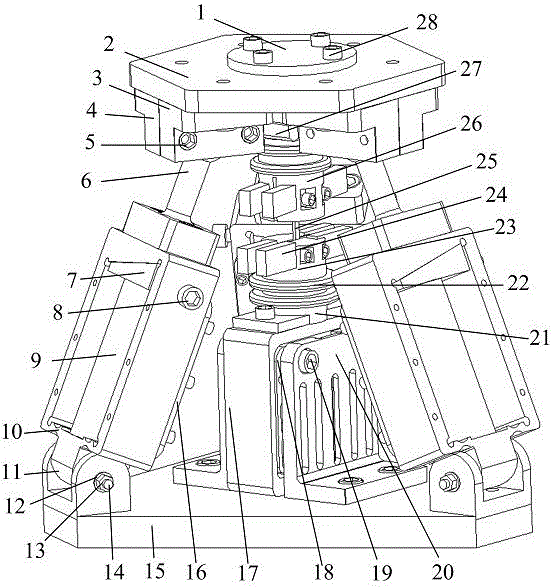

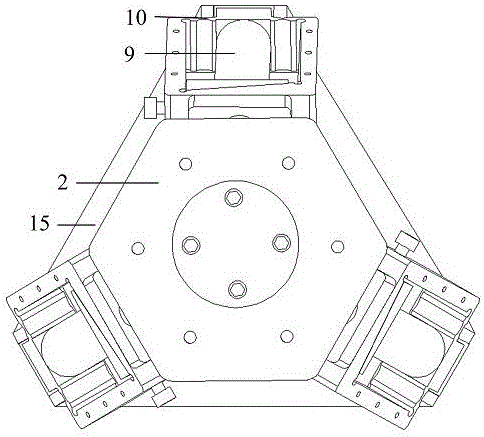

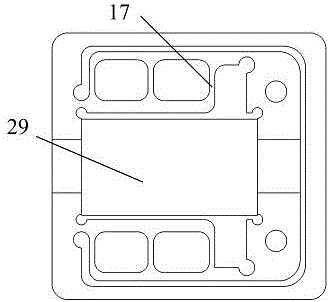

[0028] see Figure 1 to Figure 6 As shown, the high-temperature fatigue performance testing device and method of micro-components under composite stress of the present invention include a piezoelectric three-degree-of-freedom loading unit, a high-temperature loading and water cooling unit, a piezoelectric tensile loading unit, a detection unit and a support unit. Among them, the multi-load flexible hinge 10 in the piezoelectric three-degree-of-freedom loading unit is integrated with the rotating pair 11 in the supporting unit, and the moving end 6 of the spherical pair is connected to the fixed bracket 3 of the spherical pair and the movable bracket 4 of the spherical pair in the supporting unit. Spherical concavities maintain spherical contact. The silicon nitride heating plate 24 in the high temperature loading...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com