Ring groove rivet connection pair with function of adjusting initial pre-tightening force and installation method

A ring groove rivet and connecting pair technology, applied in rivets and other directions, can solve the problems of inability to adjust the pre-tightening force according to the actual situation, deviation of the installation hole, inconvenient use, etc., to facilitate subsequent installation operations, good pre-tightening force, and convenient on-site The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the specific embodiments, which further illustrate the principles of the present invention and do not limit the present invention in any way, and the same or similar technologies as the present invention do not exceed the protection scope of the present invention.

[0032] In conjunction with the attached drawings.

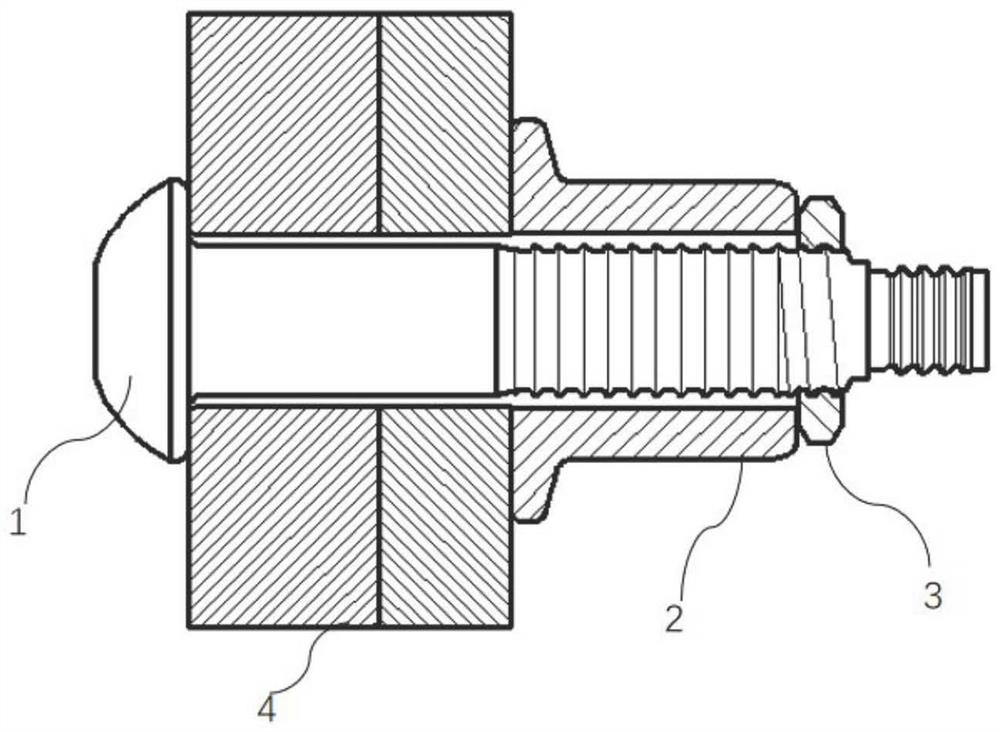

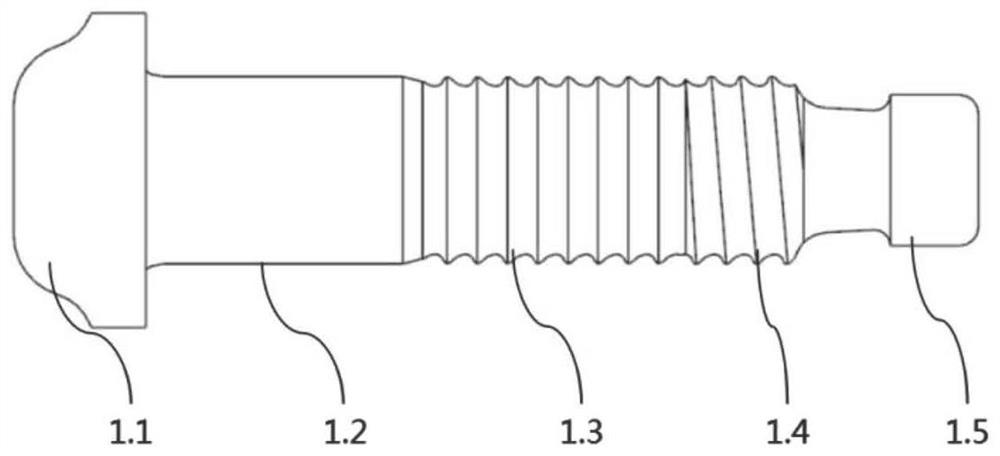

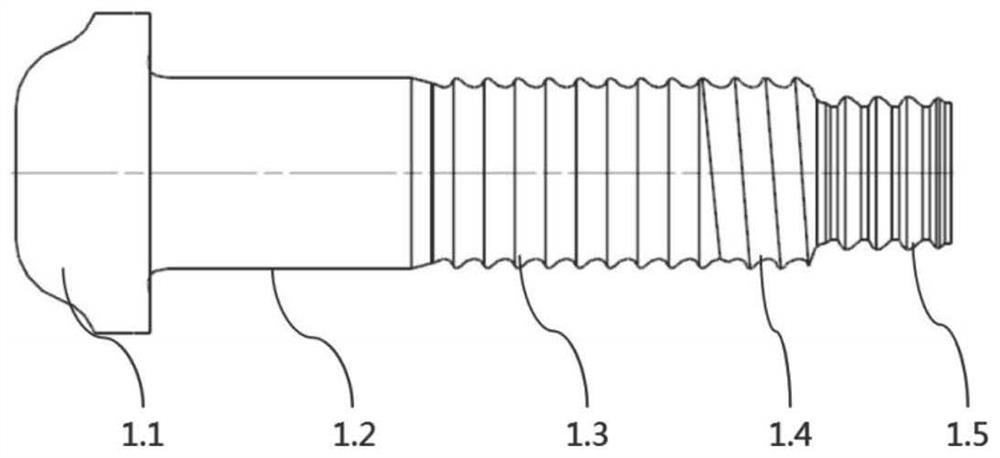

[0033] As shown in the figure, a ring groove rivet connection pair with an adjustable initial preload function includes a rivet 1 and a collar 2. The rivet 1 sequentially includes a rivet cap head 1.1, a polished rod 1.2, a ring groove locking area 1.3, a screw Slot 1.4, tail fixing structure 1.5; collar 2 includes flange 2.3 and deformation zone 2.1 in sequence; the connection pair also includes a preload nut 3 located at the outer end of the collar during riveting and tightening; wherein, the rivet spiral groove 1.4 has the same The tightening nut 3 is fitted with the tightened thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com