socket installation box

A technology for installing boxes and sockets, applied in the direction of coupling devices, parts of connecting devices, electrical components, etc., can solve the problems that cables are not easy to fix, and bottom boxes are not easy to install, and achieve the effect of simple structure and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

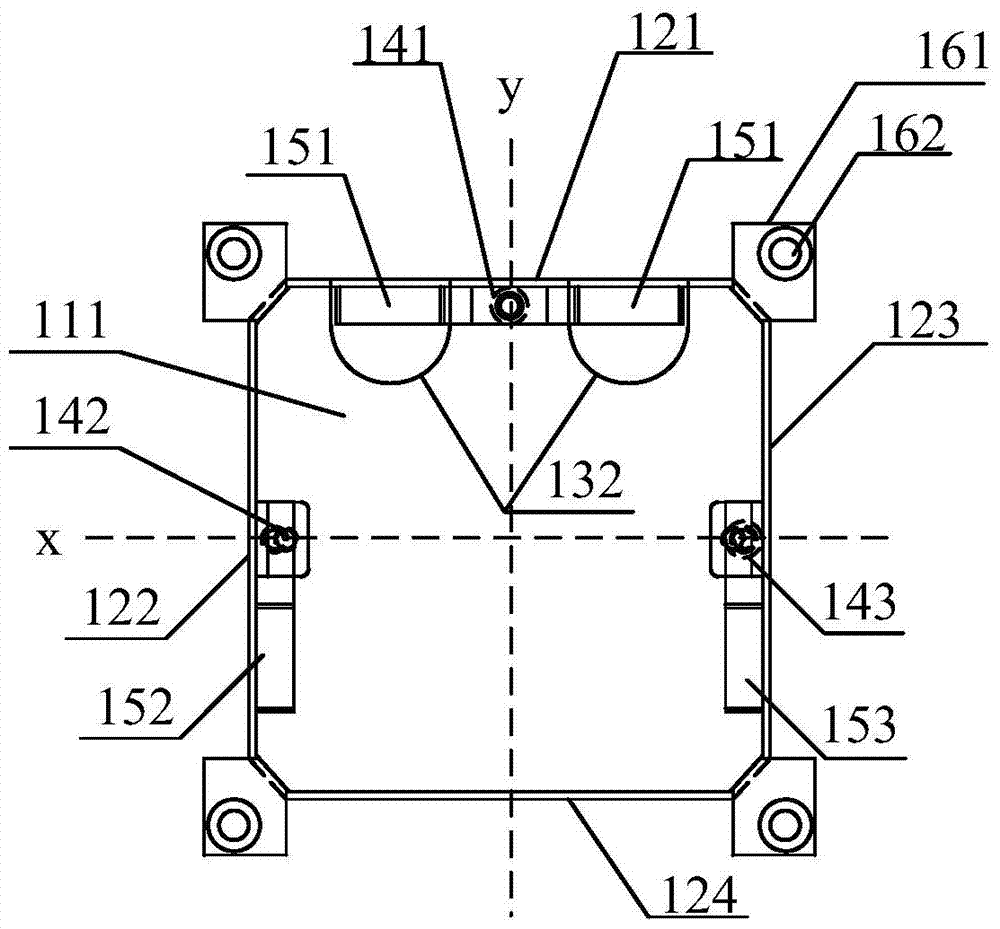

[0025] see Figure 1-6 , a socket installation box includes: a bottom box 11 embedded in the wall and a cover plate 12 formed with an insertion hole, the cover plate is buckled on the bottom box 11.

[0026] see Figure 1-3 , the bottom box 11 is a cuboid, which is formed by fixing a bottom plate 111 and four side plates, and these side plates are respectively the first side plate 121, the second side plate 122, the third side plate 123 and the fourth side plate plate 124. The bottom plate is 111 square, the first side plate 121 , the second side plate 122 , the third side plate 123 and the fourth side plate 124 are sequentially connected, and these side plates are respectively perpendicular to the bottom plate 111 .

[0027] figure 1 The first centerline y and the second centerline x of the bottom plate 111 are shown in , and the first centerline y and the second centerline x are perpendicular.

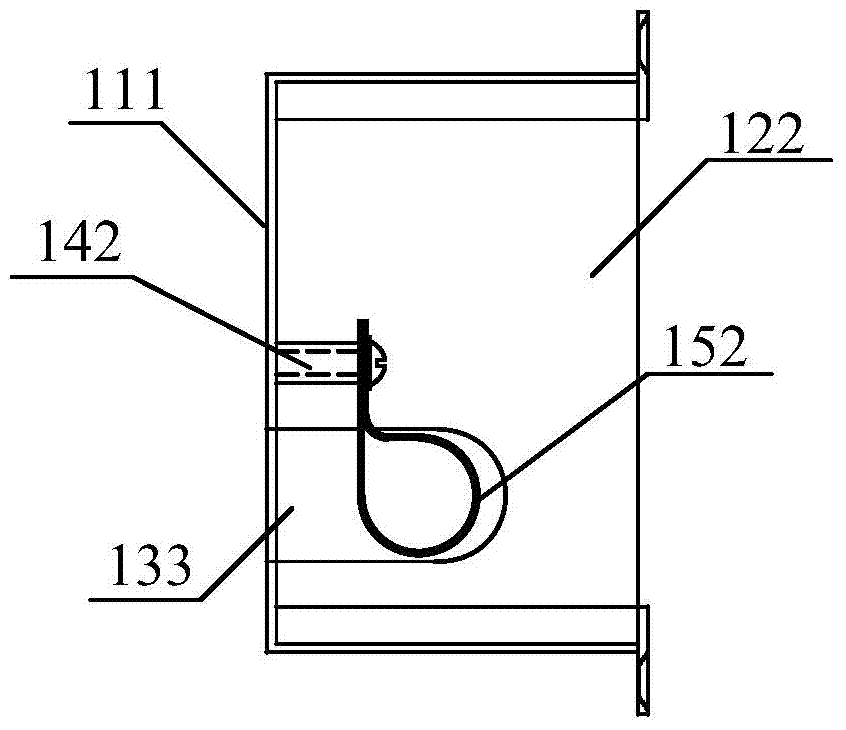

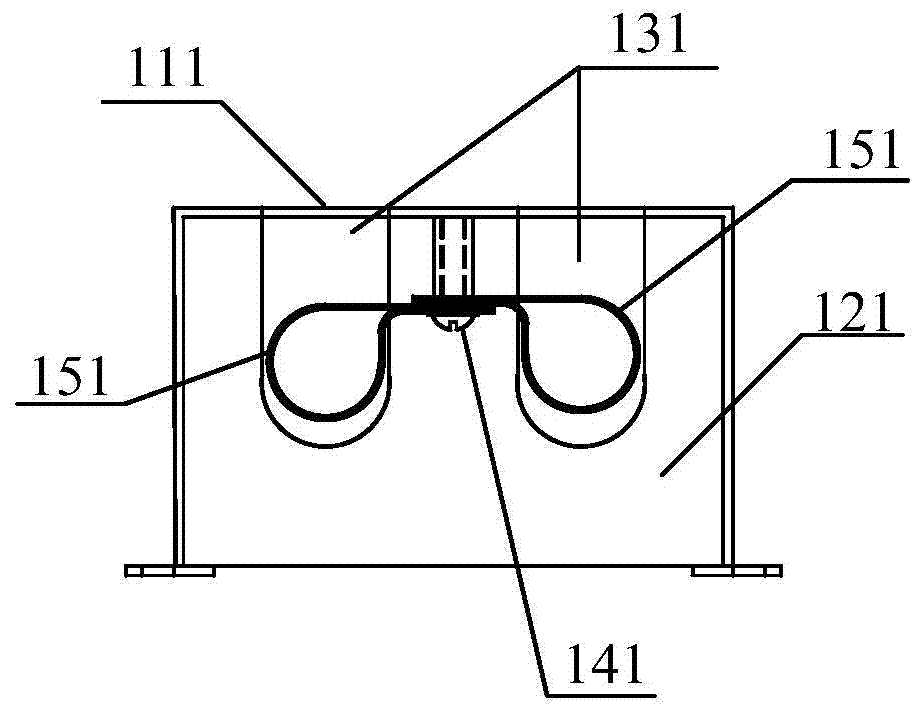

[0028] see image 3 , Two first wire inlet holes 131 are opened on the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com