Hydraulic attitude adjustment sorting device

A sorting device and posture adjustment technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of low sorting quality, unsuitable for large-scale factory production, and difficulty in realizing full automation, so as to achieve the effect of material sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

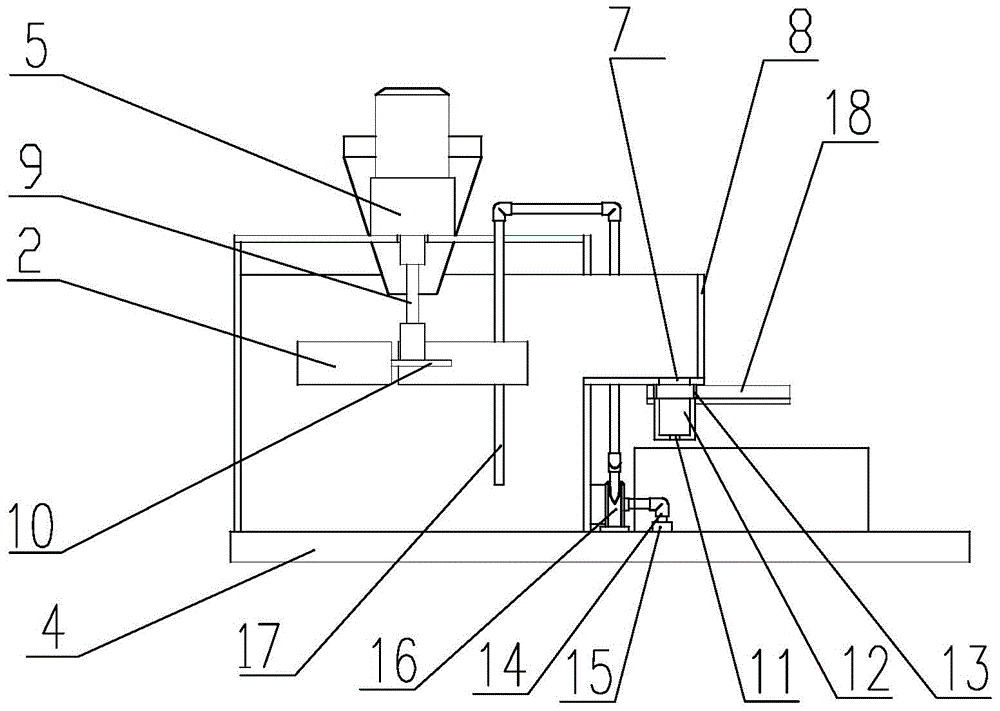

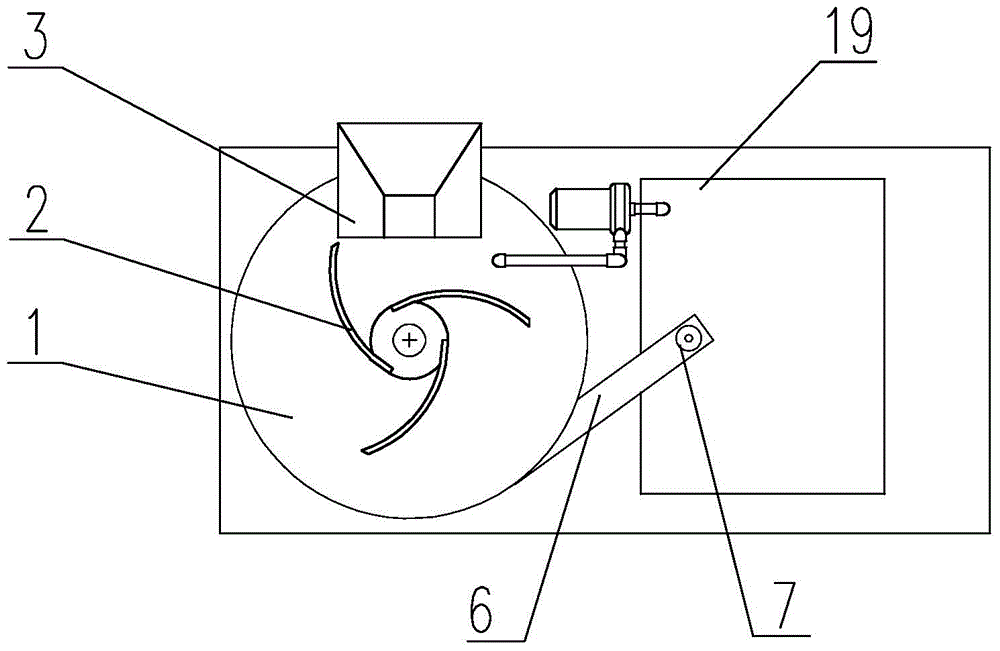

[0022] Embodiment 1: as Figure 1-Figure 2 As shown, the present invention includes a feed hopper 3, an attitude adjustment tank 1, a swirl device, a discharge sorting tank 6 and a beam frame 4, and the swirl device is installed above the attitude adjustment tank 1 through the beam frame 4, and the swirl device The impeller 2 is suspended in the attitude adjustment tank 1, the discharge sorting tank 6 is connected to the attitude adjustment tank 1, and the liquid level of the solution contained in the attitude adjustment tank 1 is higher than the bottom surface of the discharge sorting tank 6 and the height of the material and.

[0023] The outer edge of the discharge sorting groove 6 is tangent to the attitude adjustment groove 1 .

[0024] The end of the discharge sorting tank 6 is provided with a sealing plate 8, and a blanking opening 7 is arranged on the bottom plate of the tank.

[0025] The swirling device includes a motor 5, a rotating shaft 9 and an impeller 2. The ...

Embodiment 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the blades described in this embodiment have an arc-shaped structure; the base plate 10 is an outer circular plate, and the blades of the impeller 2 are two pieces, which are placed symmetrically on two sides of the circumference of the base plate 10. side. The upper surface of the blades of the impeller 2 is slightly higher than the solution surface, and the distance between the lower surface of the blades of the impeller 2 and the water surface is 3 / 4 of the average height of the seeds.

Embodiment 3

[0033] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the blade described in this embodiment has a streamlined structure. The upper surface of the blades of the impeller 2 is slightly higher than the solution surface, and the distance between the lower surface of the blades of the impeller 2 and the water surface is 4 / 5 of the average height of the seeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com