A capsule composite sorting board

A composite type, sorting board technology, applied in the direction of capsule transportation, classification, solid separation, etc., can solve the problems of reverse material arrangement of capsule shells, low work efficiency, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

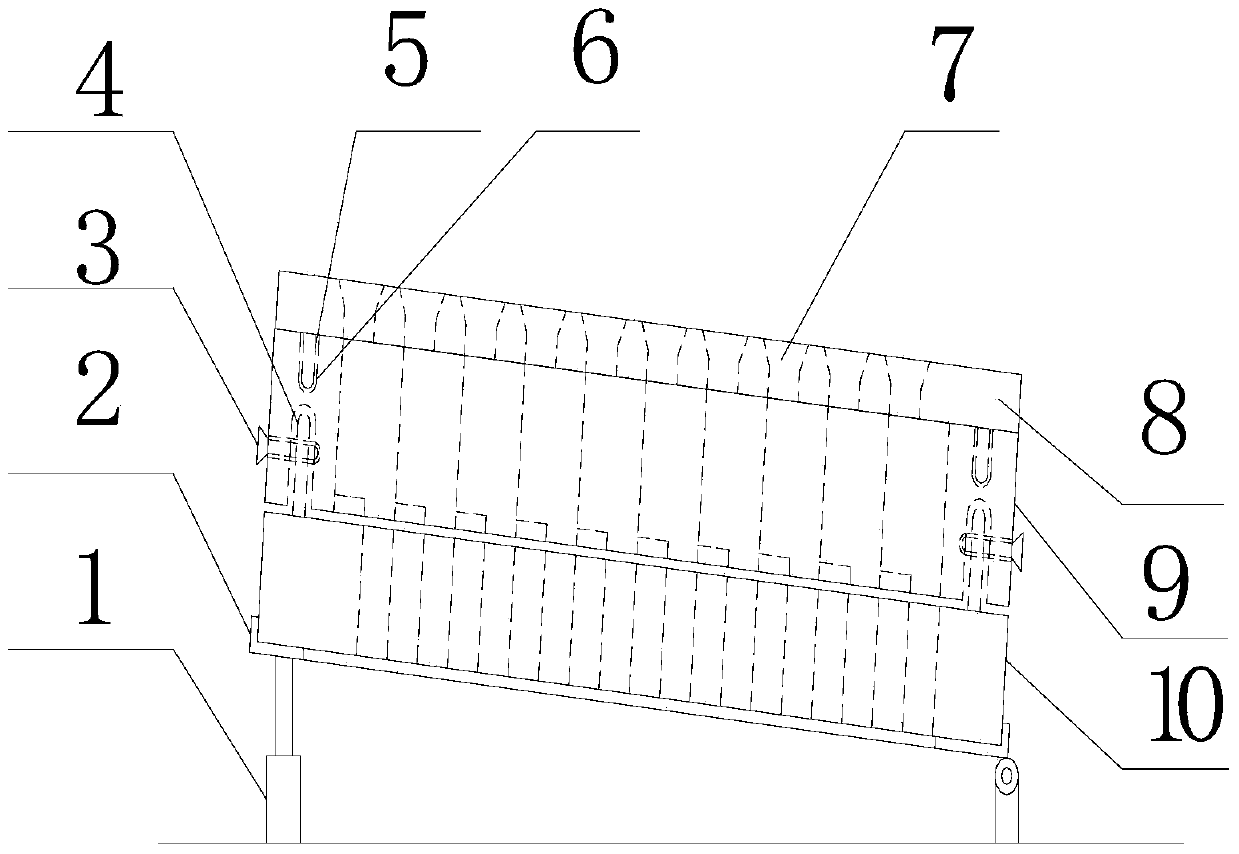

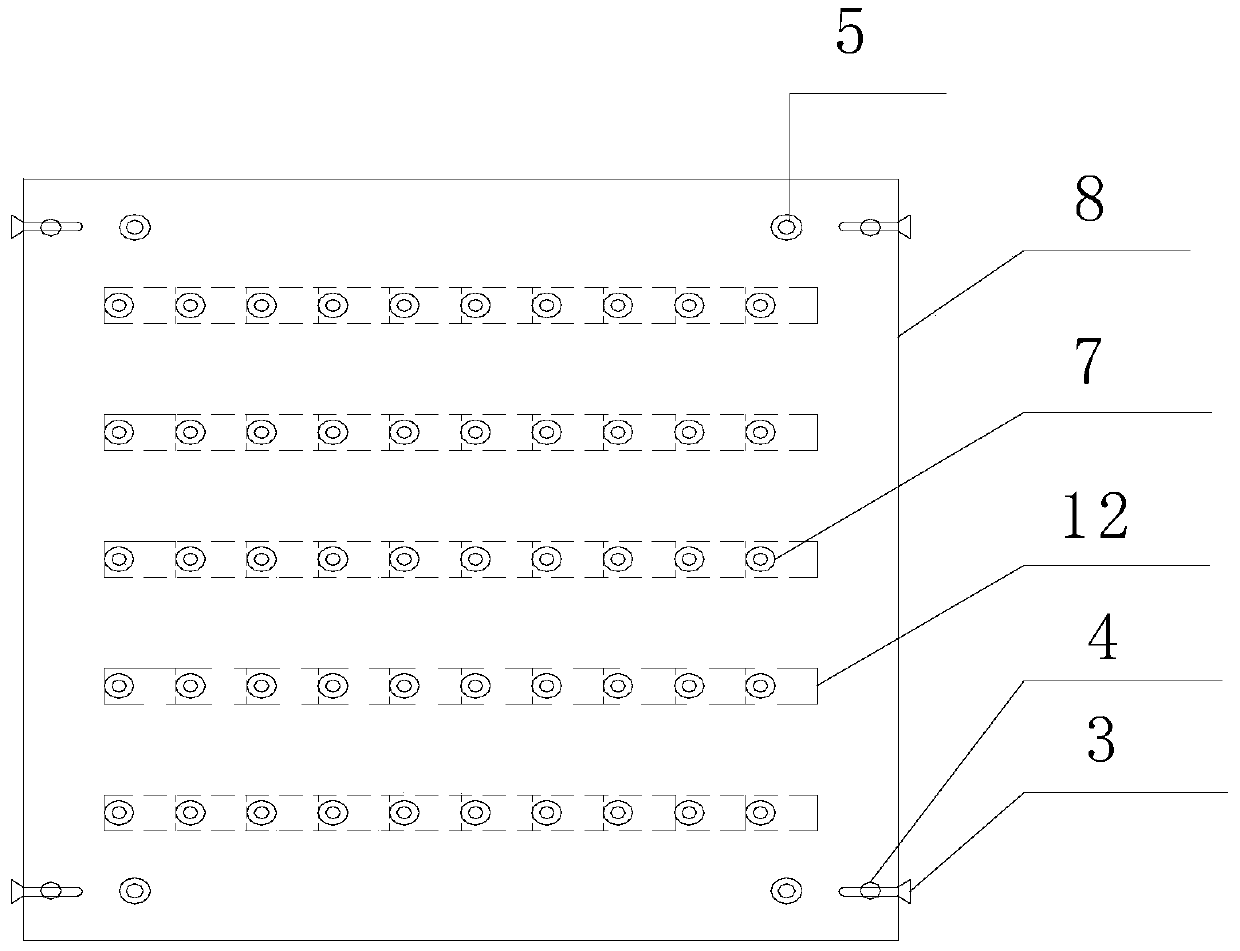

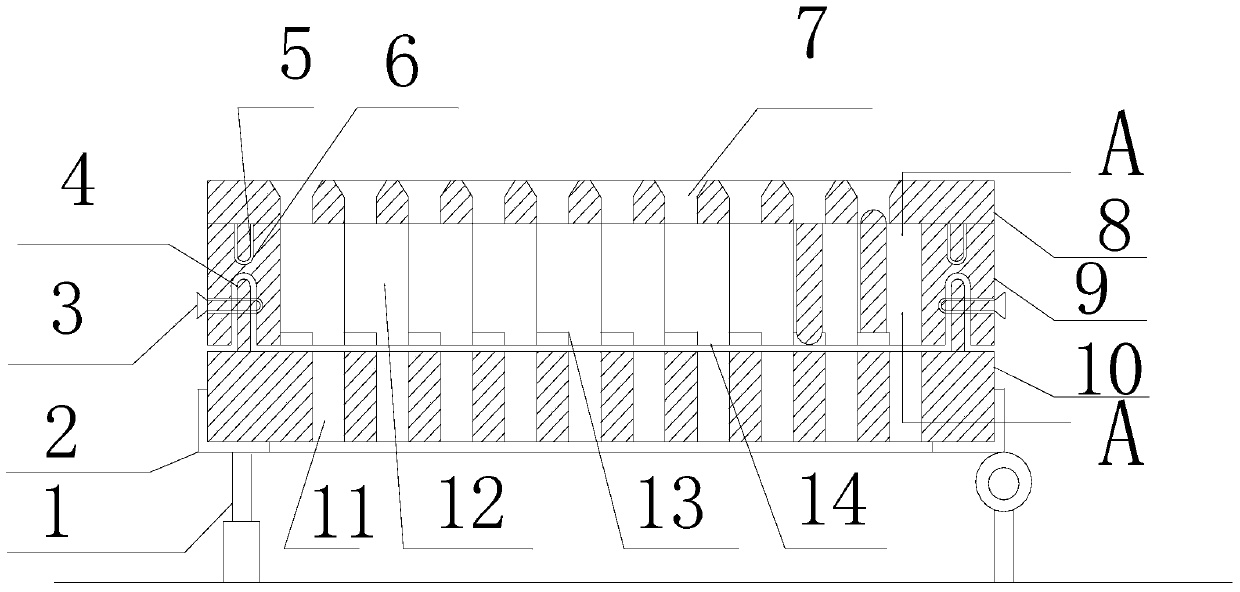

[0019] refer to figure 1 , figure 2 , image 3 and Figure 4 , a kind of capsule compound arrangement sorting plate of the present invention, comprises lifting platform 1, support slot 2, positioning pin 3, positioning rod 4, the fixed pin 5 of guide plate, the fixed pin slot 6, material guide port 7, The material guide plate 8, the upper plate body 9, the lower plate body 10, the material holding hole 11, the sorting hole 12, the U-shaped shallow groove 13 and the discharge port 14, the bracket clamping groove 2 is installed on the lifting platform 1, the The positioning rod 4 is fixed on the lower plate body 10, the fixed pin 5 of the material guide plate is fixed on the material guide plate 8, and the upper plate body 9 and the lower plate body 10 are fixedly connected by the positioning pin 3 and the positioning rod 4 , the material guide plate 8 is fixed on the upper plate body 9 by the fixed pin 5 and the fixed pin slot 6 of the material guide plate, and the upper pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com