Expansion screw sleeve

An expansion screw and bead technology, which is applied in the field of expansion screw sleeves, can solve the problems that the screw sleeves are not easy to withdraw, and the screw sleeves are easy to withdraw, etc., and achieve the effect of simple structure, good reliability and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

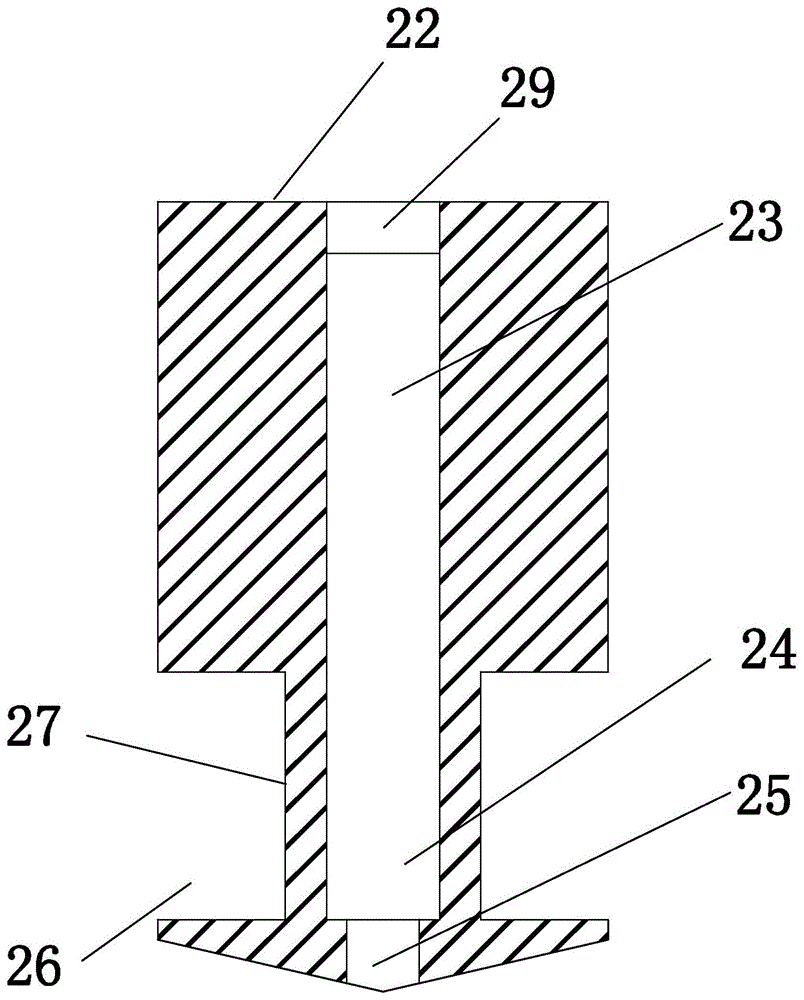

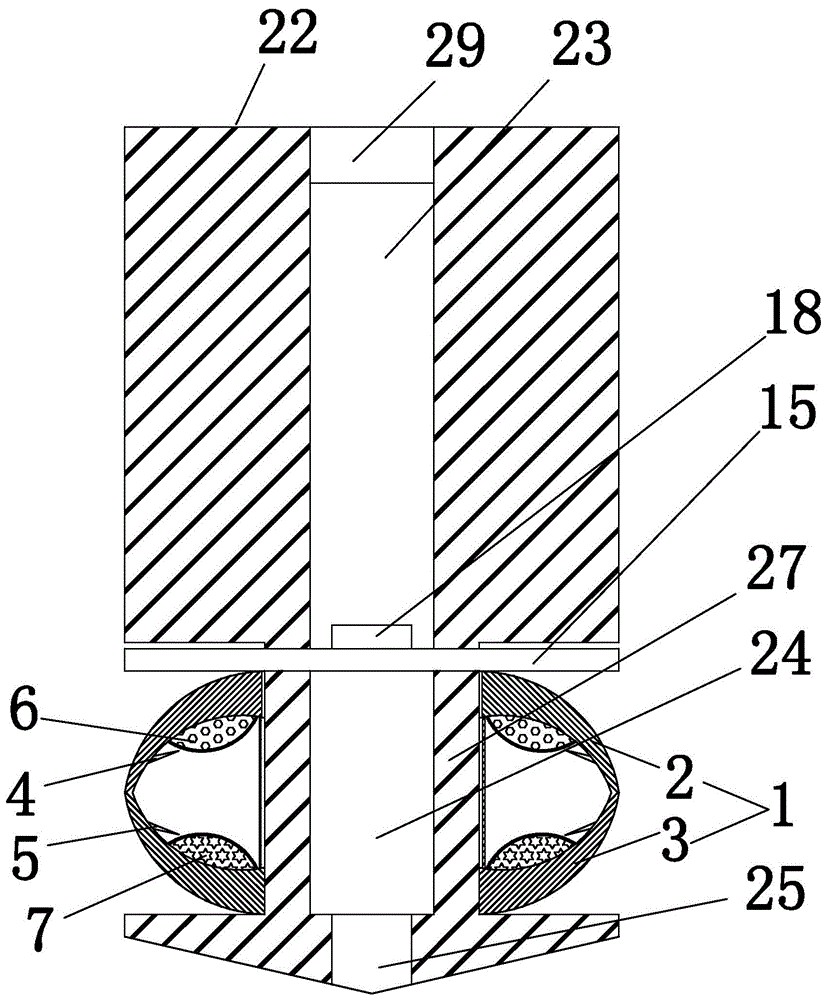

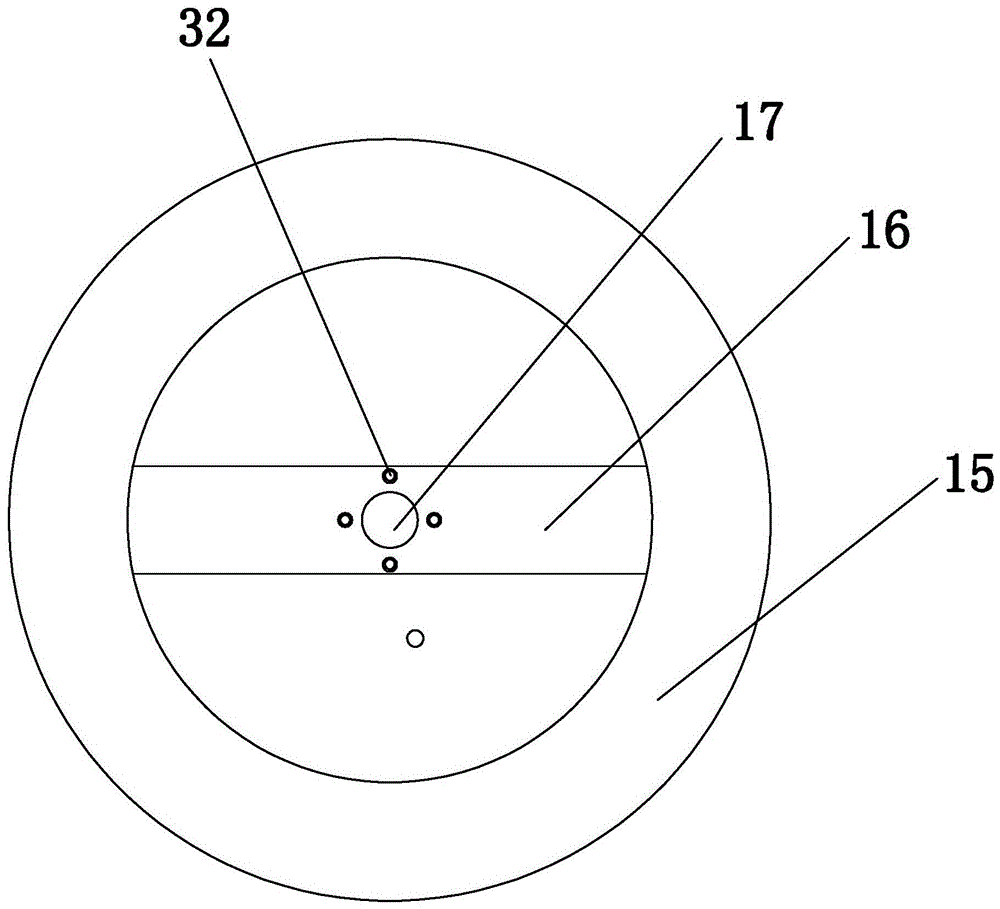

[0022] The technical examples of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0023] Example: Expansion screw sets, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6As shown, the body 22 including the expansion screw sleeve is provided with a pressure neck groove 26 along the radial circumference of the body at the front end on the outer wall of the body, and a reinforcing bead 1 is set on the neck tube 27 in the neck pressure groove. The neck tube in the neck pressure groove behind the reinforced bead is also provided with an annular pressing piece 15; a slide slot is arranged axially on the tube wall of the neck tube, and the screw hole 23 of the body is connected with the lumen 24 of the neck tube. Connected, and the axis line of the screw hole coincides with the axis line of the lumen; a pressure rod 16 is arranged in the lumen of the neck tube, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com