Phased fault detection method for rolling bearing

A rolling bearing and fault detection technology, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of historical data storage and transmission difficulties, high cost, large memory, etc., and achieve the effect of saving memory space, saving cost, and eliminating state transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The method is further described in detail with reference to the accompanying drawings for the specific embodiment:

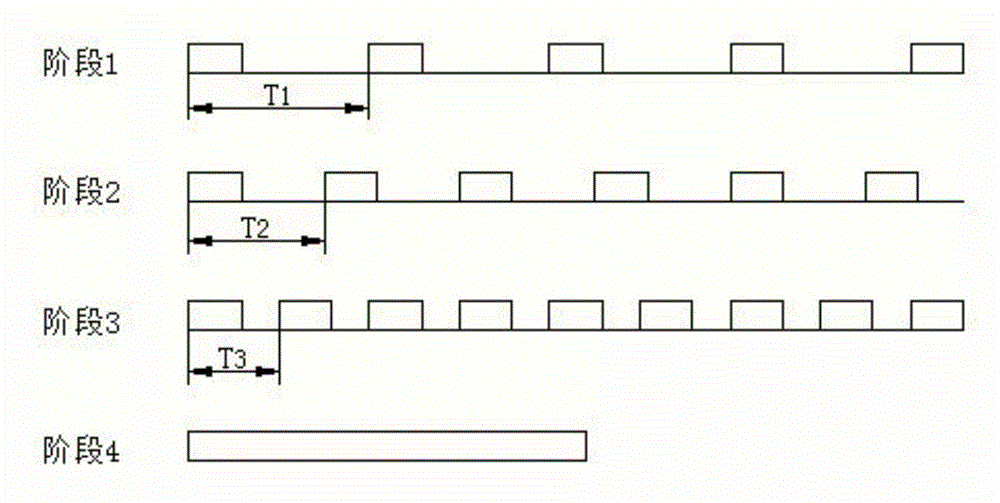

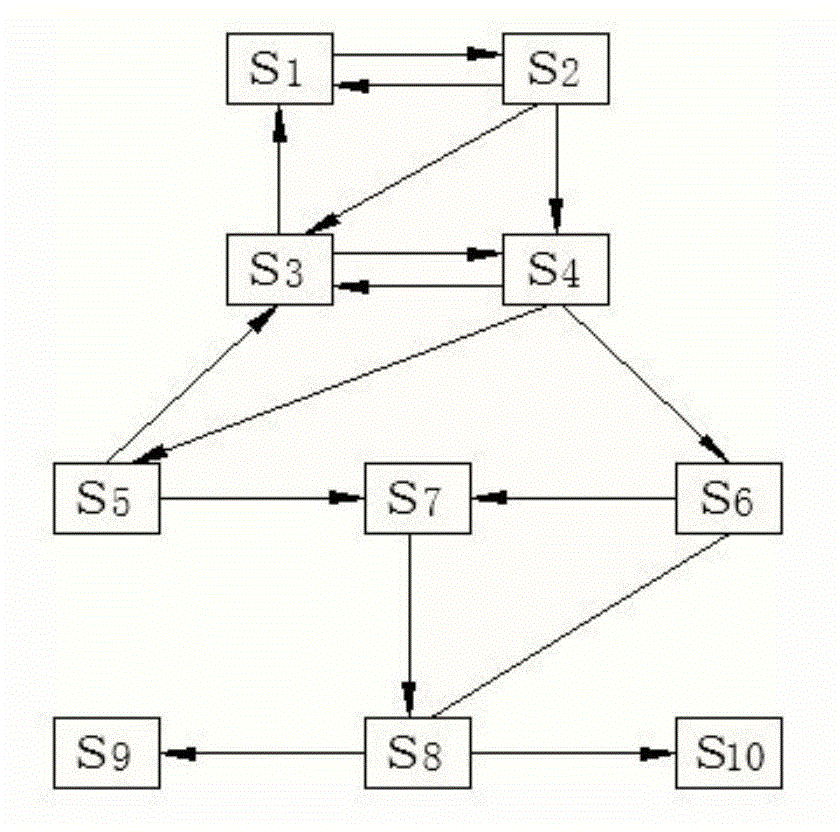

[0011] as attached figure 1 As shown, the entire life of the rolling bearing is divided into four stages, stage 1: failure is basically impossible, stage 2: the probability of failure is very small, stage 3: the possibility of failure is slightly greater, stage 4: the possibility of failure relatively large; the detection cycle in the first stage is T 1 , the detection period of the second stage is T 2 , the detection period of the third period is T 3 , the last cycle uses continuous state monitoring. as attached figure 2 As shown, the first stage is divided into two states S 1 and S 2 , the second state splits into state S 3 and S 4 , the third state is divided into S 5 ﹑S 6 and S 7 , the final state is divided into S 8 ﹑S 9 and S 10 .where S 1 Indicates that almost no failure occurs, S 2 ~S 8 Indicates that the probability of rolling b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com