Heat engine and thermodynamic cycle for converting heat into useful work

A heat engine and heat cycle technology, which is applied in the field of heat engines and heat cycles for converting heat into useful work, can solve the problems of reducing the degree of efficiency, not being able to be converted into mechanical work, and reducing the efficiency of internal combustion engines, etc., to achieve high The degree of efficiency, the effect of improving the degree of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

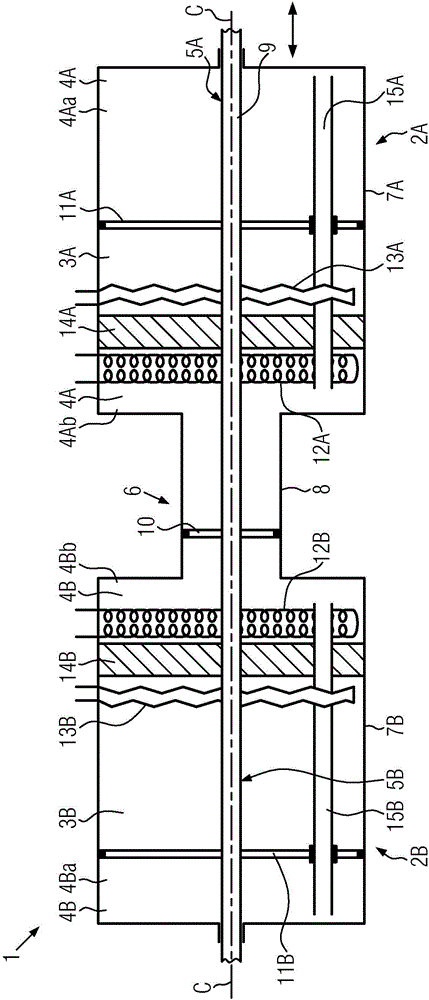

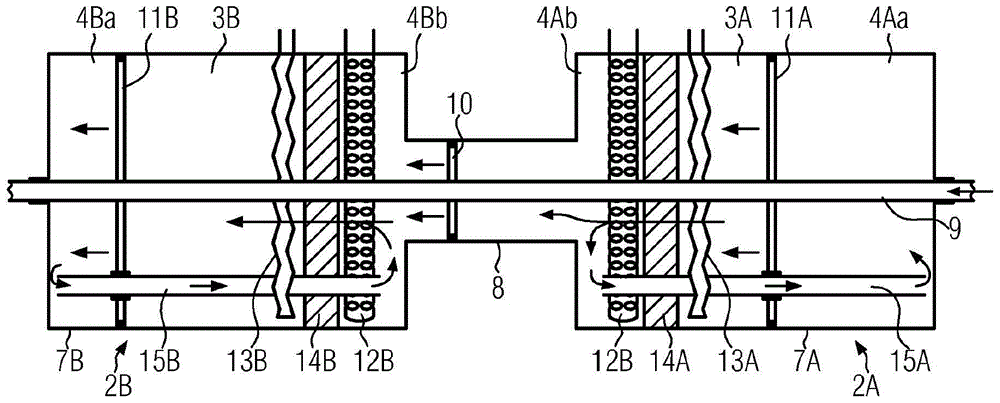

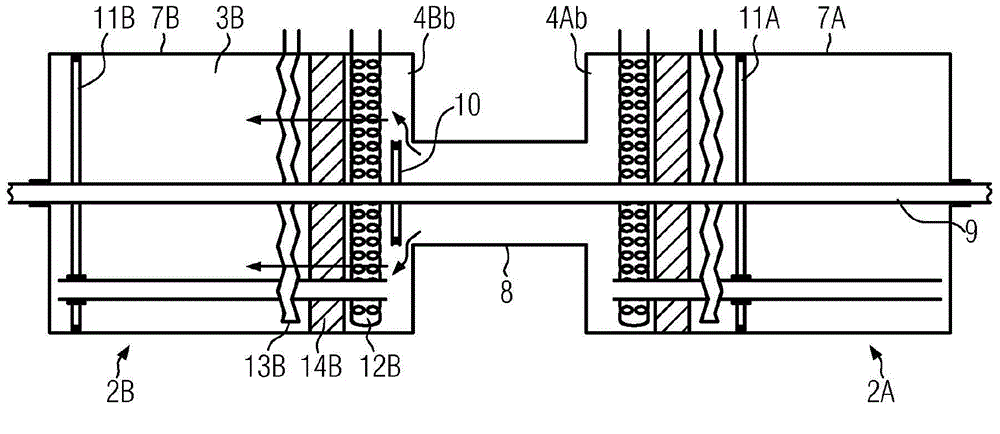

[0037] figure 1 A schematic diagram of a heat engine according to the invention is shown in side view. The first storage device 2A for working gas is in figure 1 , and is divided into a first cold chamber 3A and a first hot chamber 4A. Implemented by the first movable piston device 5A figure 1 in the division. The second storage means 2B is mirror-symmetrical to the first storage means 2A and is divided by a second movable piston means 5B into a second cold chamber 3B and a second hot chamber 4B. The two storage devices 2A, 2B are connected to each other via a connection 6 such that partial quantities of working gas can be exchanged between the two storage devices 2A, 2B during the configuration / constellation of the two piston devices 5A and 5B .

[0038] The two storage devices 2A, 2B are configured as displacement cylinders 7A, 7B with a circular cross-section and are divided into hot chambers 4A, 4B and cold chambers 3A, 3B, respectively. This division is achieved by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com