Scribing limiting adjusting mechanism for metering cloth

A technology of adjusting mechanism and fabric, applied in the direction of marking textile materials, textiles and papermaking, etc., can solve problems such as reducing efficiency and increasing labor, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

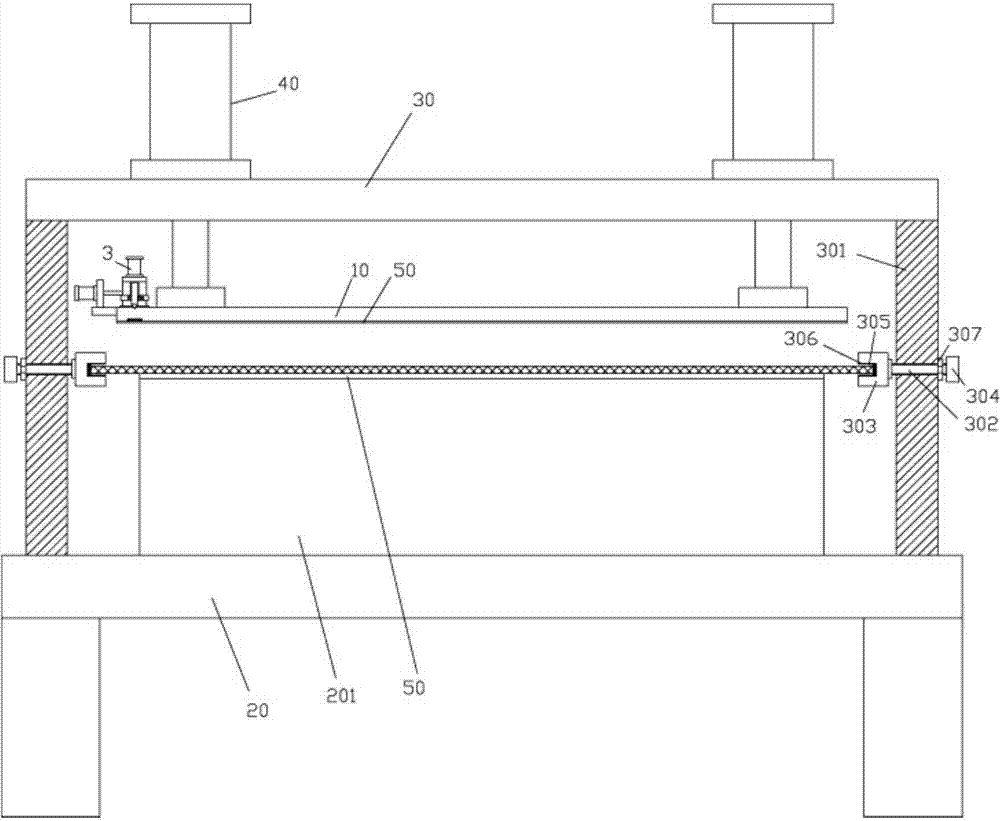

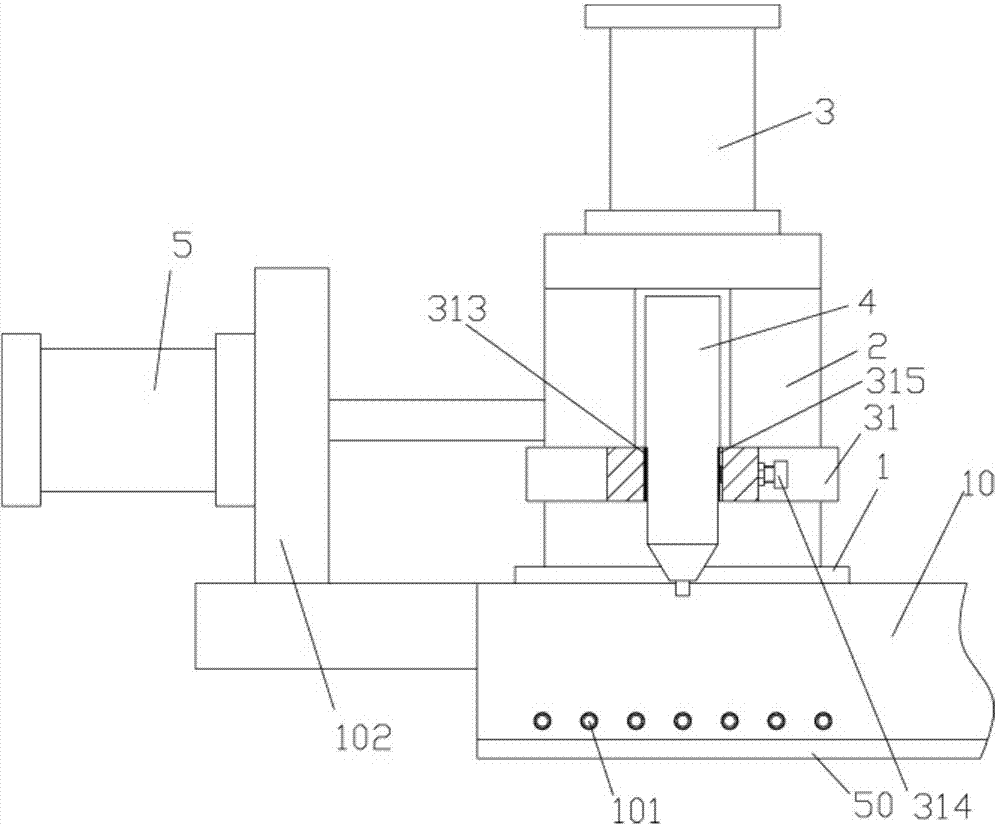

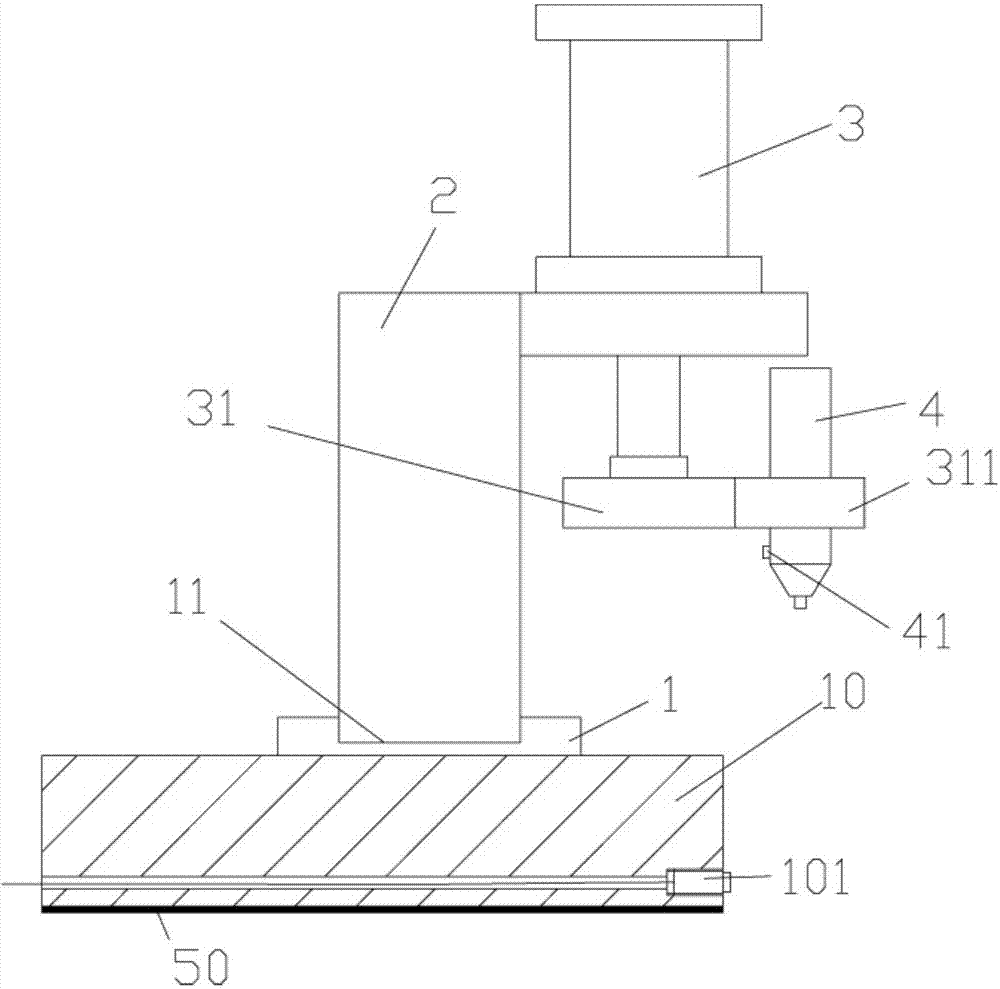

[0023] Examples, see e.g. Figure 1 to Figure 7 Shown, a kind of fabric counting meter is used the scribe limit adjustment mechanism, comprises frame 20, pressing plate 10 and portal frame 30, and the table top of described frame 20 is fixed with portal frame 30, and the top of portal frame 30 At least two compression cylinders 40 are fixed on the beam, and the push rods of the compression cylinders 40 pass down the top beam of the gantry 30 and are fixed with a pressing plate 10, and a support is fixed on the table of the frame 20 directly below the pressing plate 10. Platform 201, the cloth is on the support platform 201, the top surface of the support platform 201 and the bottom surface of the pre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap