Panel surface grinding device and grinding method with multi-degree of freedom

A degree of freedom, plate technology, used in grinding drive devices, machine tools suitable for grinding workpiece planes, grinders, etc., can solve problems such as low production efficiency, great harm to workers' health, and inability to grind the surface of plates. Achieve the effect of improving production efficiency, reducing labor intensity, and improving grinding limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

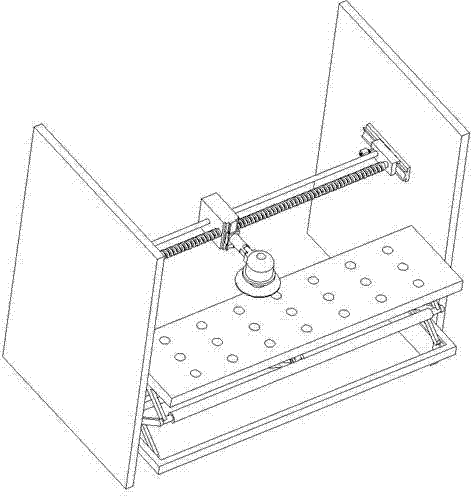

[0024] As can be seen from the accompanying drawings, a multi-degree-of-freedom plate surface grinding device of the present invention includes two left and right side plates 9, a transmission mechanism, a drive mechanism, a grinding mechanism and a lifting table mechanism, and the transmission mechanism and the lifting table mechanism are fixedly connected. Inside the left and right side plates 9, the drive mechanism and the grinding mechanism are connected to the transmission mechanism respectively.

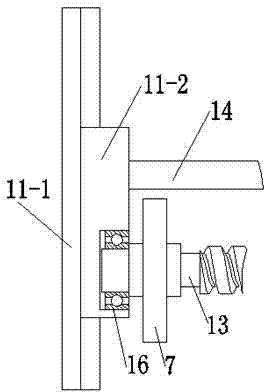

[0025] Wherein, the transmission mechanism includes two left and right sliding friction guide rails 11, a lead screw 13, a polished rod 14, a moving block 15, and a bearing 16. Each sliding friction guide rail 11 is equally divided into a bearing member 11-1 and a moving member 11-2. The guide piece 11-1 is fixed on the inner side of the side plate 9, the moving piece 11-2 is connected with the guide piece 11-1 through the guide rail, and the two ends of the lead screw 13 cooper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com