Spanner capable of controlling extension lengths of through bolt

A technology of protruding length and core-through bolts, which is applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems that the protruding length is not easy to grasp, and the protruding lengths at both ends of the core-through bolts are different, so as to achieve simple operation, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

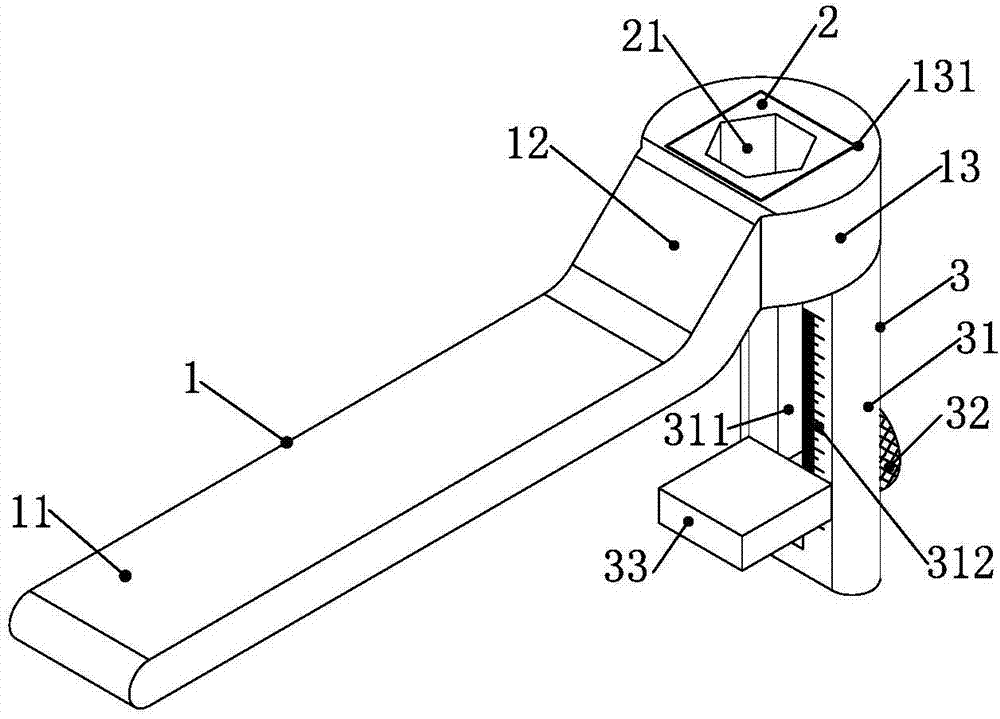

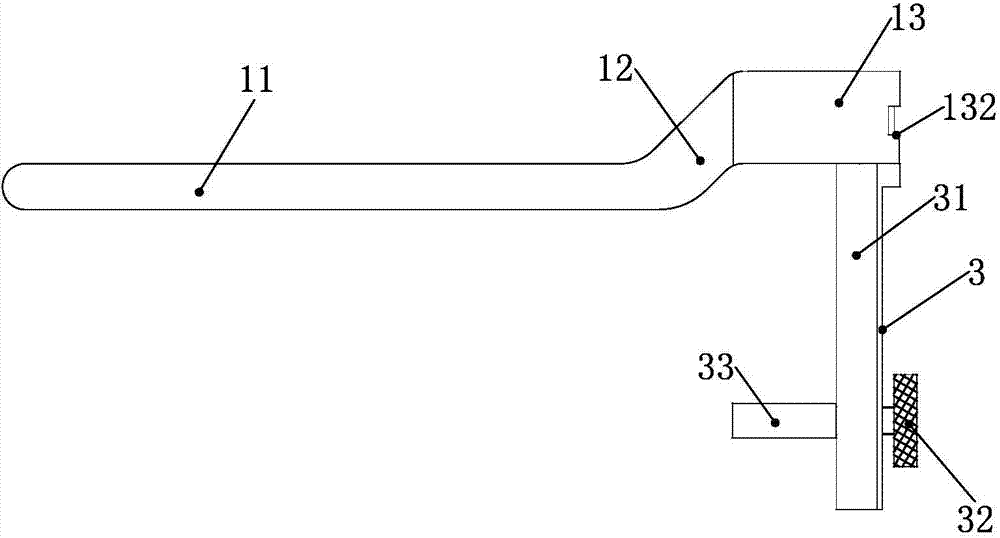

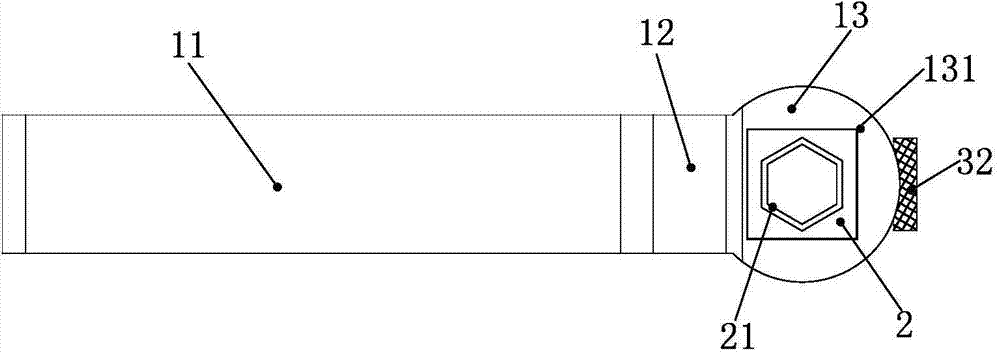

[0032] Such as Figure 1 to Figure 10 As shown, a spanner capable of controlling the extension length of a core bolt of the present invention includes a spanner 1 and a nut ferrule 2 and a positioning mechanism 3. The spanner 1 includes a handle 11, a transition part 12 and a spanner head 13. The spanner head A transition part 12 is connected between 13 and the handle 11. The transition part is arranged on an inclined plane. A first stepped hole 131 is provided in the center of the wrench head 13. The shape of the nut ferrule 2 is adapted to the first stepped hole 131 and is square. In addition, the nut ferrule 2 is embedded in the first stepped hole 131, and a second stepped hole 21 is provided at the center of the nut ferrule 2 for nut clamping.

[0033] The positioning mechanism 3 is arranged on the end face on one side of the wrench head 13, and figure 1 It faces upwards and includes a positioning plate 31, a fastening screw 32 and a positioning slider 33. A slot 311 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com