Multipurpose hole scratching device

A multi-purpose, scribing technology, applied in the direction of metal processing, etc., can solve the problems of non-replaceable, different design of scribing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

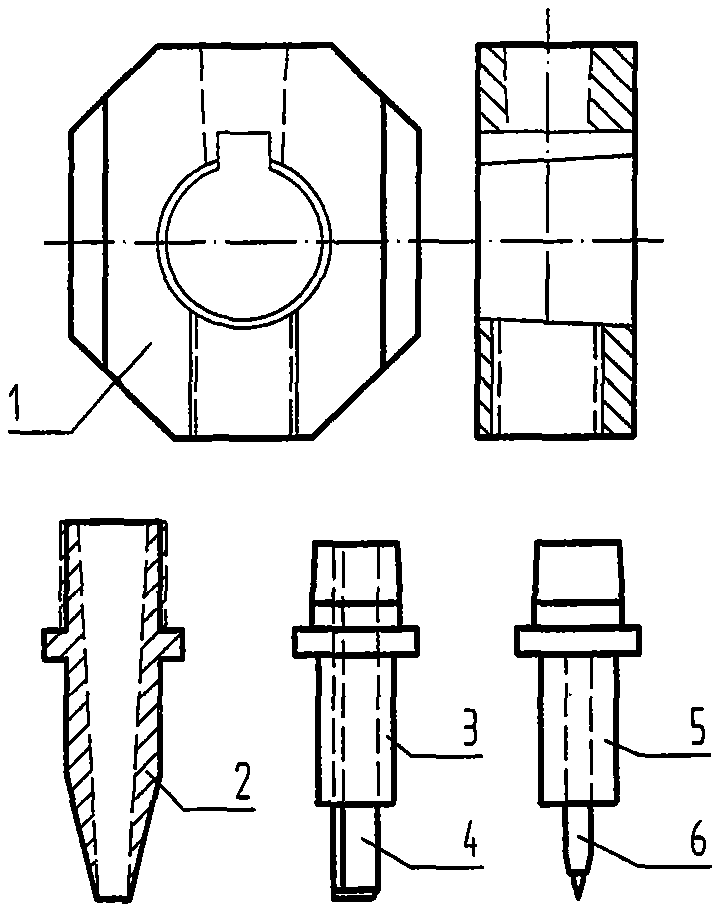

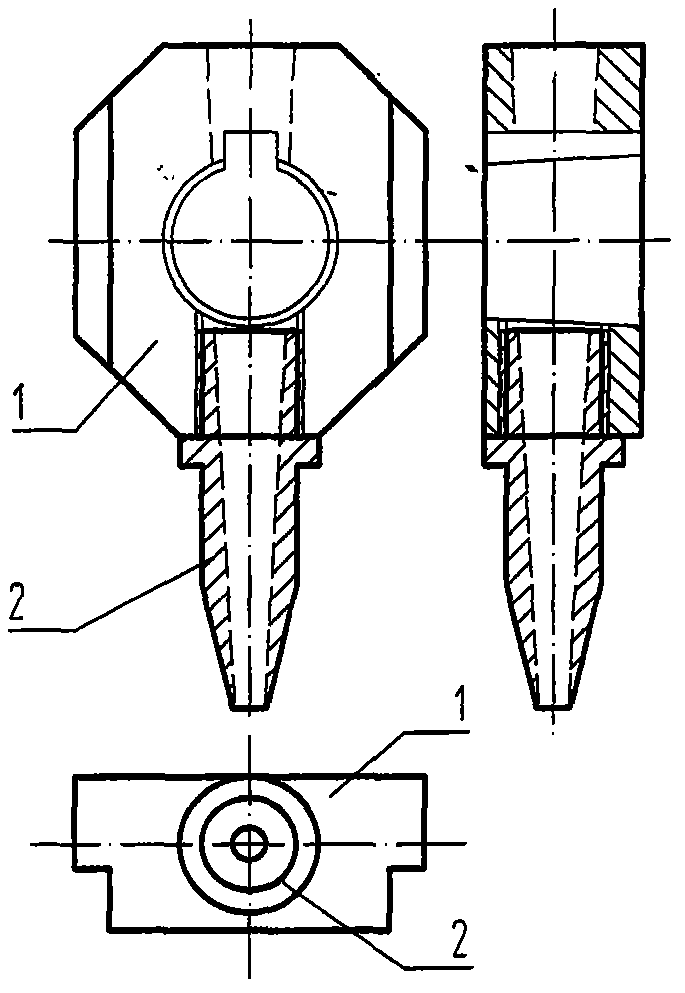

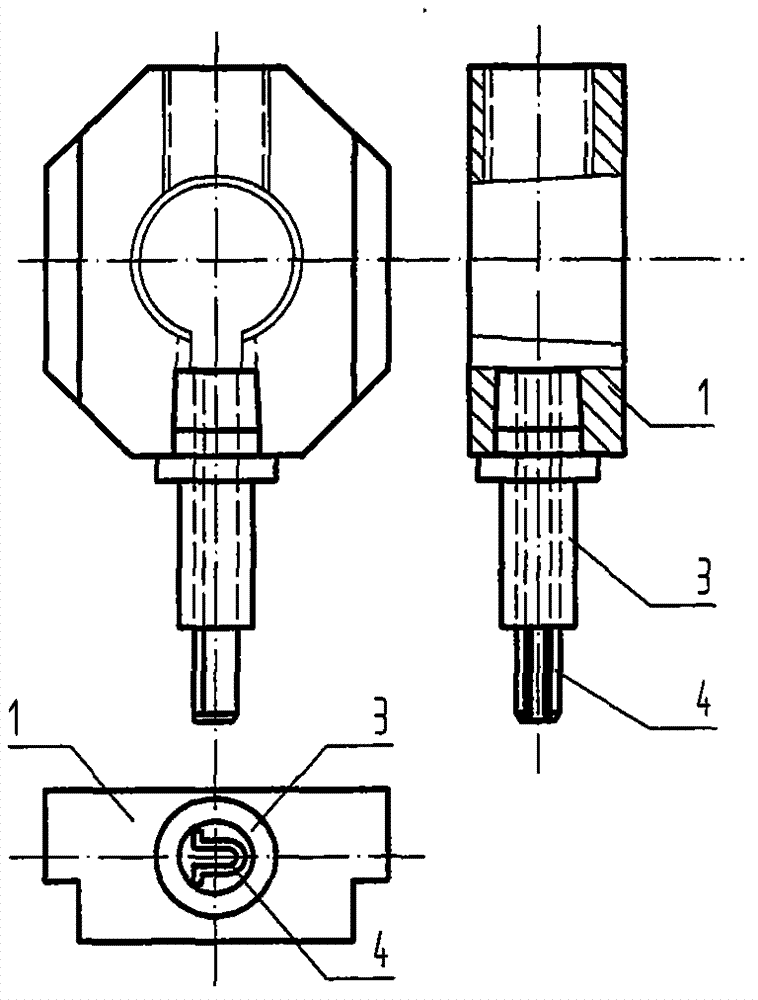

[0017] see figure 1 , the present invention is made up of multi-purpose piercing knife base 1, circular hole piercing knife 2, horseshoe-shaped piercing knife base 3, horseshoe knife 4, inline-shaped piercing knife base 5, and inline knife 6. The multi-purpose piercing tool holder 1 is installed on the piercing spindle, which is not shown here. Its exterior is an octahedron structure, and its interior is the mounting position of the piercing spindle. The mounting position has a certain taper, which is consistent with the piercing spindle The taper is consistent and is equipped with a keyway. The upper end is designed with a tapered tool mounting position, and the lower end is designed with a threaded tool mounting position. Both sides are designed with disassembly bayonets, which can be removed from the drilling spindle with special tools;

[0018] see figure 1 , 2 , the circular hole-shaped scribing knife 2 has a conical structure on the outside and a tapered cavity on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com