Pneumatic motor bearing pressing cover

A technology for bearing glands and air motors, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve problems such as inconvenient operation, and achieve the effect of convenient oil injection and good lubrication

Inactive Publication Date: 2015-06-24

付菁

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Using this traditional bearing gland, when filling the bearing with lubricating oil, it is necessary to open the entire bearing gland to achieve oil injection, which is very inconvenient to operate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0010] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

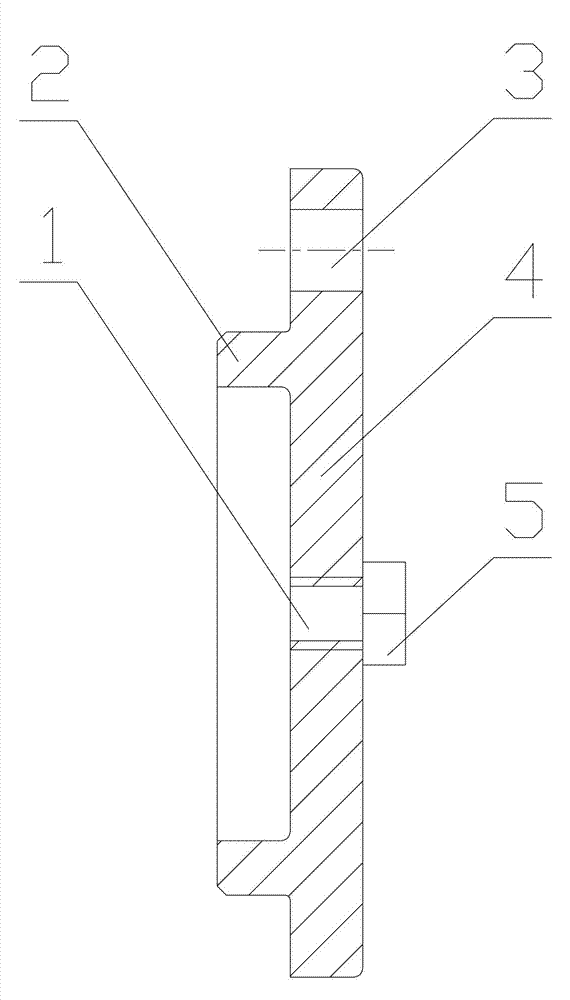

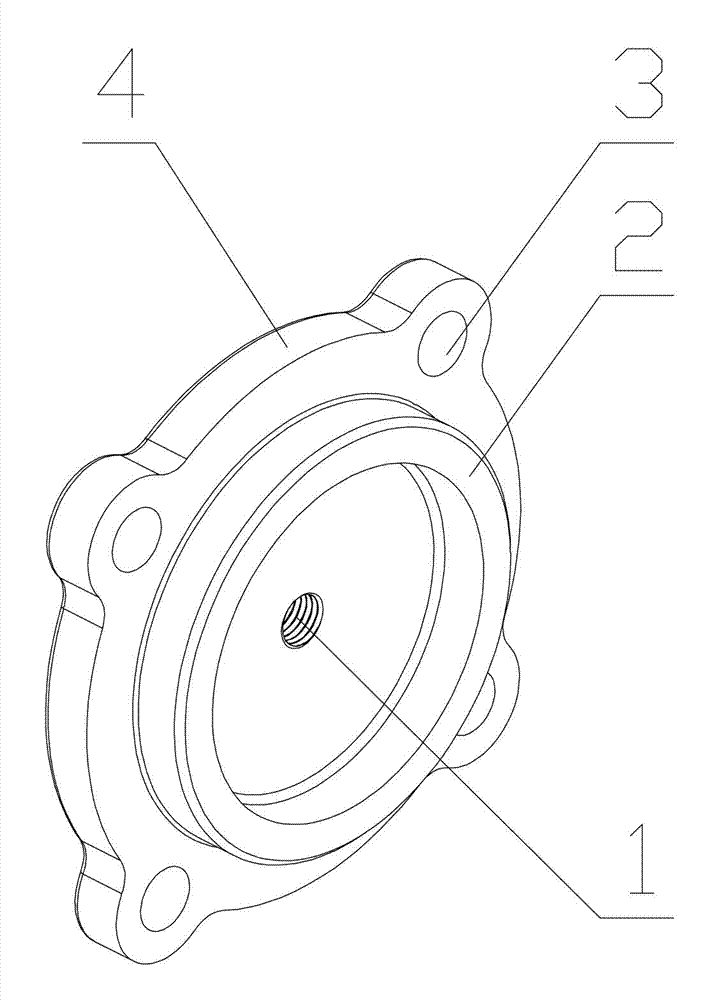

[0011] see figure 1 and figure 2 , the present invention has a cover body 4, the cover body 4 is provided with four evenly distributed bolt holes 3, and the back of the cover body 4 is provided with a positioning ring 2; , a screw 5 is connected to the inner thread of the oil filling port 1 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a pneumatic motor bearing pressing cover comprising a cover body, the cover body is provided with a plurality of uniformly distributed bolt holes, the back side of the cover body is provided with a positioning ring; the pneumatic motor bearing pressing cover is characterized in that the middle of the cover body is provided with an oil pouring orifice, the oil pouring orifice is internally in threaded connection with a screw; the pneumatic motor bearing pressing cover is provided with the oil pouring orifice, the oiling is convenient, the bearing lubrication can be very well performed, and the bearing pressing cover is mainly used as a pneumatic motor bearing pressing cover.

Description

technical field [0001] The invention relates to the technical field of air motors, in particular to a bearing gland on an air motor. Background technique [0002] The bearing gland on the traditional air motor has a cover body, a number of bolt holes are evenly distributed on the cover body, and a positioning ring is arranged on the back of the cover body. Using this traditional bearing gland, when lubricating the bearing, the entire bearing gland needs to be opened to realize the oil filling, which is very inconvenient to operate. Therefore, it is very necessary to design a bearing gland that can well solve the above problems. SUMMARY OF THE INVENTION [0003] The purpose of the present invention is to improve the above-mentioned deficiencies of the prior art, and to provide a bearing gland on an air motor. [0004] The specific scheme of the present invention is: a bearing gland on a pneumatic motor, which has a cover body, a plurality of evenly distributed bolt holes ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16C35/00

Inventor 付菁

Owner 付菁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com