Electrically simulated inertial friction welding method

A friction welding and electrical simulation technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of difficult control of different mechanical inertias, improve welding efficiency, eliminate inertia levels, and reduce tedious manual labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

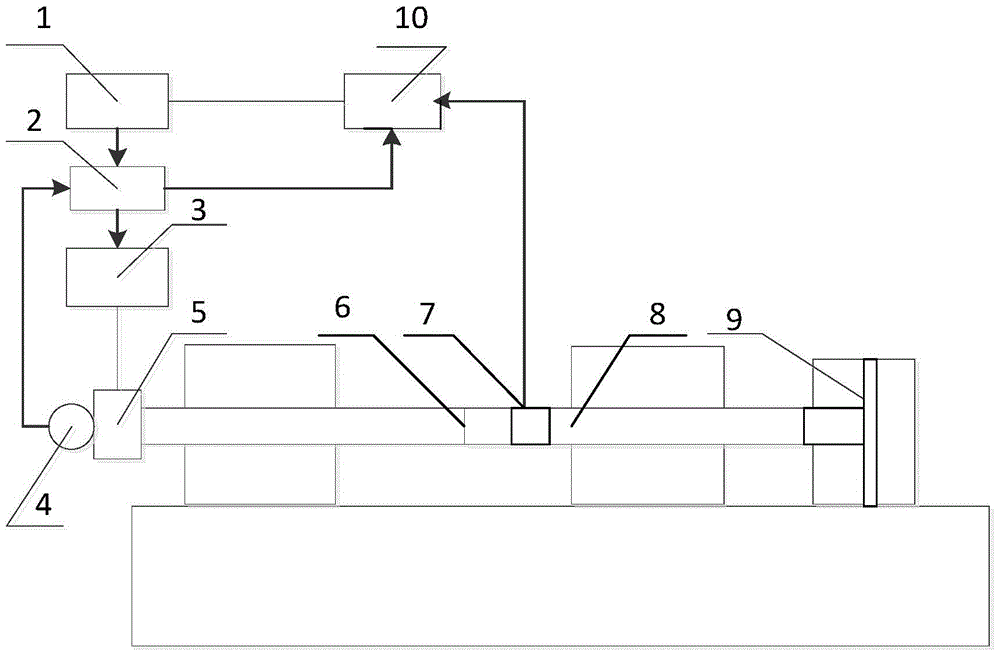

[0017] refer to figure 1 . The specific steps of the electric simulation inertial friction welding method of the present invention are as follows:

[0018] Before friction welding, inertial friction welding parameters, such as initial rotational speed, required inertia, friction pressure, upsetting pressure, etc., are stored in the computer 1 . Among them, the initial speed is 800~2000r / min, and the required inertia is 5~50kg m 2 , The friction pressure is 2~10MPa, and the upsetting pressure is 4~20MPa. After the friction welding blank is put in, the automatic welding process is started, the welding blank is clamped by the fixture, and the moving end 8 is driven by the hydraulic cylinder 9 to fast forward, work forward, pre-jack, and retreat for a certain distance and then stop. The main shaft 5 is driven and accelerated by the DC motor 3 under the control of the DC governor 2. When the speed of the main shaft 5 reaches the set initial speed value of 800-2000r / min, it rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com