Roller threader

A threading machine and roller-type technology, applied in the direction of optical fiber/cable installation, cable laying equipment, etc., can solve the problems of high labor intensity, worker suffocation, low efficiency, etc., and achieve the effect of high production efficiency and less injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

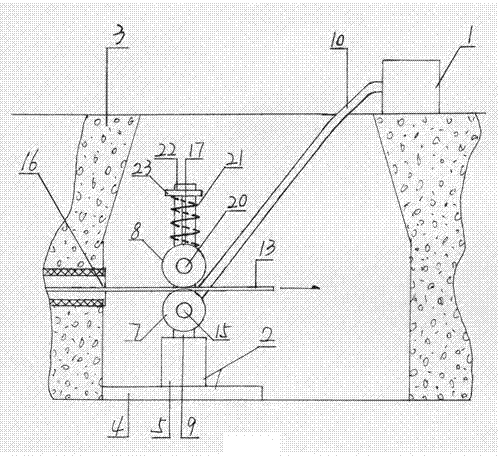

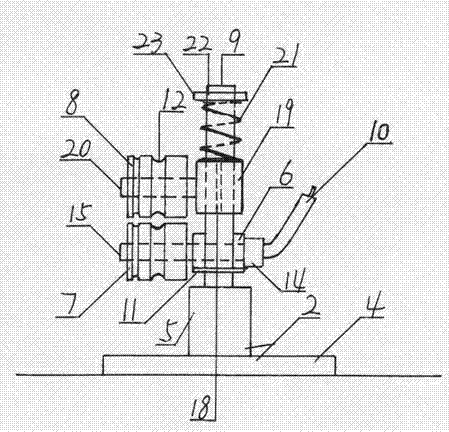

[0016] Such as figure 1 , 2 As shown, a roller-type threading machine is used to pull the optical cable directly by means of the fiberglass rod of the threader or directly to achieve the purpose of mechanized construction. The structure of the machine is composed of a vibrating rod 1 and a threading machine 2; the vibrating rod 1 is used as the power of the threading machine 2; the vibrating rod 1 is driven by an internal combustion engine, and the vibrating rod 1 adopts a plug-in concrete vibrating rod; Set on the trolley on the ground for easy moving;

[0017] The threading machine 2 can be placed in the inspection shaft 3 where the pipeline is laid, so as to facilitate the threading operation; the threading machine 2 is composed of a chassis 4, a hydraulic cylinder 5, a bearing seat 6, a driving wheel 7, and a driven wheel 8; the chassis 4 is a rectangular Corner steel plate; a hydraulic cylinder 5 is provided on the chassis 4; the hydraulic cylinder 5 adopts a manual one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com