A Whole-flow Modeling Method of Oil Refining Process

A modeling method and technology of oil refining process, applied in the direction of program control, electrical program control, comprehensive factory control, etc., can solve problems such as large amount of data, complicated mechanism of device model, and difficulty in high-precision software, and realize the simulation of the whole process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

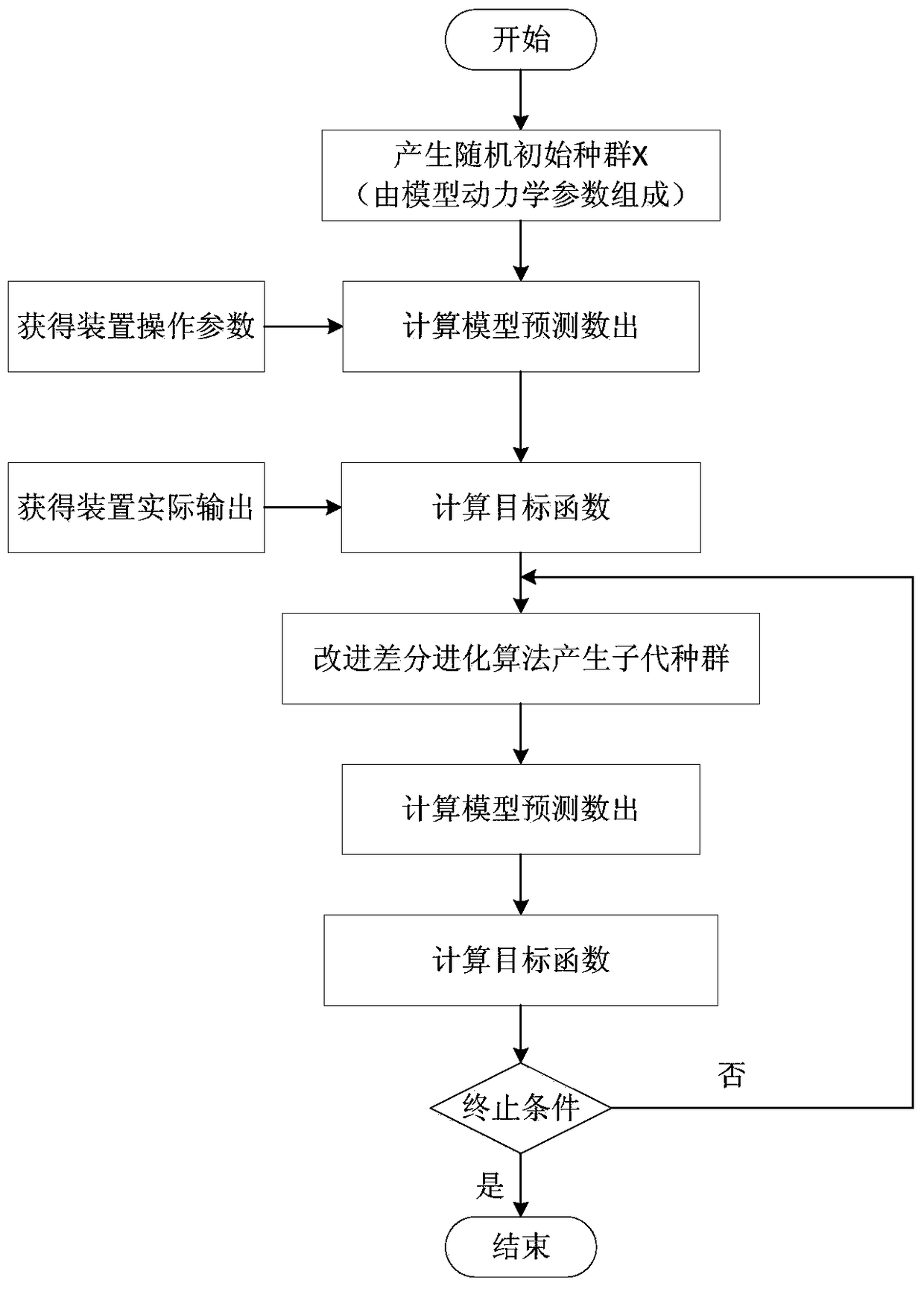

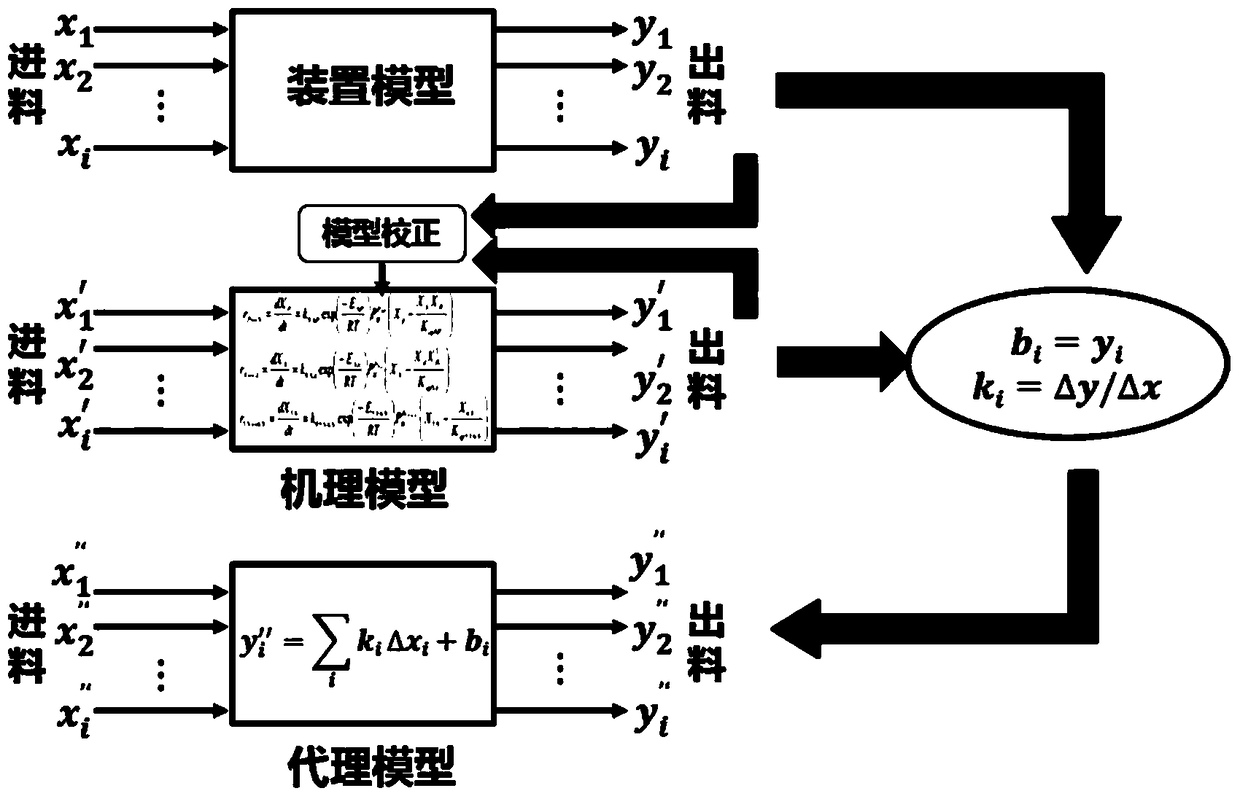

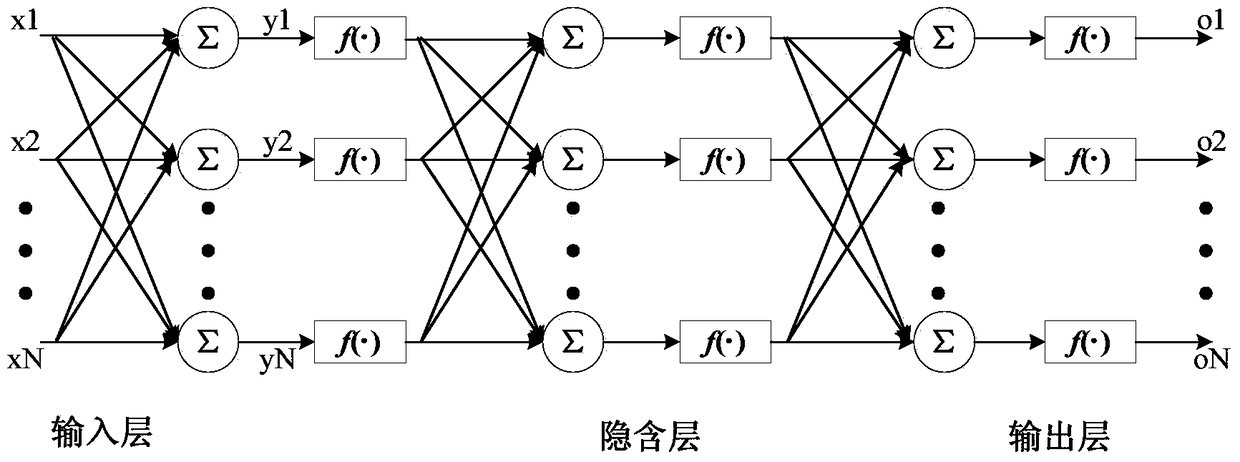

[0029] Below in conjunction with chart specifically introduces the realization method of the present invention:

[0030] 1. Modeling of refining process mechanism

[0031] (1) Based on the principle of rectification, complete the modeling and simulation of the initial distillation tower, atmospheric tower and vacuum tower, and correct the parameters of the fractionation model in combination with the actual operating data to establish an atmospheric and vacuum separation that can well describe the actual operating conditions process model.

[0032] (2) Based on the lumped kinetic mechanism of reforming 27, an accurate kinetic model of reforming reaction was established, combined with the actual operation of the reforming unit, the kinetic parameters were corrected to improve the accuracy of the reactor model.

[0033] (3) Based on the 21 lumped catalytic cracking kinetics mechanism, combined with the historical operation data of the unit, establish a catalytic cracking process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com