A fruit picking mechanism for a peanut combine harvester

A technology for combine harvesters and peanuts, which is applied to digging harvesters, harvesters, agricultural machinery and tools, etc. It can solve the problems of dirty picking, easy to break, peanuts are not easy to enter the fruit picking area, etc., and the fruit picking rate can be improved. , The effect of soil sieving process promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

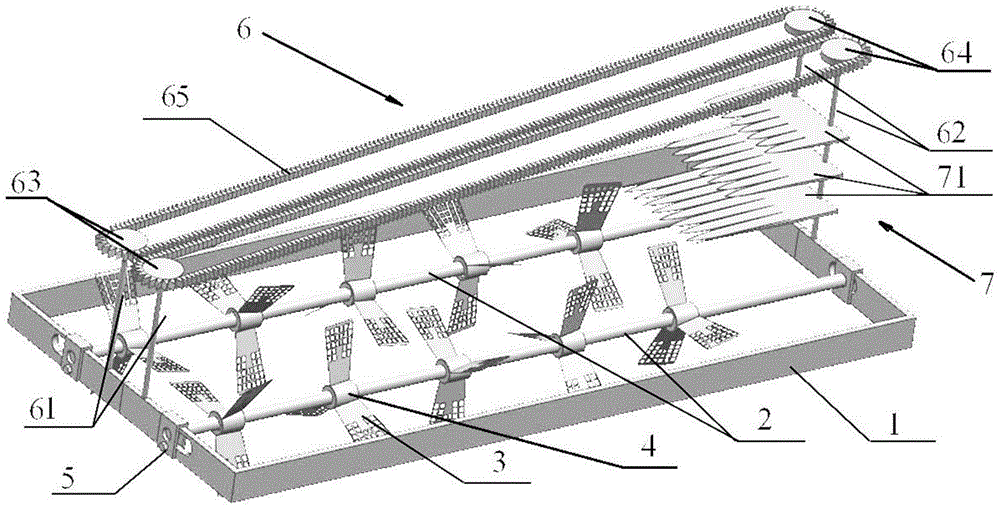

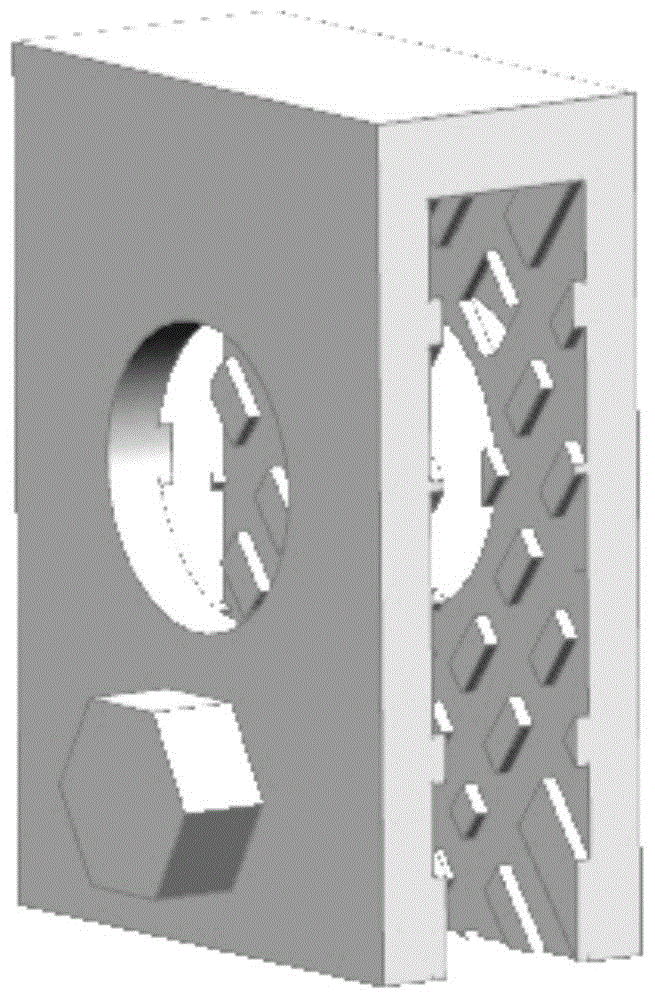

[0023] Such as figure 1 and figure 2 As shown, a fruit picking mechanism for a peanut combine harvester includes a base 1 on which two main shafts 2 whose axes lie on the same plane and turn in opposite directions are rotated. The distance between the two main shafts 2 is along the axis from one end to the other. The direction gradually decreases, and five pairs of fan blades 3 extending in the axial direction are evenly distributed on the outer peripheral surfaces of the two main shafts 2 respectively. The mechanism also includes a rack and pinion transmission device 6 installed on the base, and the rack and pinion transmission device includes a front end support 61 and a rear end support 62 respectively connected to the base, a front end gear 63 installed on the front end support, an installation The rear gear 64 on the rear bracket and the transmission rack 65 meshing with the front gear and the rear gear respectively, the height of the rear bracket 62 is higher than that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com