A device for picking peanuts

A peanut picking and fruit picking roller technology, applied in threshing equipment, agriculture, application, etc., to achieve the effect of improving fruit picking strength, improving fruit picking rate and picking rate, and reducing damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

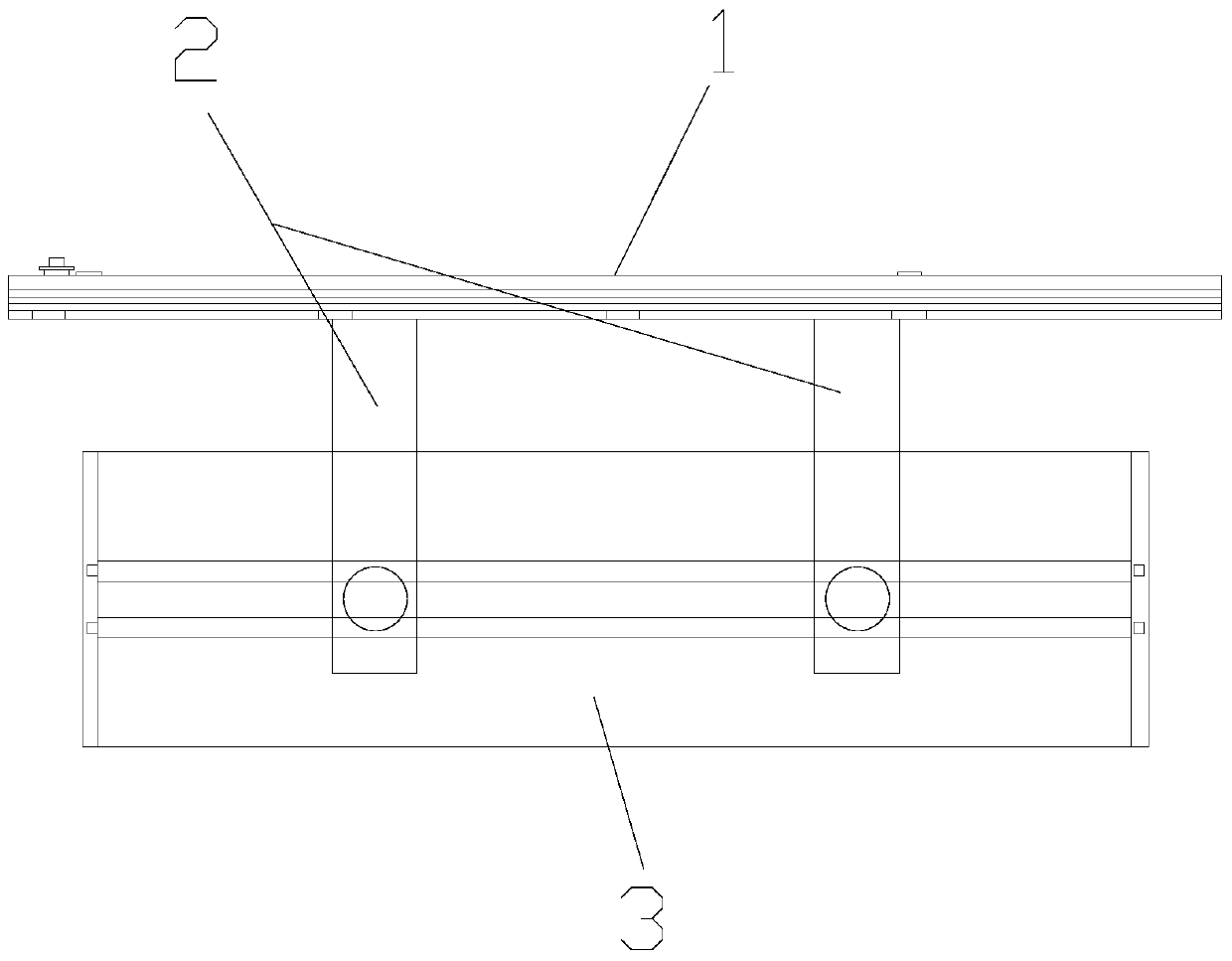

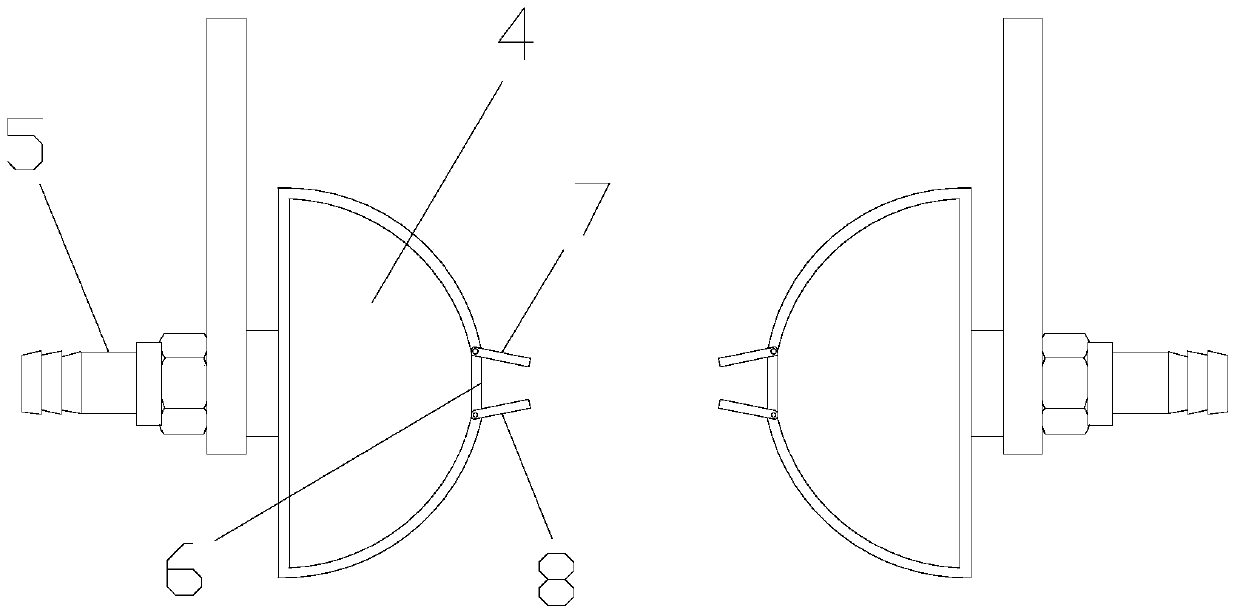

[0021] Such as figure 1 and figure 2 As shown, a peanut picking device includes a clamping conveyor chain 1, a bracket 2, a frame 3 and an air chamber 4, the bracket 2 is arranged at both ends of the clamping conveyor chain 1, and the frame 3 is located below the bracket 2 , the frame 3 is fixedly connected to the bracket 2, the air chamber 4 is installed inside the bracket 2, the air chamber 4 is a semicircular closed cavity, and an air pipe 5 is installed at one end of the air chamber 4, the air chamber 4 The other end is provided with an air outlet groove 6, and an upper adjustment plate 7 and a lower adjustment plate 8 are installed on the air outlet groove 6.

[0022] Described air chamber 4 is provided with two, keeps the fruit picking efficiency high.

[0023] Plastic balls (not shown) are arranged in the air chamber 4, which can improve the cleaning rate.

[0024] The diameter of the plastic ball is smaller than the width of the air outlet groove 6, which facilitat...

Embodiment 2

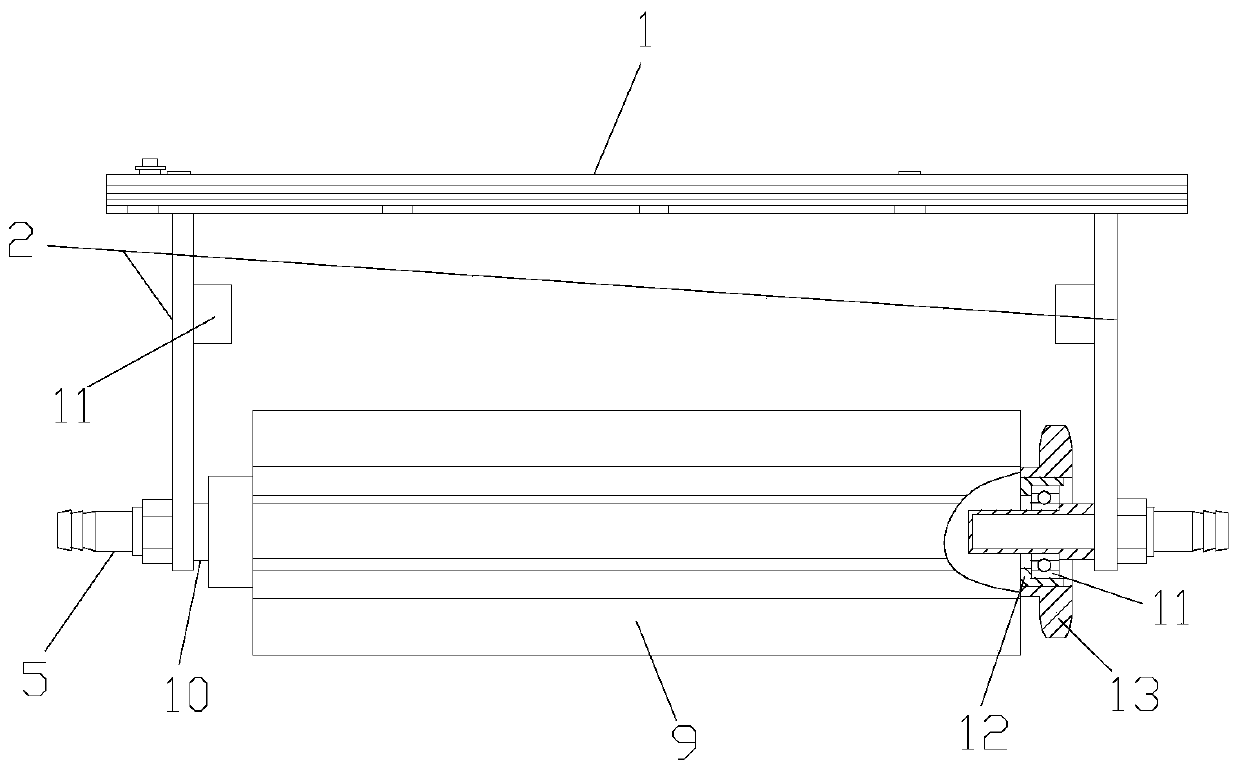

[0028] Such as image 3 and Figure 4 As shown, a peanut fruit picking device includes a clamping conveyor chain 1, a bracket 2, a fruit picking roller 9 and a drum shaft 10, the bracket 2 is installed at both ends of the clamping conveyor chain 1, and the fruit picking roller 9 is located on the bracket 2 Below, the drum shaft 10 is hollow, the two ends of the drum shaft 10 are provided with air pipes 5, and one end of the drum shaft 10 is provided with a bearing 11, a bearing seat 12 and a sprocket 13, and the bearing 11, the bearing seat 12 And sprocket wheel 13 is arranged from inside to outside in turn, and described fruit picking roller 9 comprises fruit picking cylinder 14 and second air outlet groove 15.

[0029] The second air outlet groove 15 is provided with more than one, and the second air outlet groove 15 can strike and brush the pods on the peanut seedlings.

[0030] The second air outlet slots 15 are distributed in an annular array to maintain high working ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com