Curved-surface toothless fruit picking mechanism

A curved surface and coupling rod technology, which is applied to harvesters, digging harvesters, agricultural machinery and implements, etc., can solve the problems of high harvest loss, dirty fruit picking, and high damage rate, so as to reduce fruit damage rate and improve fruit picking. efficiency, to avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

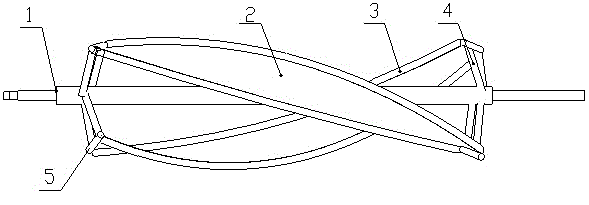

[0018] The curved toothless fruit picking mechanism includes an auger shaft 1, two sets of auger rods 3 and four auger coupling rods, each set of auger rods 3 includes two auger rods 3, and the two auger rods The middle of 3 is auger plate 2. The auger coupling rod includes a bottom rod 4 and an ejector rod 5; the number of the bottom rods 4 is two, and the bottom end of the bottom rod 4 is connected with the auger shaft 1 and there is a 40° between the two bottom rods 4. °; the top rods 5 are connected to the tops of the two bottom rods 4 respectively. The four auger coupling rods are distributed at both ends of the auger shaft 1, and are evenly arranged in a center-symmetric manner along the midpoint of the auger shaft 1; The auger shaft 1 is fixedly connected; the auger coupling rods at both ends of each set of helical auger rods 3 are evenly arranged in a center-symmetric manner along the midpoint of the auger shaft 1 .

[0019] During work, the curved surface toothless ...

Embodiment 2

[0021] The curved toothless fruit picking mechanism includes an auger shaft 1, two sets of auger rods 3 and four auger coupling rods, each set of auger rods 3 includes two auger rods 3, and the two auger rods The middle of 3 is auger plate 2. The auger coupling rod includes a bottom rod 4 and an ejector rod 5; the number of the bottom rods 4 is two, and the bottom end of the bottom rod 4 is connected with the auger shaft 1 and there is a 50° gap between the two bottom rods 4. °; the top rods 5 are connected to the tops of the two bottom rods 4 respectively. The four auger coupling rods are distributed at both ends of the auger shaft 1, and are evenly arranged in a center-symmetric manner along the midpoint of the auger shaft 1; The auger shaft 1 is fixedly connected; the auger coupling rods at both ends of each set of helical auger rods 3 are evenly arranged in a center-symmetric manner along the midpoint of the auger shaft 1 .

Embodiment 3

[0023] The curved toothless fruit picking mechanism includes an auger shaft 1, two sets of auger rods 3 and four auger coupling rods, each set of auger rods 3 includes two auger rods 3, and the two auger rods The middle of 3 is auger plate 2. The auger coupling rod includes a bottom rod 4 and an ejector rod 5; the number of the bottom rods 4 is two, and the bottom end of the bottom rod 4 is connected with the auger shaft 1 and there is a 60° between the two bottom rods 4. °; the top rods 5 are connected to the tops of the two bottom rods 4 respectively. The four auger coupling rods are distributed at both ends of the auger shaft 1, and are evenly arranged in a center-symmetric manner along the midpoint of the auger shaft 1; The auger shaft 1 is fixedly connected; the auger coupling rods at both ends of each set of helical auger rods 3 are evenly arranged in a center-symmetric manner along the midpoint of the auger shaft 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com