Patents

Literature

49results about How to "Improve fruit picking efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

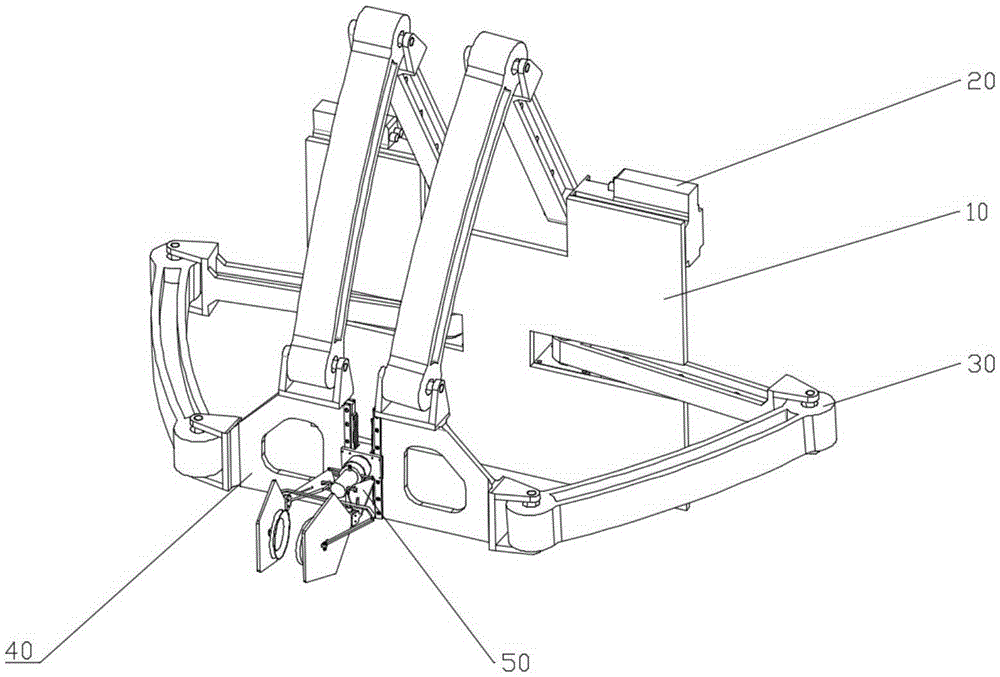

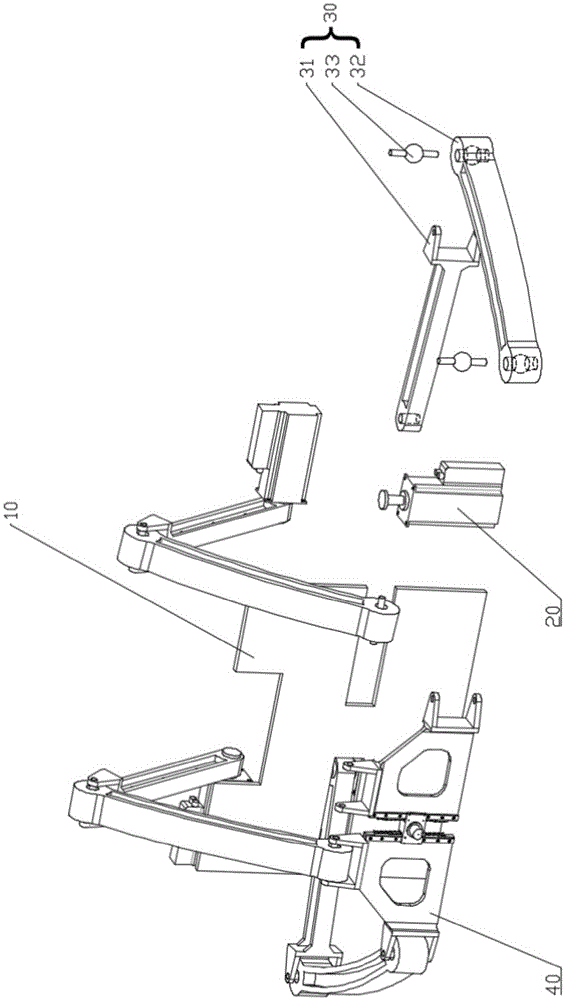

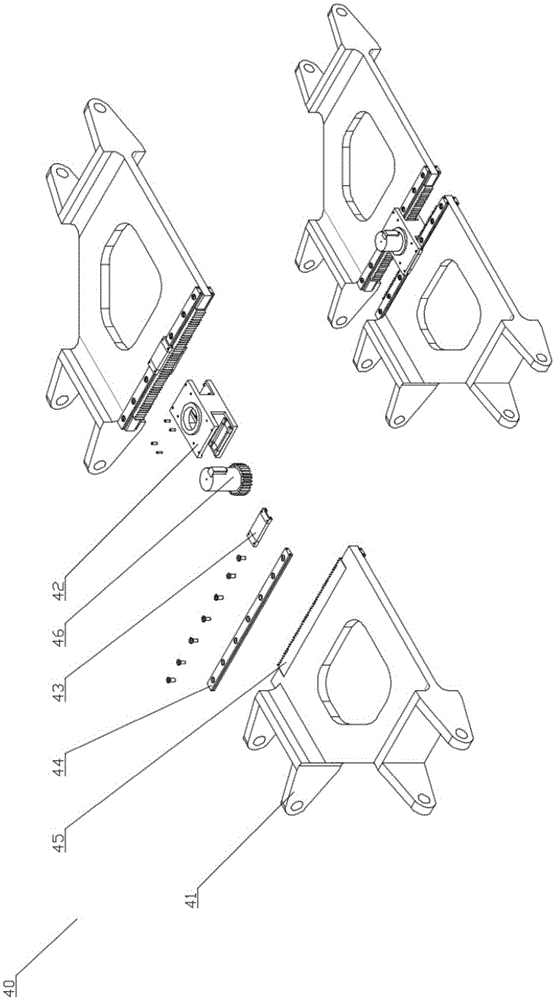

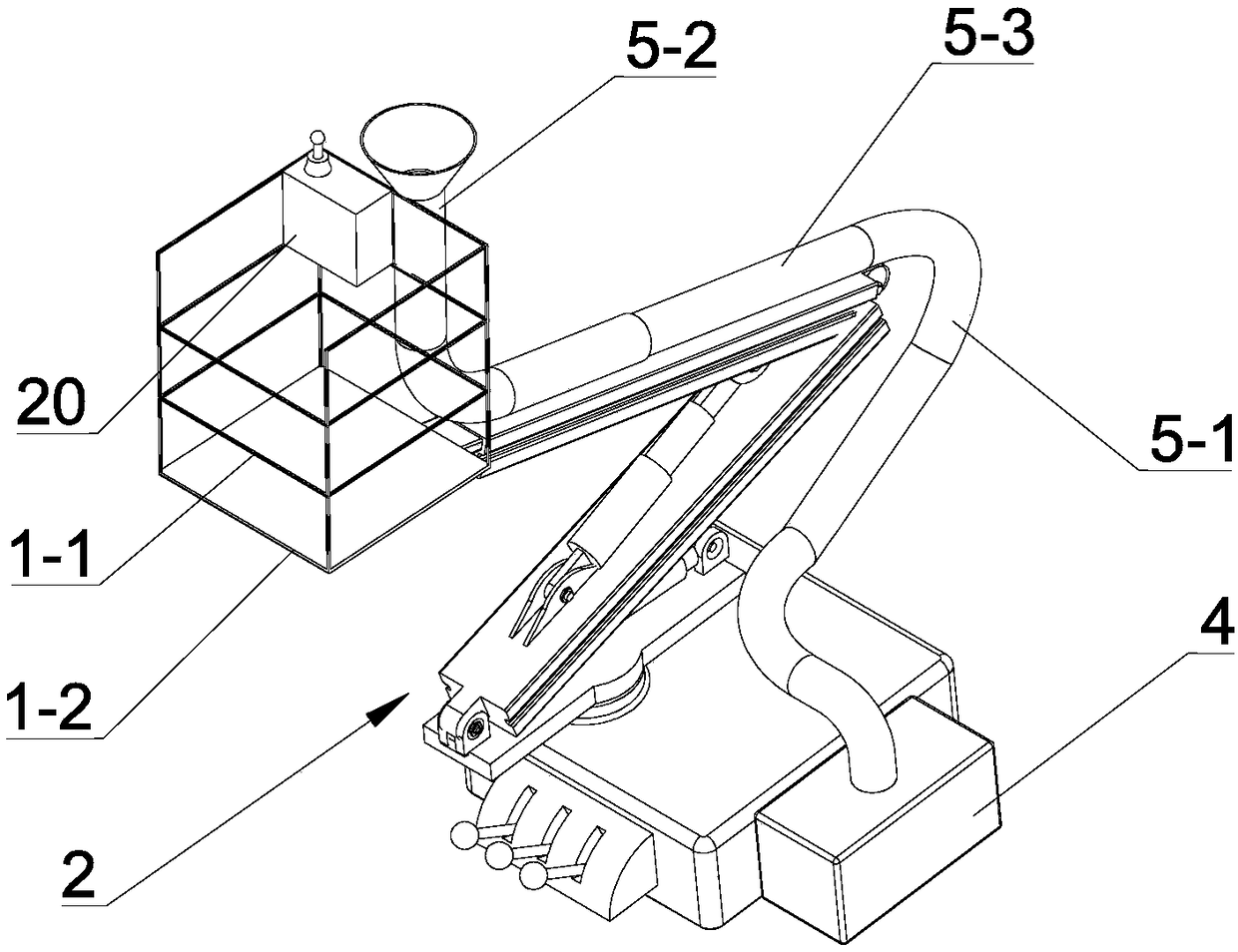

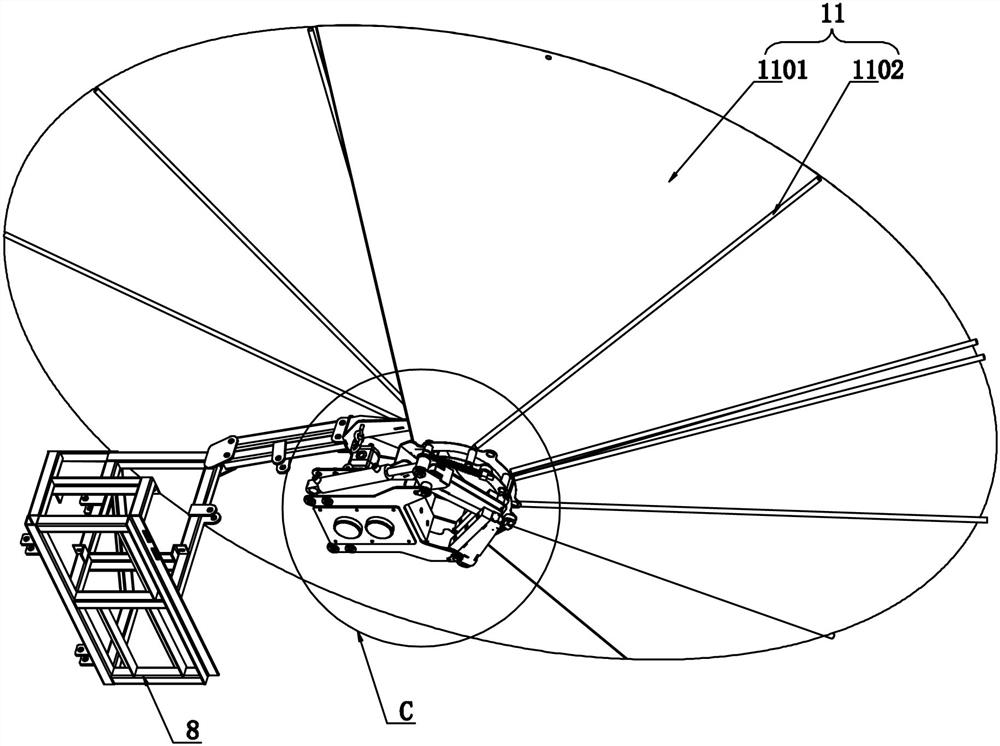

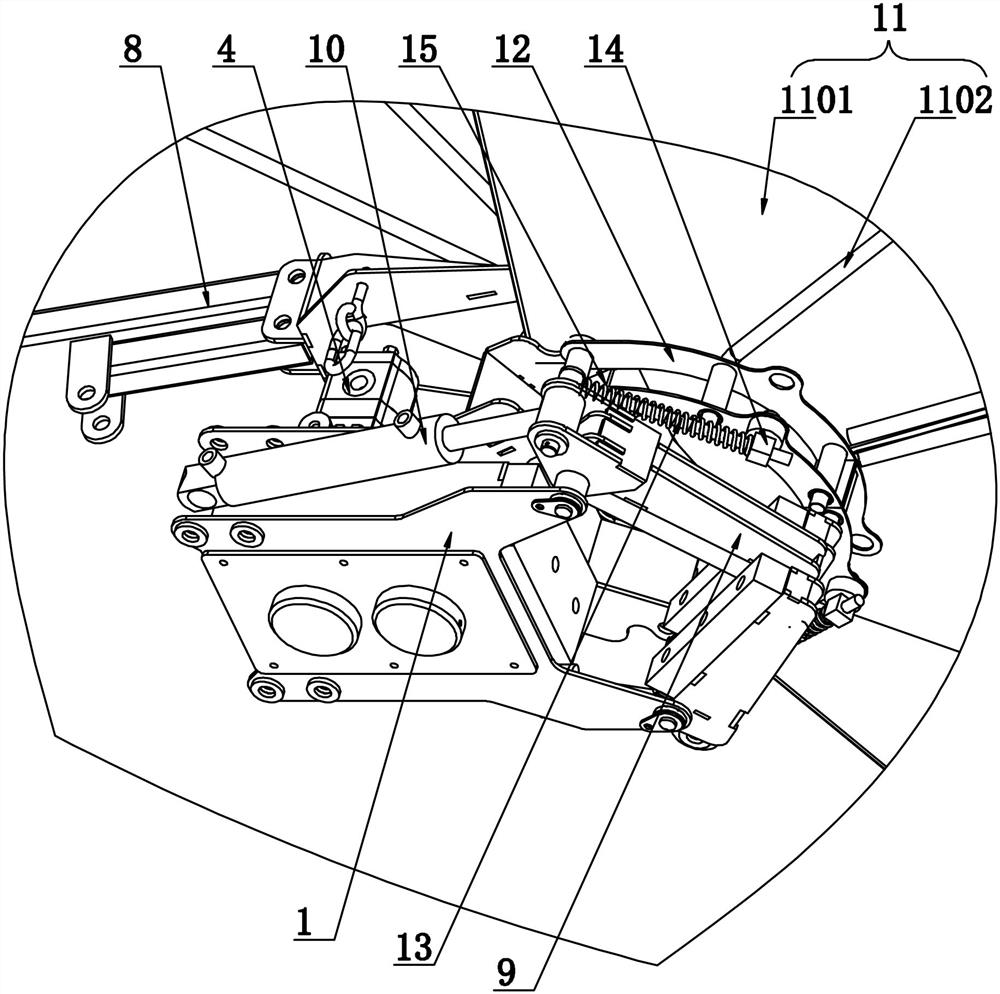

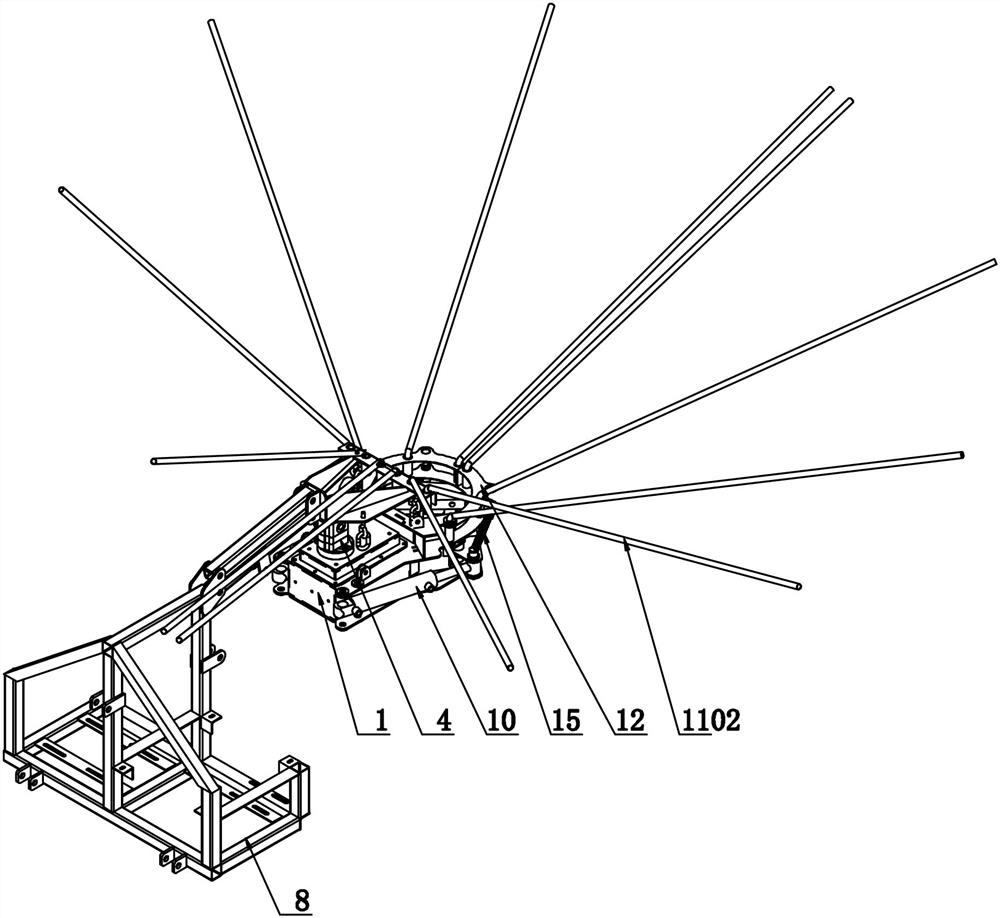

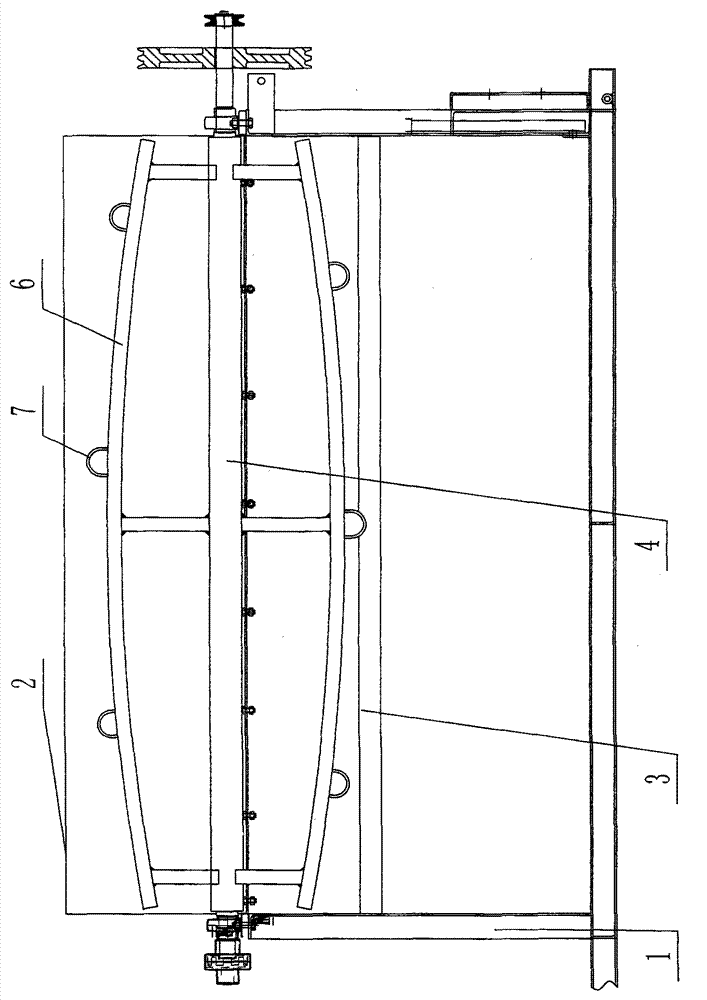

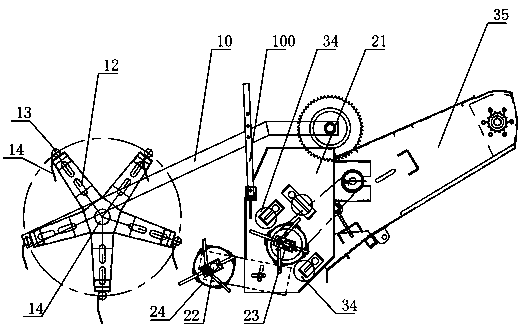

Fruit picking device based on non-uniform distribution parallel mechanism

ActiveCN105313106ASmall inertiaAccelerateProgramme-controlled manipulatorGripping headsElectric machineryEngineering

The invention discloses a fruit picking device based on a non-uniform distribution parallel mechanism. The fruit picking device comprises a fixed platform, four motors, four sets of controlling arms, a movable platform, a tail end picking mechanism and a control system. The fixed platform is placed vertically. The four motors are connected with the movable platform in front of the fixed platform through the corresponding controlling arms. The tail end picking mechanism used for picking fruits is installed on the front portion of the movable platform. The four motors and the tail end picking mechanism are connected with the control system. According to the fruit picking device, the tail end picking mechanism can be controlled to position the fruits at any angles, the fruits can be picked at any angles, the inertia of the picking mechanism is greatly reduced, and the accuracy of the picking mechanism is improved; damage to the fruits can be reduced during picking, and the fruit picking device has the fruit picking advantages of being flexible, accurate, fast and low in damage.

Owner:ZHEJIANG UNIV

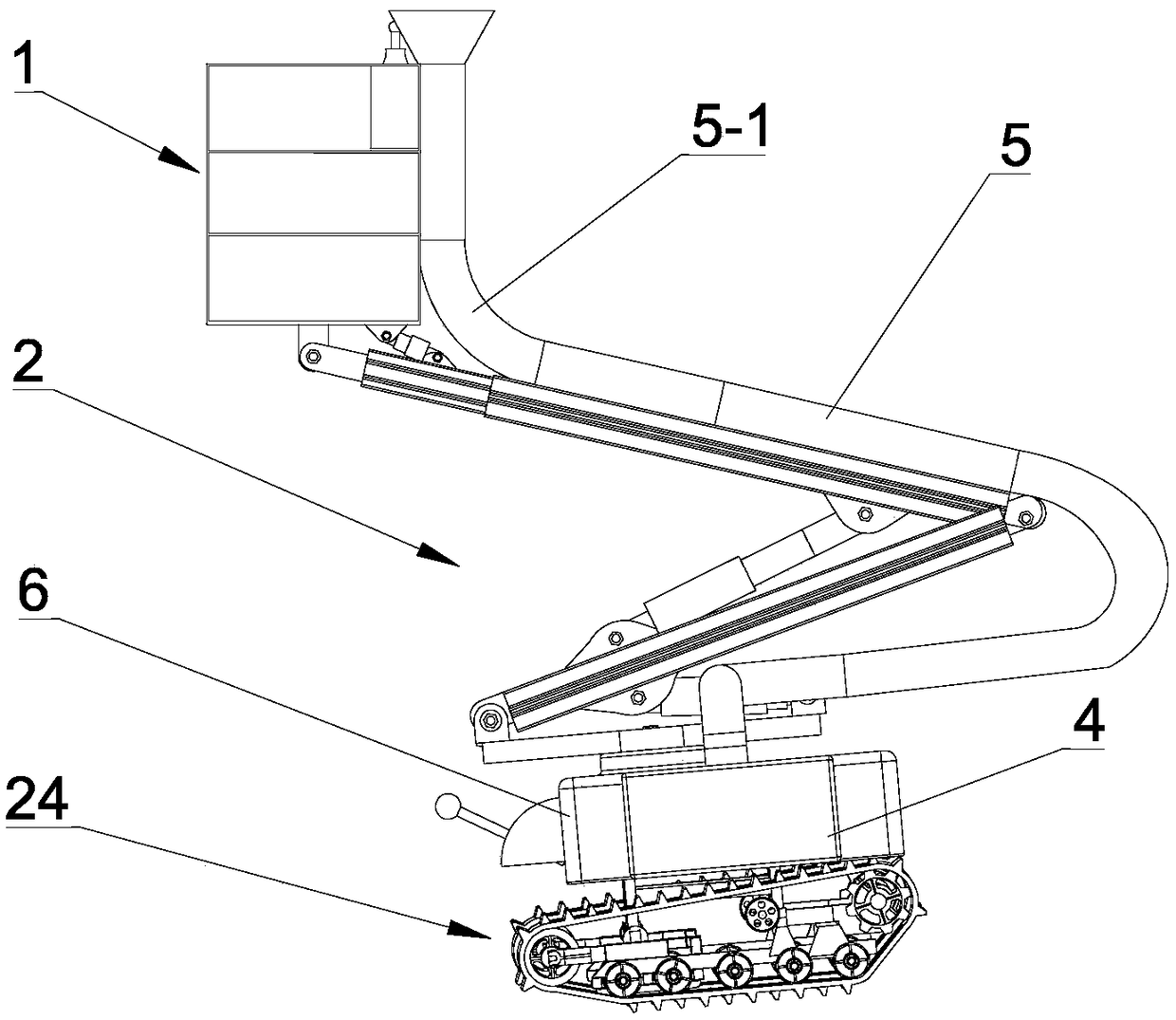

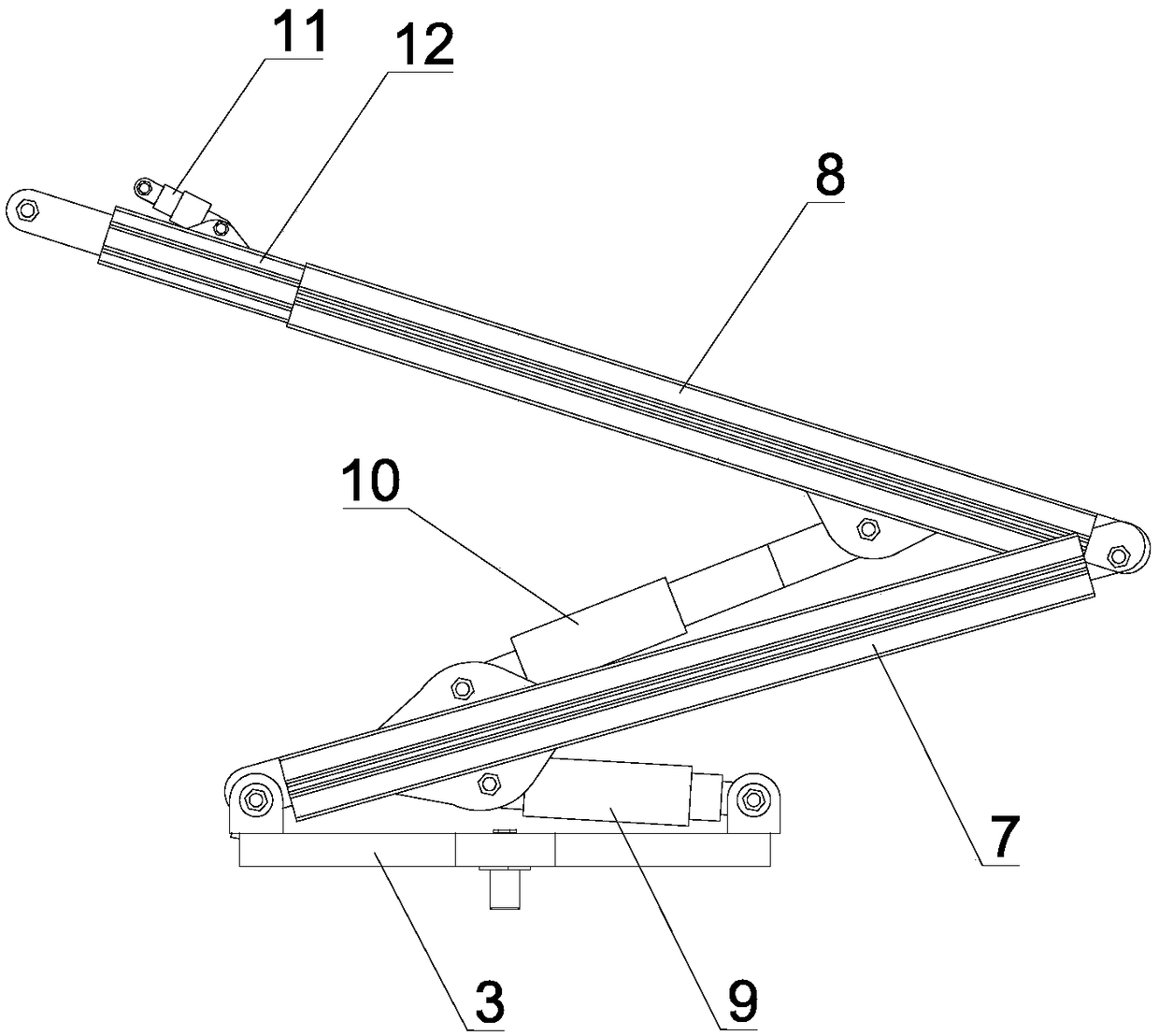

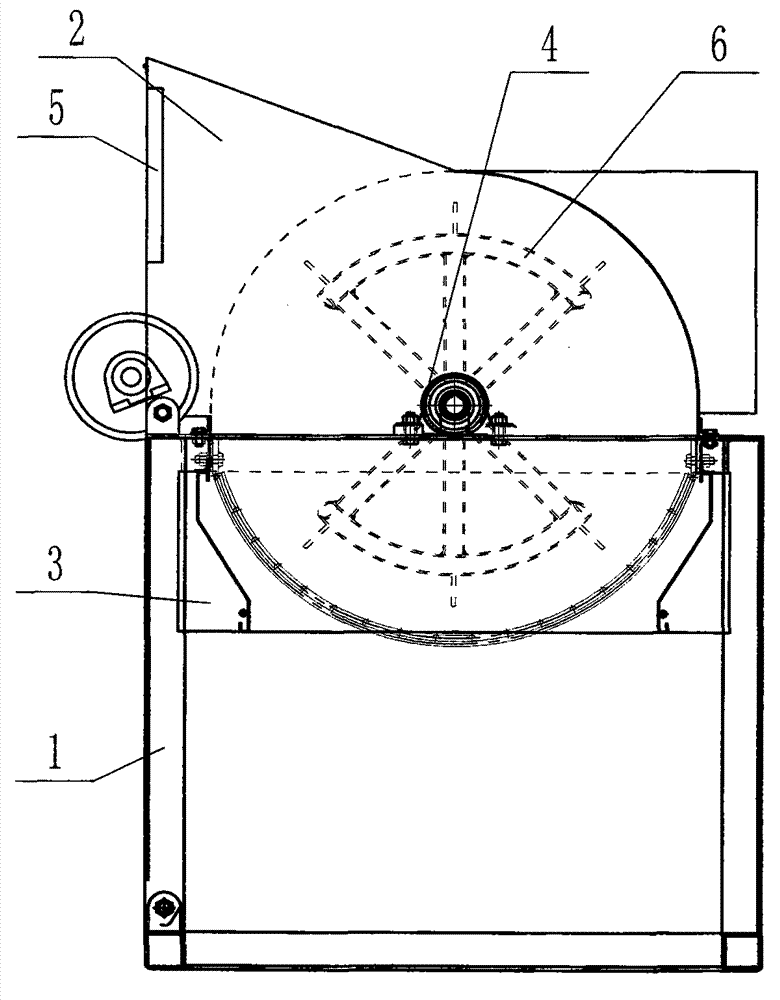

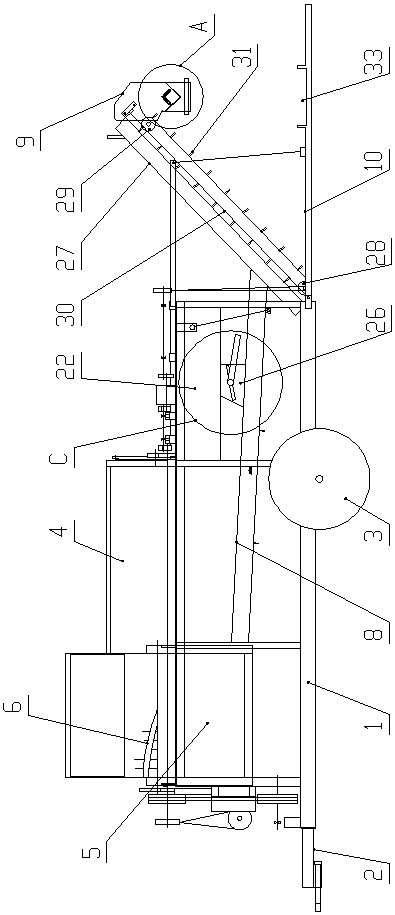

Self-propelled auxiliary fruit picker for mountainous region

The invention discloses a self-propelled auxiliary fruit picker suitable for a mountainous region. The fruit picker comprises a manual working platform, a lifting and rotating driving mechanism, a crawler walking mechanism and a fruit collecting device; wherein the lifting and rotating driving mechanism comprises a lifting driving mechanism and a rotating driving mechanism; the rotating driving mechanism includes a rotating member and a rotating mechanism for driving rotation of the rotating member; the lifting driving mechanism includes a lifting arm and a lifting power member; the manual working platform is disposed on the lifting arm; the fruit collecting device comprises a fruit collecting box and a fruit collecting pipe; the upper end of the fruit collecting pipe extends to one side of the manual working platform, the middle is arranged along the lifting arm, and the lower end extends to the fruit collecting box, wherein the corner of the fruit collecting pipe is provided with a hose. The fruit picker can not only cope with orchards of different terrains, but also be used for picking work of fruit trees with different heights, and is favorable for collecting fruit after picking, thereby effectively improving the fruit picking efficiency.

Owner:EAST CHINA JIAOTONG UNIVERSITY

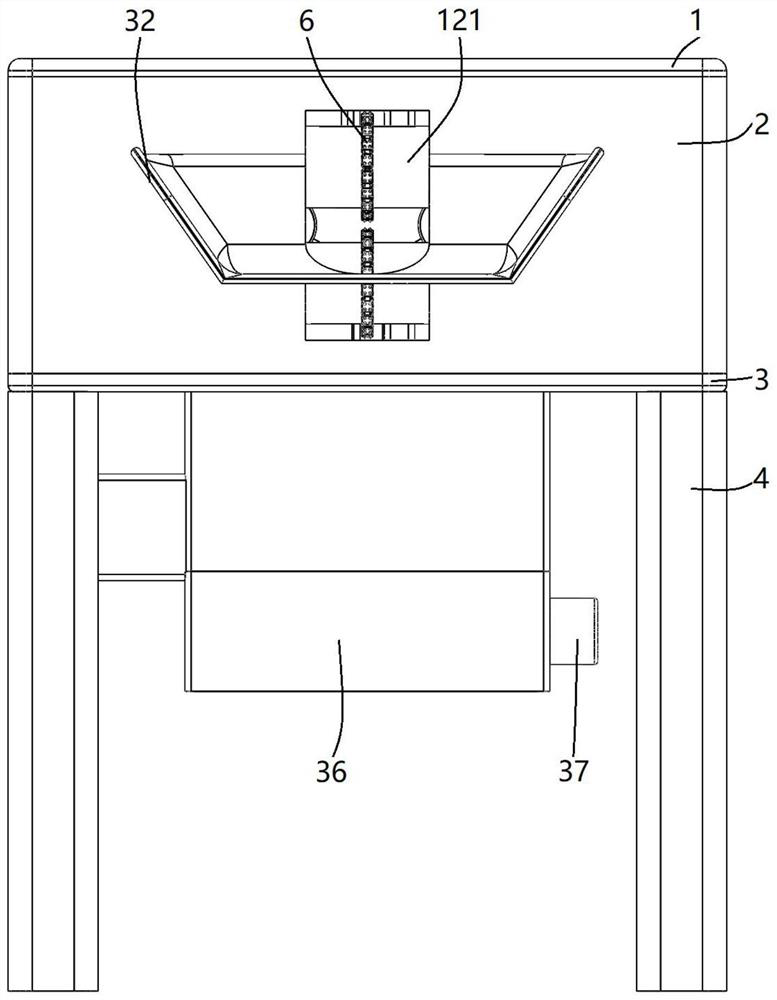

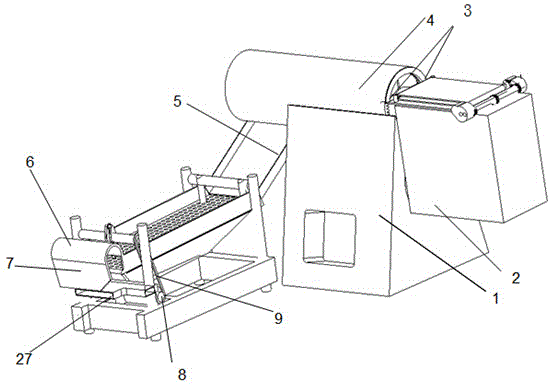

Peanut picker

InactiveCN103597962ASimple structureImprove fruit picking efficiencyThreshersMechanical engineeringEngineering

The invention discloses a peanut picker comprising a threshing frame, a cleaning frame, a master motor, a threshing cylinder, threshing rolls, a vibrating screen, a cleaning cylinder, and a cleaning fan. The threshing frame is transversely connected with the cleaning frame in parallel. One end of the threshing frame is provided with the master motor. The threshing rolls are mounted inside the threshing cylinder. One ends of the threshing rolls are connected with a master motor belt, and the other ends of the threshing rolls are connected with one end of the cleaning fan in a chain drive manner. The threshing cylinder is mounted on the threshing frame. One end of the threshing cylinder, close to the master motor, is provided with a feed hole. The cleaning cylinder is disposed on the cleaning frame and provided with a vine discharge hole. The cleaning fan is disposed inside the cleaning cylinder. The vibrating screen penetrates the threshing frame, and the cleaning frame is disposed below the threshing cylinder and the cleaning cylinder. The peanut picker is simple in structure, capable of picking in a whole-fed manner and cleaning with the vibrating screen, high in picking efficiency and good in cleaning effect.

Owner:QINGDAO HONGSHENG AUTO PARTS

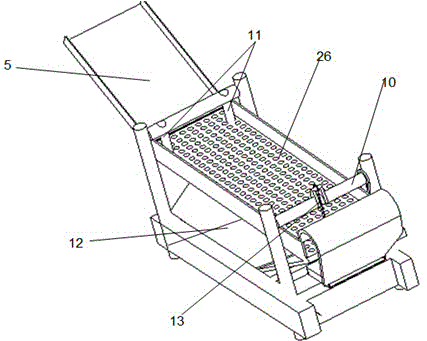

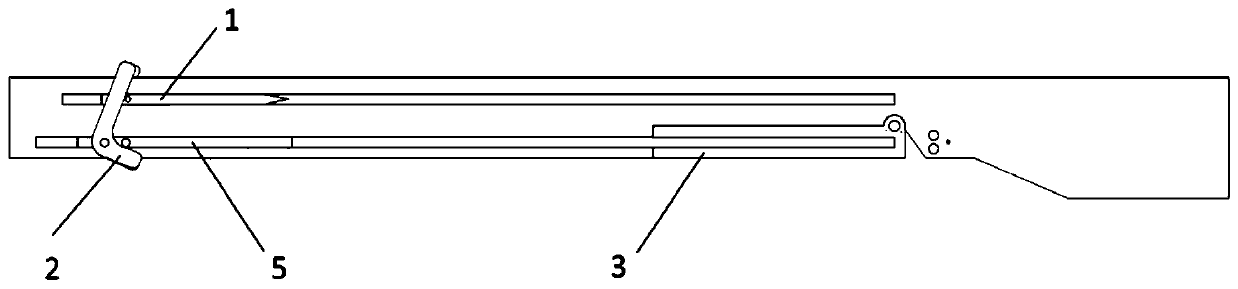

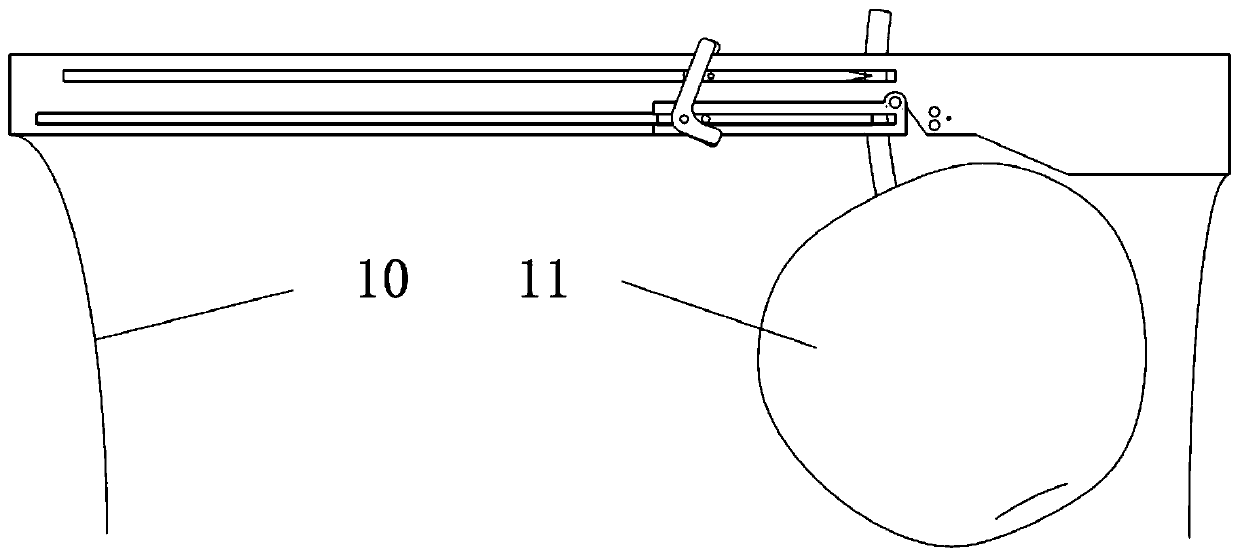

Peanut fruit picking device

ActiveCN103828552AReduce breakage rateImprove fruit picking efficiencyThreshersArachis hypogaeaLegume

The invention discloses a peanut fruit picking device. The peanut fruit picking device is characterized in that paired fruit picking rollers are arranged under a seedling clamping plate, and peanut seedlings vertically clamped in the seedling clamping plate are guided into places among the paired fruit picking rollers with the seedling clamping plate to pick up the fruit. By the arrangement, fruit picking effect can be effectively improved, complete picking rate can be increased, and damage rate of picked fruit can be reduced.

Owner:CHUZHOU UNIV

Alternate pruning method for fructus schisandrae

InactiveCN107197667AQuality improvementIncrease productionHorticulture methodsTransmittancePlant disease

The invention provides an alternate pruning method for fructus schisandrae. By the characteristic of flourishing nutrition growth of the fructus schisandrae and annual alternate pruning of sprout tillers branches of roots, the shortcomings that by the traditional pruning mode in cultivation and management of the fructus schisandrae, the technical points are complicated, and the labor cost is high are overcome, lots of problems caused by ageing of branches of perennial fructus schisandrae are avoided, meanwhile, on the premise of properly increasing planting density, the ventilating and transmittance conditions of a garden are improved, diseases are reduced, the use amount of pesticide is reduced, pollution is also reduced, and the yield is improved remarkably. In addition, the fruit harvesting efficiency is also improved, and the labor cost for fruit harvesting is reduced.

Owner:SHENYANG AGRI UNIV

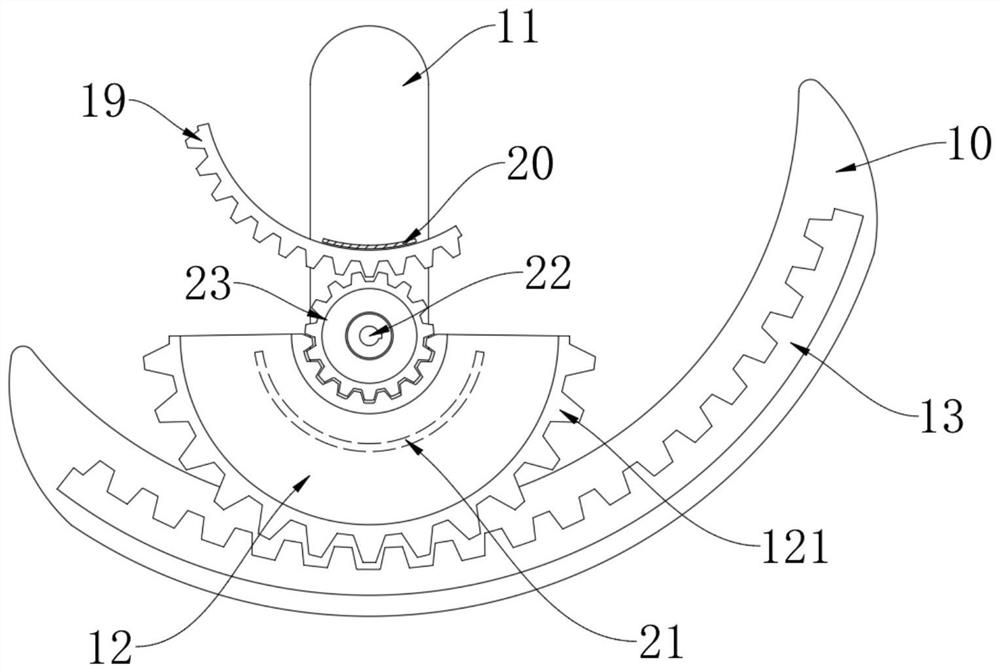

Tree shaking device

The invention relates to a tree shaking device. The tree shaking device comprises a frame body, a holding and clamping mechanism and a tree shaking device body, wherein the tree shaking device body istransversely and slidably arranged at one end of the frame body; the holding and clamping mechanism used for fixing the tree shaking device body to a trunk is arranged at the end, away from the framebody, of the tree shaking device body; the tree shaking device body comprises a shell, a first rotating shaft, a second rotating shaft and a motor; the motor is mounted on the shell; the first rotating shaft is in transmission connection with the motor; the first rotating shaft and the second rotating shaft are fixedly sleeved with transmission gears; the two transmission gears are meshed with each other; the first rotating shaft and the second rotating shaft are fixedly sleeved with a first cam and a second cam respectively; and the first cam and the second cam are identical in shape mirrorimage. The invention aims to solve or at least relieve the problem that an existing tree shaking device is relatively low in shaking strength and frequency, and provides the tree shaking device.

Owner:洛阳四达农机有限公司

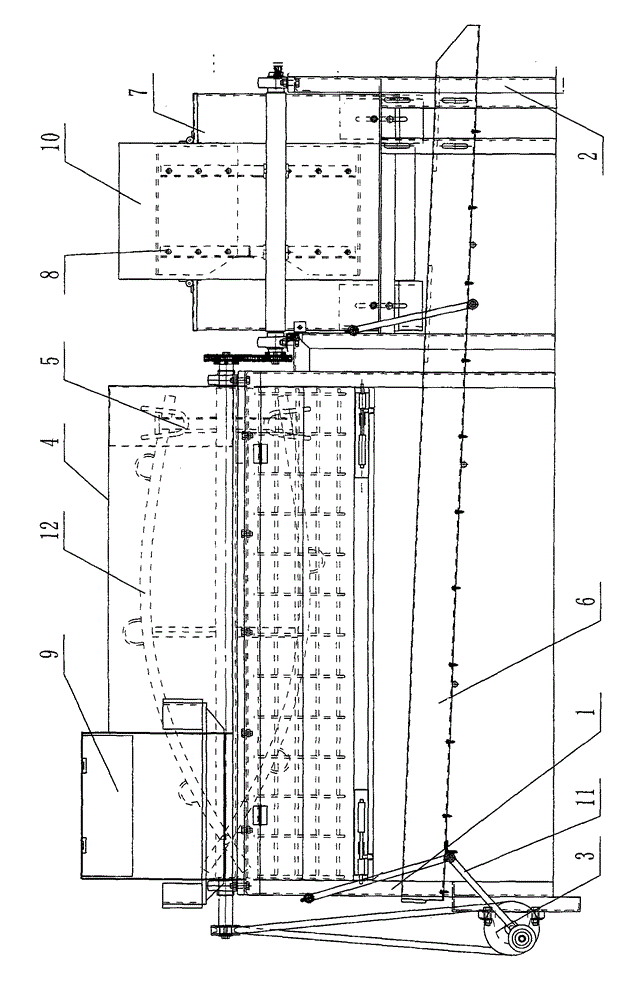

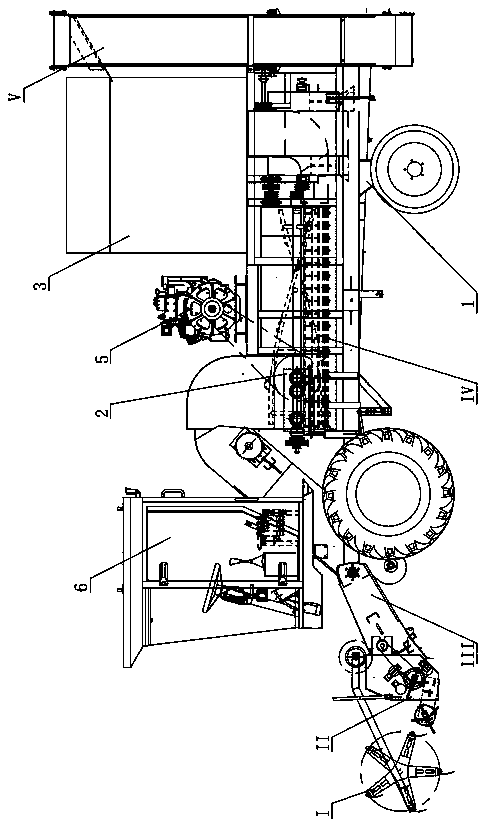

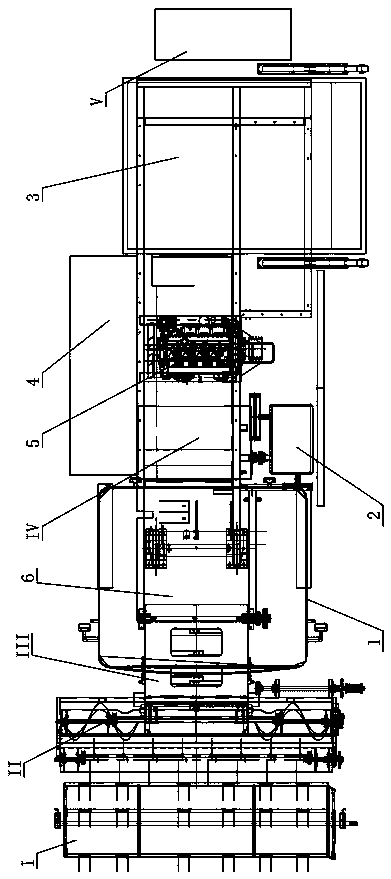

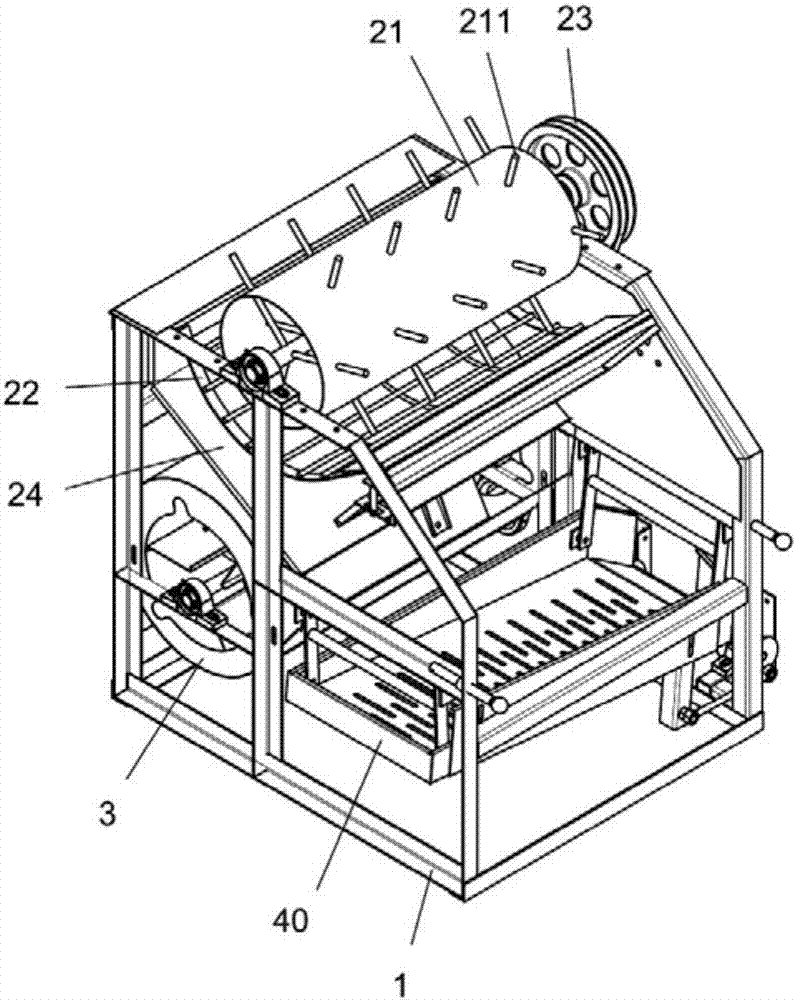

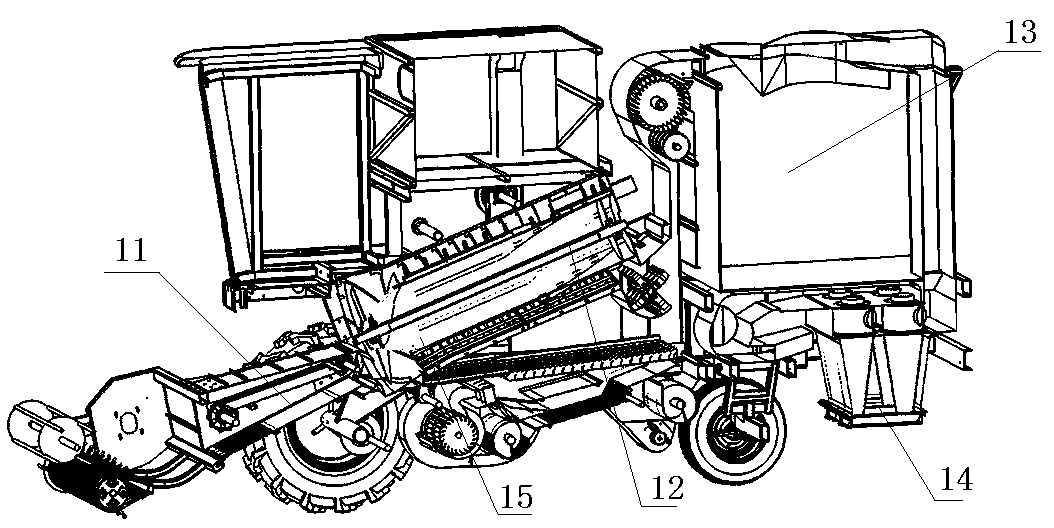

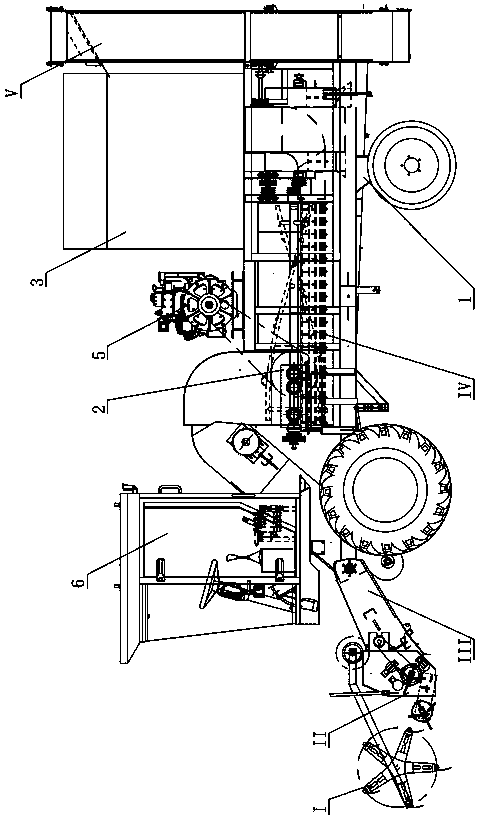

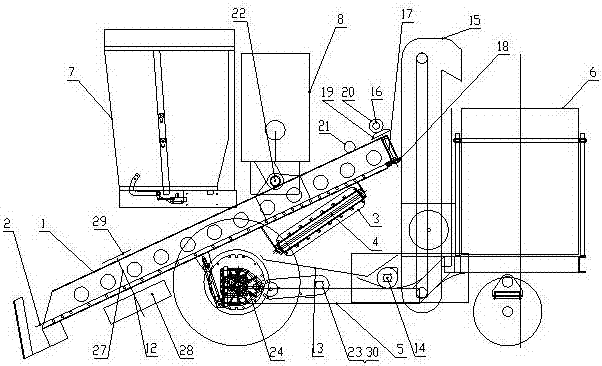

Self-propelled automatic pickup picker

ActiveCN105284301AGuaranteed accuracyGuaranteed harvesting efficiencyLoadersThreshersTurning framesEngineering

The invention discloses a self-propelled automatic pickup picker which comprises a frame, wherein a power machine and a traveling mechanism are arranged on the frame; a main-gear box is arranged on the frame; a peanut vine fruit pick-up device is arranged at the forefront of the frame; a peanut vine fruit feeding device positioned behind the peanut vine fruit pick-up device is connected to the frame; a vine fruit transport bridge assembly which is positioned behind the peanut vine fruit feeding device and corresponds to the outlet of the peanut vine fruit feeding device is arranged on the frame; a vine fruit conveying chain is arranged in the vine fruit transport bridge assembly; a picking device which corresponds to the outlet of the vine fruit transport bridge assembly and is in power connection with the main-gear box is connected with the middle of the frame; the rear part of the frame is connected with a grain store; a peanut transport device which is in power connection with the main-gear box is connected between the fruit outlet of the picking device and the feeding hole of the grain store; and a vine box capable of collecting peanut vines separated by the picking device is connected to one side of the frame. The self-propelled automatic pickup picker disclosed by the invention has the advantages of compact structure, high picking quality and high picking efficiency.

Owner:WEIFANG ZHONGDI MACHINERY TECH CO LTD

Full-feeding fruit picking device

Owner:QINGDAO HONGSHENG AUTO PARTS

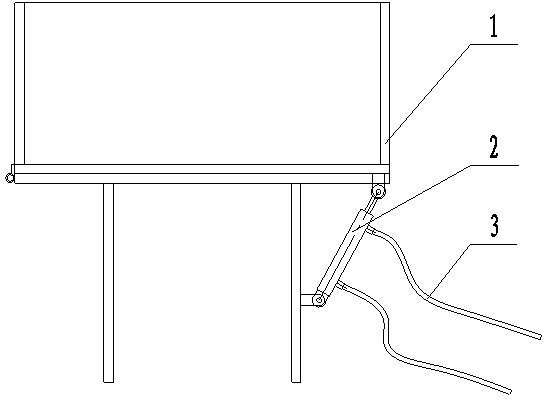

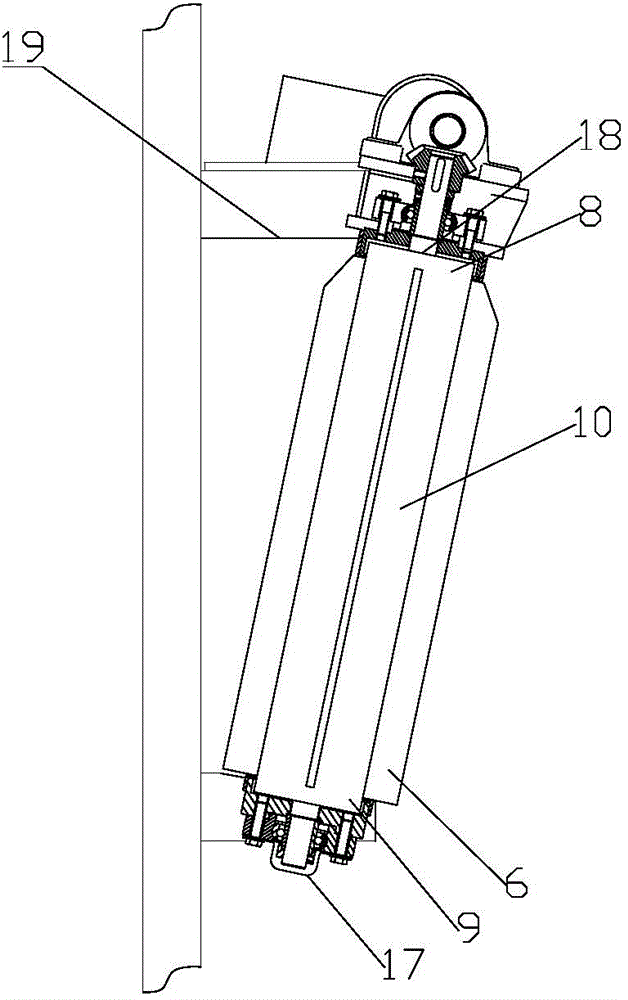

Hydraulic self-unloading mechanism of self-propelled peanut combined picking machine

InactiveCN103718759ASolve the problem of manual loading and unloadingReduce labor intensityThreshersPulp and paper industryUltimate tensile strength

The invention discloses a hydraulic self-unloading mechanism of a self-propelled peanut combined picking machine. The hydraulic self-unloading mechanism comprises a collecting box, a self-unloading oil cylinder and hydraulic oil pipes. One end of the self-unloading oil cylinder is movably connected with one end of the collecting box, and the other end of the self-unloading oil cylinder is fixed to a supporting arm of the collecting box. The upper surface of the self-unloading oil cylinder is connected with the hydraulic oil pipes, and the other ends of the hydraulic oil pipes are connected with a tractor hydraulic system. The hydraulic oil pipes are two in number. The hydraulic self-unloading mechanism of the self-propelled peanut combined picking machine solves the problem that manual unloading is needed after peanuts are collected, labor intensity is greatly lowered, work and labor are saved, and the picking efficiency can be obviously improved.

Owner:QINGDAO FEIERTE IND

Practical fruit-bearing forest fruit picking device

The invention discloses a practical fruit-bearing forest fruit picking device which comprises a bottom rod. The top end of the bottom rod is connected with a connecting rod in a threaded manner, the top end of the connecting rod is connected with an ejector rod in a threaded manner, one side of the top of the ejector rod is fixedly connected with a fixing frame, and the bottom of the fixing frameis fixedly connected with a fruit net bag. According to the practical fruit-bearing forest fruit picking device, by coordination of a first knife handle, a second knife handle, a knife edge, a limit spring, a pull rope, a shear frame, a telescopic sleeve, a plate, a blade and a supporting spring, the problem of generally single structure of fruit picking equipment used in the current market is solved, practicability of the fruit picking equipment is greatly improved, better use effects are achieved, great effects on completeness of fruits is avoided, attractiveness of the appearance of the fruits is ensured, sale level is improved, use of people is more effectively facilitated, fruit picking efficiency is improved, and working time is shortened.

Owner:盱眙启睿矿业有限公司

Peanut picking device

The invention discloses a peanut fruit picking device, which comprises a frame, a top cover is fixedly installed on the upper part of the frame, a fruit picking roller is installed through a bearing seat between the frame and the top cover, and a fruit picking filter is arranged under the fruit picking roller. The fruit-picking filter has an arc-shaped structure, and a fan is installed under the rear baffle of the filter. The fan is installed on the bottom longitudinal beam of the first frame and the second frame through the bearing seat. The sieve is provided with an opening at one end of the vibrating sieve. The invention has simple structure and high fruit-picking efficiency, which is dozens of times that of manual fruit-picking. At the same time, through the organic cooperation of various structures, effective fruit-picking operations can be carried out to ensure that peanuts are picked from the stalk and avoid manual secondary fruit-picking.

Owner:DONGGUAN BEIYANG IND DESIGN CO LTD

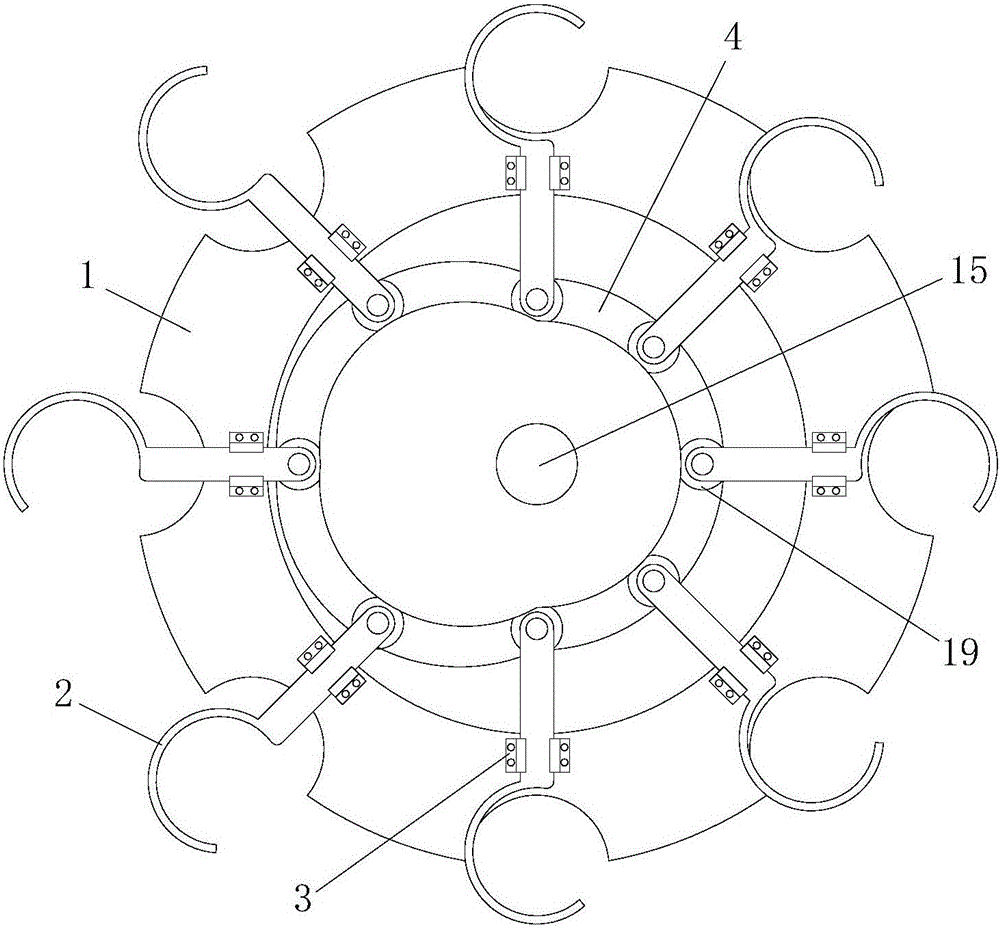

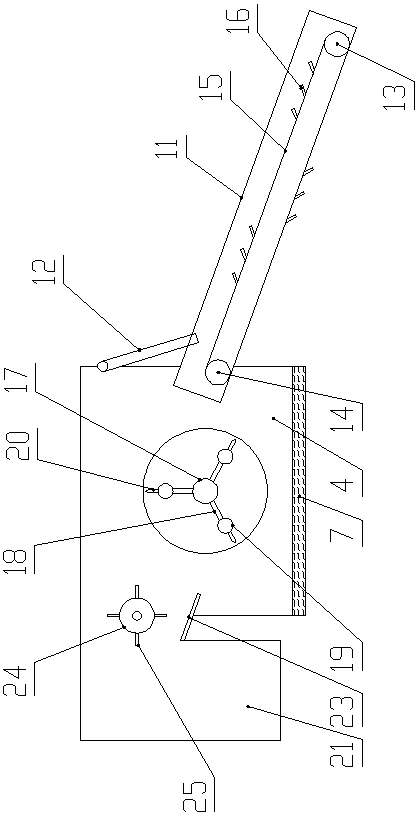

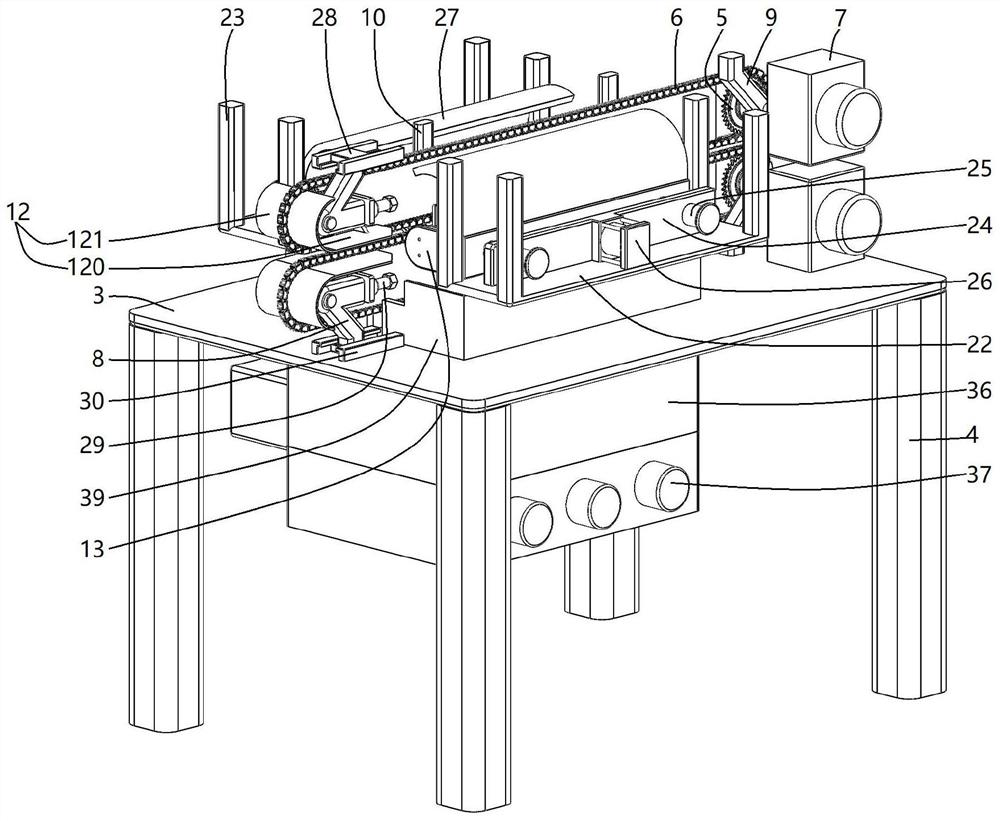

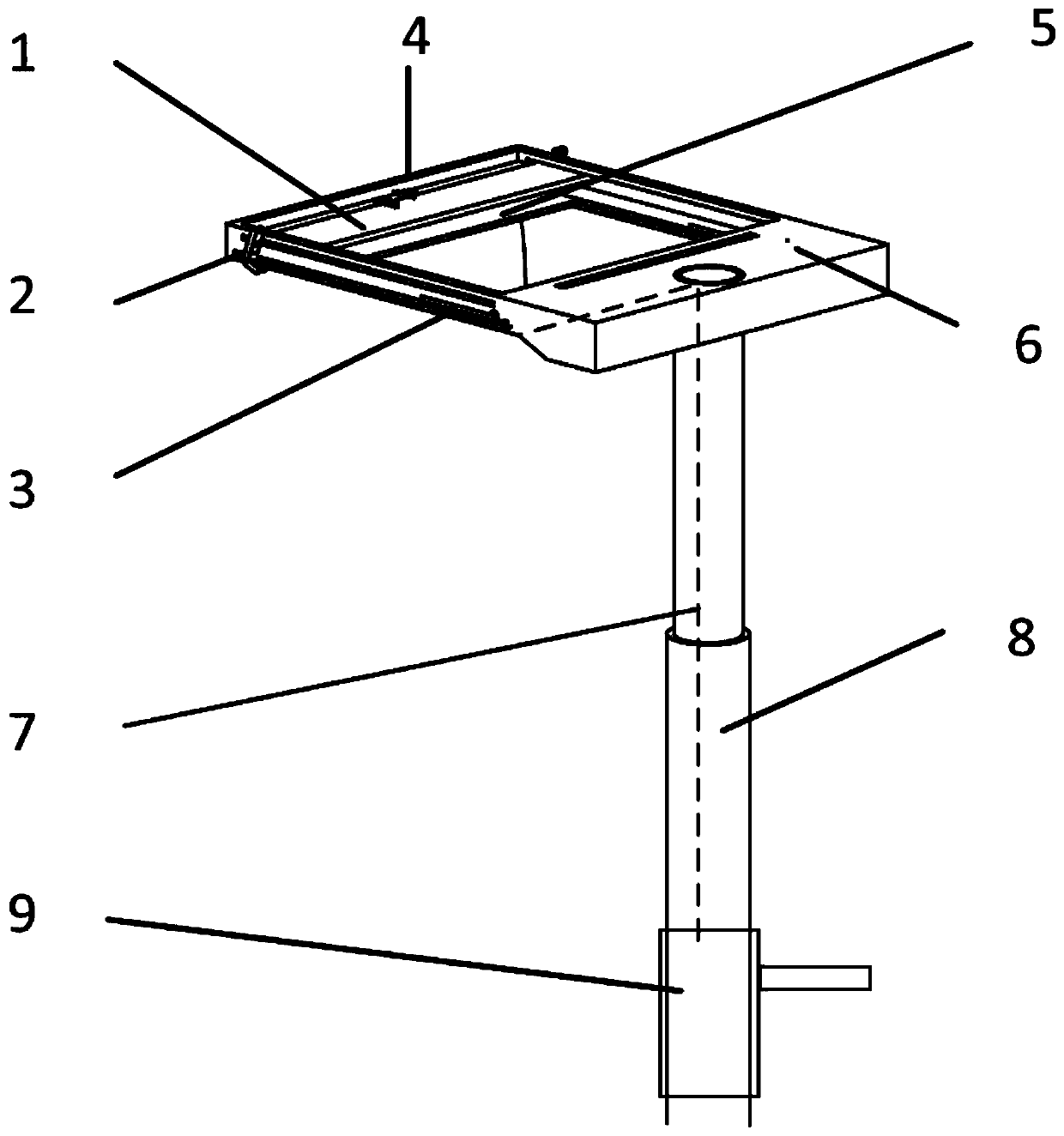

Vertical clamping-type peanut picking device and working principle thereof

The invention discloses a vertical clamping-type peanut picking device and working principle thereof. The vertical clamping-type peanut picking device includes a motor, a workbench, a pedestal, a picking roller, and a stand column, wherein the workbench is provided with a grasping mechanism including the same number of grasping claws and guiding slide ways, the guiding slide ways are fixed to the workbench, and a claw bar of each grasping claw is disposed in the matching guiding slide way; a guide rail having a cam structure is positioned at the top of the workbench, and the end of each claw bar is positioned in the guide rail; the picking roller is positioned below the grasping claws and is located in one side where each grasping claw retracts into the workbench; a picking rod in the picking roller is fixed to a picking rod base, and the picking rod base is connected to the motor. According to the invention, peanut seedlings can be mechanically and automatically clamped by the cam-shaped guide rail with a non-circular structure; the picking rod and spike teeth are together to achieve peanut picking; the peanut plants are effectively hit, and the hit range and hit effect are improved; the quality of obtained peanut pods is greatly improved, the picking efficiency and the picking rate are effectively improved, and the pod breakage rate is reduced.

Owner:CHUZHOU UNIV

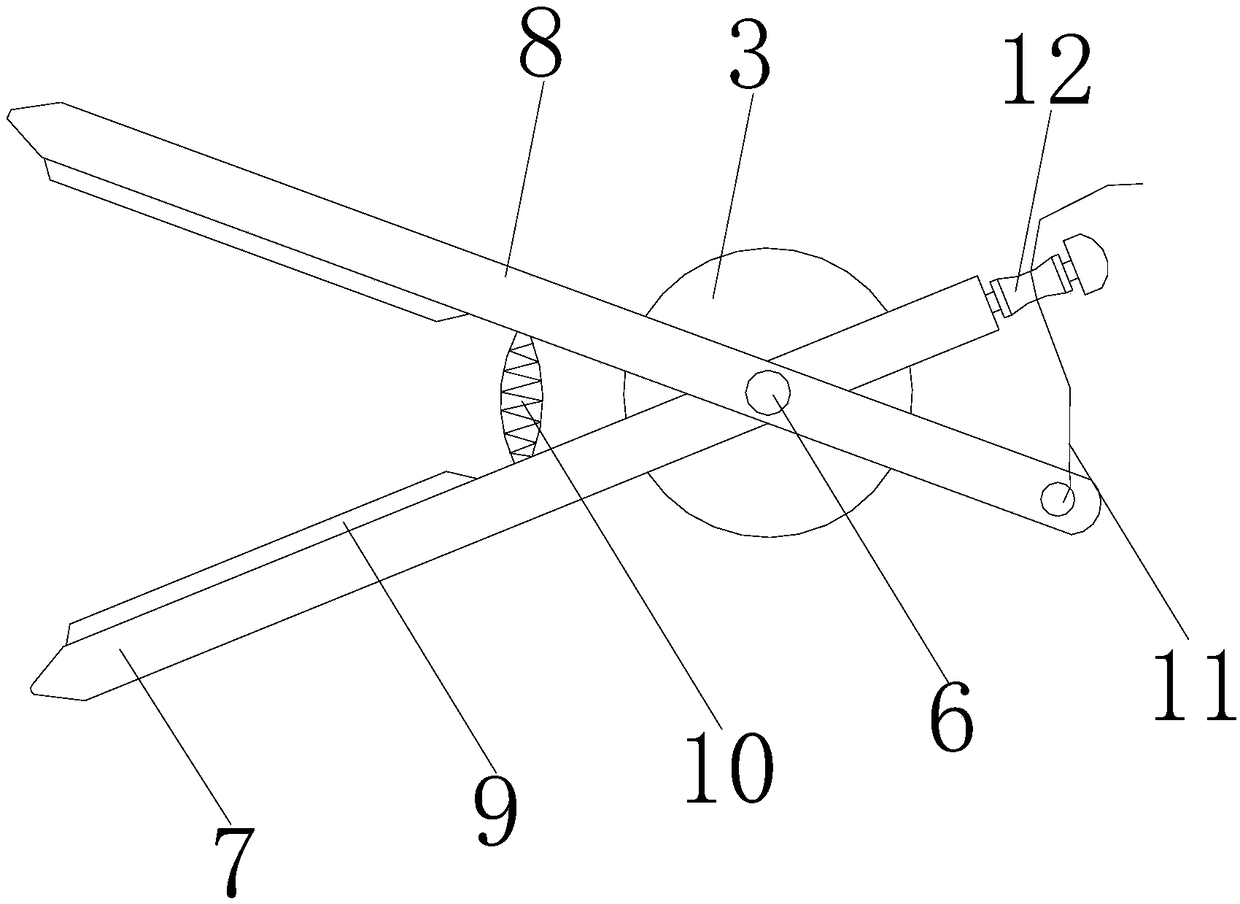

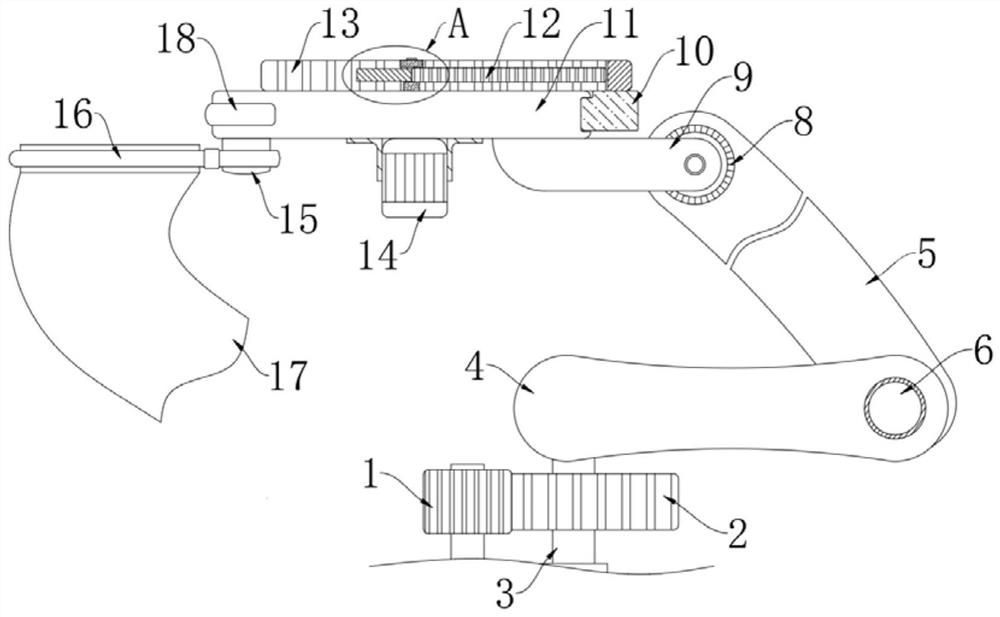

Fruit picking mechanical arm of agricultural robot

InactiveCN112868382AFlexible moving processEasy to adjustPicking devicesAgricultural scienceAgricultural engineering

The invention discloses a fruit picking mechanical arm of an agricultural robot. The fruit picking mechanical arm comprises a first rotating arm body and a second rotating arm body, a first rotating part is connected to the lower end of the first rotating arm body, a second rotating part is installed between the upper end of the first rotating arm body and the lower end of the second rotating arm body, and a third rotating part is arranged at the upper end of the second rotating arm body. A third rotating arm is fixedly supported at the output end of the third rotating part, a stem shearing mechanism is fixedly installed on the third rotating arm, and the stem shearing mechanism comprises a transmission mechanism, a shearing device and a fruit collecting device. According to the fruit picking mechanical arm of the agricultural robot, fruit stems can be completely cut off during cutting, and the integrity of the fruit is ensured; and meanwhile, the image survey range is expanded, more comprehensive fruit parameters are obtained, and the situation that the quality of the fruit is misjudged by a central control device due to the fact that a conventional camera device only collects information of a fruit orientation surface or a nightside is avoided.

Owner:一度智能科技(深圳)有限公司

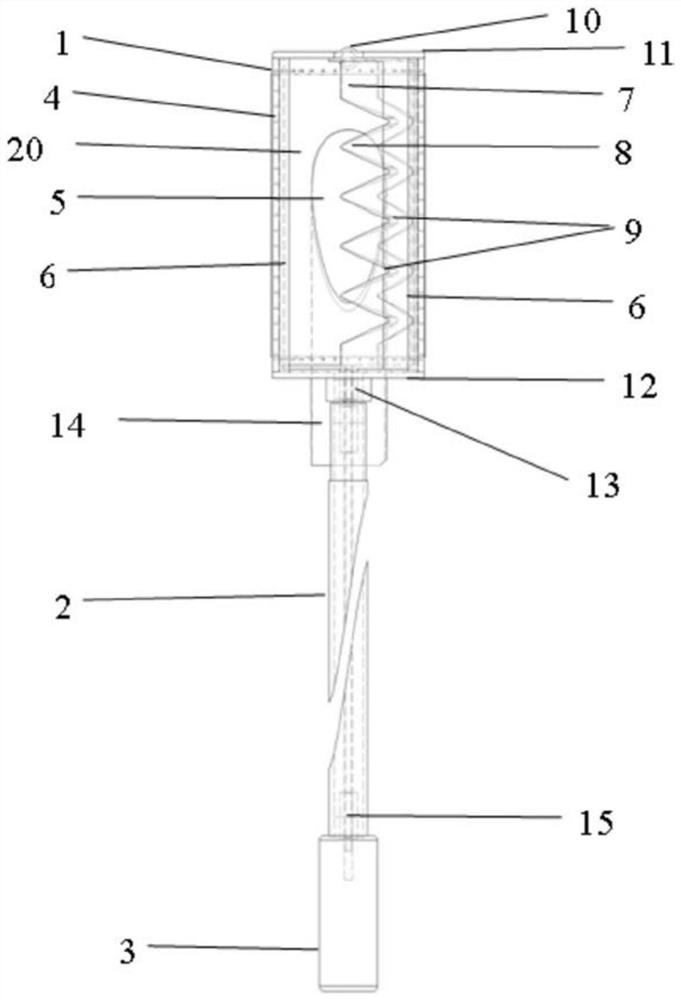

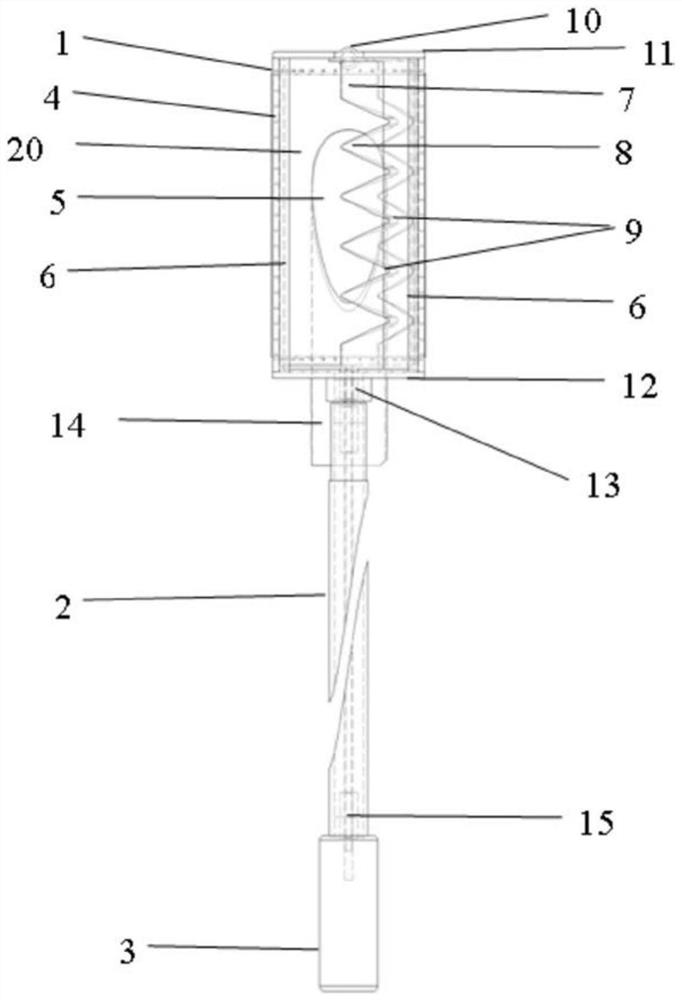

Manual peanut picking device

InactiveCN112673814AImprove fruit picking efficiencyShorten the timeThreshersHand equipmentsAgricultural engineeringStructural engineering

The invention relates to the technical field of agricultural equipment, and discloses a manual peanut picking device. The manual peanut picking device comprises a first shell, a peanut removing device is arranged below the first shell, the peanut removing device comprises a rotating handle, an arc plate, a stop lever, a transverse rod and a second shell, the stop lever is fixedly connected with the transverse rod, the rear wall face of the transverse rod is fixedly connected with the first shell, the arc plate is fixedly connected with the inner bottom face of the first shell, the rotating handle penetrates through the left side wall of the first shell and is fixedly connected with the first shell, a seedling clamping device is arranged on the first shell, and a reciprocating device and a seedling feeding device are further arranged on the first shell. The rotating handle rotates to drive a first rotating shaft to rotate, a scraping plate on the first rotating shaft can also rotate synchronously, peanut vines are clamped by first notches in the scraping plate, peanuts are hooked by the stop lever and fall into a second shell, the peanut vines are continuously pulled by the first rotating shaft to move backwards, the peanuts are separated from the peanut vines, the peanut picking efficiency is improved, time is saved, the working intensity is reduced, the fluffy peanut vines are compressed, and space is saved.

Owner:蔡根福

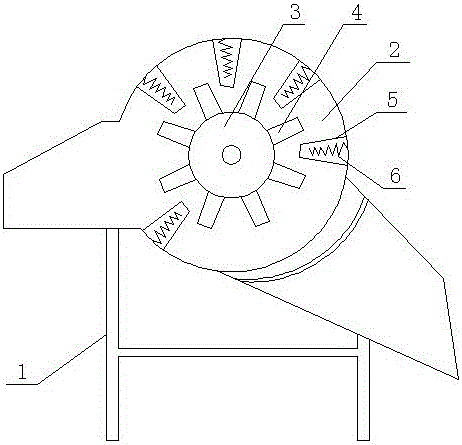

Peanut picker

InactiveCN105815047AImprove fruit picking efficiencyGood fruit qualityThreshersArachis hypogaeaEngineering

The invention relates to the technical field of agricultural machinery, and the name is a peanut picking machine, which includes a frame, a fruit picking room is installed on the frame, a fruit picking roller is arranged in the fruit picking room, and there are a plurality of protruding fruit picking rollers around the fruit picking roller; There are a plurality of picking room protrusions around the inner side of the fruit picking room. The picking room protrusions are outside the path where the fruit picking roller protrusions run. The fruit picking room protrusions are made of rubber rods. The fruit picking room protrusions A spring is provided inside. Such a peanut picking machine has the advantages of high fruit picking efficiency and good fruit picking quality; the protrusion of the picking room is made of rubber rods, and has the advantage of preventing peanuts from breaking; the protrusion of the picking room is equipped with a spring , also has the advantage of better use effect.

Owner:CHANGGE JINAN AGRI MACHINE SPECIALIZED COOP

Peanut picking device

Provided is a peanut picking device. The device comprises a fruit seedling transmission band. The front part of the fruit seedling transmission band is provided with a seedling feeding position. The rear part of the fruit seedling transmission band is provided with a fruit separating position. At least a side part of the fruit seedling transmission band between the seedling feeding position and the fruit separating position is provided with a seedling cutting device at interval. The fruit seedling transmission band is a grid-shaped transmission band which sieves peanuts downwards. A threshing transmission band is arranged below the fruit separating position. The threshing transmission band is provided with a plurality of fruit gathering knife. The fruit gathering knife is arranged close to the lower surface of the grid-shaped transmission band. A seedling turning transmission band is arranged above the fruit separating position. A plurality of seedling turning claws are arranged on the fruit seedling transmission band at interval. A seedling and fruit separating device is arranged on the rear of the fruit seedling transmission band. The device is simple in structure and convenient in operation, and reduces working intensity of farmers, and effectively improves picking efficiency of peanuts.

Owner:樊坤声

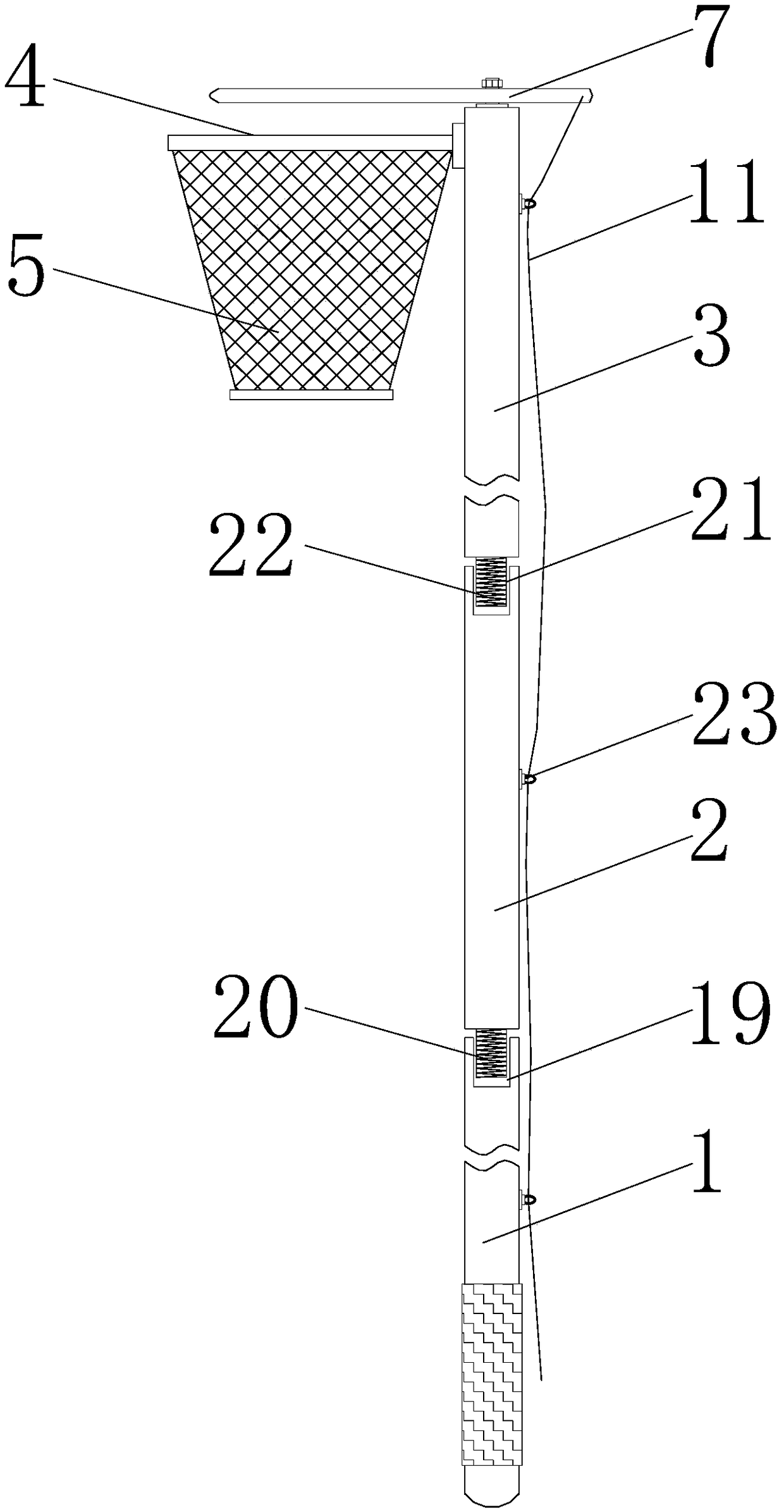

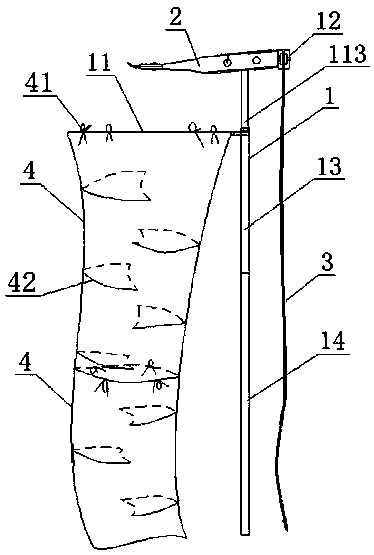

High-altitude fruit picker

The invention relates to the technical field of agricultural picking devices, in particular to a high-altitude fruit picker. The high-altitude fruit picker comprises a picking rod, a fruit shear, a drawstring and a plurality of net pockets; the picking rod comprises an open support ring, a pulley block, a fixing rod and a plurality of connecting rods; the fruit shear includes a lower shear blade,an upper shear blade, a lower handle, an upper handle, a pin shaft, a spring and a pull ring; one end of the drawstring is connected to the pull ring of the fruit shear, and the other end of the drawstring bypasses a pulley ring groove and extends downward to the same length as the picking rod; and openings and tails of the net pockets are opened, and a plurality of blocking pockets are verticallyand alternatively distributed in the net pockets. The high-altitude fruit picker is simple in structure, and is easy to operate; the height of the picking rod and the length of the net pockets can beadjusted according to the height; multi-person cooperation picking can be avoided, and the picking efficiency is improved; the use safety is ensured, climbing operations can be avoided, and manpowerand material resources can be saved; and the picked fruits will not be damaged, and the incomes of farmers can be increased.

Owner:丁钰宸

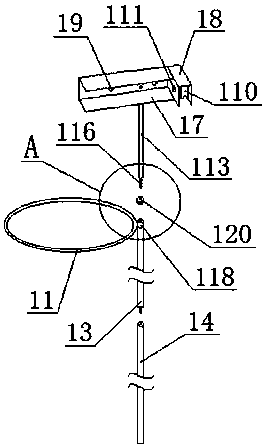

Fruit picker for clustered fruits

The invention discloses a fruit picker for clustered fruits. A fruit picking rod is formed by connecting a plurality of pipe barrels; every two pipes are connected by a fixing ring; running noose loops are assembled on the two sides outside each pipe; the top end of the fruit picking rod is bifurcated; a support point and a support ring are assembled at the top end of the fruit picking rod; a support plate is mounted at the top end of the fruit picking rod; rope pulleys are mounted on the both sides of the pipe at the tail end of the fruit picking rod; bolts are configured on the rope pulleys; a pair of shears is mounted at the support point and has an automatic opening function; a shearing loop is configured at the tail end of one shearing arm; the shearing loop is connected with a pulling rope; the pulling rope penetrates through the running noose loop and is mounted on one rope pulley in a sleeving manner; the support ring is sleeved with a push rod; one end of the push rod is connected with a pulling rope; the pulling rope penetrates through the running noose loop and is connected to the other rope pulley in a sleeving manner; a spring is placed in a sleeve; the sleeve is connected with the support plate; a through hole is formed in the support plate; the pulling rope connected with the push rod penetrates through the through hole; and elasticity of the spring acts on the push rod. The picker picks the clustered fruits more easily, and the fruits are not damaged.

Owner:赵百华

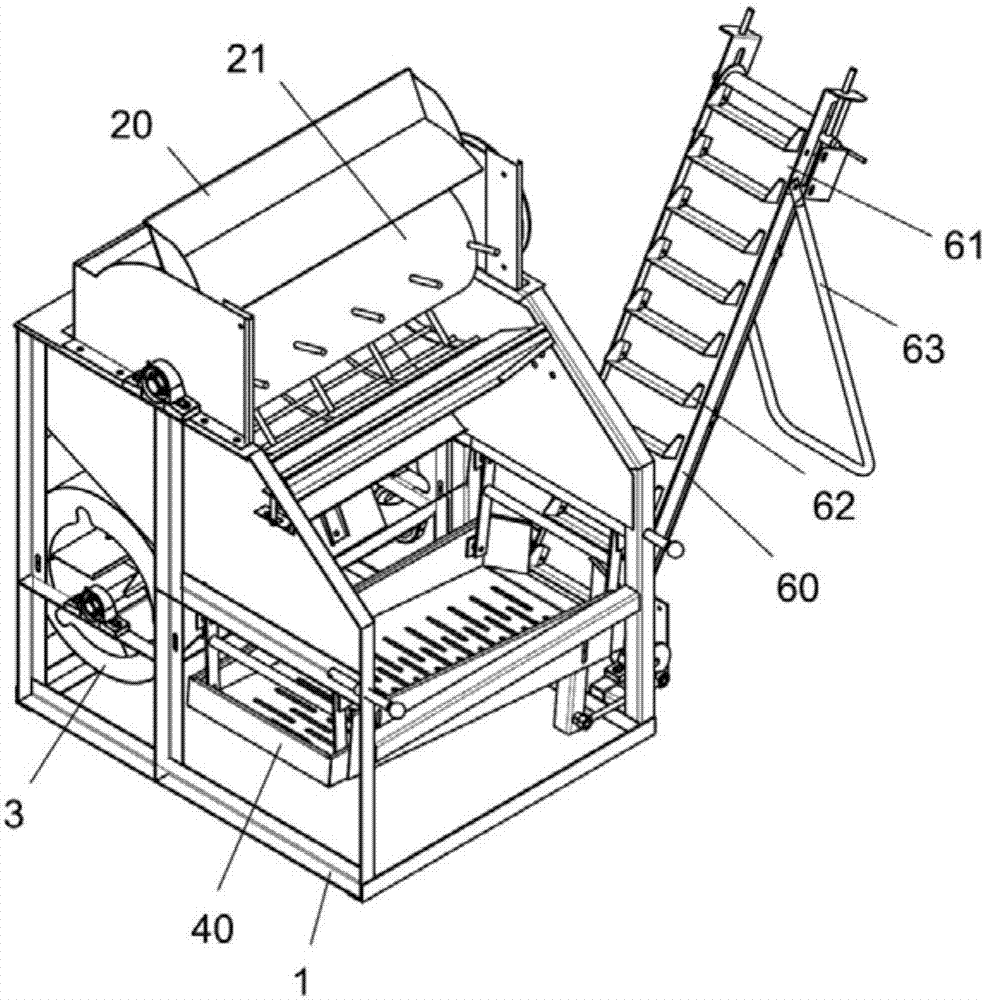

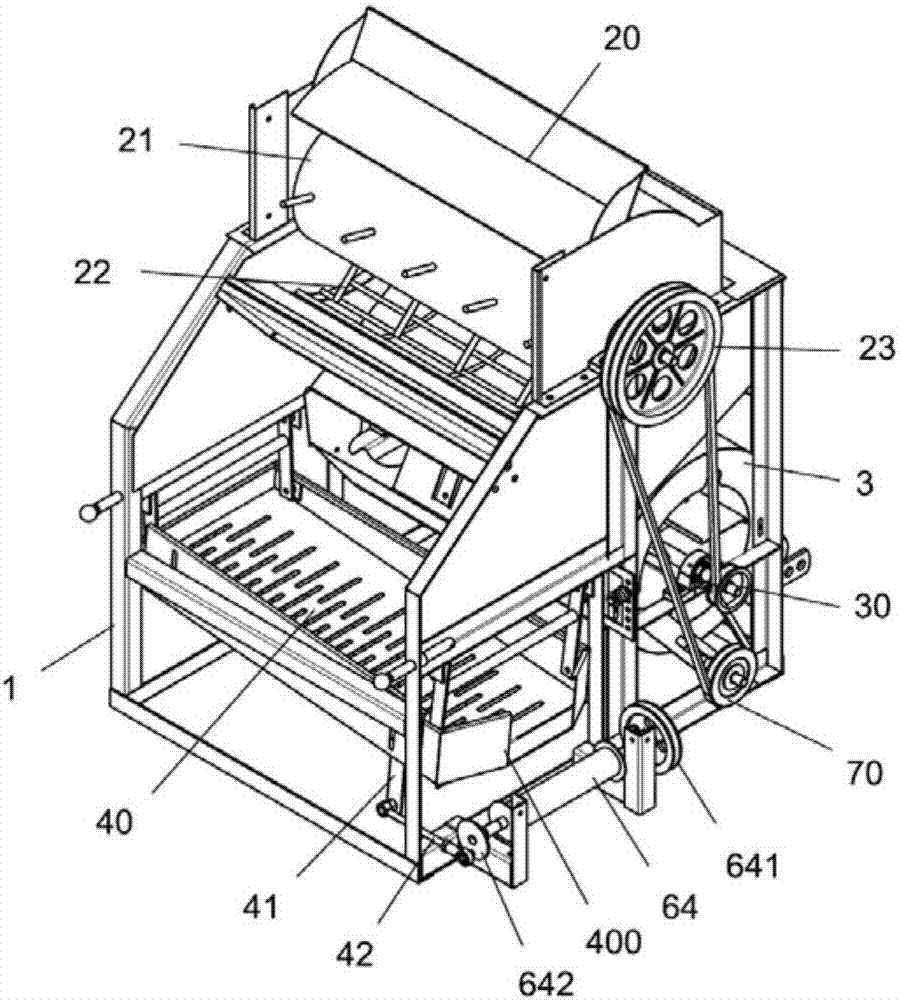

Peanut fruit picker

PendingCN107616000AAvoid congestionImprove fruit picking efficiencyThreshersTraction frameEngineering

The invention provides a peanut fruit picker. The peanut fruit picker comprises a rack, a traction frame is fixedly connected to the bottom of the front end of the rack, walking wheels are arranged atthe bottom of the rack, the rack is provided with a fruit picking box, a feed inlet conveyor is arranged in a feed inlet of the fruit picking box, the fruit picking box is internally provided with afruit picking roller, the fruit picking roller comprises a central guiding roller, at least three arc stirring rods are fixedly connected to the central guiding roller through connecting rods, cuttingknifes are fixedly connected to the surface of each arc stirring rod in the length direction of the arc stirring rod at intervals, a bottom sift located below the fruit picking roller and a vibrationsift located below the bottom sift are arranged at the bottom of the fruit picking box, a peanut fruit conveyor which tilts upwards is engaged with the tail end of the vibration sift, a peanut vine collecting device is arranged between the fruit picking box and the peanut fruit conveyor, a fruit collecting box is arranged at the tail end of the peanut fruit conveyor, and a package bag placing shelf located below the fruit collecting box is arranged at the bottom of the rear end of the rack. The peanut fruit picker is compact in structure, stable in work, convenient to operate, low in peanut breaking rate and high in work efficiency.

Owner:正阳县豫丰机械有限公司

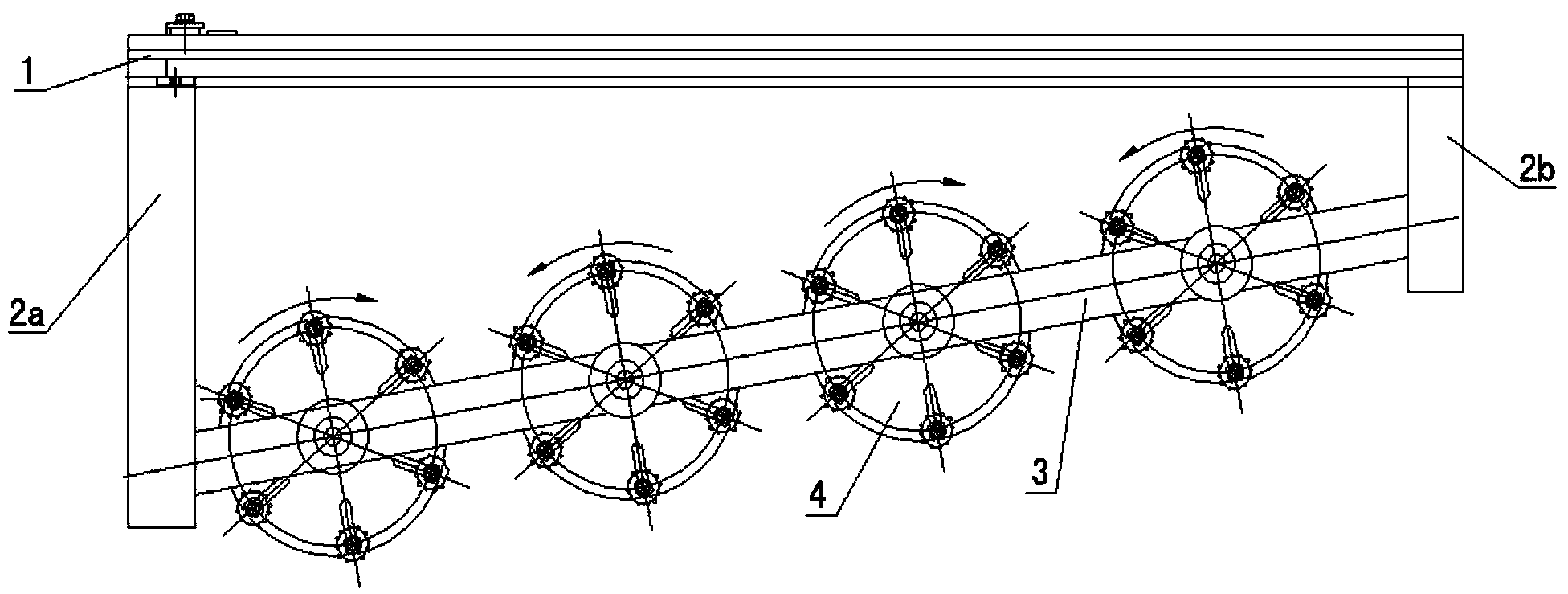

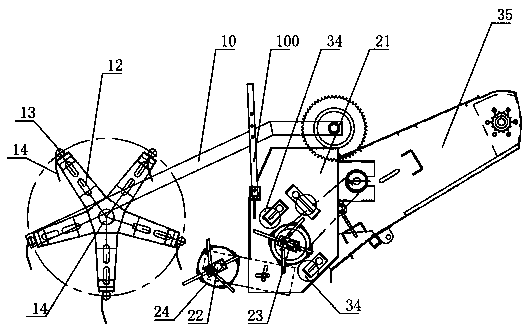

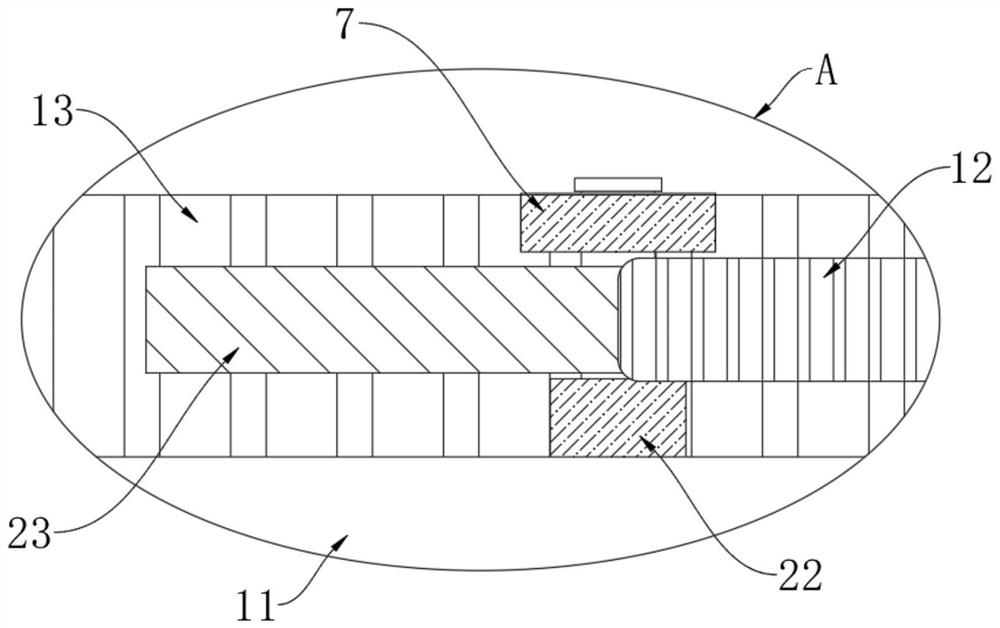

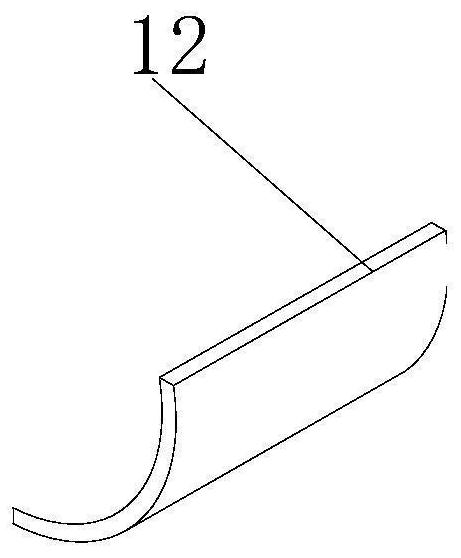

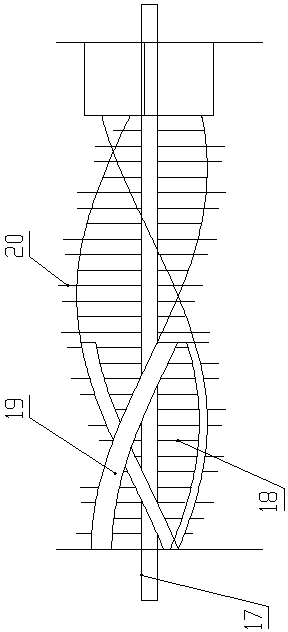

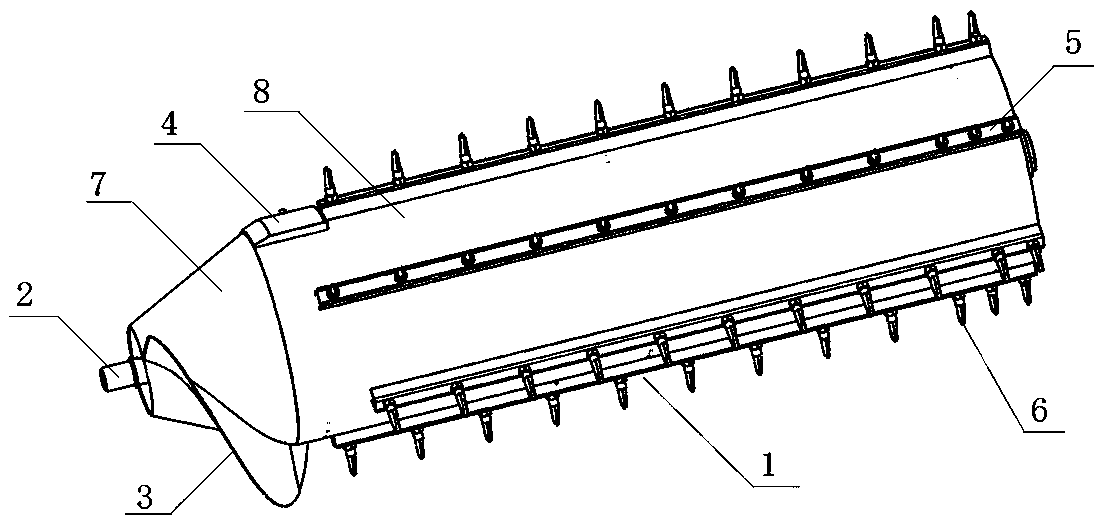

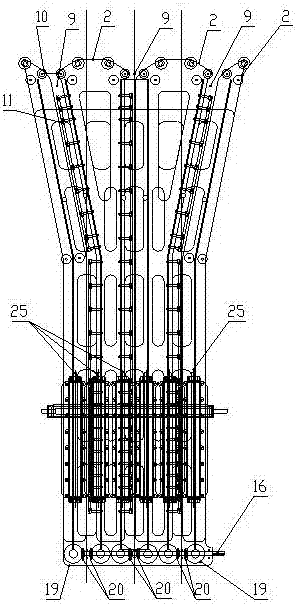

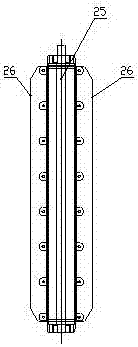

Blade type anti-winding fruit picking roller

ActiveCN103636345BEasy to cause entanglementAvoid entanglementDigger harvestersThreshersSpiral bladeAgricultural engineering

Provided is a blade type anti-winding fruit picking roller. A pair of fruit picking roller bodies are symmetrically arranged between an upper fruit picking roller base and a lower fruit picking roller base, the fruit picking roller bodies are cylinders, each fruit picking roller body comprises a fruit picking roller main body and a fruit picking vane, the fruit picking vanes are fixed to the fruit picking roller main bodies through vane bases, the two ends of each fruit picking roller body are respectively provided with a connecting shaft, a bearing end plate is arranged on the outer side of each connecting shaft, gaps exist between the connecting shafts and the bearing end plates, each fruit picking roller body comprises an upper end portion, a middle portion and a lower end portion, the upper end portions, the middle portions and the lower end portions are cylindrical, the diameter of each upper end portion and the diameter of each lower end portion are smaller than the diameter of each middle portion, each fruit picking roller body further comprises a spiral blade, and the spiral blades are fixed to the peripheries of the upper end portions and the peripheries of the lower end portions of the fruit picking roller main bodies; the end face of the upper end portion of each fruit picking roller main body is an upper end face, the lower end face of the lower end portion of each fruit picking roller main body is a lower end face, the connecting shafts are arranged on the upper end faces and the lower end faces, the connecting shafts are provided with circular tube section protective sleeves, the bottom of each circular tube section protective sleeve is round, and the side wall of each circular tube section protective sleeve is of a semi circular tube shape.

Owner:QINGDAO AGRI UNIV

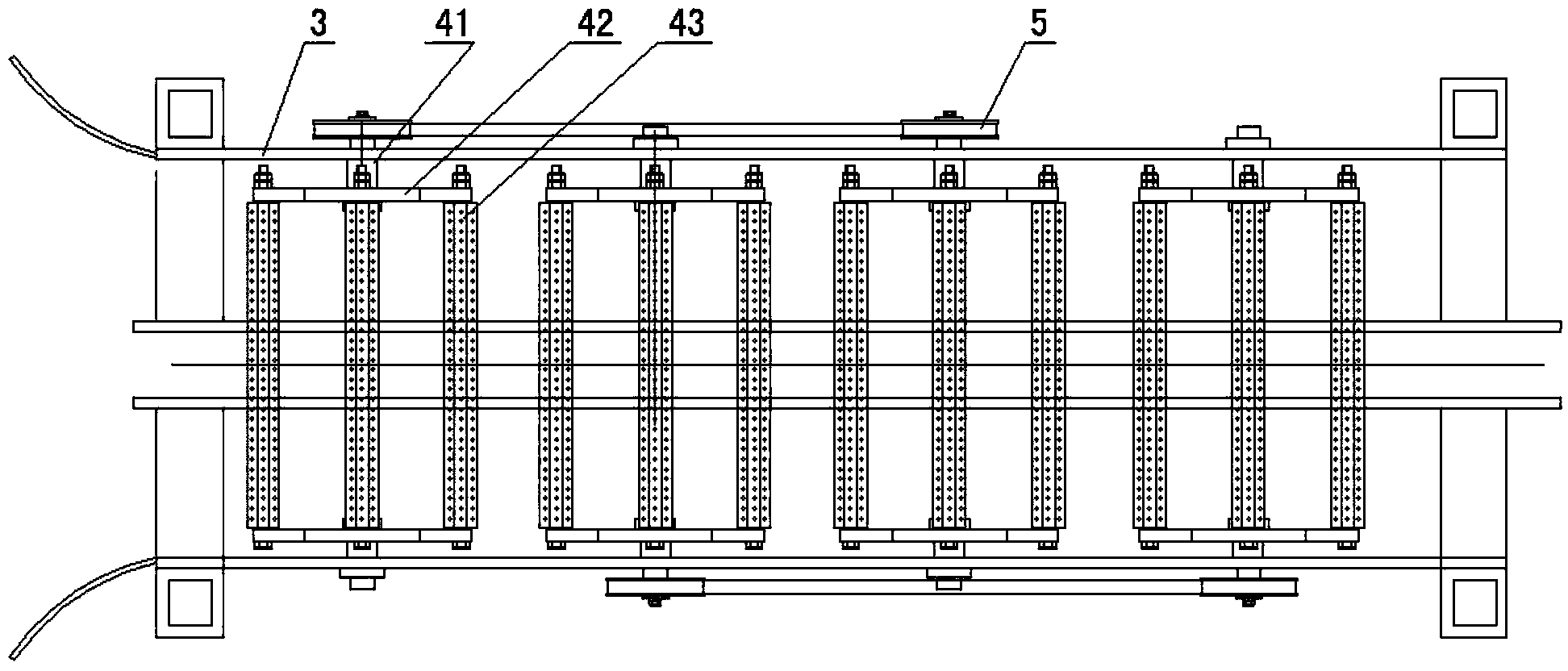

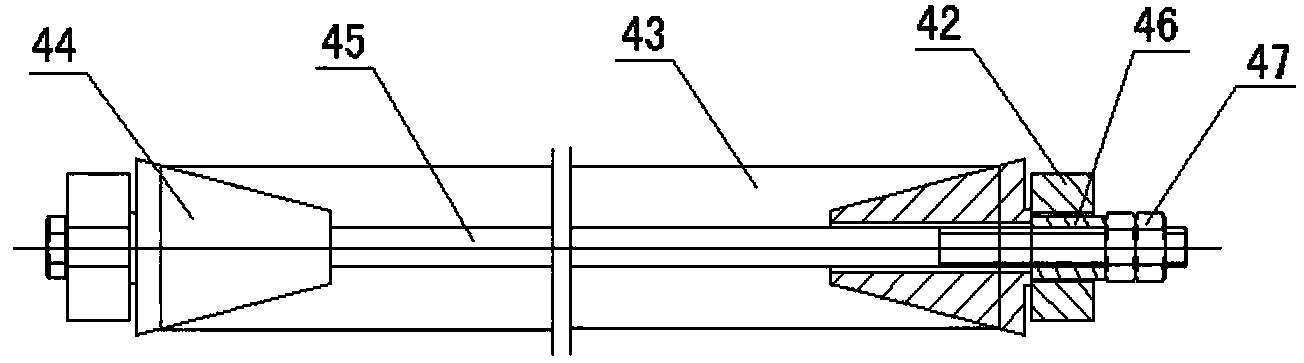

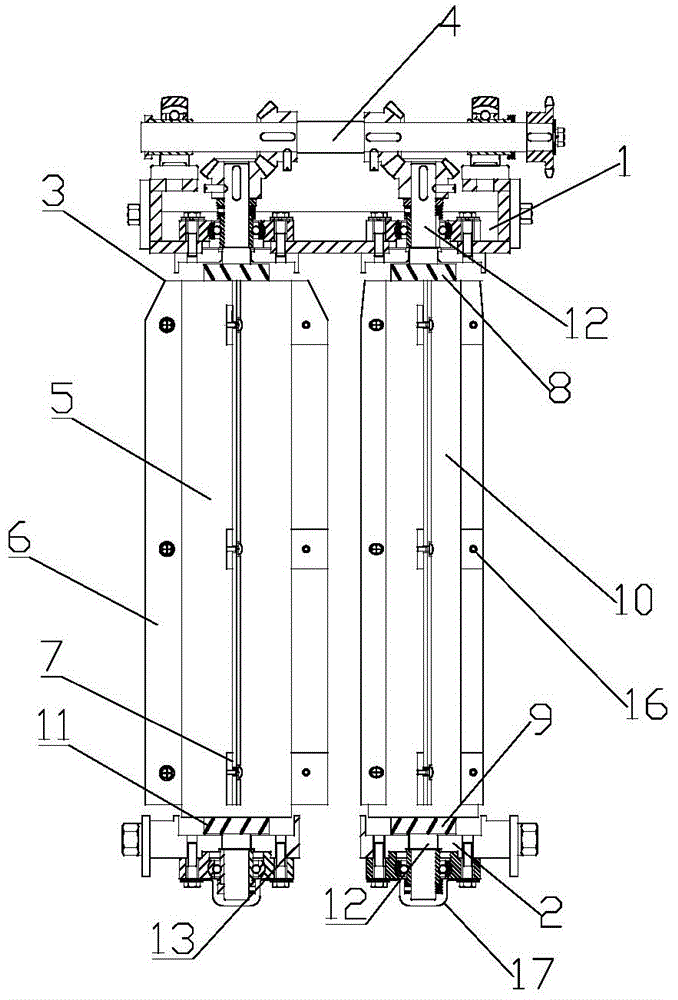

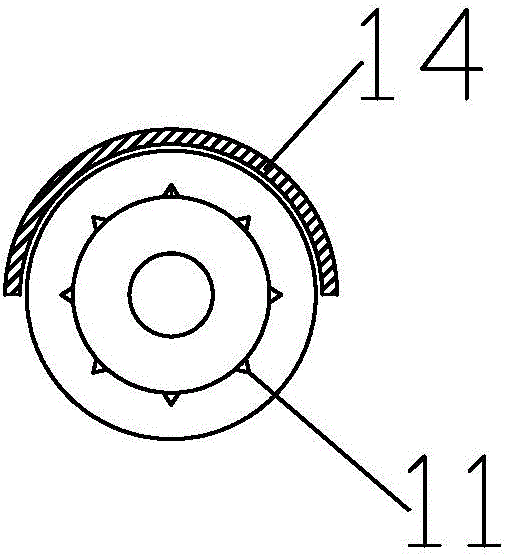

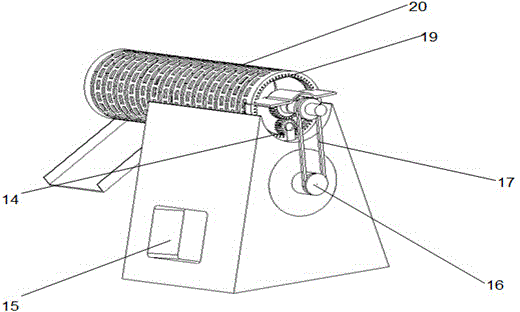

Fruit picking roller for peanut harvester, and peanut harvester

PendingCN111010974AReduce breakage rateIncrease feed intervalDigger harvestersThreshersDynamic balanceAgricultural engineering

The invention relates to a fruit picking roller for a peanut harvester, and the peanut harvester. The roller includes a cylinder body and a rolling shaft installed on the cylinder body to drive the cylinder body to rotate; the feeding end of the cylinder body is connected to one spiral importing blade, and the spiral importing blade rotates with the cylinder body so as to grab peanut seedlings; the cylinder body is provided with a weight for maintain the dynamic balance of the cylinder body. Through the adopting of the single spiral importing blade, the breakage rates of peanut fruits can be reduced, and fruit picking efficiency can be enhanced; and the blocking at the feeding mouth of the cylinder body is not easy to occur, so that the roller is very practical.

Owner:郑州中联收获机械有限公司

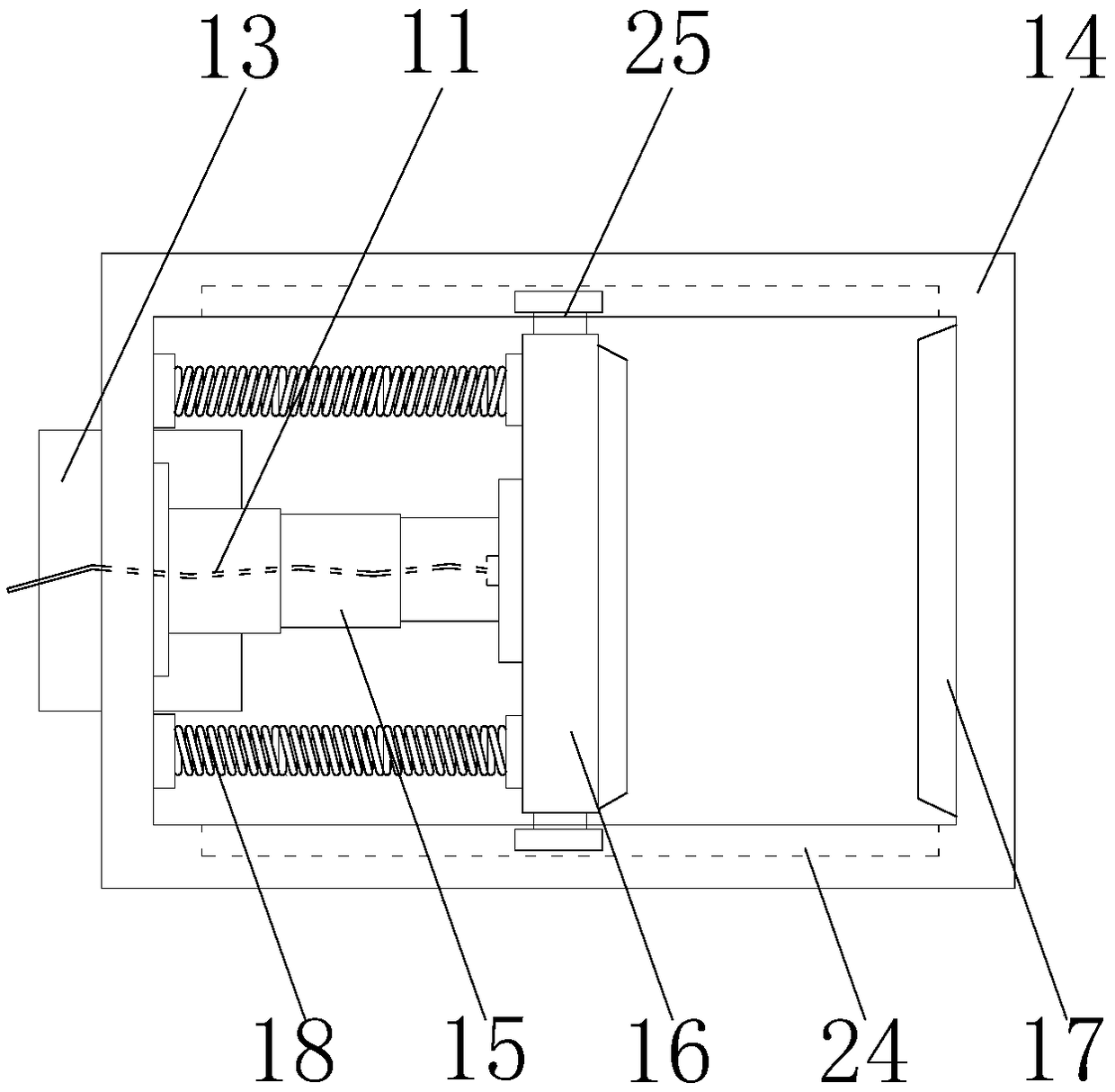

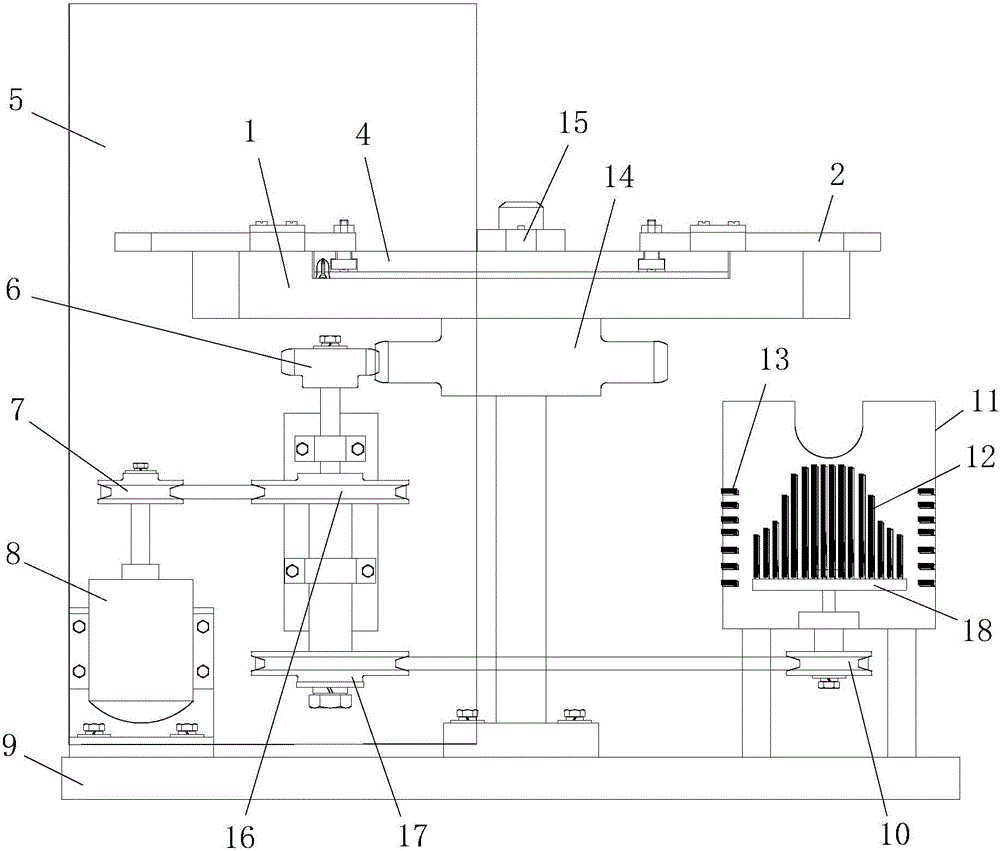

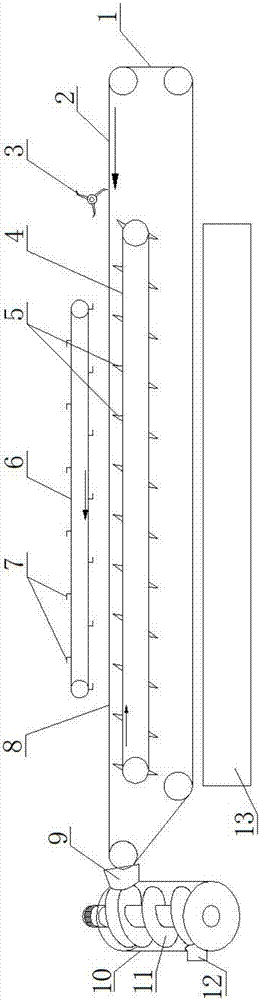

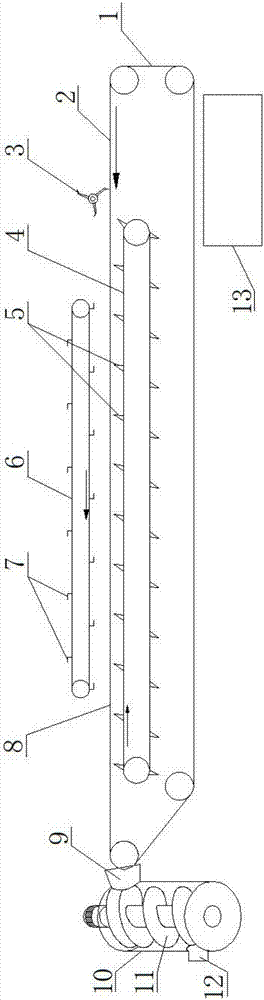

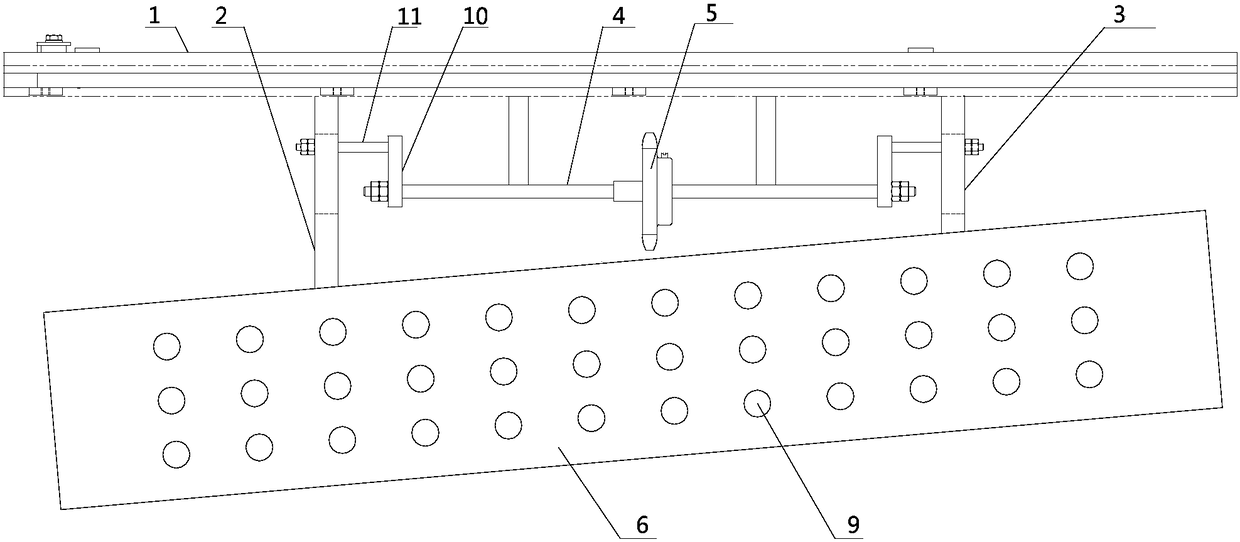

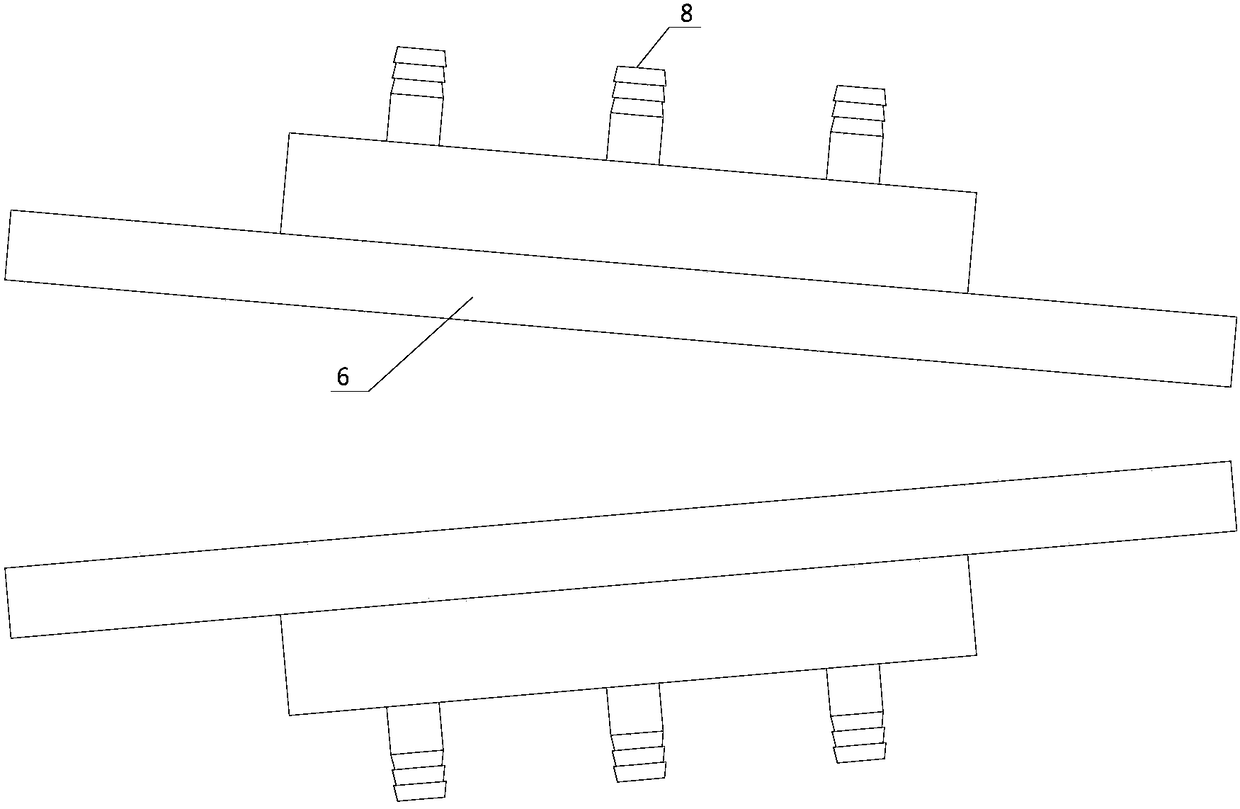

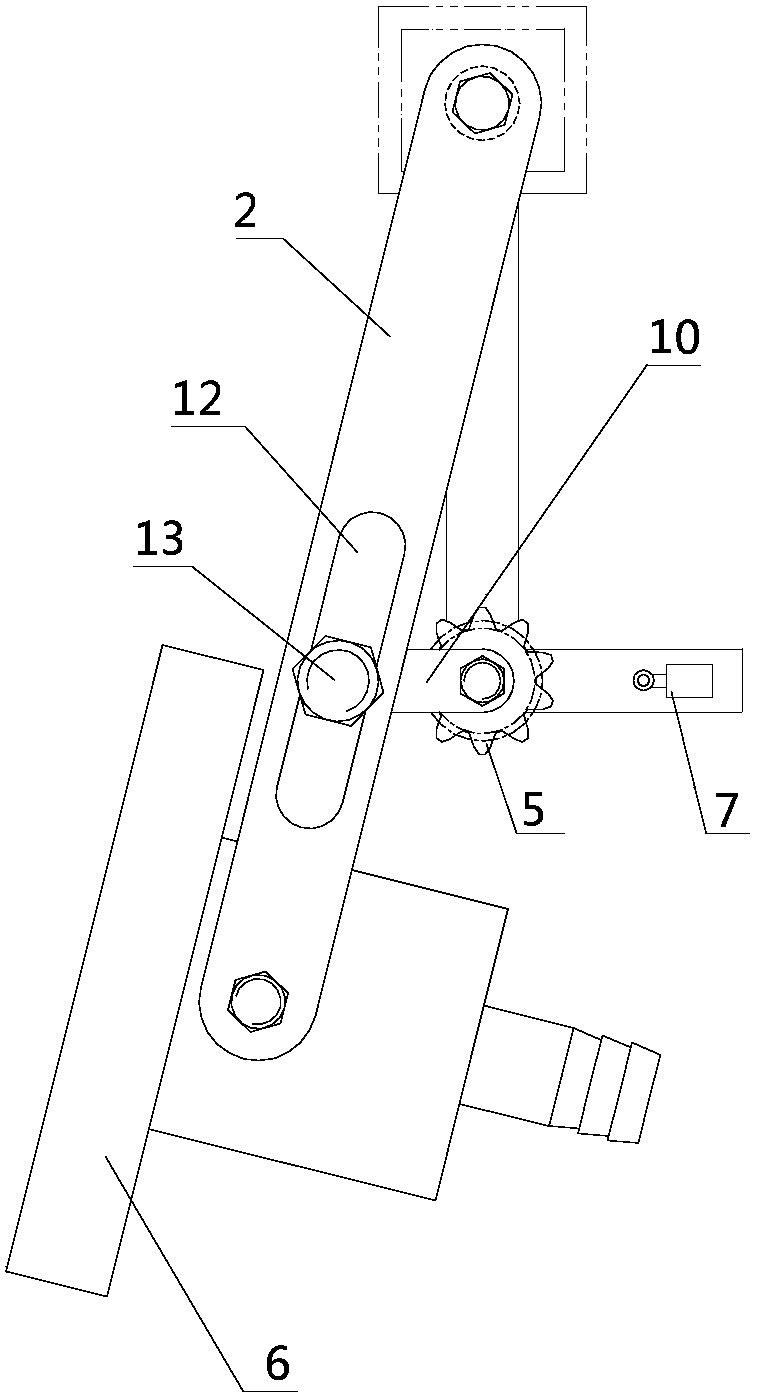

An air-suction peanut picking device

ActiveCN105940876BImprove fruit picking efficiencyHigh removal rateThreshersEngineeringBreakage rate

The invention provides an air suction type peanut picking device comprising a vine clamping and conveying chain and an air suction type peanut picking plate pair, which are arranged in the top-to-bottom direction. The air suction type peanut picking plate pair comprises two peanut picking plates arranged on the left and right symmetrically; the front end and the rear end of each peanut picking plate are hinged and suspended to an overhead rack via a front end connecting plate and a rear end connecting plate; each peanut picking plate is driven to swing back and forth in left-right direction by a back-and-forth swing mechanism; each peanut picking plate is hollow, having a cavity inside; the cavity of each peanut picking plate forms an air chamber; the inner side of each peanut picking plate is provided with a plurality of suction holes and the outer side is provided with an air pipe connector; each air pipe connector is connected with a negative pressure air source via an air pipe; each air pipe is provided with a limiting valve; the front end connecting plates or the rear end connecting plates can touch the limiting valves in the process of outward swing and break the negative pressure air source. The air suction type peanut picking device can increase the peanut picking efficiency, increase the picking rate and reduce the peanut breakage rate.

Owner:CHUZHOU UNIV

A device for picking peanuts

ActiveCN113196934BImprove fruit picking efficiencyQuality improvementDigger harvestersThreshersAgricultural engineeringMechanical engineering

The invention discloses a device for picking peanuts, which comprises: a frame, a conveying device, the conveying device includes a sprocket, a conveying chain and a driving machine, and the sprockets respectively set on two pairs of conveying chains are respectively connected to the two driving machines for transmission. Connected, the running speed of the two conveyor chains is the same and the running direction is opposite, there is a gap between the two conveyor chains for conveying peanut seedlings; the fruit picking device, the fruit picking device includes a support plate, a roller, and a tooth, and the rotation support on the support plate has The drum is equipped with a plurality of shifting teeth on the outer peripheral side of the drum. In the present invention, the conveying device and the fruit picking device are arranged so that when the peanut seedlings are clamped from one end of the conveying chain and moved to the other end, the peanuts at the end of the peanut seedlings will be slapped by the teeth on the drum to ensure that the peanuts are When the seedlings are clamped and transmitted by the transmission chain, no matter how the peanut seedlings are placed and in any posture on the transmission chain, the peanuts at the ends will be slapped down by the teeth.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

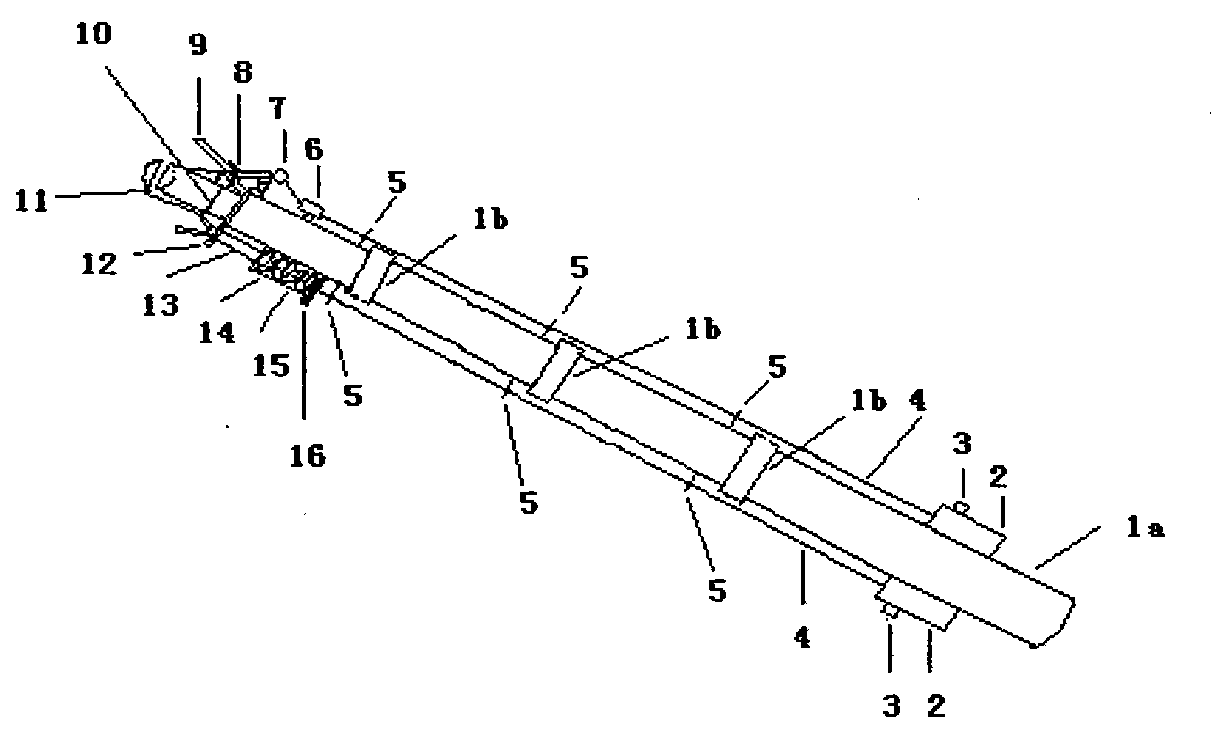

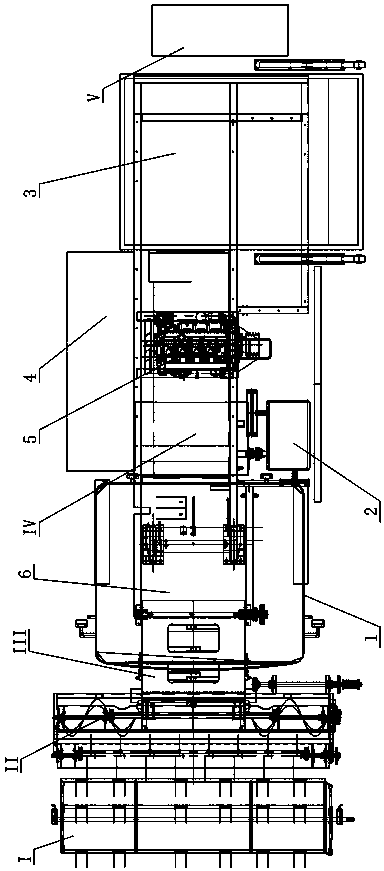

Self-propelled automatic fruit picking machine

ActiveCN105284301BCompact structureImprove quality and efficiencyLoadersThreshersTurning framesEngineering

The invention discloses a self-propelled automatic pickup picker which comprises a frame, wherein a power machine and a traveling mechanism are arranged on the frame; a main-gear box is arranged on the frame; a peanut vine fruit pick-up device is arranged at the forefront of the frame; a peanut vine fruit feeding device positioned behind the peanut vine fruit pick-up device is connected to the frame; a vine fruit transport bridge assembly which is positioned behind the peanut vine fruit feeding device and corresponds to the outlet of the peanut vine fruit feeding device is arranged on the frame; a vine fruit conveying chain is arranged in the vine fruit transport bridge assembly; a picking device which corresponds to the outlet of the vine fruit transport bridge assembly and is in power connection with the main-gear box is connected with the middle of the frame; the rear part of the frame is connected with a grain store; a peanut transport device which is in power connection with the main-gear box is connected between the fruit outlet of the picking device and the feeding hole of the grain store; and a vine box capable of collecting peanut vines separated by the picking device is connected to one side of the frame. The self-propelled automatic pickup picker disclosed by the invention has the advantages of compact structure, high picking quality and high picking efficiency.

Owner:WEIFANG ZHONGDI MACHINERY TECH CO LTD

Fruit picking machine

A fruit picking head of a fruit picking machine comprises a curly blade matched with the shell of the fruit picking head, the curly blade and the fruit picking head have two basic states when rotatingrelatively, namely an open state and a closed state, when the curly blade is in the open state, fruits are easily sleeved in the inner cavity of the fruit picking head, and the curly blade does not hinder the fruits from entering the inner cavity and does not damage the fruits, the fruits can be effectively separated from branches and leaves during rotating, when the blade rotates to cut off fruit stems, the fruits with the fruit stems cut off are kept in a relatively sealed space formed by the blade and the fruit picking head, and the state is the closed state, so that the fruits cannot fallout from an inlet, and the fruits can only directly fall into a fruit basket provided with a buffer pad along a pipeline connected with the shell. In addition, a plurality of branch teeth are arranged on the curled blade, a plurality of fruits can be picked at the same time, and therefore the fruit picking machine has very good practical value for fruit picking of orchard workers.

Owner:肖慧

Intelligent peanut picker

ActiveCN104429393AGuaranteed normal operationEnsure safetyThreshersTransmission beltAgricultural engineering

The invention discloses an intelligent peanut picker which comprises a motor, a rotating shaft, a spiral knife net and a sieve plate, wherein the motor is arranged on a rack and connected with the rotating shaft through a transmission belt; a feeding belt is arranged on one side of the rotating shaft, and a rotating track is arranged on the other side of the rotating shaft; the spiral knife net is mounted on the outer side of the rotating track in a sleeving manner, and an outer blocking barrel is arranged on the outer side of the spiral knife net; the sieve plate is arranged under the spiral knife net, and the inner end of the sieve plate is connected with the spiral knife net through a sliding plate; a reversing baffle plate is arranged at the outer end of the sieve plate, and a reversing air port is formed in the reversing baffle plate; the sieve plate is connected with the rack through a crank shaft and a spring sleeve, and the crank shaft is connected with an auxiliary motor; a guide plate is arranged under the sieve plate. The peanut picker is simple and convenient, improves the peanut picking efficiency, reduces the burden of agricultural laborers, reduces the production cost, and is suitable for families and individual workshops.

Owner:润桐(苏州)技术服务有限公司

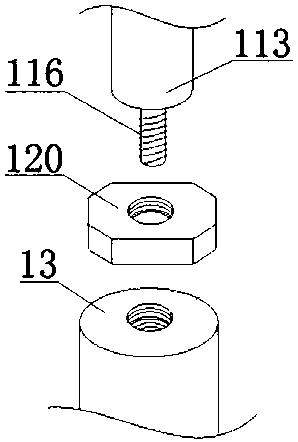

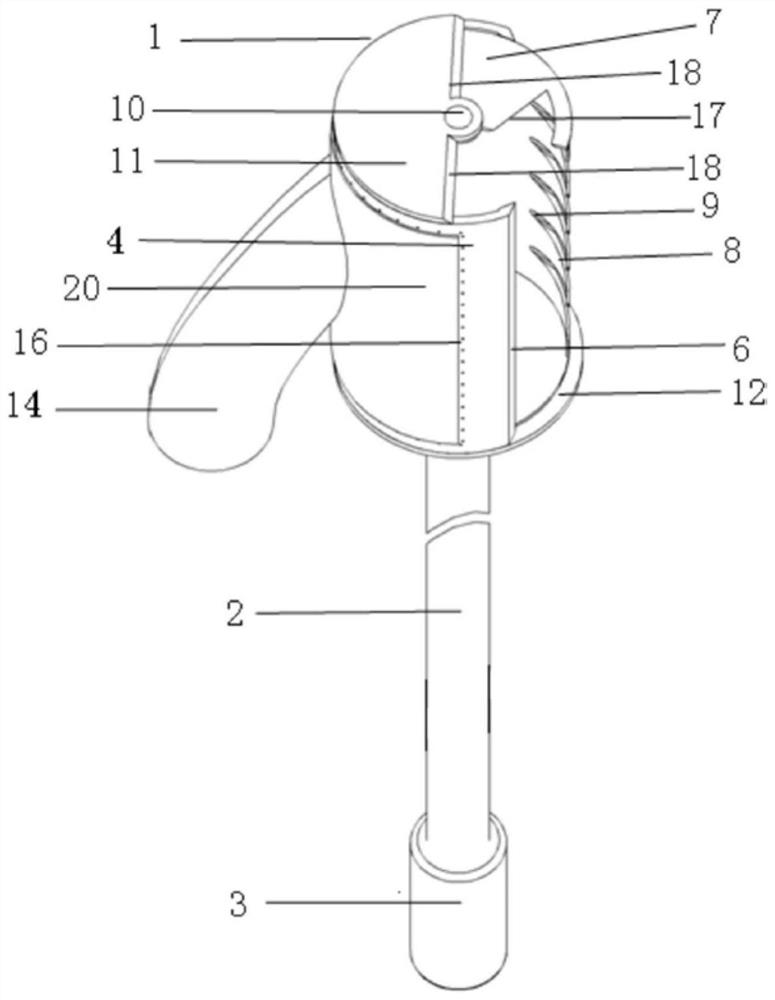

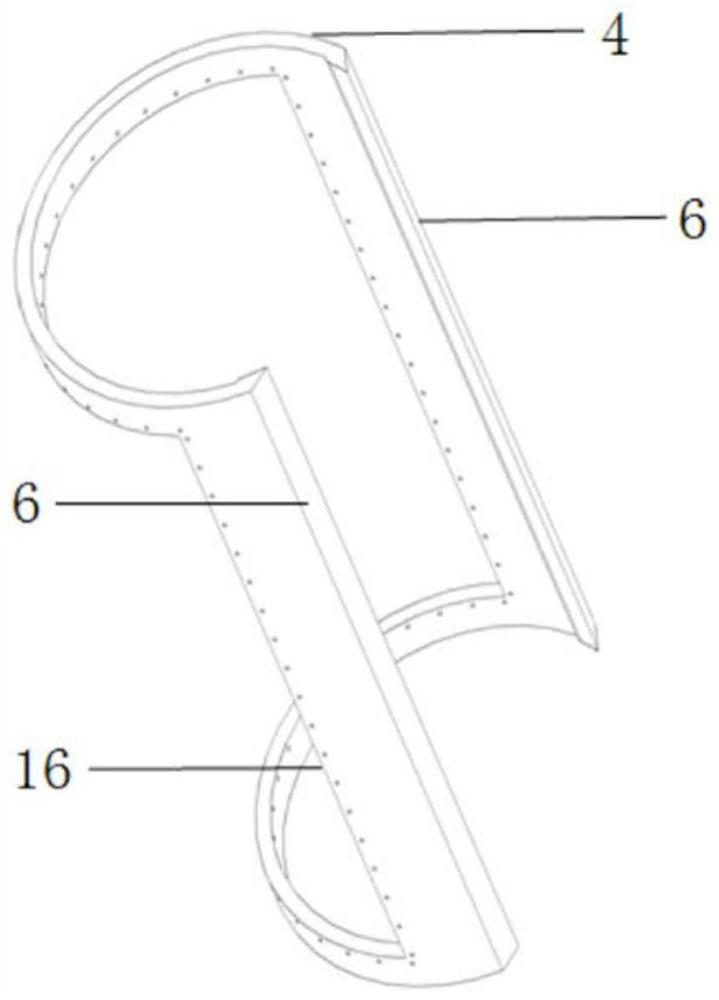

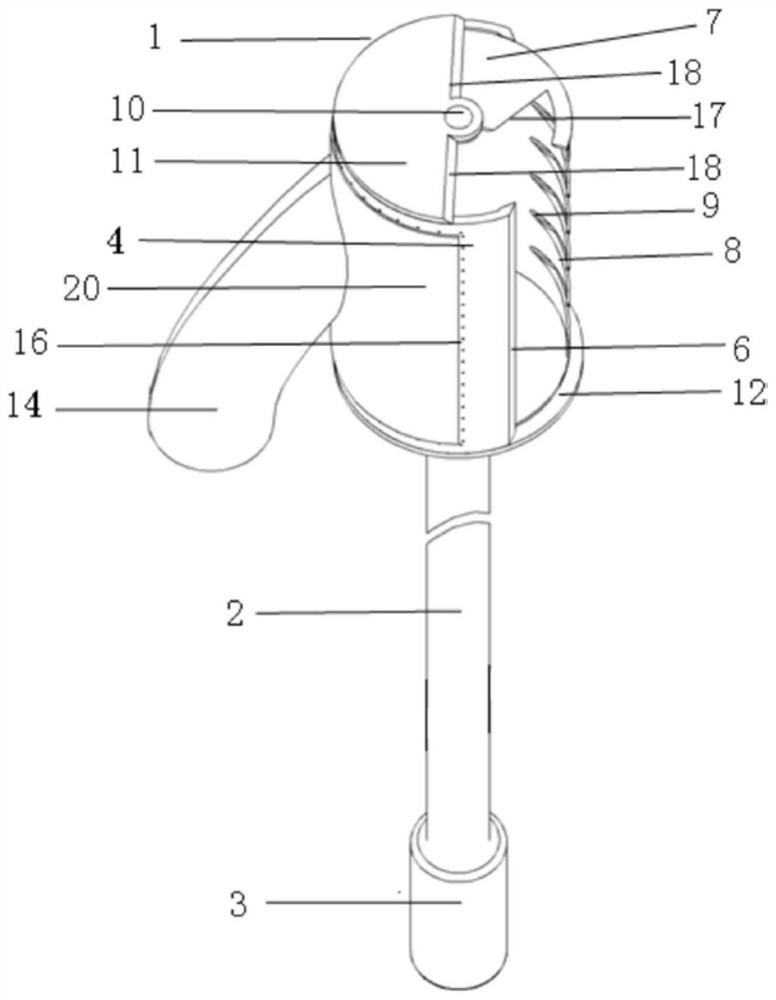

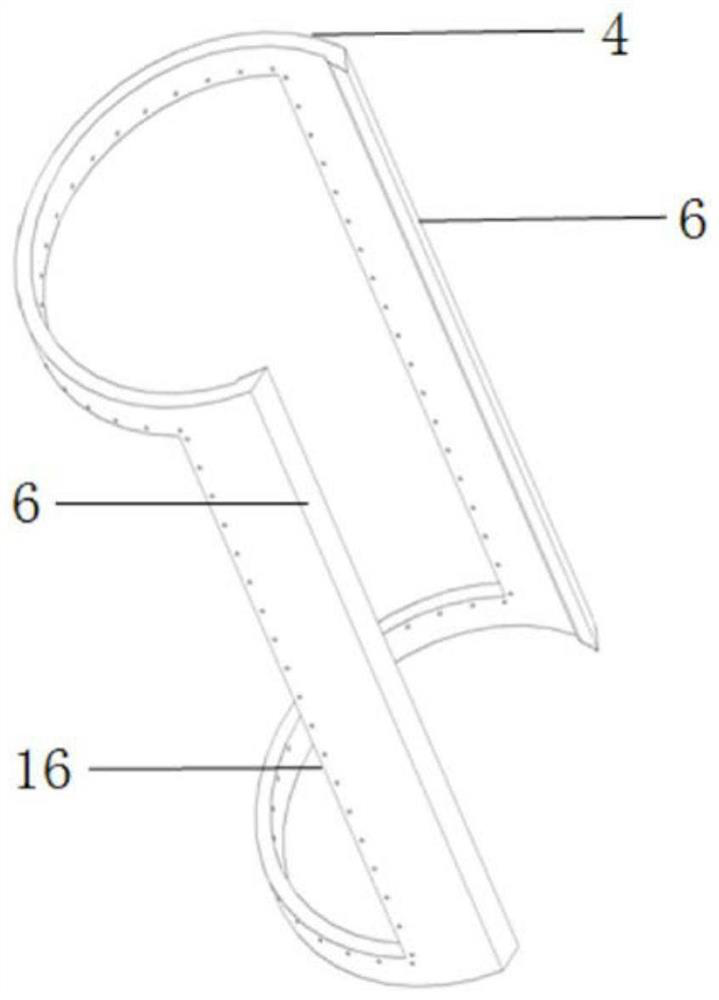

A high-altitude fruit picking tool

InactiveCN109041798BEasy to trapEasy to usePicking devicesAgricultural engineeringStructural engineering

The invention discloses a tool for picking high-altitude fruits, which comprises a fruit picking support frame; a telescopic rod connected with the fruit picking support frame; a first sliding grooveand second sliding groove which are arranged on the wall of the fruit picking support frame; a blade arranged in the first sliding groove; a fixing poking plate arranged in the second sliding groove;a synchronous transmission element, which is hinged with the fixing poking plate and is used for limiting the synchronous transmission of the blade; a turnover poking mechanism matched with the fixingpoking plate; a transmission line connected with the fixing poking plate. By using the fruit picking support frame, the target fruit can be conveniently sleeved, and the fruit picking efficiency is improved; the blade and the fixing poking plate are used for cutting and poking the fruit handle, and the fruit cutting force can be adjusted so as to ensure the fruit picking effect. The operation ofworkers is simple, and the action of the pull rod conforms to the ergonomics.

Owner:ZHEJIANG UNIV

Multiple-ridge peanut combine harvester

The invention discloses a multiple-ridge peanut combine harvester. The multiple-ridge peanut combine harvester comprises a power device, a machine body, a harvesting table and a fruit collecting box, wherein the harvesting table and the fruit collecting box are installed on the machine body. The harvesting table and the fruit collecting box are installed on the front side and the back side of the machine body respectively, and a grain lifter and a soil shoveling device are connected to the front end of the harvesting table of the machine body; the harvesting table comprises a harvesting table frame, three or above slant peanut channels arranged upwards are arranged in the harvesting table frame side by side, chain-type elevating chains are arranged in all the peanut channels, and each chain-type elevating chain comprises two conveying chains engaged each other; a flapping soil shaking device is arranged in the middle of the harvesting table frame, a fruit picking assembly is connected to the lower side of the back portion of the hing table frame, and comprises a plurality of fruit picking rollers arranged side by side, and a slant vibrating screen arranged downwards is arranged below the fruit picking assembly. According to the multiple-ridge peanut combine harvester, a mechanical continuously-variable transmission is adopted, and is matched with static hydraulic driving, continuously-variable transmission is achieved, the variable speed mode is mellow, and the variable speed accuracy is high; meanwhile, the wheel type is matched, the walking speed can be increased, the fruit picking speed is in direct proportion to the walking speed of a vehicle accordingly, the fruit picking efficiency is improved, and the fruit completing rate is not influenced; the fruit completing rate mainly incarnates the completing degree of a fruit.

Owner:河南冬强农机装备有限公司

Picking machine

The invention relates to a picking machine. A picker contains a curled cutter blade adaptive to a shell of the picker, and two basic states, i.e., an open state and a closed state are involved duringrelative rotation between the picker and the cutter blade; when in the open state, a fruit is very easily nested in an internal cavity of the picker, the curled cutter blade does not hinder entering of the fruit into the internal cavity and does not damage the fruit, and the fruit can be effectively separated from branches and leaves during rotation; and when the cutter blade rotates to cut off afruit stem, the fruit-stem-cut fruit is maintained in a relative-sealed space formed by the cutter blade and the picker, this state is called the closed state, and the fruit cannot fall off from an inlet and can only directly fall into a fruit basket loaded with a cushion pad along a pipe connected with the shell. In addition, the curled cutter blade of the picking machine is provided with a plurality of sub-teeth, and a plurality of fruits can be picked off simultaneously, so that the picking machine has a very good practical value for fruit picking of fruit growers.

Owner:肖慧

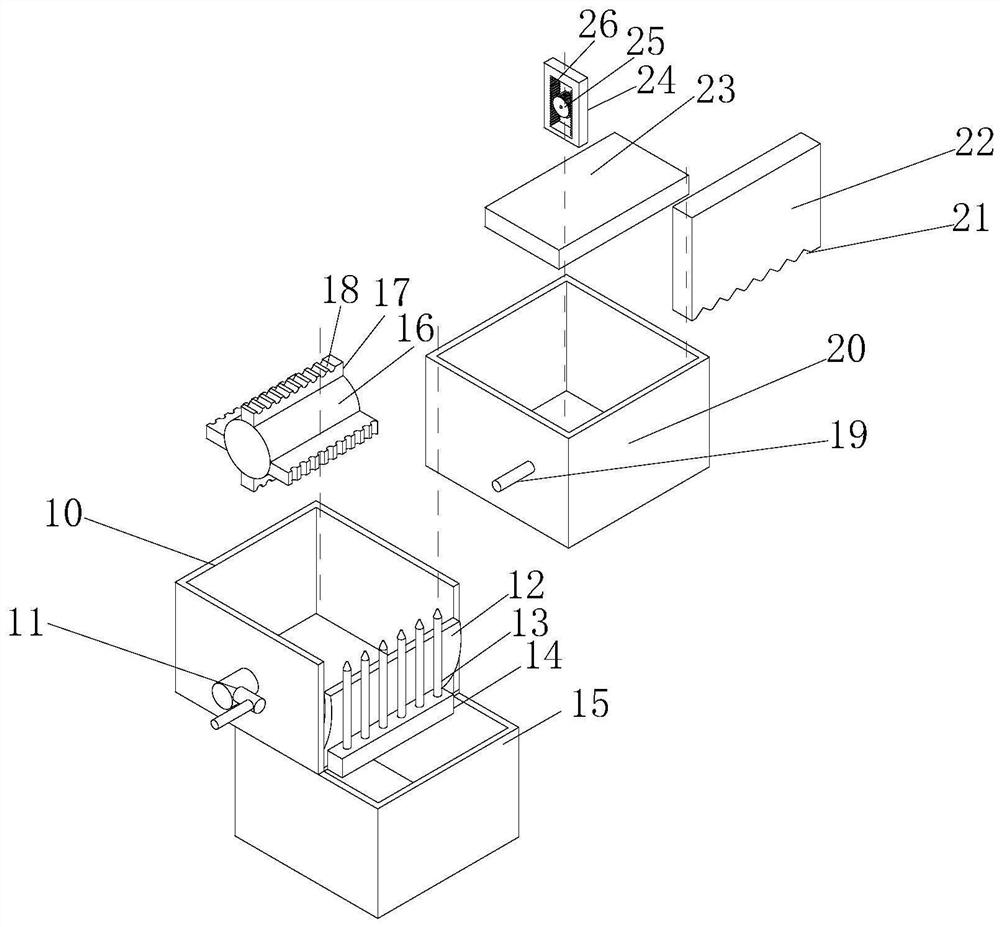

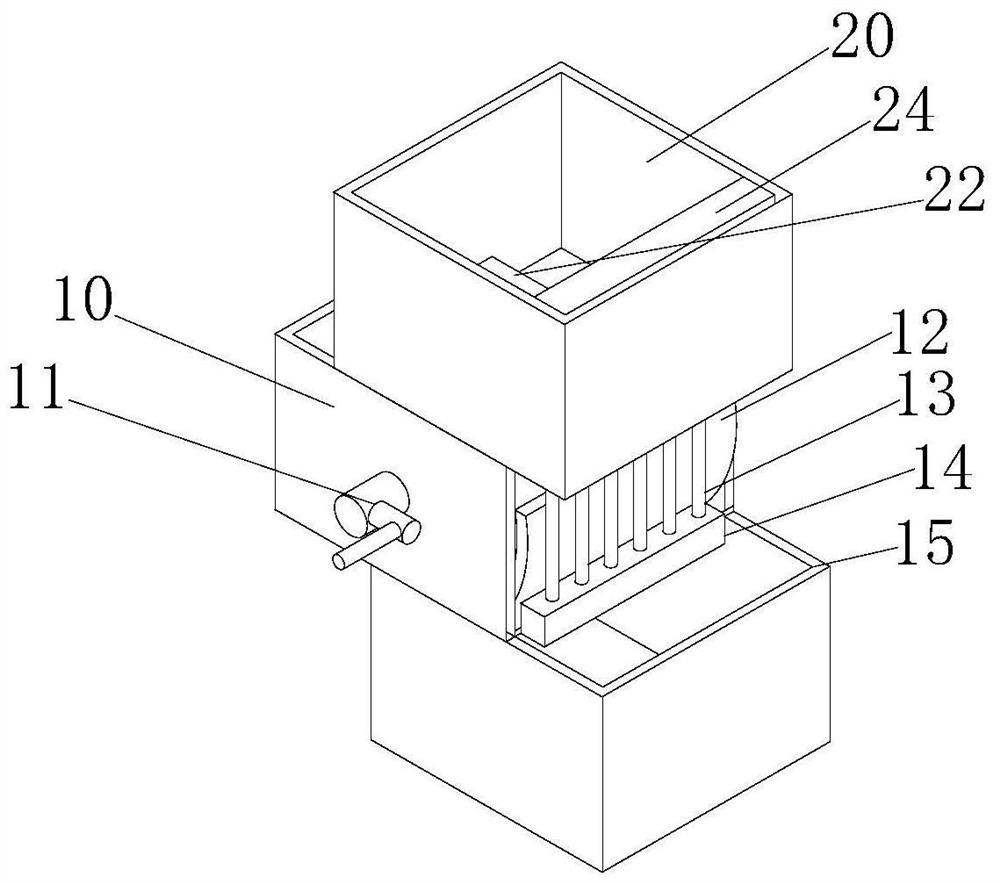

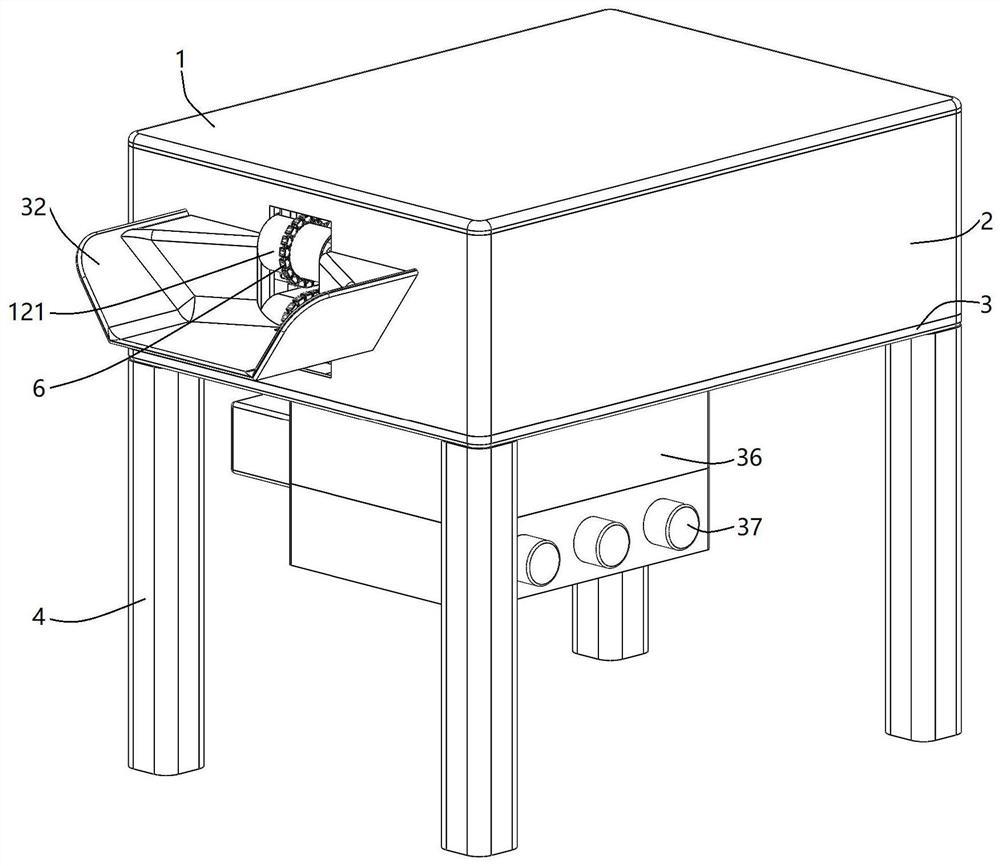

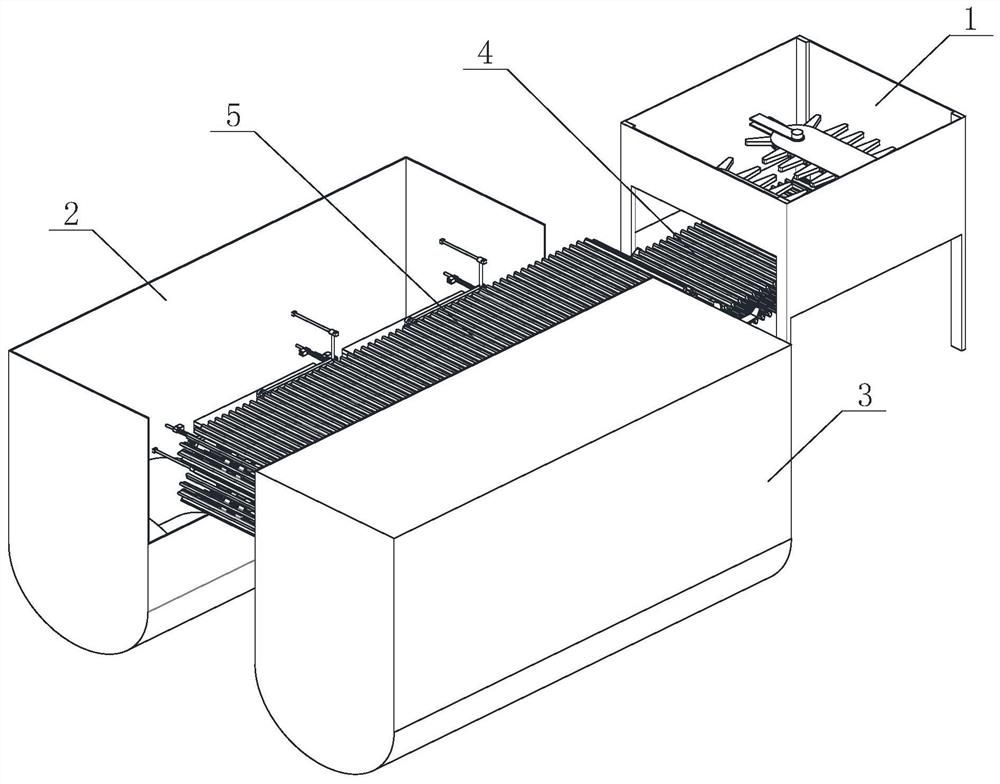

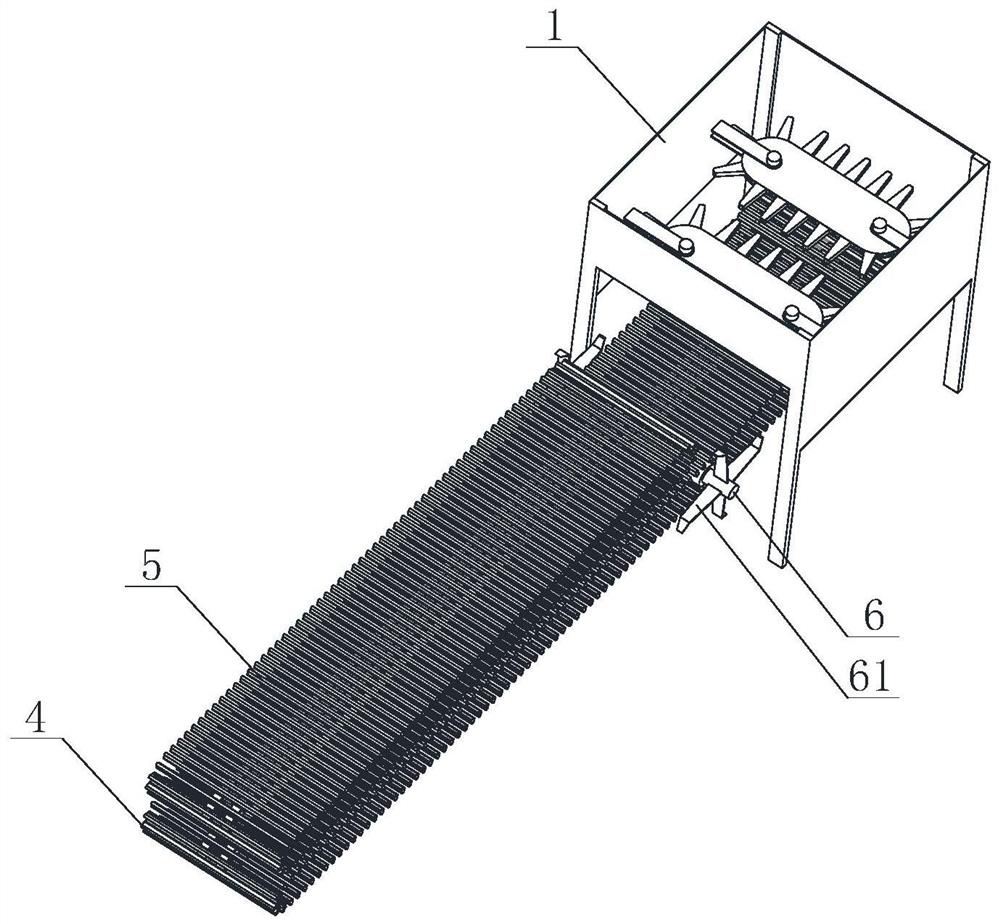

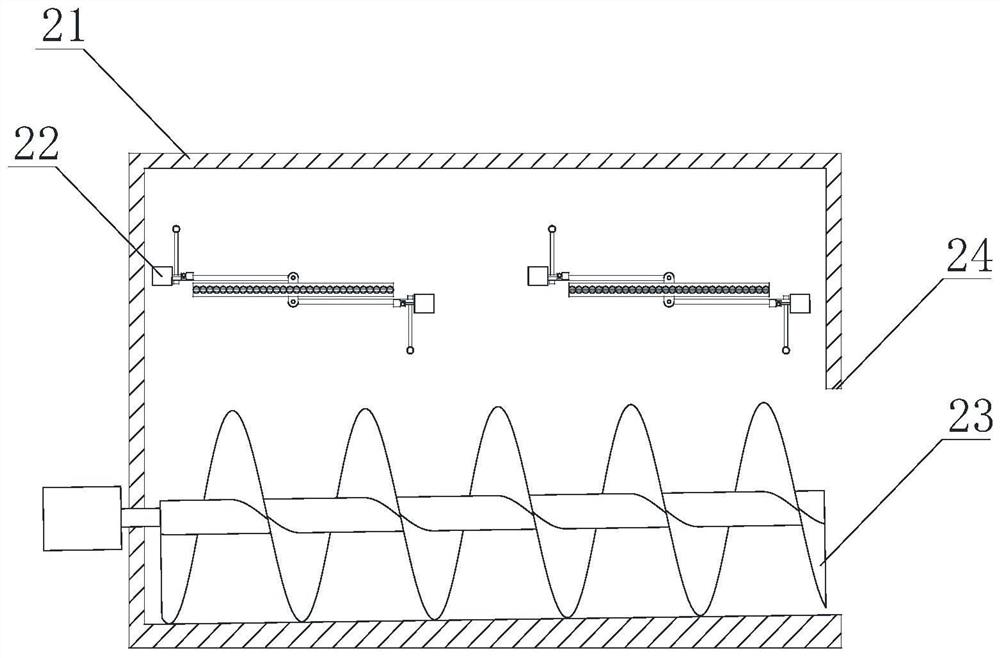

A system and method for picking fruits of Ophiopogon japonicus seedlings

ActiveCN113016337BImprove toughnessImprove fruit picking efficiencyHarvestersMetal working apparatusAgricultural engineeringOphiopogon japonicus

A system and method for picking fruits for cut seedlings of Ophiopogon japonicus. The system includes a lower conveyor chain and an upper conveyor chain. A conveying area is formed between the lower conveying chain and the upper conveying chain. A fruit picking device is arranged on one side of the conveying area, and the fruit picking device includes a fruit picking mechanism. The fruit picking mechanism group includes two fruit picking mechanisms set up on the upper and lower sides. The fruit picking mechanism includes a control mechanism and a knife set. The knife sets of the two fruit picking mechanisms are used to move along a rectangular motion track driven by the control mechanism, and then pass through the rectangular motion. In the cutting section and the gripping section of the trajectory, in the cutting section, two cutter groups cooperate and cut the root of the Radix Ophiopogon japonicus, and in the gripping section, the two cutter groups cooperate and grip the cut root. The invention realizes the separation method combining cutting and clamping. For the situation that the root of the tuber and the stem of Ophiopogon japonicus are not easy to cut off, after cutting to form an incision, the root of the tuber can be further separated by clamping and pulling, which significantly improves the quality of fruit picking of Ophiopogon japonicus. Efficiency and picking rate.

Owner:四川省农业机械科学研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com