A system and method for picking fruits of Ophiopogon japonicus seedlings

A technology of Ophiopogon japonicus and cutting seedlings, applied in agricultural machinery and implements, agriculture, metal processing, etc., can solve the problem of single separation method, low fruit picking efficiency and fruit picking rate of Ophiopogon japonicus, and easy removal of the force exerted by separation. and other problems, to achieve the effect of improving separation effect, improving fruit picking efficiency and fruit picking rate, and improving fruit picking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

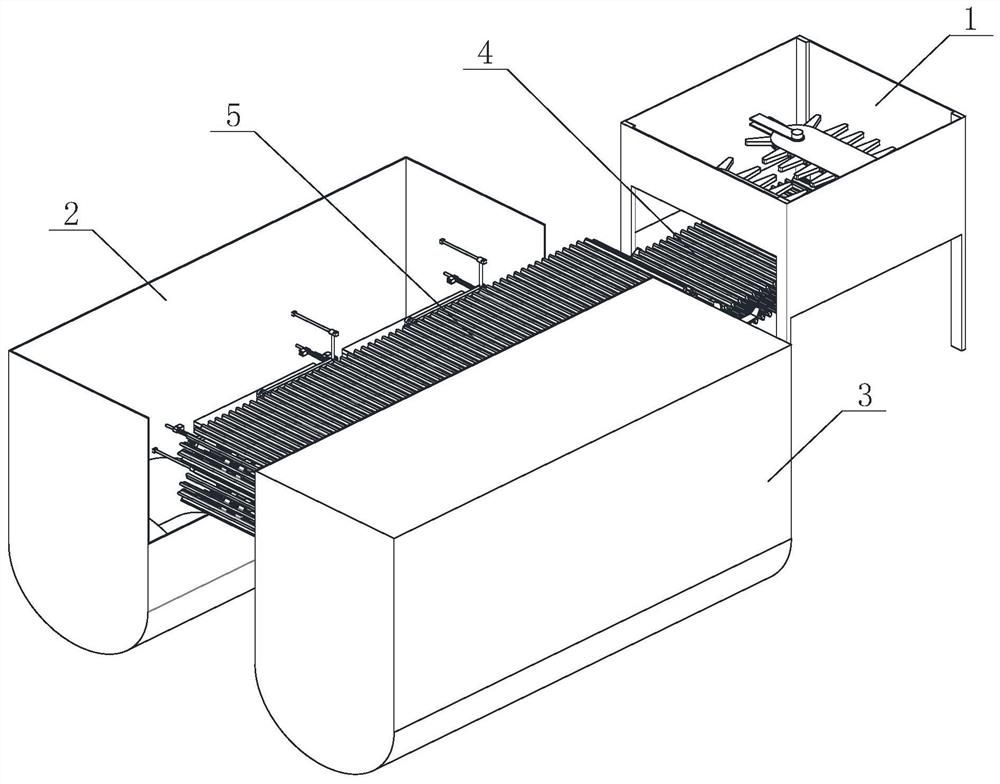

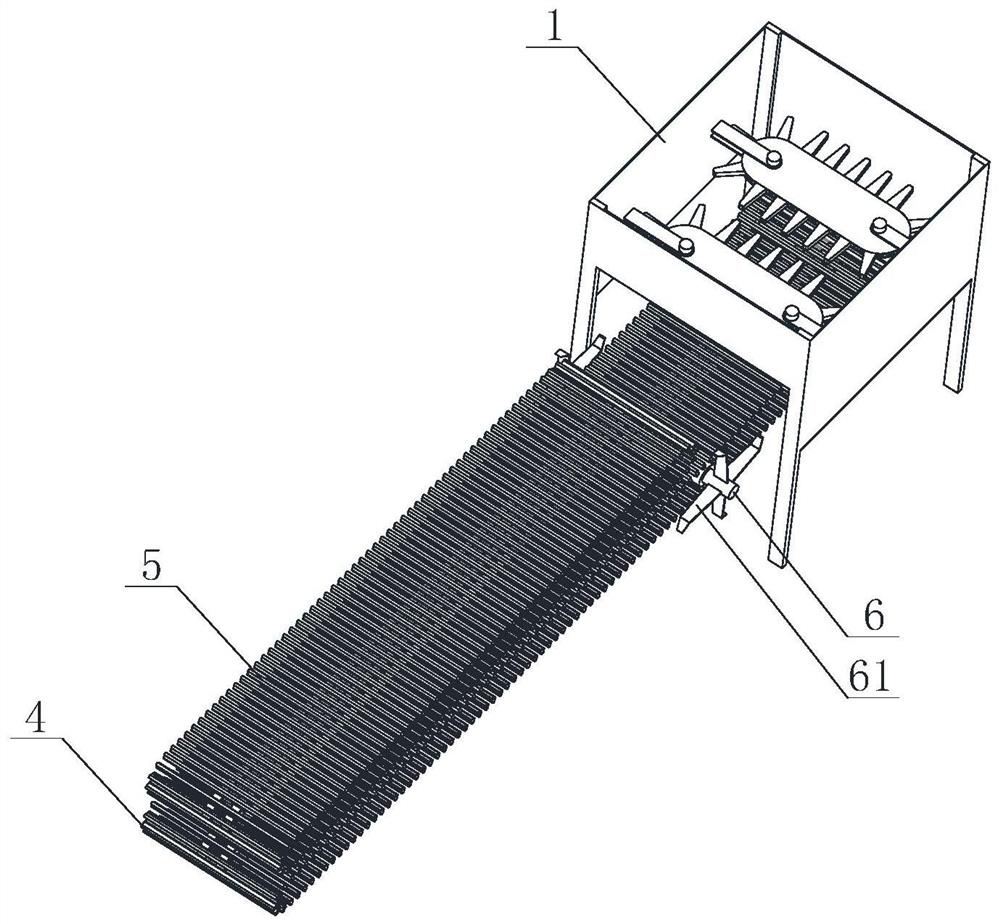

[0066] Such as Figure 1 to Figure 4 A kind of Ophiopogon japonicus seedling cutting and fruit picking system shown includes a lower conveying chain 4 and an upper conveying chain 5, and a conveying area for clamping and conveying wheat seedlings is formed between the lower conveying chain 4 and the upper conveying chain 5, and the conveying One side of the area is provided with a fruit picking device 2, said fruit picking device 2 includes at least one set of fruit picking mechanism group 22, said fruit picking mechanism group 22 includes two fruit picking mechanisms arranged up and down, said fruit picking mechanism includes a control mechanism and a knife Group 229, the cutter groups 229 of the two fruit-picking mechanisms are used to move along the rectangular motion trajectory under the drive of the control mechanism, and pass through the cutting section and the clamping section of the rectangular motion trajectory in turn. In the cutting section, the two cutter groups 22...

Embodiment 2

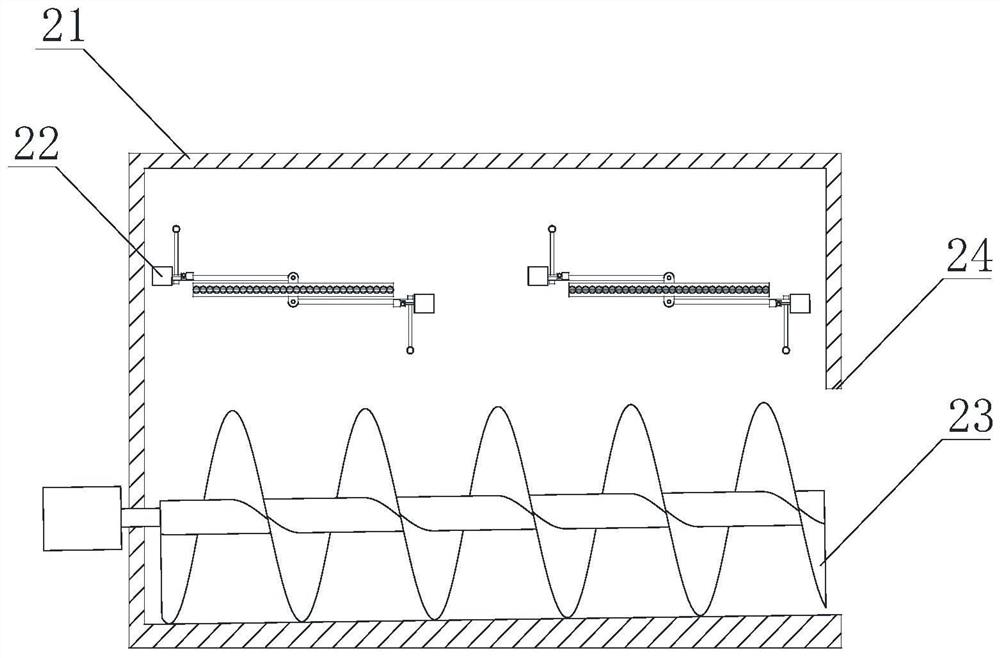

[0076] On the basis of Example 1, such as Figure 4 to Figure 9 As shown, the control mechanism includes a first driving device 227 and a first guide rod 221, a slide block 223 is slidably arranged on the first guide rod 221, and a slider 223 corresponding to the first guide rod 221 is arranged on the slide block 223. A vertical second guide rod 222, on which a connecting rod 228 is slidably arranged, and the connecting rod 228 is connected to a tool set 229, and a push rod 226 is hinged on the connecting rod 228, and the push rod 226 The outer side of the push rod 226 is sheathed with a steering block 225, which is connected to the output end of the first driving device 227, and the outer side of the push rod 226 is also sleeved with a first spring located between the steering block 225 and the connecting rod 228. 224.

[0077] When working, take the above fruit-picking organization as an example, such as Figure 4 As shown, the first driving device drives the steering bloc...

Embodiment 3

[0083] On the basis of the above examples, if Figure 10 with Figure 11 As shown, the cutter set 229 includes a mounting plate 230, and a plurality of grooves 231 are arranged side by side on the mounting plate 230, and a second spring 232 and a cutter 233 are slidably arranged in the groove 231, and the second spring 232 Connect the inner wall of the cutter 233 and the groove 231; the cutter 233 includes a blade 234 and a clamping groove 235. When the upper and lower cutters 233 cooperate, the upper and lower clamping grooves 235 form a clamping area for clamping the root of the block , the clamping area is a tapered structure, and the inner diameter of the tapered structure gradually increases along the direction from the end of the clamping groove 235 close to the blade 234 to the end of the clamping groove 235 away from the blade 234 .

[0084] In this embodiment, the second spring can not only reset the cutting knife, but also keep the cutting knife still when clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com