Self-propelled automatic pickup picker

A self-propelled and automatic technology, applied to loaders, agricultural machinery and implements, threshing equipment, etc., can solve the problems of low fruit picking efficiency, time-consuming and laborious, etc., and achieve high fruit picking efficiency, high cleaning rate, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

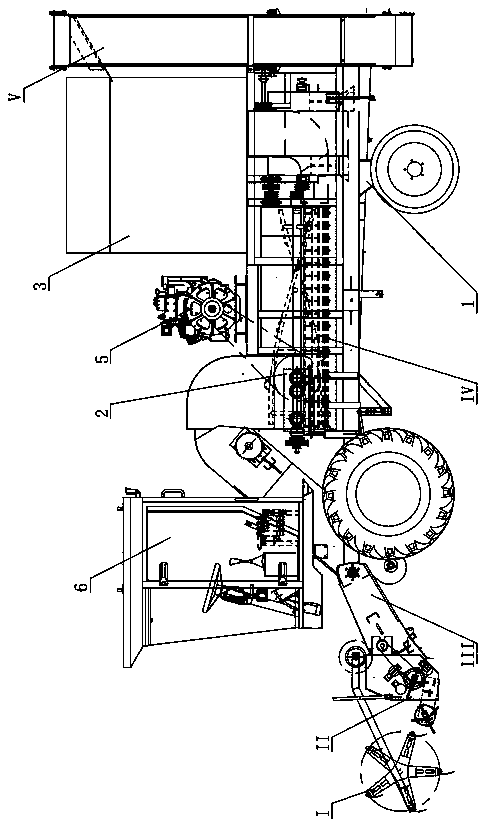

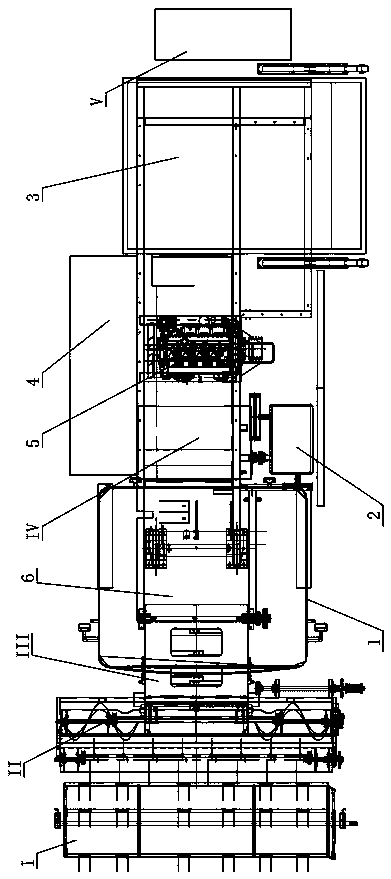

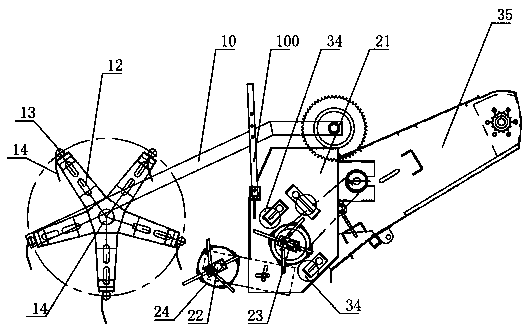

[0046] like figure 1 , figure 2 As shown, the present invention provides a kind of embodiment of self-propelled automatic picking up fruit picking machine, and it comprises vehicle frame 1, and power machine 5 and the running mechanism driven by power machine 5 are installed on the vehicle frame 1, and the front part of vehicle frame 1 A cab 6 is installed, and the cab 6 is equipped with a clutch control system, a steering gear assembly, a brake control system, an accelerator control system, a shift control system, a hydraulic control assembly, a hand brake system, and a mechanical main clutch assembly , seat assembly and other control devices, each system is used for the self-propelled and the control of each action of the fruit picker, its specific control principle and structure can be designed according to the following structural action process, its control structure is the existing The technology will not be described in detail here. After the above-mentioned control i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com