Multiple-ridge peanut combine harvester

A combine harvester and peanut technology, applied in the field of agricultural machinery, can solve the problems of high production cost, high labor intensity, low precision of speed change, etc., and achieve the effect of fast walking speed, flexible steering and wide field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

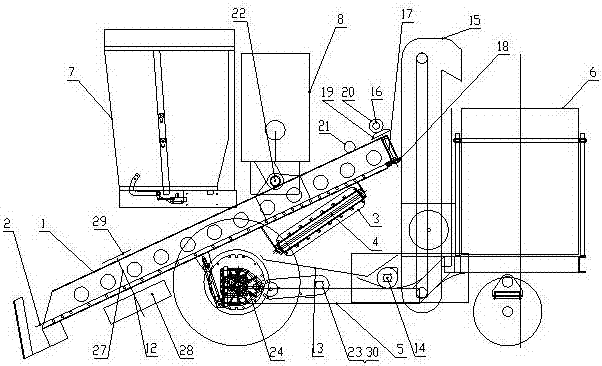

[0044] like figure 1 , 2 As shown, the multi-ridge type peanut combine harvester includes a power unit, a body 5 and a harvesting platform installed on the body 5, and a fruit box 6.

[0045] The harvesting platform and the fruit collection box 6 are respectively installed on the front and rear sides of the body 5. The harvesting platform includes a harvesting platform frame 1, and the front end of the harvesting platform frame 1 is connected with a grain supporter and a shovel, and a driver's cab is arranged above the middle position of the harvesting platform frame 1. 7. The rear side of the cab 7 is provided with a power unit, and the power unit includes an engine 8 .

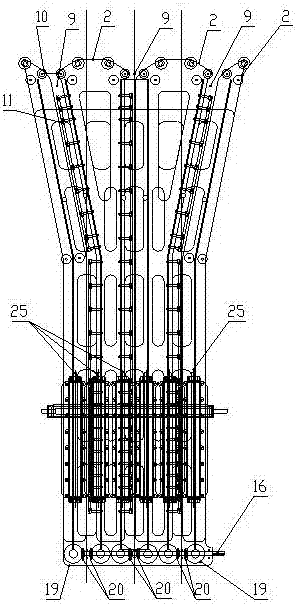

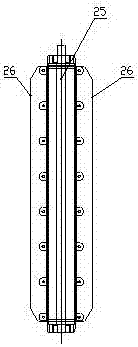

[0046] In the header frame 1, more than three (3 in this embodiment) peanut passages 9 that are arranged obliquely upwards are arranged side by side. Transport chain 2. The header frame 1 is an integral frame. Not only the overall strength is high, but also it is convenient to design the running space of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com