Peanut fruit picking device

A peanut picking and fruit picking roller technology, which is applied in the field of agricultural machinery, can solve problems such as not being well promoted, and achieve the effects of improving fruit picking efficiency, reducing pod damage rate, and improving the cleaning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

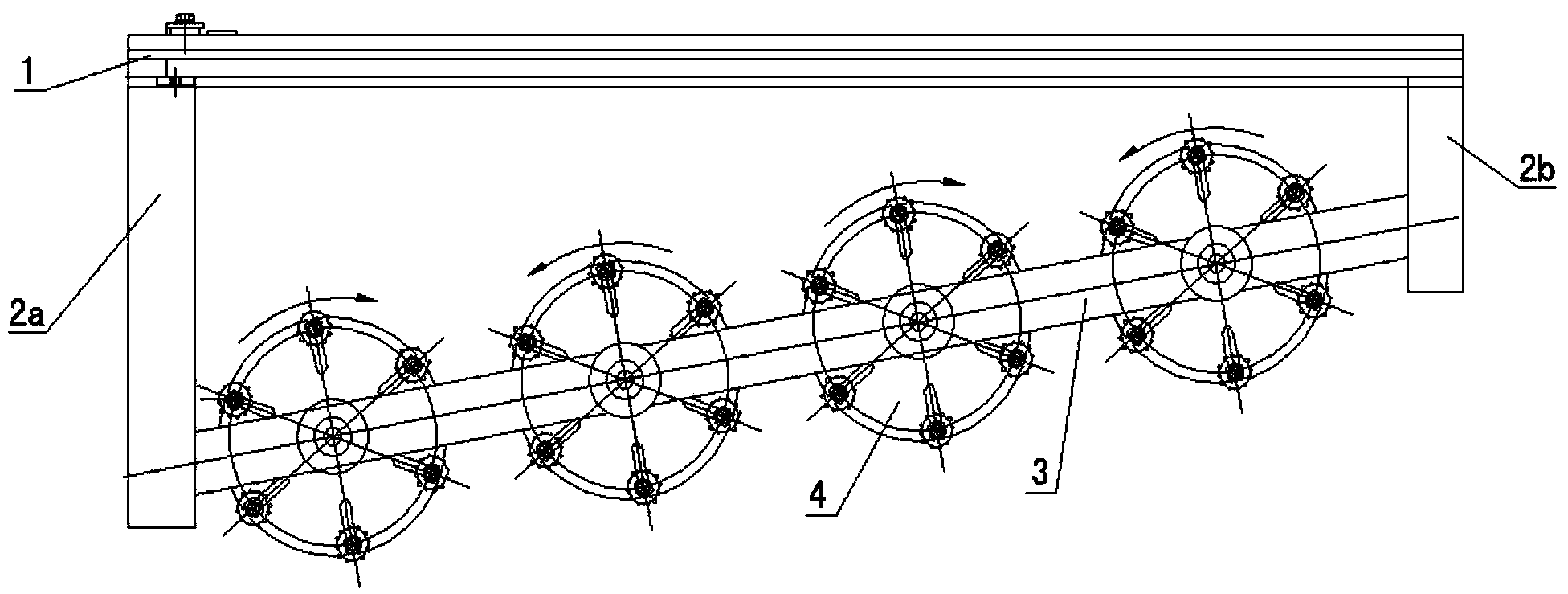

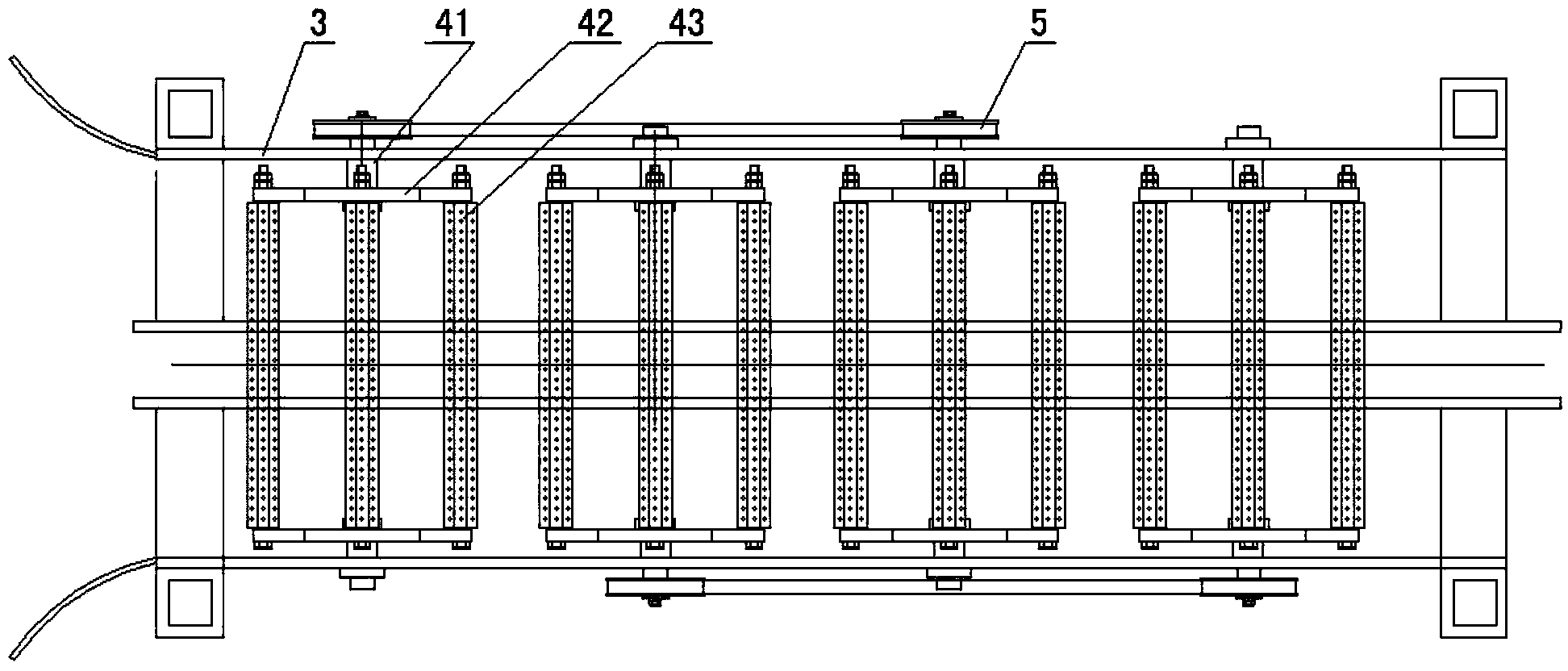

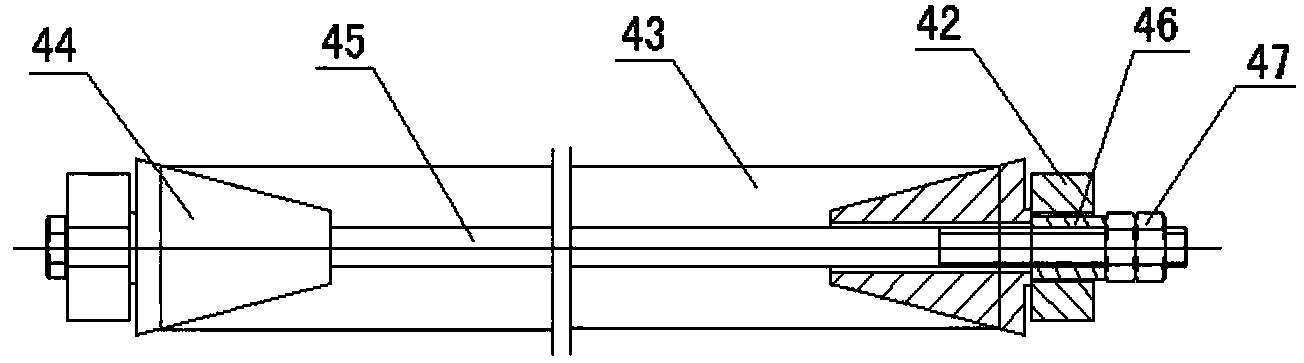

[0036] In this embodiment, the structural form of the horizontal half-feed peanut picking roller is: a pair of fruit picking rollers are arranged under the seedling and tendril clamping plate 1, and the peanut seedlings are clamped in the seedling and tendril clamping plate 1 upright. The advance introduction of holding plate 1 realizes fruit picking between the fruit picking pair of rollers.

[0037] see figure 1 with figure 2 As shown, the structure of the fruit-picking rollers in this embodiment is set as follows: the front end and the tail of the seedling and tendril clamping plate 1 are suspended and respectively provided with a front end connecting plate 2a and a tail connecting plate 2b, which are located on the seedling and tendril clamping plate 1. A pair of roller brackets 3 arranged in parallel below are connected between the front connecting plate 2a and the tail connecting plate 2b to form a frame structure; 4. The adjacent horizontal fruit picking rollers rota...

Embodiment 2

[0050] In this embodiment, the vertical tapered peanut fruit picking rollers are provided with fruit picking rollers below the seedling and tendril clamping plate, and the peanut seedlings clamped in the seedling and tendril clamping plate in an upright manner are introduced into the fruit picking as the seedling and tendril clamping plate advances. Fruit picking is realized between the pair of rollers.

[0051] see Figure 4 and Figure 5 In this embodiment, the structure of the fruit-picking rollers is set as follows: the front end and the tail of the seedling and tendril clamping plate 1 are suspended and respectively provided with a front end support 2a and a rear end support 2b, and the mounting seat 3 located below the seedling and tendril clamping plate 1 is fixed. Be arranged between the front end bracket 2a and the tail bracket 2b, each vertical fruit picking roller 4 is arranged at intervals on the mounting seat 3, the vertical fruit picking roller 4 is a tapered ro...

Embodiment 3

[0062] see Figure 7 , Figure 8 , the structural form of the longitudinal semi-feeding type peanut fruit picking roller in the present embodiment is: a pair of fruit picking rollers are arranged under the seedling and tendril clamping plate 1, and the peanut seedlings with seedlings and tendrils are clamped in the seedling and tendril clamping plate 1 upright. The advance introduction of clamping plate 1 realizes fruit picking between the fruit picking pair of rollers.

[0063] Such as Figure 7 and Figure 8 As shown, the structure of the fruit-picking rollers in this embodiment is set as follows: a pair of longitudinal roller shafts 4 arranged along the direction of travel of the seedling and tendril holding board 1 under the seedling and tendril holding board 1, and the vertical roller shafts 4 The front end is arranged on the front end suspension 2 of the seedling vine clamping plate 1 through a bearing, the rear end of the longitudinal roller shaft 4 is supported by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com