Blade type anti-winding fruit picking roller

A fruit picking roller and anti-winding technology, applied in excavating harvesters, threshing equipment, agricultural machinery and implements, etc., can solve problems such as plastic film winding, reduce resistance loss, avoid accumulation, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

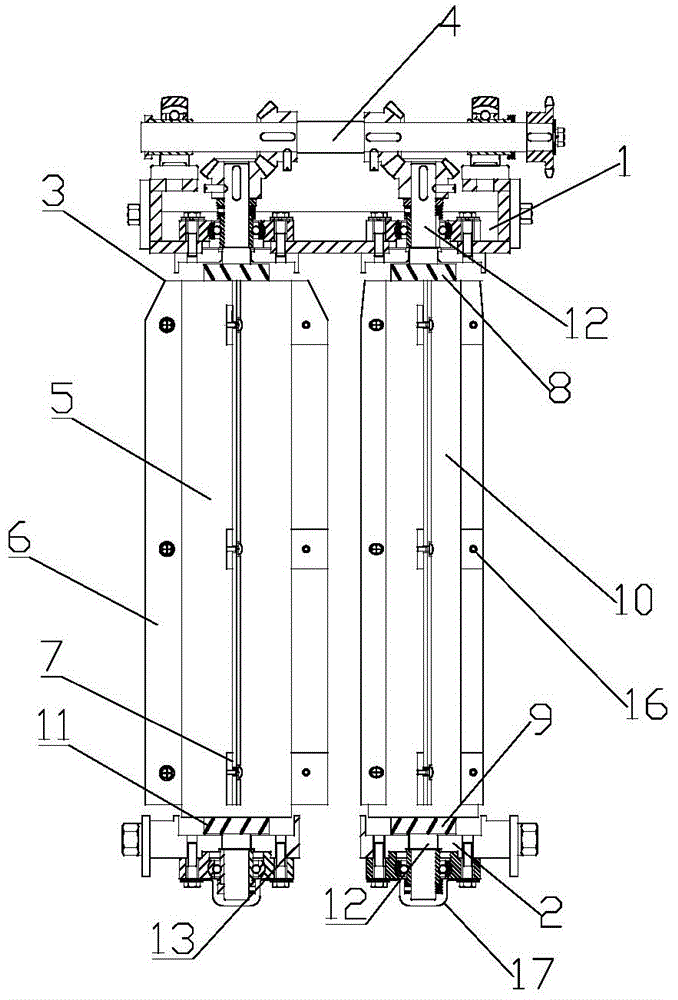

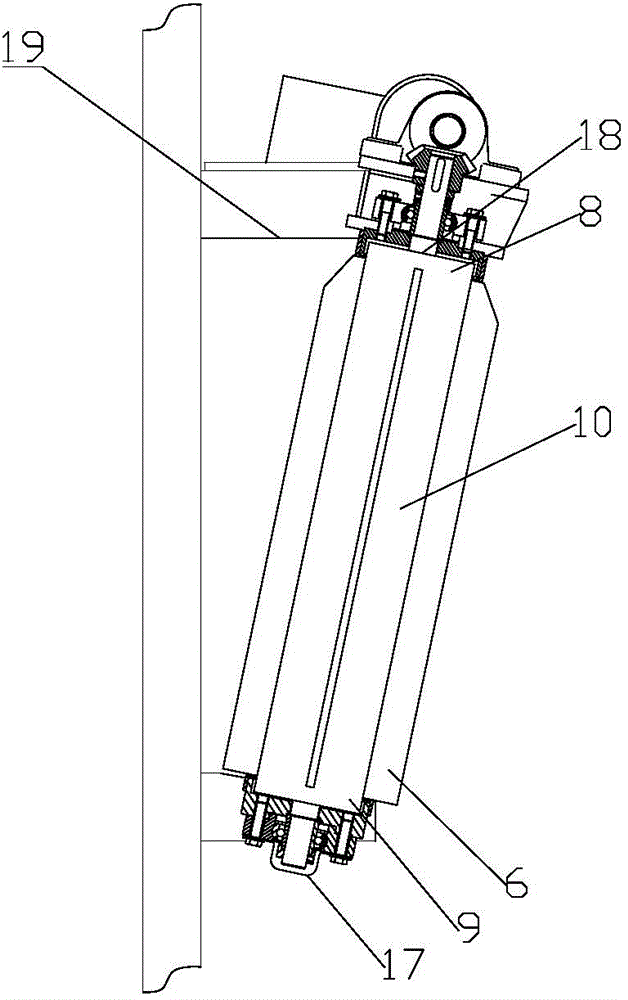

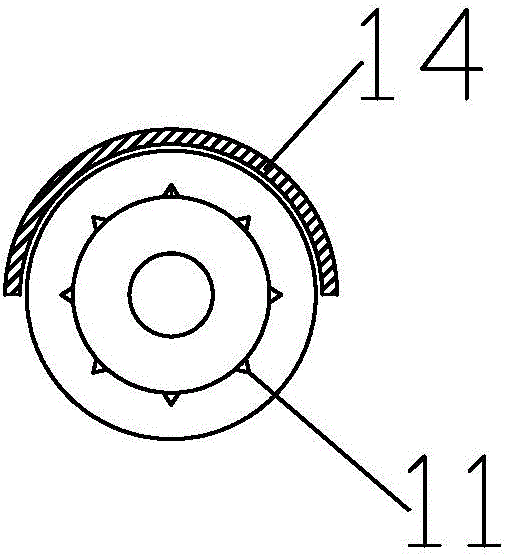

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] Blade type anti-winding fruit picking roller, including fruit picking roller seat, fruit picking roller seat is divided into upper fruit picking roller seat 1 and lower fruit picking roller seat 2, symmetrical between upper fruit picking roller seat 1 and lower fruit picking roller seat 2 A pair of fruit-picking roller bodies 3 are provided, and the upper fruit-picking roller seat 1 is connected with a transmission mechanism 4. The fruit-picking roller body 3 is a cylinder, and the fruit-picking roller body 3 includes a fruit-picking roller 5 and a fruit-picking blade 6. The fruit-picking blade 6 passes through the blade Seat 7 round head bolts are fixedly installed on the fruit-picking roller 5, the two ends of the fruit-picking roller 5 are provided with connecting shaft 12, and the outer connecting shaft 12 is provided with a bearing end plate, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com