Vertical clamping-type peanut picking device and working principle thereof

A peanut picking and clamping technology, which is applied to threshing equipment, applications, agricultural machinery and implements, etc., can solve problems such as restricting popularization and application, and achieves improved quality, improved fruit picking efficiency and net rate, and improved striking range and effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

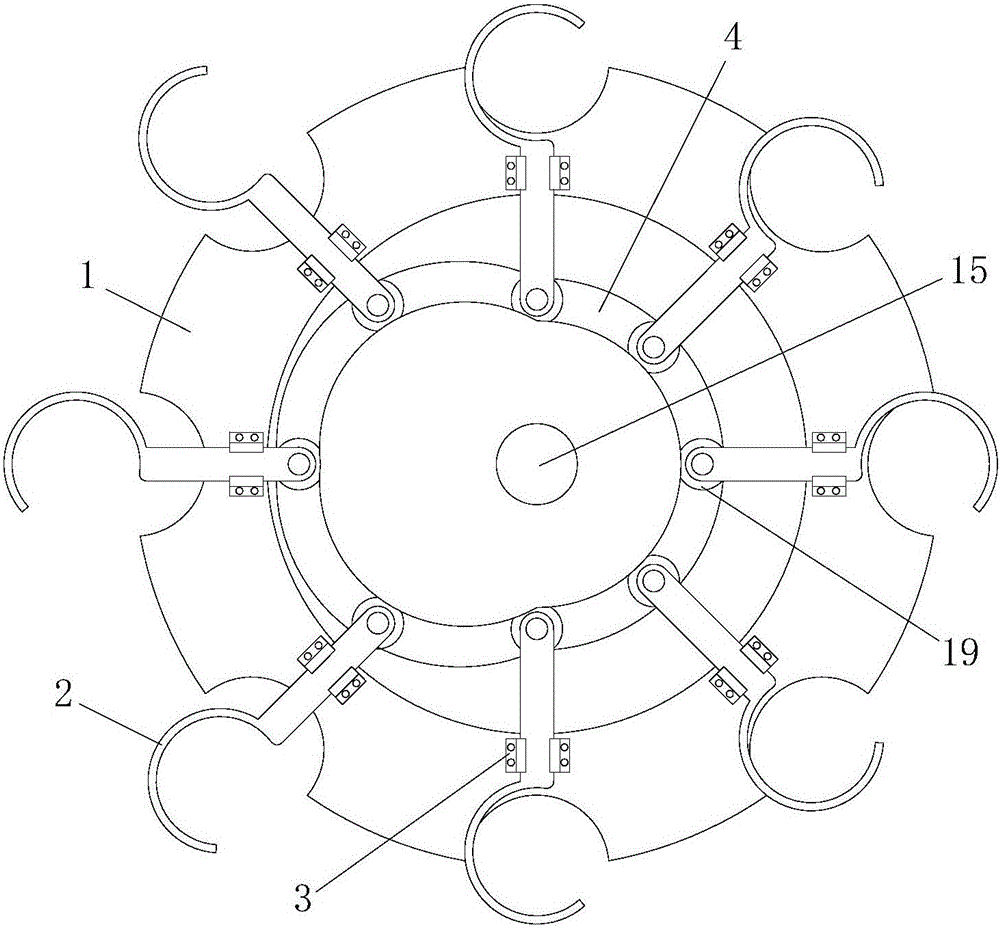

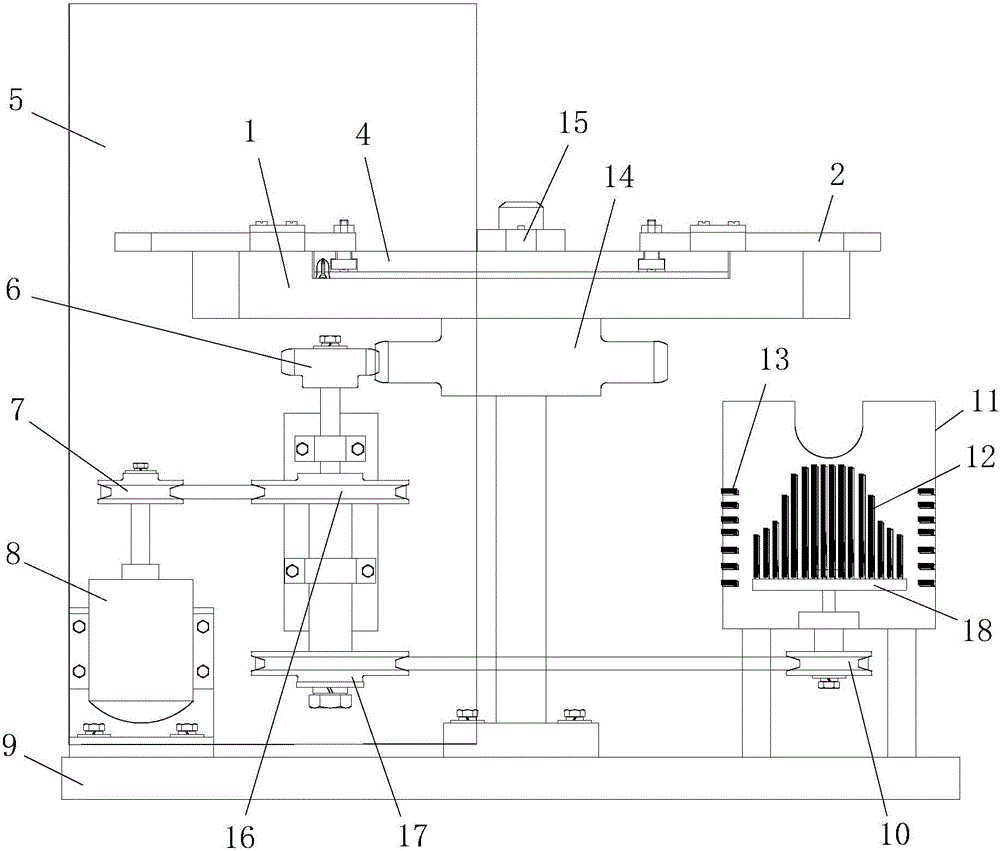

[0015] In this example, refer to figure 1 with figure 2 , the vertical clamping type peanut picking device includes a motor 8, a workbench 1, a base 9, a fruit picking cylinder 11 and a column 15, the motor 8 and the fruit picking cylinder 11 are fixed on the base 9, and the workbench 1 is installed on the column 15, The column 15 is installed on the base 9, the column 15 is connected to the motor 8 through the deceleration pulley group, and a grip mechanism is installed on the workbench 1; Circumferentially fixed on the workbench 1, the claw rod of the clamping claw 2 is set in the guide slideway 3, and each clamping claw 2 is provided with a lateral groove corresponding to the position of the workbench 1; There is a guide rail 4 with a cam structure, and the tail end of the claw rod is installed in the guide rail 4 in a slidable manner; the fruit picking roller 11 is installed under the clamping claw 2, and is positioned at the position where the clamping claw 2 is indente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com