Fruit picking roller for peanut harvester, and peanut harvester

A peanut harvester and drum technology, which is applied to excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of peanut fruit crushing, low peanut crushing rate, clogging of feeding inlets, etc. Fruit picking efficiency and the effect of reducing the number of times of hitting peanuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

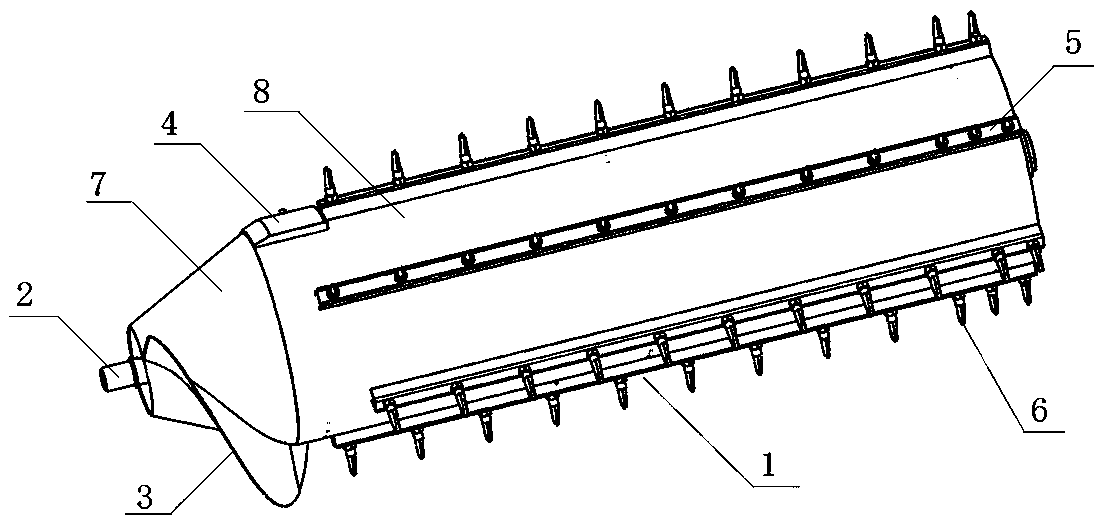

[0047] Such as figure 1 As shown, the fruit picking drum for the peanut harvester in this embodiment is a vertical axial flow fruit picking drum, which includes a cylinder body 1 and a roller 2, and the roller shaft 2 is installed on the cylinder body 1 and is coaxial with the axis of the cylinder body 1. When the roller shaft 2 rotates, it drives the cylinder body 1 to rotate.

[0048] In this embodiment, the barrel body 1 includes a conical barrel section 7 and a cylindrical barrel section 8, and the conical barrel section 7 is welded and fixed to the front end of the cylindrical barrel section 8 to form a feeding section. The outer diameters of the cylindrical barrel section 8 are equal everywhere, and the outer diameter of the conical barrel section 7 gradually increases along the conveying direction of peanut seedlings, and the maximum outer diameter of the conical barrel section 7 is the same as the outer diameter of the cylindrical barrel section 8 .

[0049] On the ou...

Embodiment 2

[0057] The difference between this embodiment and the above-mentioned Embodiment 1 is that in this embodiment, the counterweights and the introduction blades are respectively located on the radial sides of the cylinder, but they are arranged asymmetrically, and the position of the counterweights is based on the needs of the dynamic balance of the cylinder. , is set within a certain range, and the position is not unique, for example, it is set away from the joint between the conical barrel section and the cylindrical barrel section.

Embodiment 3

[0059] The difference between this embodiment and the above-mentioned embodiment 1 is that in this embodiment, the counterweight is detachably connected to the barrel, for example, threaded holes are set on the barrel wall of the barrel, and the counterweight is fastened by threaded fasteners. It is fixed on the cylinder, so that when replacing a different cylinder, the counterweight on the discarded cylinder can be removed for reuse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com