Peanut picking device

A technology for peanuts and peanuts, applied in the field of agricultural tools, can solve the problems of large manpower burden, delayed harvest time, slow speed, etc., and achieve the effects of reducing labor intensity, improving fruit picking efficiency, and improving threshing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

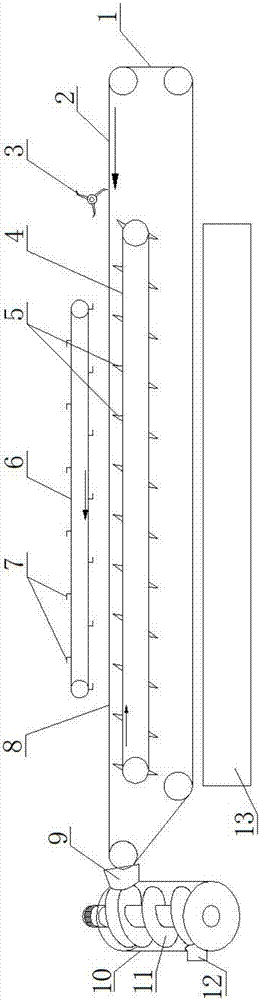

[0018] Embodiment 1, with reference to figure 1 , a peanut fruit harvesting device, comprising a fruit seedling conveyor belt 1, the front portion of the fruit seedling conveyor belt is set as a seedling loading station 2, and the rear portion of the fruit seedling conveyor belt is set as a fruit removing station 8, and the seedling loading station At least one side of the fruit seedling conveyor belt between 1 and the fruit removal station 8 is provided with a seedling cutting device 3, and the operator places the peanut seedlings on the seedling loading station to remove the upper peanut leaf stem through the seedling cutting device, and then The seedlings at the bottom enter the threshing station 8 for fruit removal, and the seedling conveyer belt 1 is a grid-shaped conveyer belt that drains peanuts downward.

[0019] Below the fruit threshing station 8 is provided with a threshing conveyor belt 4, the described threshing conveyor belt is arranged between the upper and lowe...

Embodiment 2

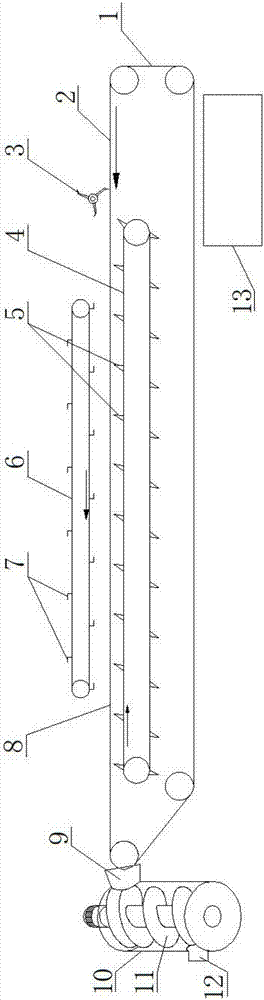

[0024] Embodiment 2, with reference to figure 2 , a peanut fruit harvesting device, comprising a fruit seedling conveyor belt 1, the front portion of the fruit seedling conveyor belt is set as a seedling loading station 2, and the rear portion of the fruit seedling conveyor belt is set as a fruit removing station 8, and the seedling loading station At least one side of the fruit seedling conveyor belt between 1 and the fruit removal station 8 is provided with a seedling cutting device 3, and the operator places the peanut seedlings on the seedling loading station to remove the upper peanut leaf stem through the seedling cutting device, and then The seedlings at the bottom enter the threshing station 8 for fruit removal, and the seedling conveyer belt 1 is a grid-shaped conveyer belt that drains peanuts downward.

[0025] Below the fruit threshing station 8 is provided with a threshing conveyor belt 4, the described threshing conveyor belt is arranged between the upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com