Fast connecting mechanism for joints

A technology of quick connection and docking mechanism, applied in the direction of joints, manipulators, manufacturing tools, etc., can solve the problems of slow connection process and locking process, inconvenient installation and disassembly, low limit bearing capacity, etc., to improve installation and disassembly. High efficiency, ingenious locking structure, and the effect of large ultimate bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

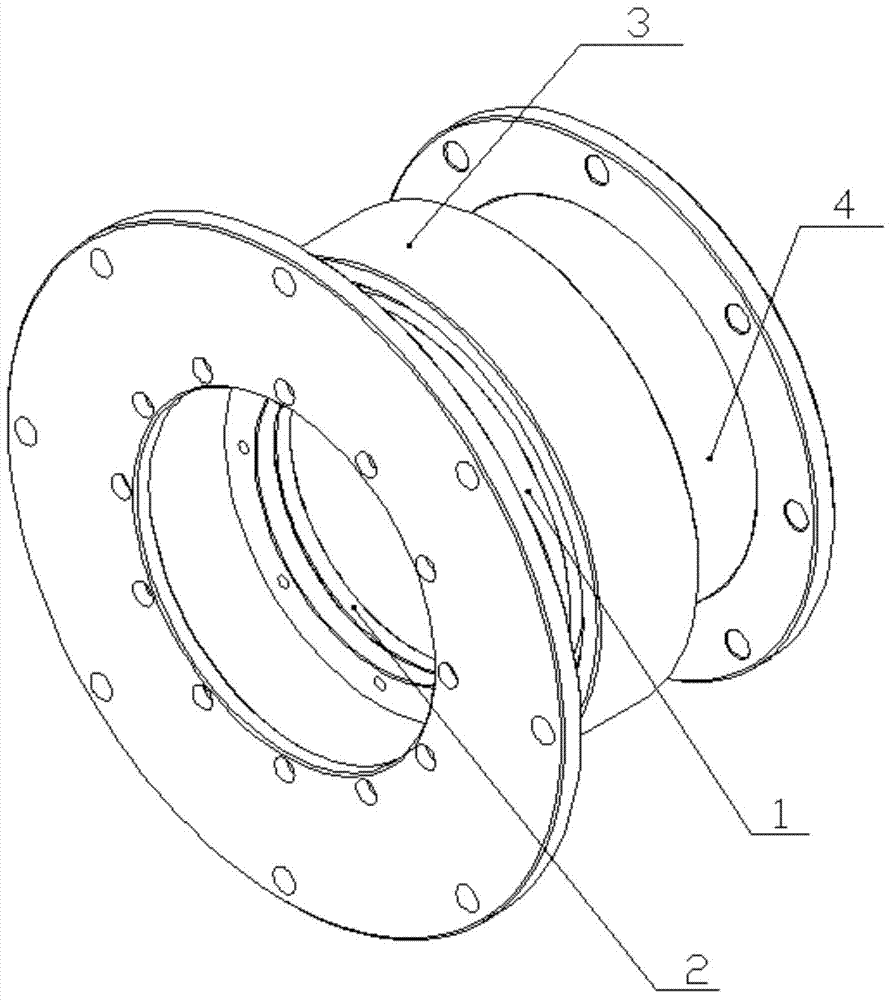

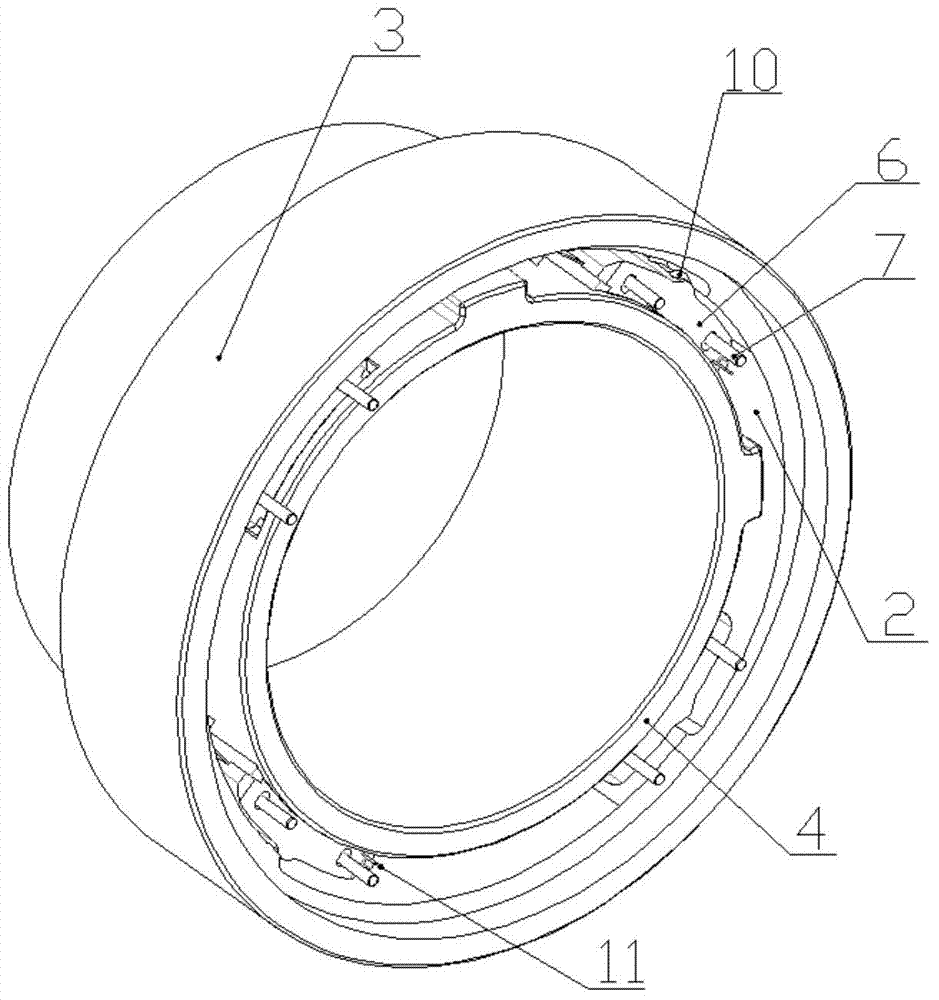

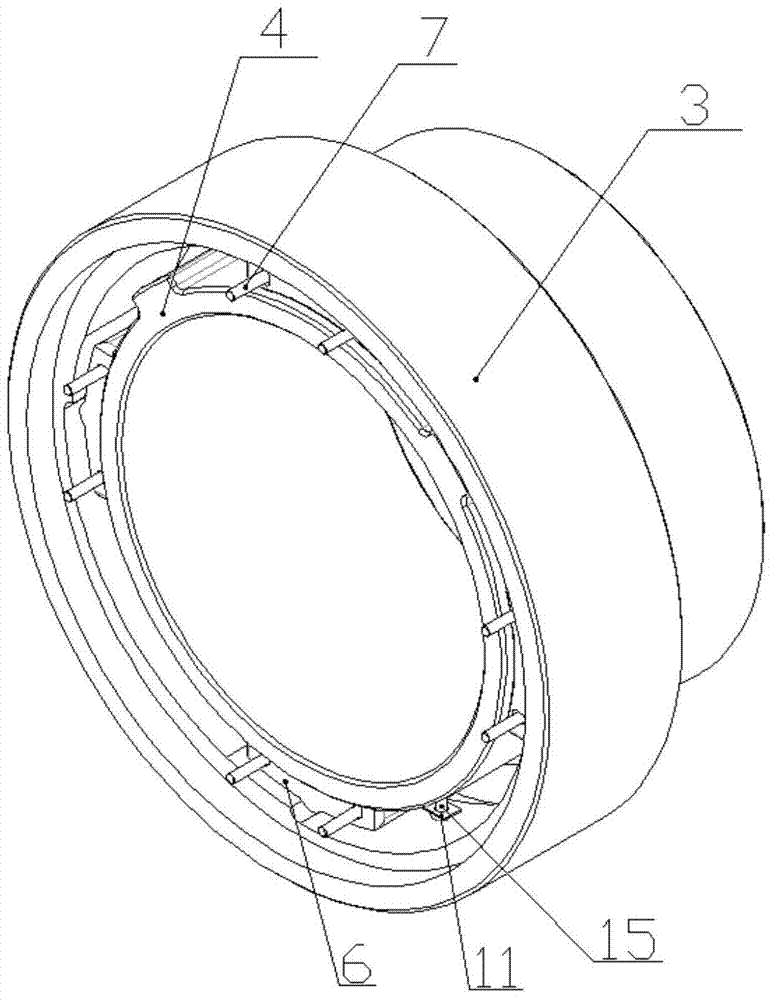

[0014] combine Figure 1 to Figure 5 , the present invention includes a support platform 1, a fixing flange 2 mounted on the support platform 1, a locking ring 3 sleeved on the outside of the fixing flange 2, and a docking mechanism 4 located inside the fixing flange 2, and the docking mechanism 4 The outer surface is provided with two shoulders 4-1, and the corresponding position of the fixed flange 2 is provided with two grooves 2-1 matched with the two shoulders 4-1, and the circumferential direction of the fixed flange 2 Four opening slots 2-2 are symmetrically arranged, and a locking fixture 6 is arranged in each opening slot 2-2, and the left and right ends of each locking fixture 6 are fixedly connected to the fixed flange 2 through leaf springs 11, respectively. The upper and lower ends of each locking fixture 6 are connected...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap