Cooling device of plastic extruder

A technology of a plastic extruder and a cooling device, applied in the field of plastic machinery manufacturing, can solve the problems of uneven temperature, poor cooling effect, affecting the performance and texture of plastics, etc., to achieve uniform temperature, ensure performance and texture, and best water temperature uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

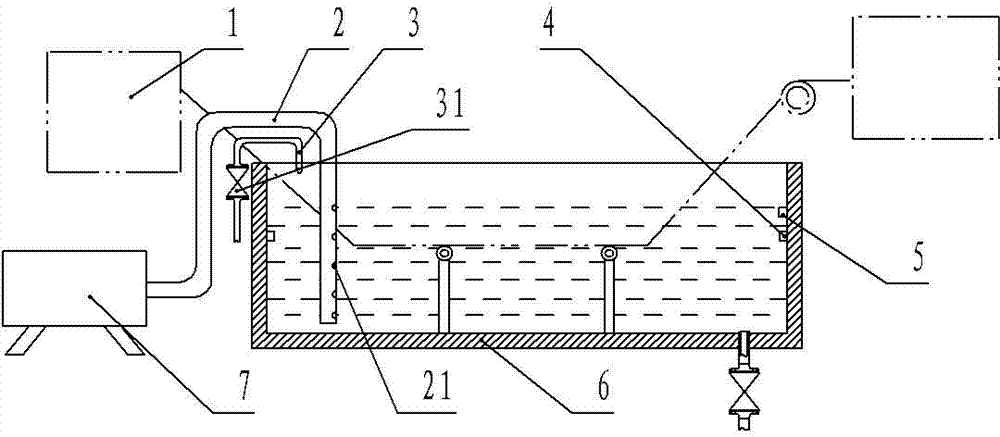

[0013] Such as figure 1 The plastic extruder cooling device shown includes a plastic extruder 1 and a tank body 6 filled with cooling water therein. The tank body 6 is provided with a water inlet pipe 3, and the outside of the tank body 6 is provided with an air outlet connected to the outlet. The blower 7 of the air pipe 2, the air outlet pipe 2 stretches into the tank body 6, the air outlet pipe 2 corresponds to the water inlet end of the plastic strip, and the air outlet pipe 2 is provided with a plurality of air outlets, and the air outlets of the air outlet pipe 2 all face The direction of movement of the plastic strip; the two ends of the tank body 6 are respectively provided with a water level sensor 5 and a temperature sensor 4; the water inlet pipe 3 is provided with a solenoid valve 31, the water level sensor 5 is electrically connected to the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap