Braking and reversing integrated valve assembly

A technology of integrated valves and components, applied in the direction of servo motor components, fluid pressure actuators, mechanical equipment, etc., can solve the problems of affecting the working efficiency of hydraulic valves, complex systems, and many control pipelines, and achieve compact structure and difficult processing Small, good looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

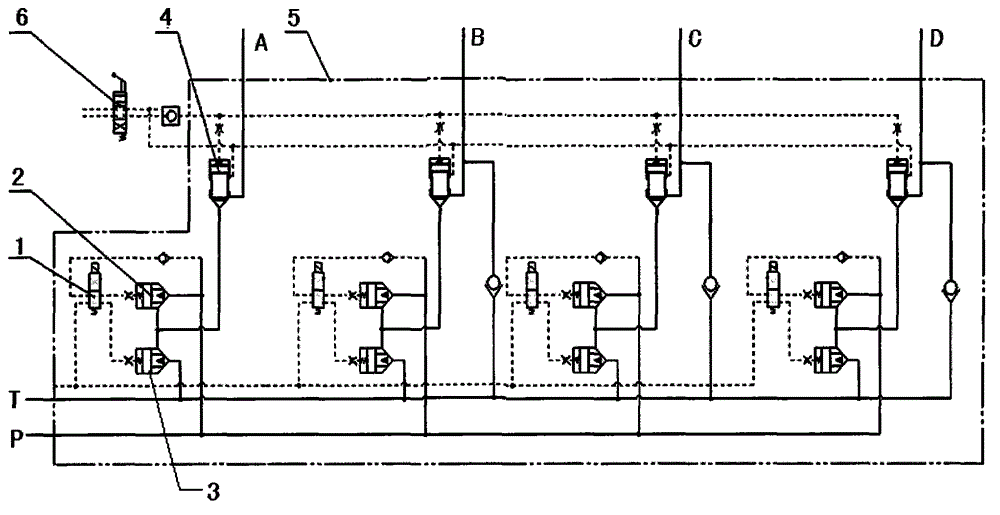

[0010] combined with Figure 1-2 , to further describe the present invention:

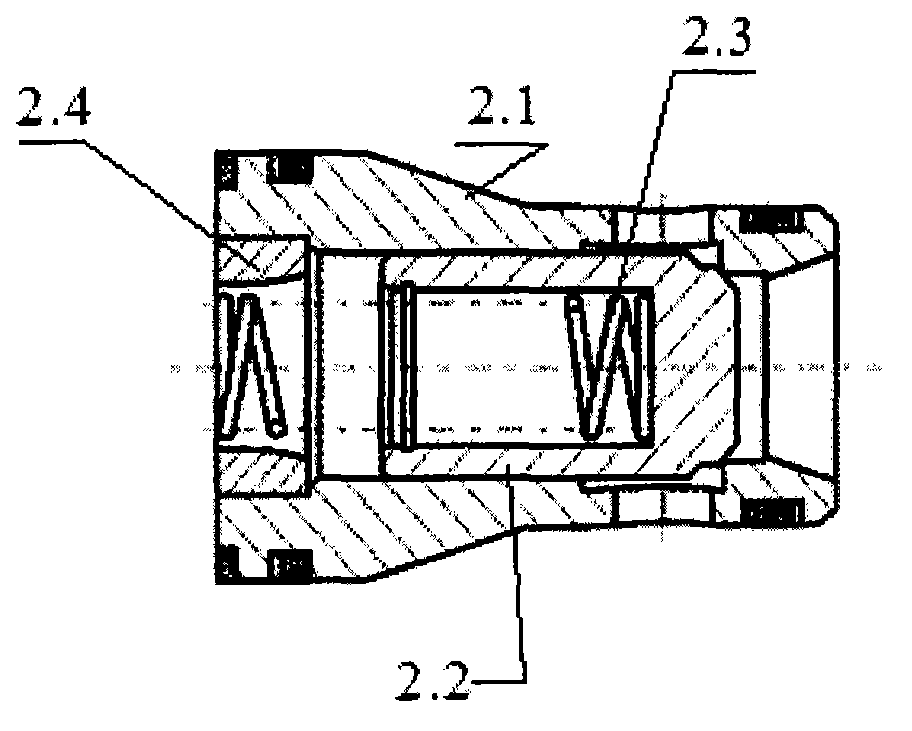

[0011] The present invention includes a valve body 5 and an integrated valve. A cavity is provided inside the valve body 5, and multiple sets of integrated valves are inserted in the cavity. The integrated valves are respectively connected to the actuators A, B, C, and D. The integrated valve includes the first A plug-in 2 and a second plug-in 3, the first plug-in 2 and the second plug-in 3 are connected in the cavity inside the valve body 5 by bolts, the first plug-in 2 and the second plug-in 3 are connected in parallel in the valve body 5, The first plug-in 2 and the second plug-in 3 are respectively connected to the solenoid valve 1, and the valve body 5 is provided with a high-pressure port P and a low-pressure port T. Port T, the outlet ports of the first plug-in 2 and the second plug-in 3 are connected in parallel to the dynamic valve 4, the dynamic valve 4 is connected to the manual valve 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com