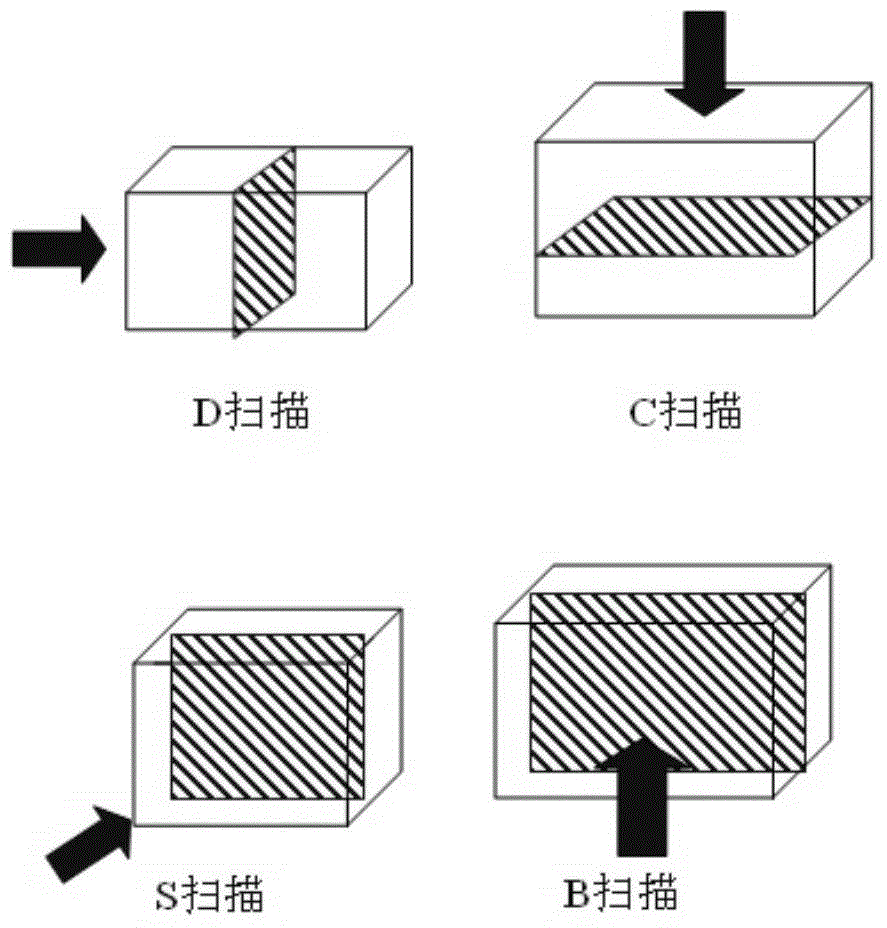

An ultrasonic b+c+d+s scanning identification method for internal defects of steel ingots

A scanning method and a technology for internal defects, applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, can solve the problems of insufficient imagery and intuition, and achieve the effects of eliminating universal forging process cards, accurate description of map features, and comprehensive detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

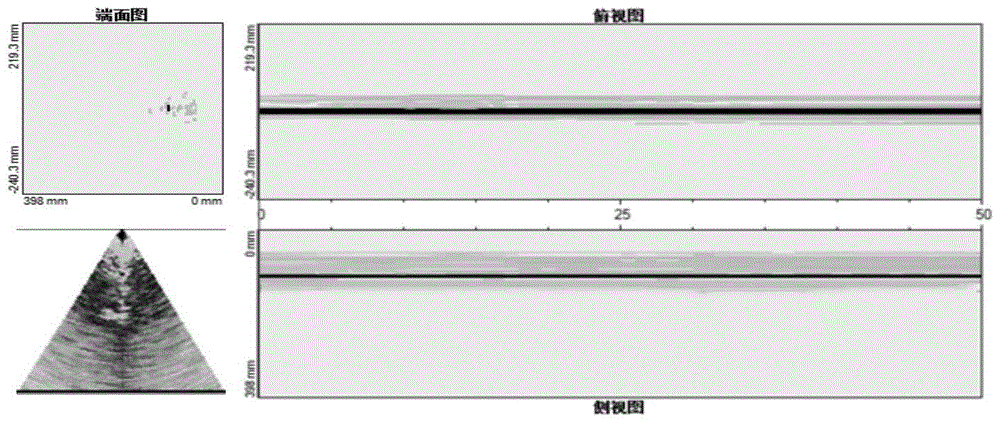

[0044] Example 1 The continuous casting ingot is detected. In the ultrasonic B+C+D+S scanning atlas, the B-scan image is a non-central intermittent strip, the C-scan image is a central intermittent strip, and the D The scan image is a non-central spot; the S-scan image is a non-central spot. Defects are single point defects. see figure 2 shown.

Embodiment 2

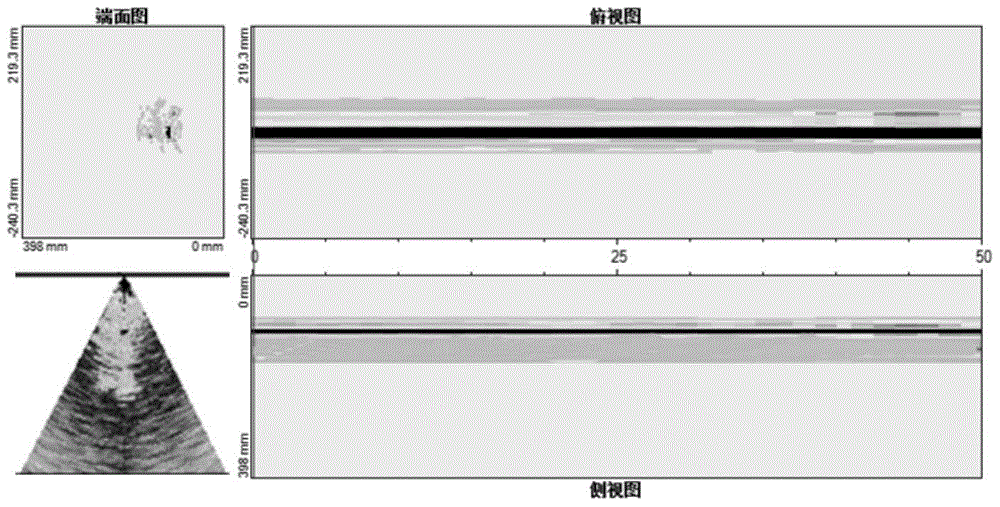

[0045] Example 2 The molded ingot is detected. In the ultrasonic B+C+D+S scanning atlas, the B-scan image is a non-central intermittent strip, the C-scan image is a central intermittent strip, and the D The scan image is a non-central spot; the S-scan image is a non-central spot. Defects are single point defects. see image 3 shown.

Embodiment 3

[0046] Example 3 The electroslag remelting ingot is detected. In the ultrasonic B+C+D+S scanning atlas, the B-scan image is a non-central intermittent strip, and the C-scan image is a central intermittent strip. , the D-scan image is a non-central spot; the S-scan image is a non-central spot. Defects are single point defects. see Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com