Anchor bolt expansion sleeve and manufacturing method thereof

A manufacturing method and anchor bolt technology are applied to the structure of metal stamping sheets used in the manufacture of expansion sleeves, and the manufacturing field of anchor bolt expansion sleeves, which can solve the problems of falling plates, complicated manufacturing processes, and inability to achieve balanced expansion of load tongues. To achieve the effect of preventing false expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

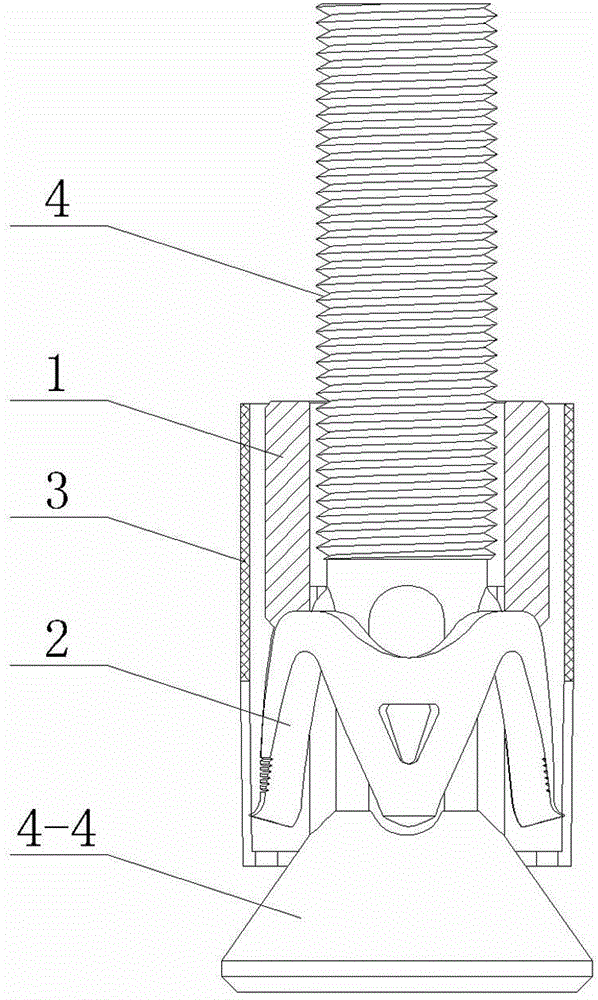

[0033] In order to further explain the technical means and functions adopted by the present invention to achieve the intended technical purpose, the structure, features and functions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

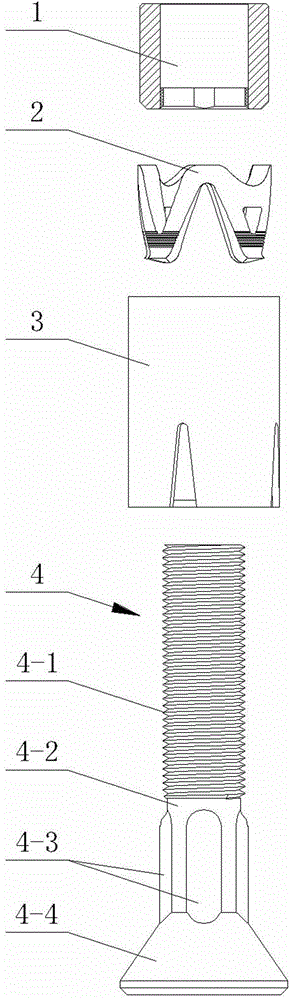

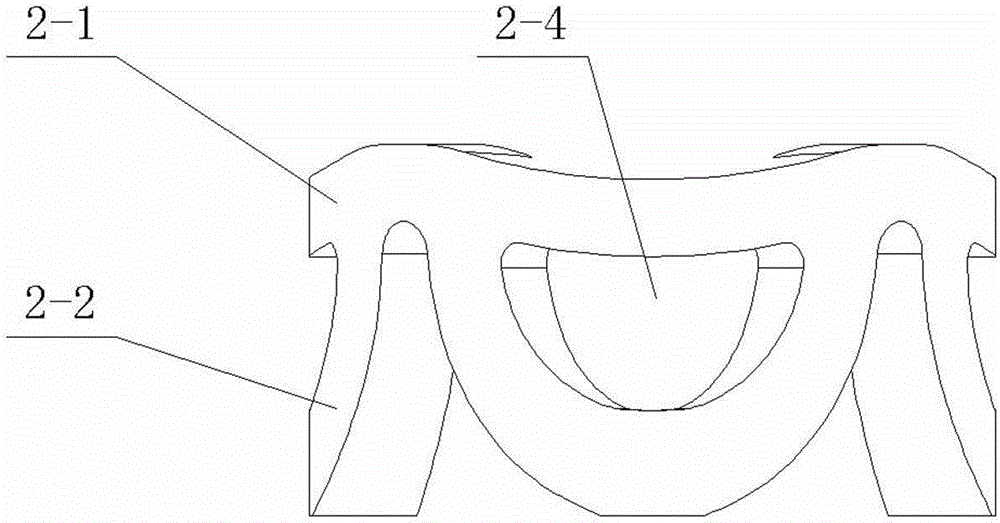

[0034] A method of manufacturing an anchor bolt expansion sleeve described in this embodiment, firstly, a sheet metal body is made, such as Figure 10 , Figure 11 As shown, the sheet body is petal-shaped, including several petal bodies, the number of petal bodies is equal to the number of load tongues of the expansion sleeve, and a circular arc transition is adopted between adjacent petal bodies; a polygonal central hole 2-5 is set in the middle of the sheet body , the top corners of the polygonal central hole 2-5 are set as rounded corners; secondly, the metal sheet body is made into an expansion sleeve through a stamping process, and the stamping direction is alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com