Centrifugal blade, centrifugal fan and air conditioner

A technology of centrifugal fan blades and fan blades, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of eddy current noise, ineffective drainage, and affecting the aerodynamic performance of centrifugal fan blades, so as to avoid eddy current noise, Eliminates the effect of vortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

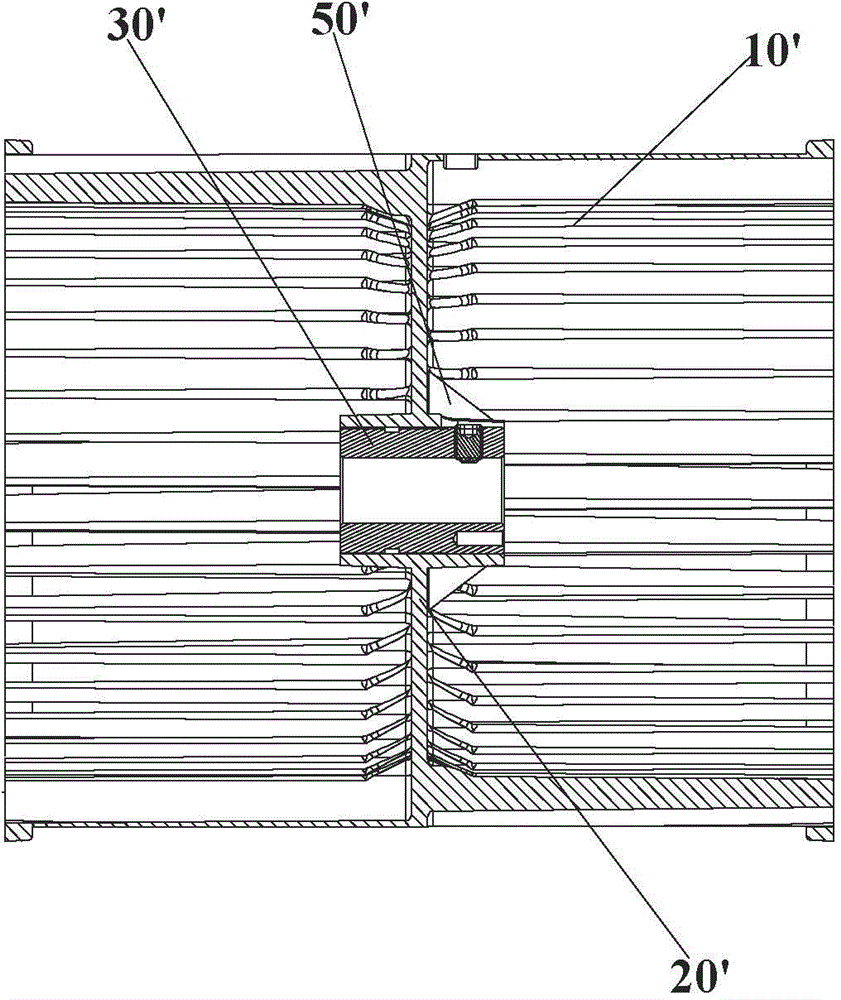

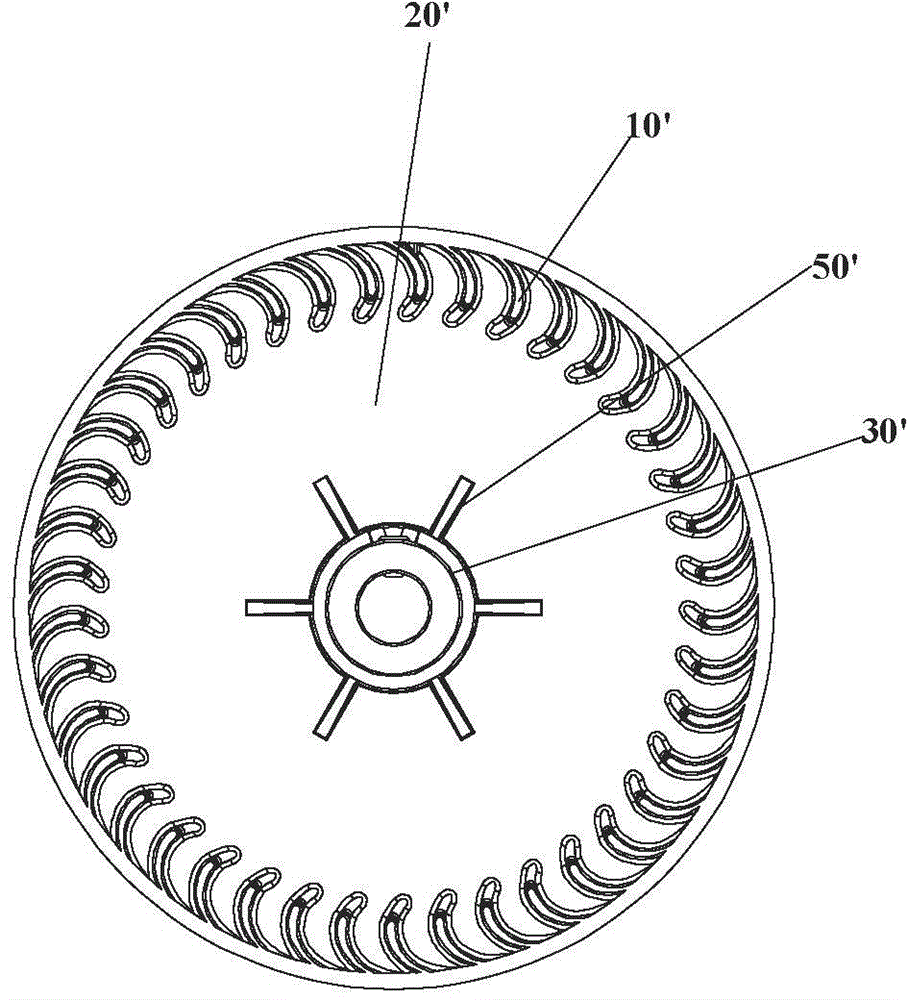

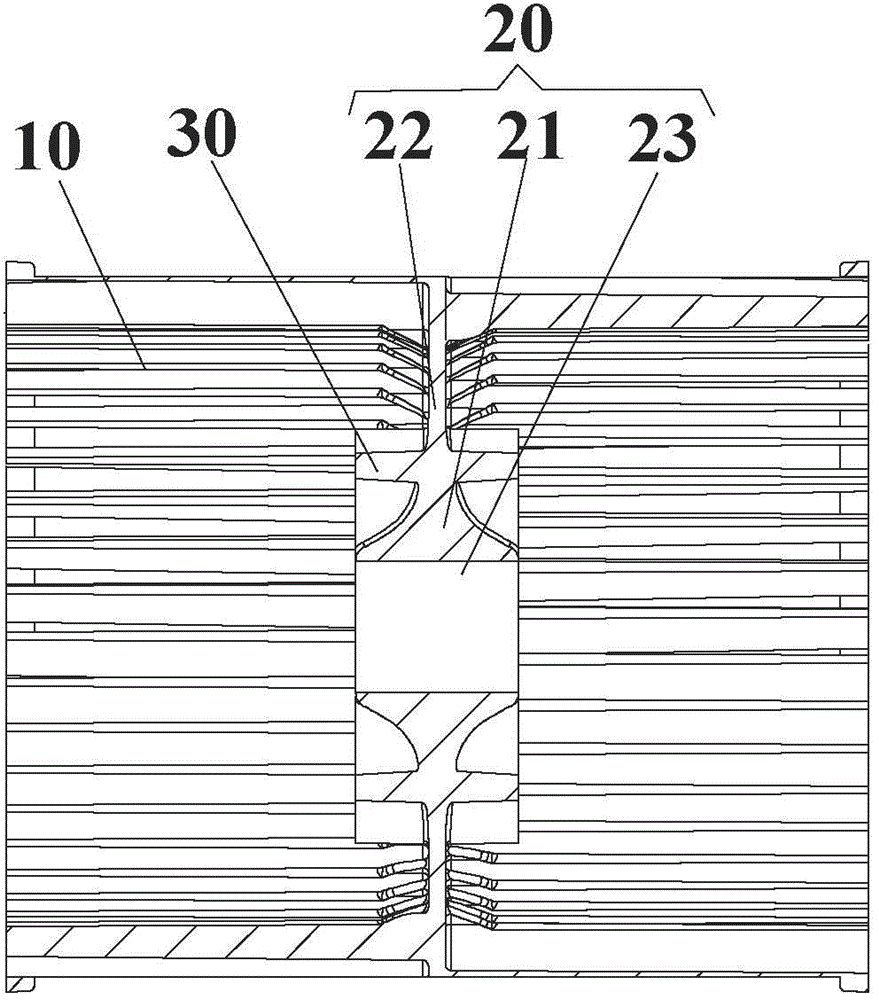

[0029] like Figure 3 to Figure 8 As shown, the embodiment of the present invention provides a centrifugal blade, including a blade body 10 and a partition 20 . The baffle 20 is arranged inside the blade body 10 and includes an arc-shaped transition portion 21, a baffle body 22 and a bushing accommodation portion 23. The baffle body 22 is arranged perpendicular to the axial direction of the blade body 10, and the bushing accommodating portion 23 extends along the axial direction of the blade body 10 and penetrates from the first side of the partition body 22 to the second side of the partition body 22 . The arc-shaped transition portion 21 is disposed at the connection between the above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com