A Shafting Electromagnetic-Hydraulic Comprehensive Simulation Test Loading Device

A technology of loading device and simulation test, which is applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc. It can solve problems such as unsatisfactory simulation conditions of the real working state of the object axis and difficulty in accurate simulation. , to achieve the effects of sensitive adjustment of loading force, stable and controllable magnetic field, and rapid boost adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

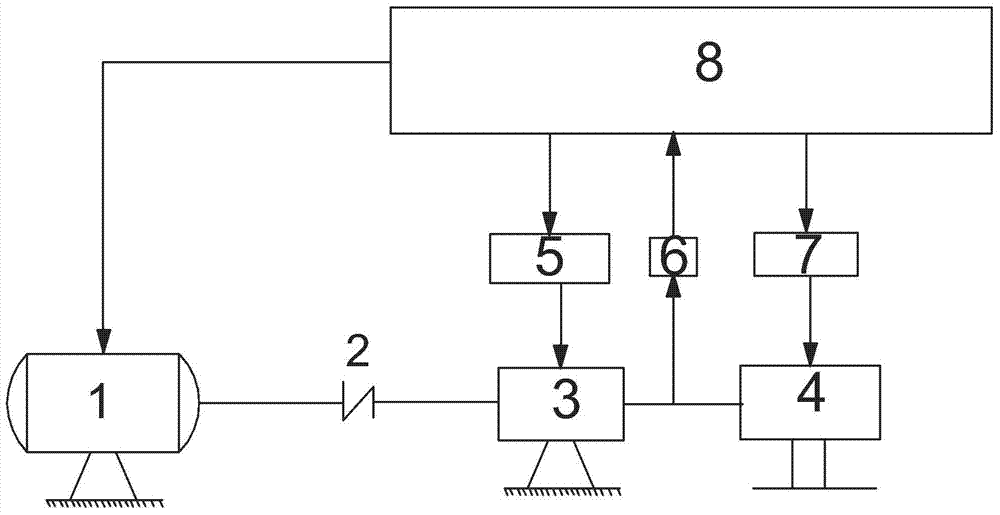

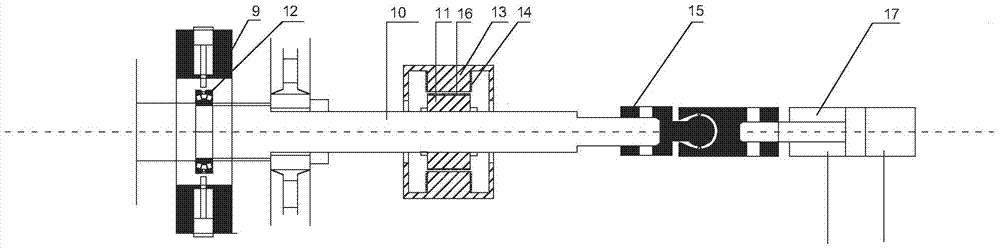

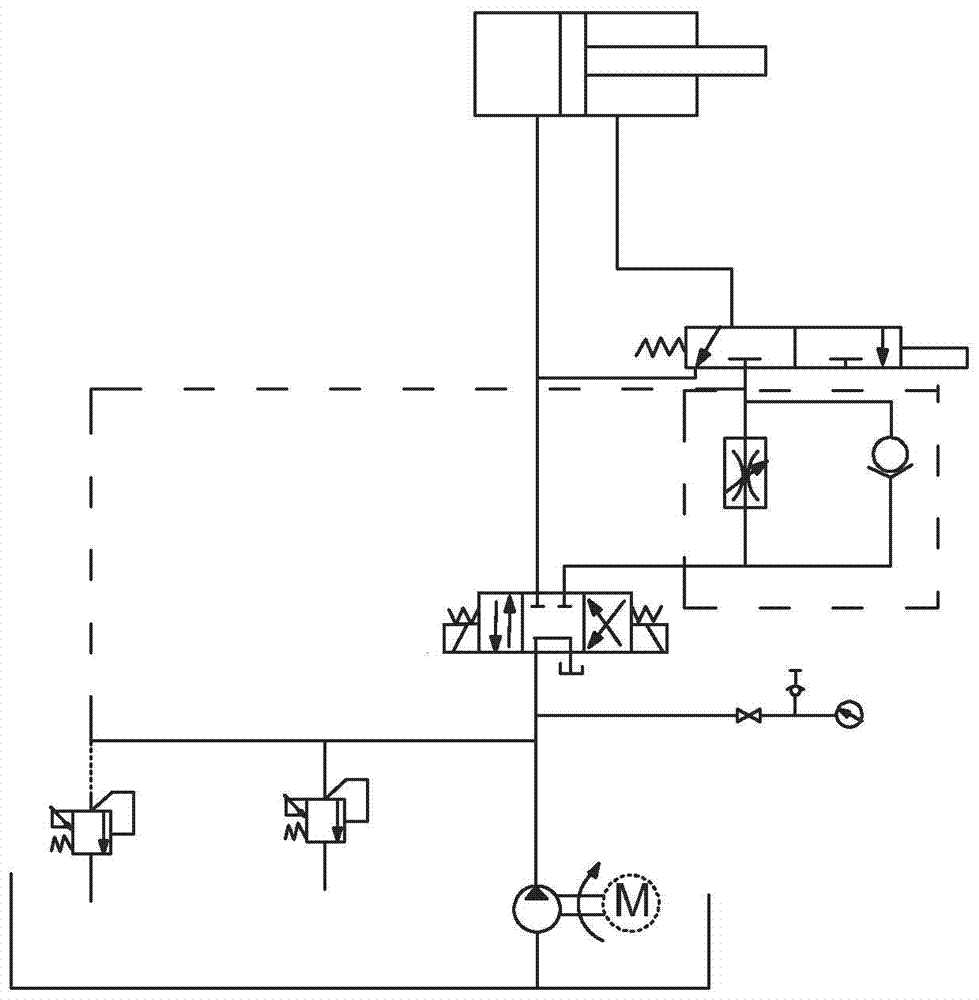

[0023] The invention provides a shafting electromagnetic hydraulic comprehensive simulation test loading device, such as figure 1 and figure 2 As shown, it includes a prime mover 1 connected to the test shaft 10 through a first shaft coupling 2 and a main control unit 8. The prime mover 1 is used to provide power to the test shaft 10 to make it rotate, and the speed of the prime mover 1 is determined by Controlled by the main control unit 8 , it also includes an electromagnetic torque loading device 3 , a hydraulic pressure loading device 4 , a sensor detection feedback unit 6 and a hydraulic control unit 7 . The electromagnetic torque loading device 3 generates magnetic force through the direct current 5 to provide torque to the moving test shaft 10 , and the main control unit 8 controls the magnitude of the torque by controlling the current of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com