A blade type terahertz wave broadband linear polarizer

A terahertz and polarizer technology, which is applied in the field of blade-type terahertz wave broadband linear polarizers, can solve the problems of low polarization conversion rate and narrow polarization conversion band of linear polarizers, and achieve polarization conversion. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

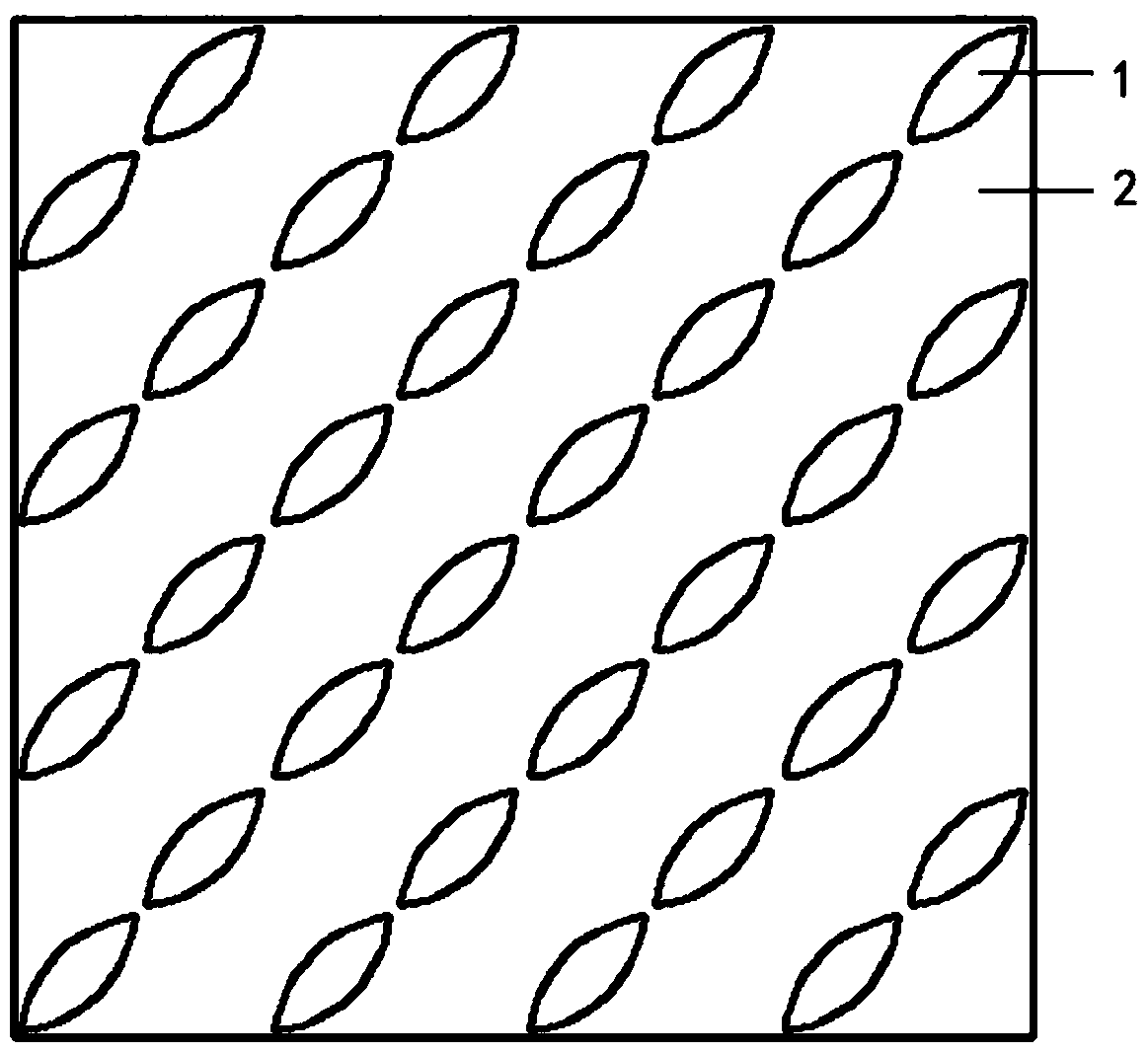

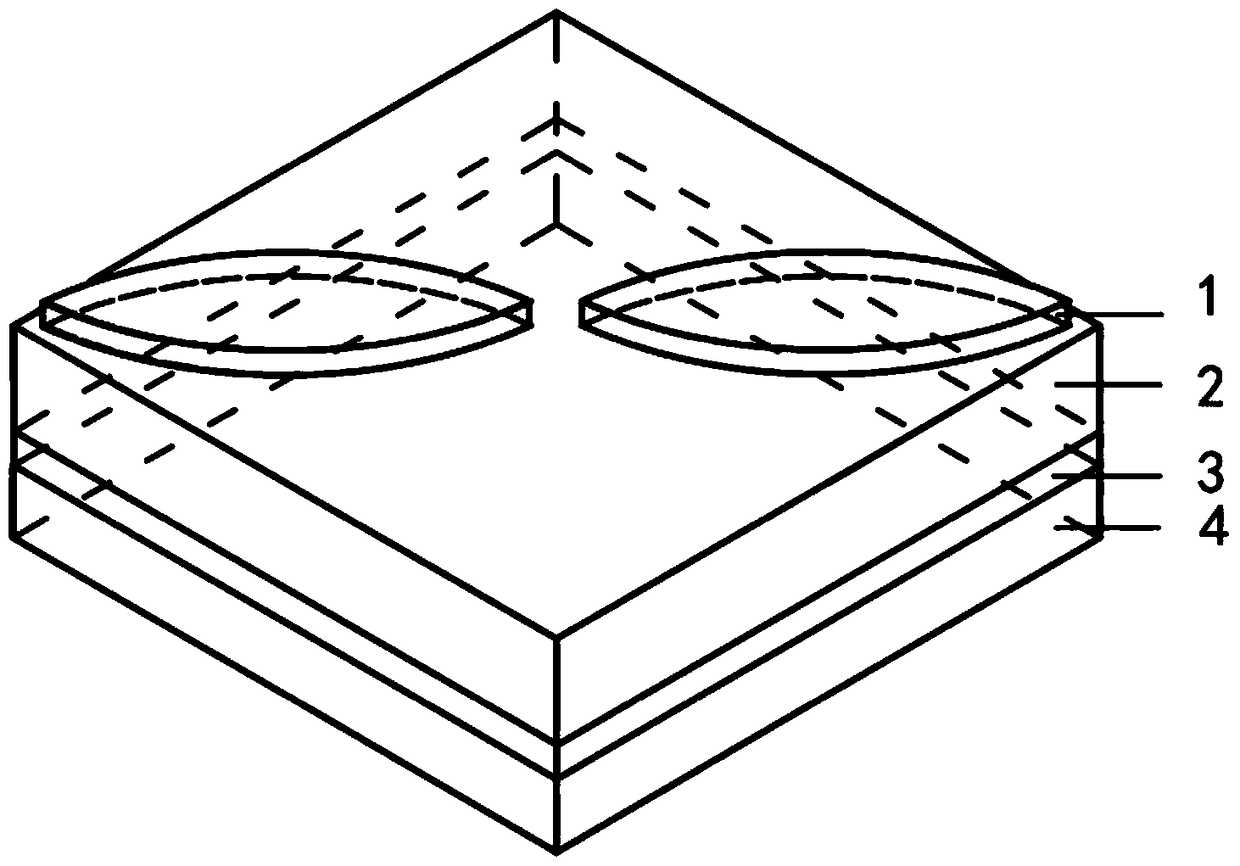

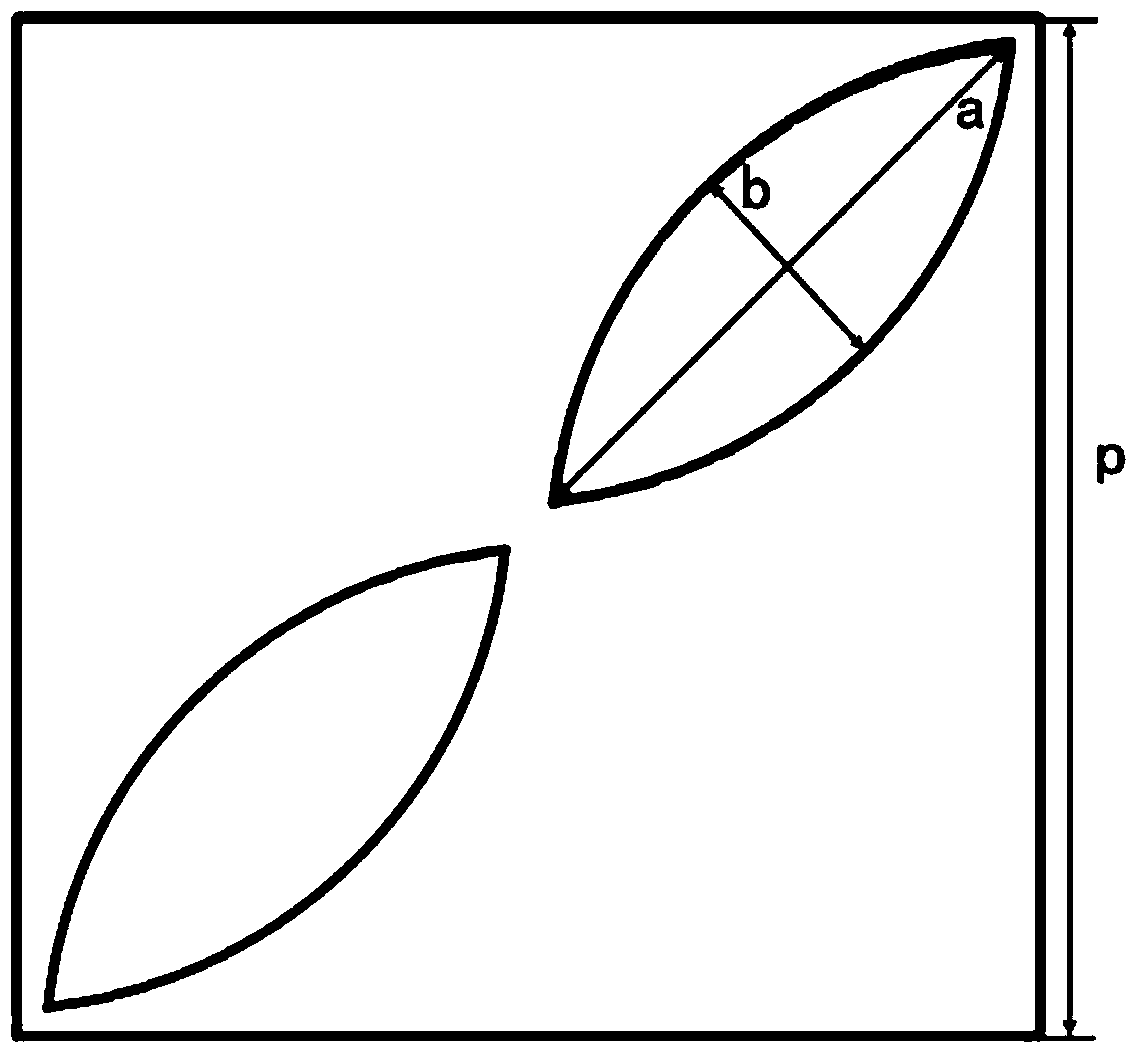

[0033] The thickness of the substrate set in this embodiment is 1 micron, the material is silicon, the metal reflective layer is 0.5 micron, the material is silver, the thickness of the dielectric layer is 48 micron, the material is PMMA, the real part of its dielectric constant is 3, and the virtual part is 3. Part is 0.03, the thickness of the upper metasurface is 0.05 microns, and the material is silver. The size of the unit structure is p=260 microns, a=165 microns, b=57 microns, and the value of k is 1 at this moment. Through numerical simulation, the copolar conversion amplitude (R ss ) and vertical polarization conversion amplitude (R ps ),Such as Figure 4 shown.

Embodiment 2

[0035] The thickness of the substrate set in this embodiment is 1000 microns, the material is silicon, the metal reflective layer is 0.5 microns, the material is silver, the thickness of the medium layer is 24 microns, the material is PMMA, the real part of its dielectric constant is 3, and the virtual part is 3. Part is 0.03, the thickness of the upper metasurface is 0.05 microns, and the material is silver. The size of the unit structure is p=130 microns, a=82.5 microns, b=28.5 microns, and the value of k at this time is 0.5. Through numerical simulation, the copolar conversion amplitude (R ss ) and vertical polarization conversion amplitude ((R ps ),Such as Figure 5 shown.

Embodiment 3

[0037] The thickness of the substrate set in this embodiment is 1 micron, the material is silicon, the metal reflective layer is 0.5 micron, the material is silver, the thickness of the dielectric layer is 4.8 micron, the material is PMMA, the real part of its dielectric constant is 3, and the virtual part is 3. Part is 0.03, the thickness of the upper metasurface is 0.05 microns, and the material is silver. The size of the unit structure is p=26 microns, a=16.5 microns, b=5.7 microns, and the value of k at this moment is 0.1. Through numerical simulation, the copolar conversion amplitude (R ss ) and vertical polarization conversion amplitude (R ps ),Such as Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com