Brush manufacturing method and brush manufactured thereby

一种制造方法、刷具的技术,应用在刷具,产业用及/或兴趣用刷具领域,能够解决电势差、金属线断裂、昂贵等问题,达到降低成本、改良机械特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

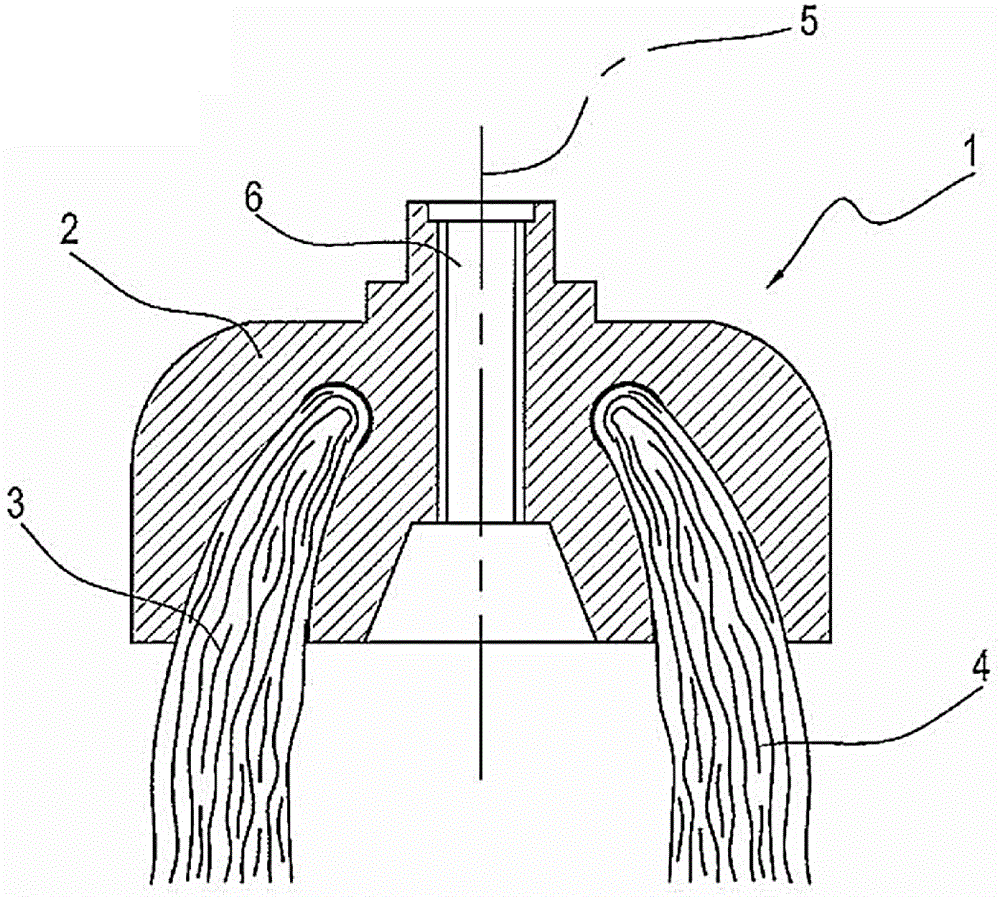

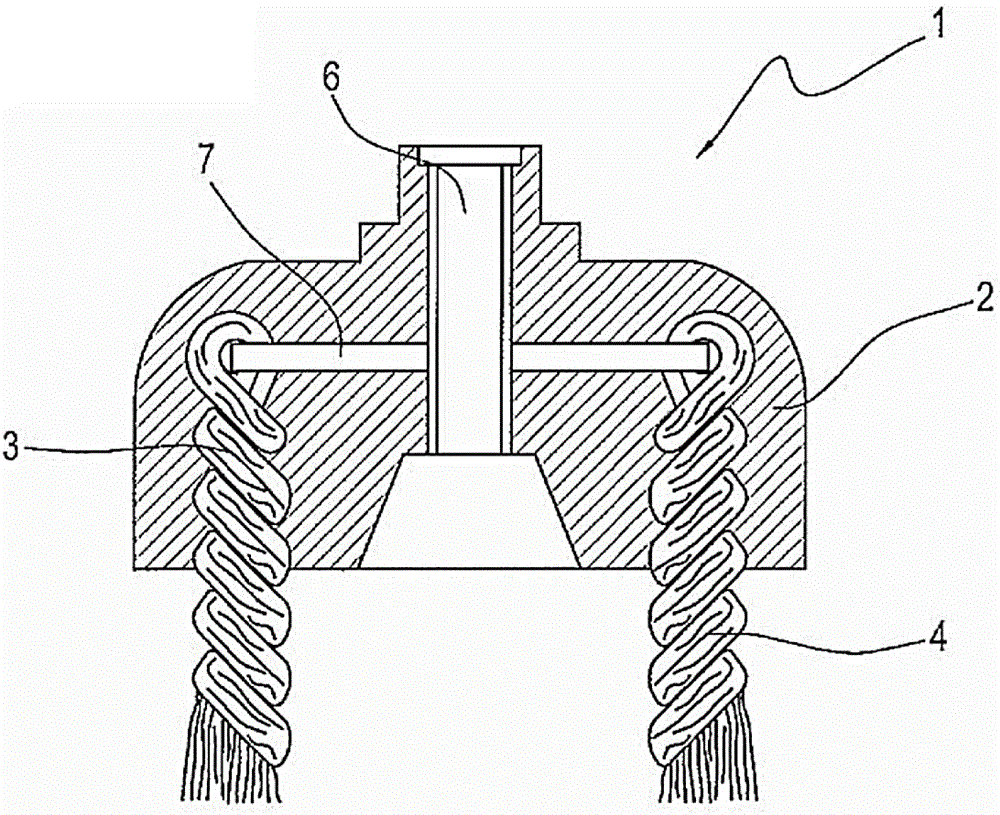

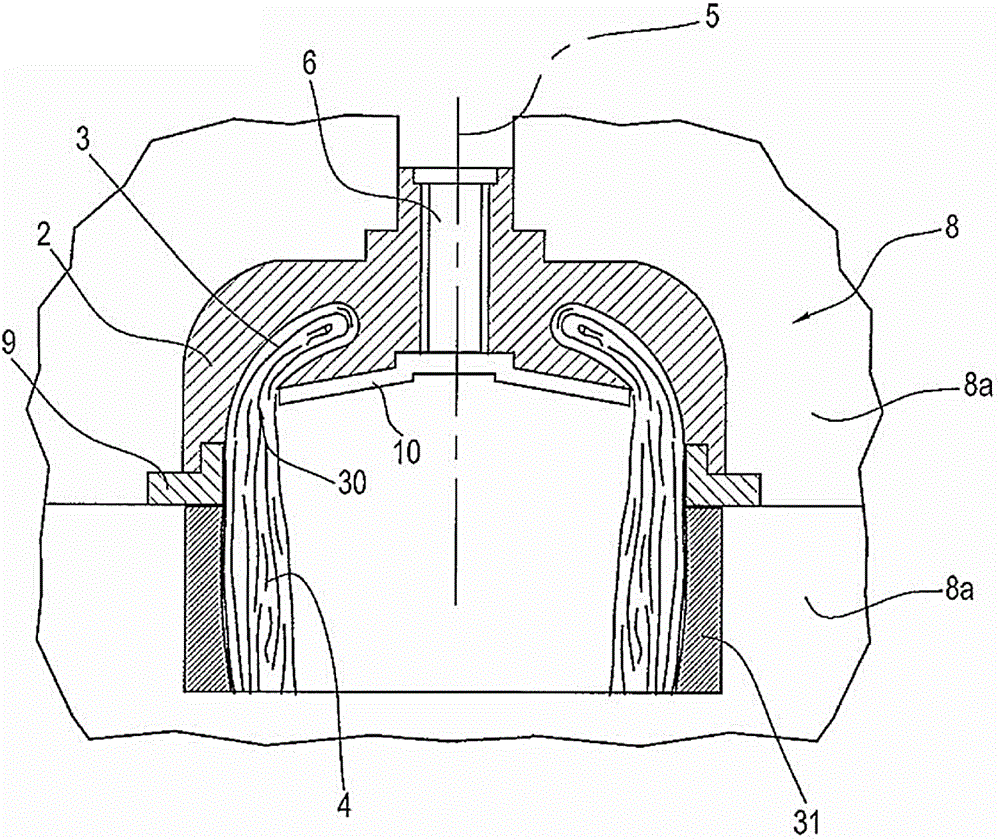

[0128] Referring to the accompanying drawings, number 1 represents the industrial brush tool of the present invention.

[0129] The brush 1 includes a brush body 2 and a plurality of metal wires.

[0130] The wire has a first wire part 3 embedded in the metal brush body 2 and a second wire part 4 for performing a brushing action when said brush 1 (ie brush body 2) rotates on its rotating shaft 5 .

[0131] Initially, the brush body 2 is made of molten metal in which the first wire part 3 of the metal wire is embedded; the bonding metal merges the first wire part 3 so that it is in contact with the brush body 2 firmly combined into a whole.

[0132] The manufacturing method of the above-mentioned brush 1 includes a step of preparing a plurality of metal wires, which are placed in at least one bundle, and the wire bundle has a predetermined width and thus occupies a predetermined space.

[0133] The wire is placed in the cavity of the mold, which has a predetermined geometry, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com