Adjustable pull rod of core bar support frame

A mandrel support and tie rod technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve problems such as inability to support and guide the mandrel, non-adjustable tie rods, poor neutrality of the three support rollers, etc., to meet the needs of the site Use requirements, precise centering, and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] For better understanding and implementation, specific embodiments are given below in conjunction with the accompanying drawings to describe the present invention in detail; the illustrated embodiments are only used to explain the present invention, and are not intended to limit the protection scope of the present invention.

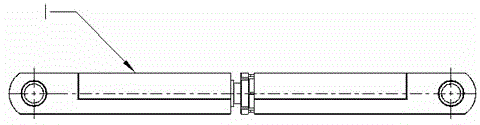

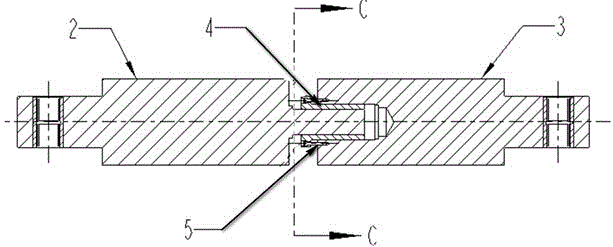

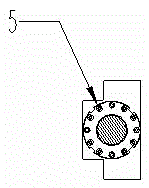

[0011] Example: see figure 1 , 2 , 3, 4, according to the design needs, the first tie rod 2, the second tie rod 3, the adjusting nut 4 and the fixing bolt 5 are processed; The protruding external thread, the external thread part is cylindrical, and the end is cylindrical; the second pull rod 3 is also an integral structure, one end is a pin hole with a bushing, and the center of the other end is an internal thread; the adjusting nut 4 is Internal and external thread structure, the inner thread is M72X4, the outer thread is M100X6, it is connected with the external thread of the first draw rod 2 through the internal thread, and is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com