Adjustable repetition frequency femtosecond solid-state laser and adjusting method

A solid-state laser, repetition rate technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of relatively high machining accuracy, complex resonator design, and resonator detuning, and achieve precise control of repetition. The effect of frequency variation, low machining accuracy requirements, and reduced adjustment difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

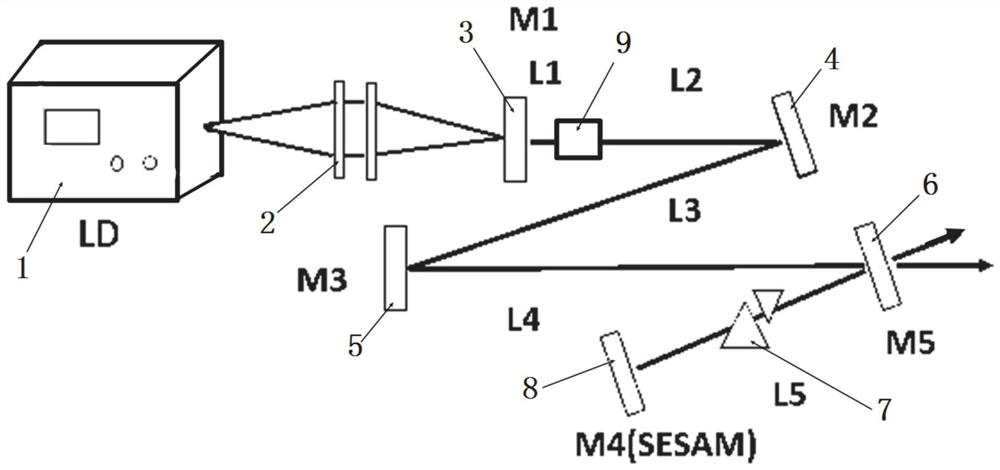

[0030] In a typical implementation of the present disclosure, such as Figure 1-Figure 2 As shown, a femtosecond solid-state laser with tunable repetition rate is proposed.

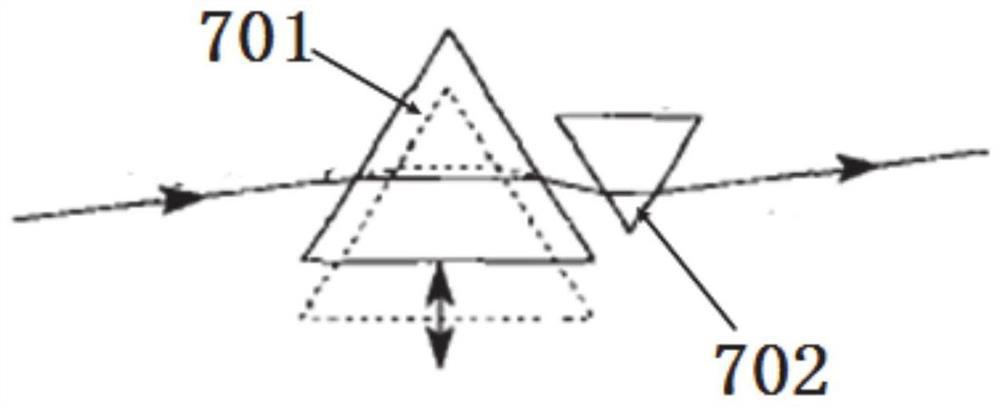

[0031] It mainly includes a light source module, a mirror group, an output mirror and a semiconductor saturable absorption mirror. A W-shaped resonant cavity is formed inside the laser. In order to solve the traditional method of mechanical or piezoelectric ceramic moving cavity mirror proposed in the background technology to fine-tune the resonant cavity The length of the resonator does not meet the requirements. By inserting a cavity length precision compensator composed of a pair of isosceles prisms in the optical path of the resonator, the optical path of the resonator is changed, thereby controlling the change of the repetition rate of the all-solid-state femtosecond laser.

[0032] Specifically, a light source module, a mirror group, an output mirror, and a semiconductor saturable absorber mirror ar...

Embodiment 2

[0057] In another typical implementation of the present disclosure, such as Figure 1-Figure 2 As shown, a method for adjusting the repetition rate of a femtosecond solid-state laser is proposed.

[0058] Utilize the adjustable repetition rate femtosecond solid-state laser as described in embodiment 1, comprise the following steps:

[0059] The mirror group acquires the laser light output by the light source module and reflects it to the output mirror;

[0060] The output mirror reflects the laser light and outputs it to the semiconductor saturable absorbing mirror through the compensator;

[0061] The semiconductor saturable absorbing mirror reflects the laser light and passes through the compensator, and transmits the output laser light through the output mirror;

[0062] The two triangular prisms are equilateral triangular prisms with different side lengths. Fix the triangular prism with the smaller side length and adjust the position of the other triangular prism. By adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com