Pneumatic tire

A technology for pneumatic tires and treads, which is applied to the reinforcement layers, tire parts, and treads of pneumatic tires, can solve the problems of affecting the rolling resistance of tires, affecting the quality of tires, and damaging the fuel consumption performance of vehicles, so as to improve the in-plane torsion. Rigidity, maintaining handling stability, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

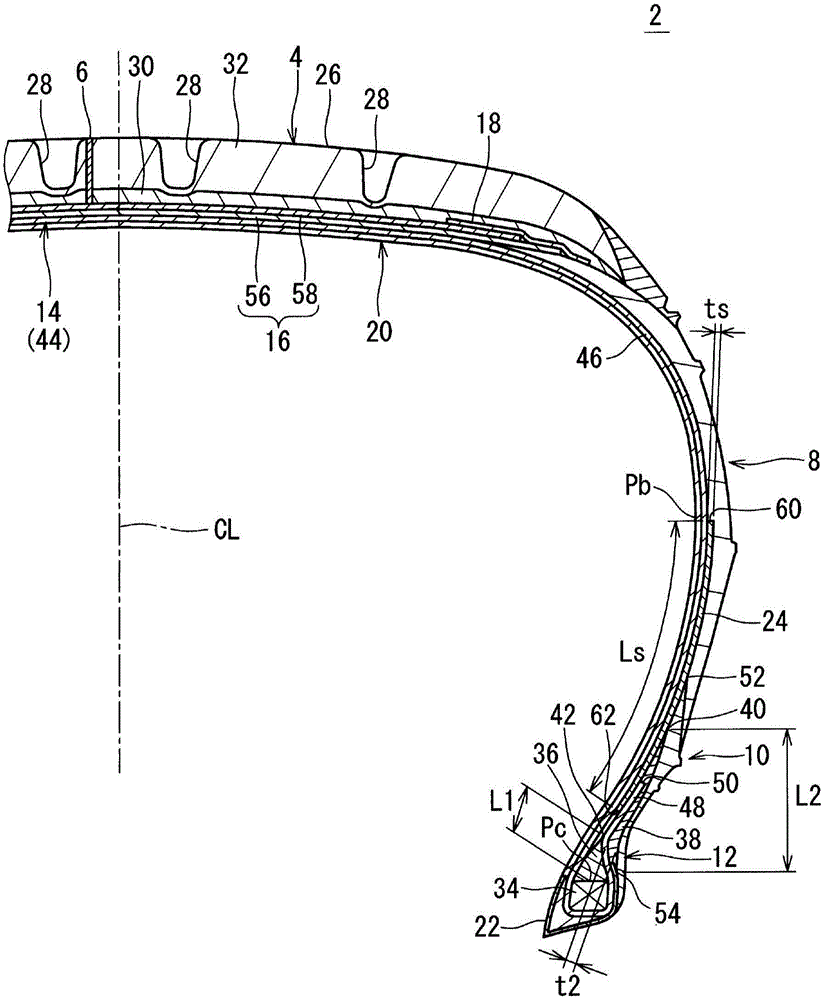

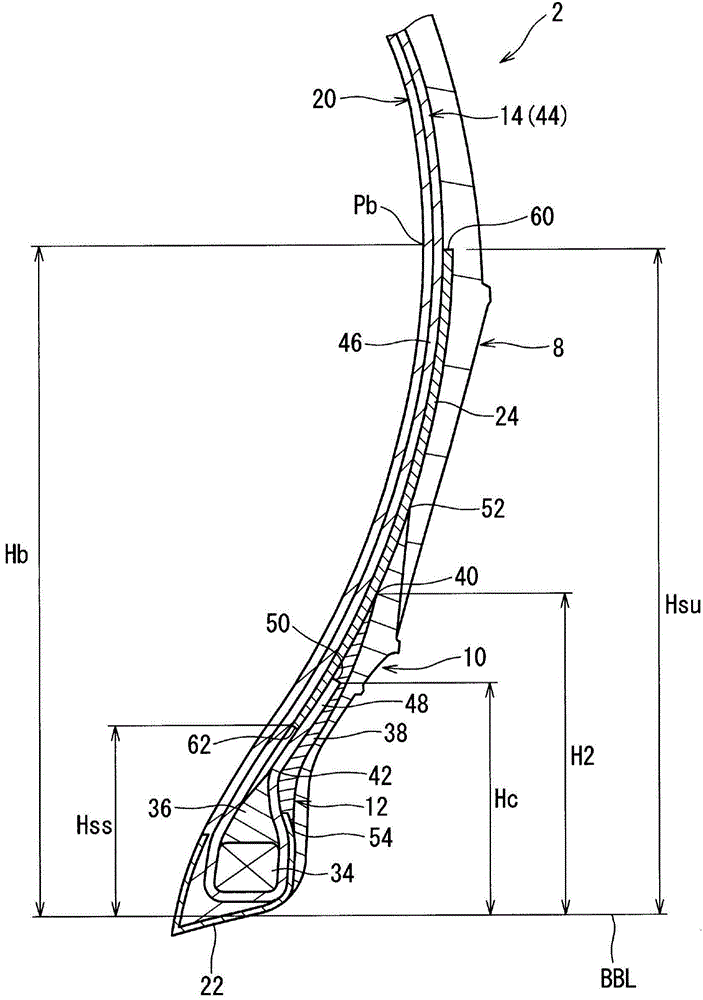

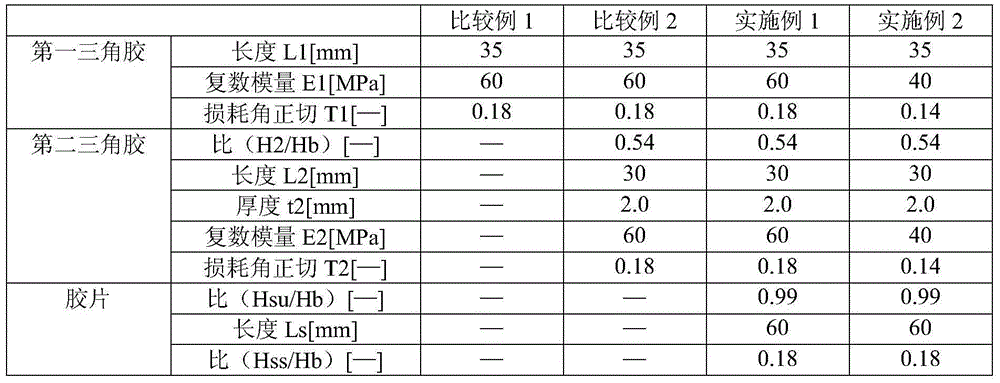

[0108] obtained with figure 1 The pneumatic tire of Example 1 having the basic structure shown and the specifications shown in Table 1 below. The size of this tire is 195 / 65R15. The first apex, the second apex and the film are formed by crosslinking the same rubber components. Therefore, the complex modulus E1 of the first apex, the complex modulus E2 of the second apex and the complex modulus Es of the film are the same. The loss tangent T1 of the first apex, the loss tangent T2 of the second apex and the loss tangent Ts of the film are the same.

Embodiment 2

[0114] Except changing the rubber composition used for the first apex, the second apex and the film and making the complex modulus E1, the complex modulus E2 and the complex modulus Es and the loss tangent T1, the loss tangent T2 and the loss tangent Ts as follows Except as described in Table 1 above, the tires of Example 2 were obtained in the same manner as in Example 1.

Embodiment 3-7

[0116] Tires of Examples 3-7 were obtained in the same manner as in Example 1 except that the length L1 of the first apex was as shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Complex modulus | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com