Open-end rotor spinning device and method of operating an open-end rotor spinning device

A rotor spinning and free end technology, which is applied in the directions of free end spinning machines, spinning machines, measuring devices, etc., can solve problems such as damage to the spinning rotor bearing device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

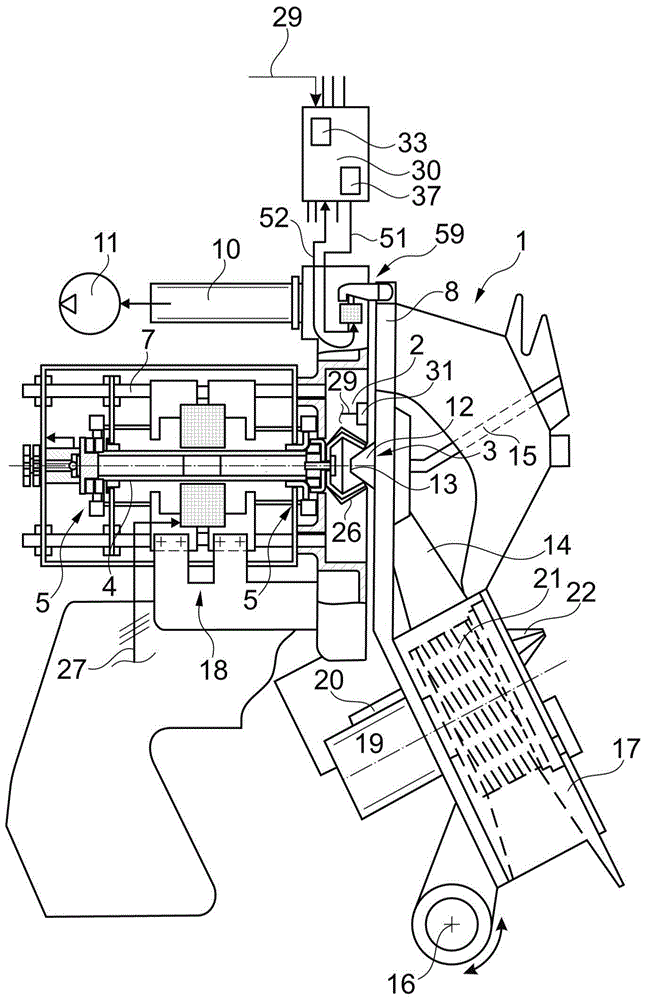

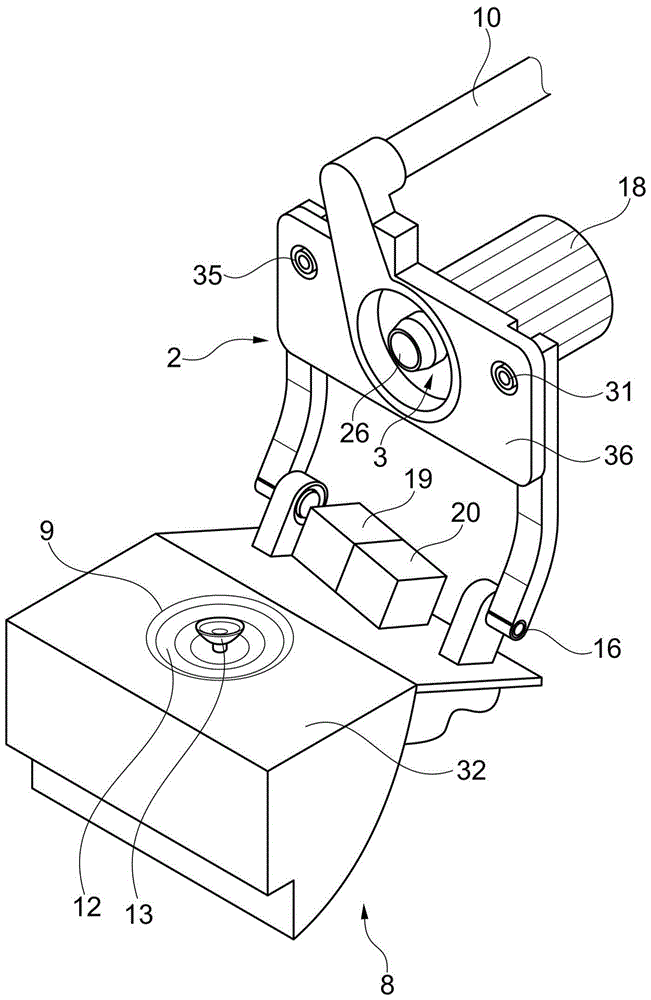

[0031] figure 1 The shown open-end rotor spinning device generally bears the reference numeral 1 and, as usual, has a rotor housing 2 in which a rotor body 26 of a spinning rotor 3 rotates at high rotational speeds.

[0032] The spinning rotor 3 is now driven by an electric motor independent drive, preferably a DC motor 18 , and is mounted with its rotor shaft 4 in the magnetic bearing arrangement 5 . The DC motor 18 is supplied with electrical energy via a line 27 .

[0033] As is known, the rotor housing 2 itself, which is open to the front, is closed during the spinning operation by means of a rotatably mounted cover 8 and is connected to a vacuum source 11 via a corresponding suction line 10, the vacuum The source generates the spinning vacuum required in the rotor housing 2 for yarn production. As can be seen, a channel plate connection 12 is provided in the recess of the cover part 8 , which has a thread delivery nozzle 13 and an opening region of a fiber guide channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com