Bellows compensator

A technology of bellows and compensators, which is applied in the direction of expansion compensation devices, pipe components, pipes/pipe joints/fittings, etc. for pipelines, which can solve the deformation of bellows, the adverse effects of connected equipment or Stability and other issues to achieve the effect of avoiding deformation and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

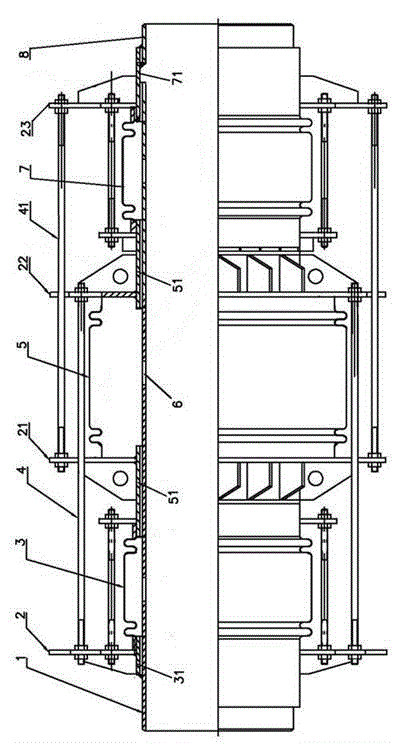

[0009] The specific embodiments of the present invention will now be described with reference to the accompanying drawings.

[0010] The bellows compensator includes a balance bellows 5, and a first bellows 3 and a second bellows 7 are respectively welded at both ends of the balance bellows through a middle joint 51. The diameter of the first bellows is the same as the diameter of the second bellows. The pipe diameters are equal, and the pipe diameter of the balance bellows is larger than that of the first bellows. The left end of the first corrugated pipe is welded with a left joint 31, one end of the left joint is welded with a first pipe 1, the right end of the second corrugated pipe is welded with a right joint 71, and one end of the right joint is welded with a second pipe 8, the first pipe and the second pipe It is used to connect with the pipeline. When the pipeline expands or contracts linearly, the gap between the facing end faces of the first connecting pipe 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com