Bearing holder

A bearing seat, bearing technology, applied in the direction of bearing components, shafts and bearings, rigid brackets of bearing components, etc., can solve the problems of inconvenient movement and temporary use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

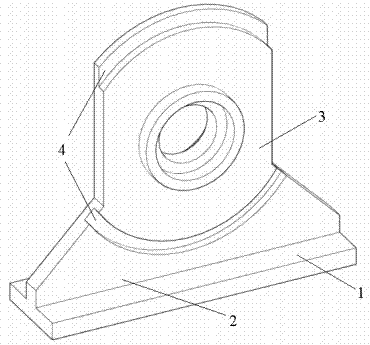

[0008] Below in conjunction with accompanying drawing, the present invention will be further described:

[0009] As shown in Figure 1, a bearing seat includes a base plate 1, a connecting plate 2 and a mounting plate 3, the base plate 1 is generally rectangular, the base plate 1 has a connecting plate 2, the connecting plate 2 is generally trapezoidal, There is a mounting plate 3 on the connecting plate 2, the lower end of the mounting plate 3 is connected with the connecting plate 2, and the left and right sides form an upwardly protruding arc with the vertical upper end of the substrate 1, and the center position of the mounting plate 3 has a bearing mounting hole. The mounting plate 3 and the connecting plate 2 form a plate-shaped whole, and there is an arc-shaped groove 4 below the bearing mounting hole on the plate-shaped whole. The arc-shaped groove 4 is concentric with the bearing mounting hole and has a rectangular cross section. .

[0010] The length of the lower bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com