Patents

Literature

50results about How to "Arbitrary arrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

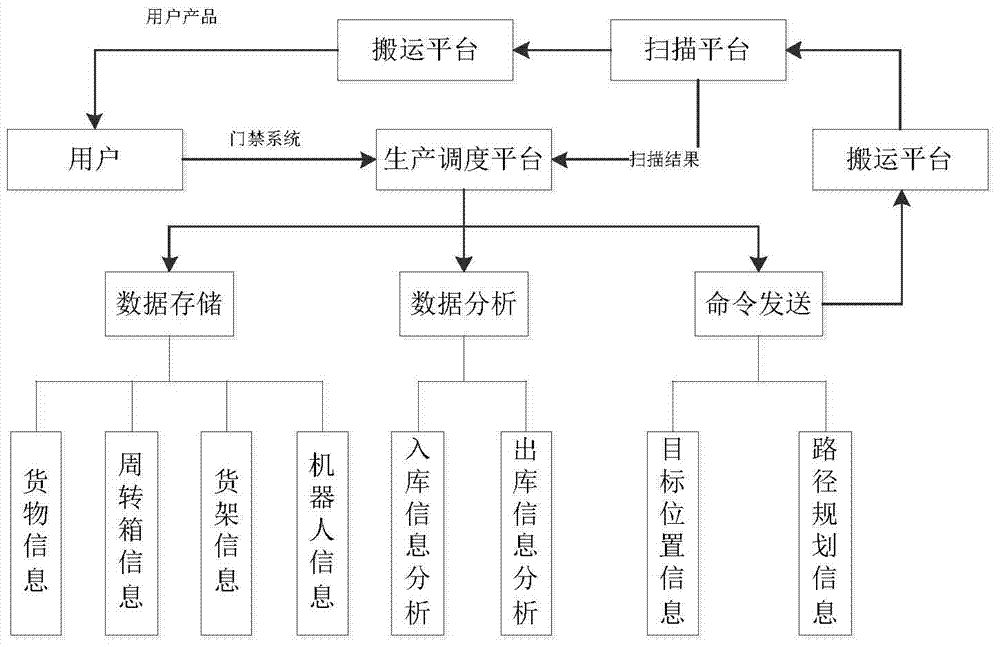

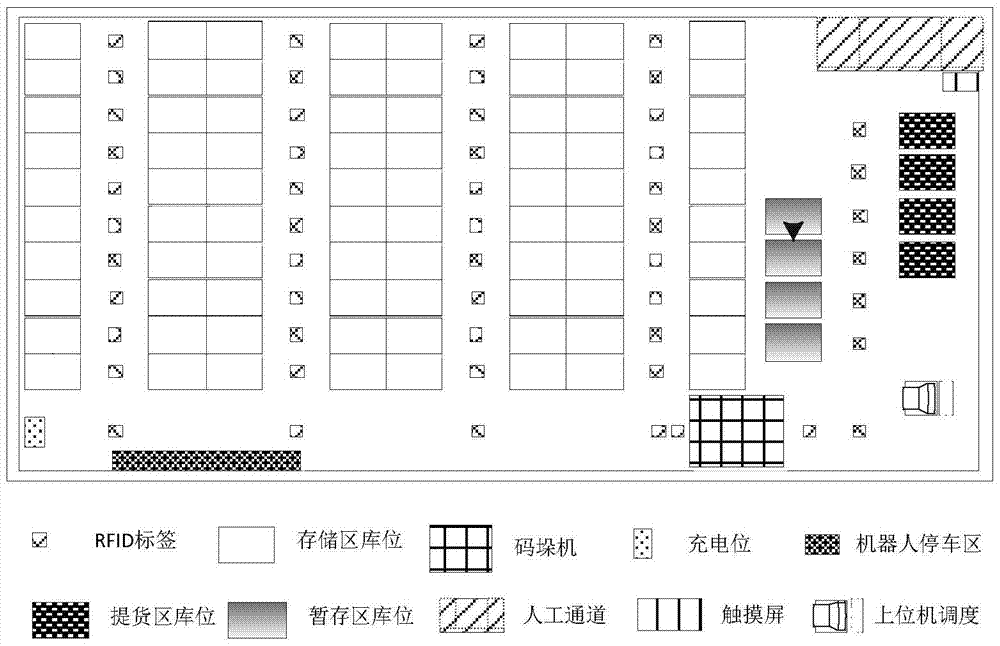

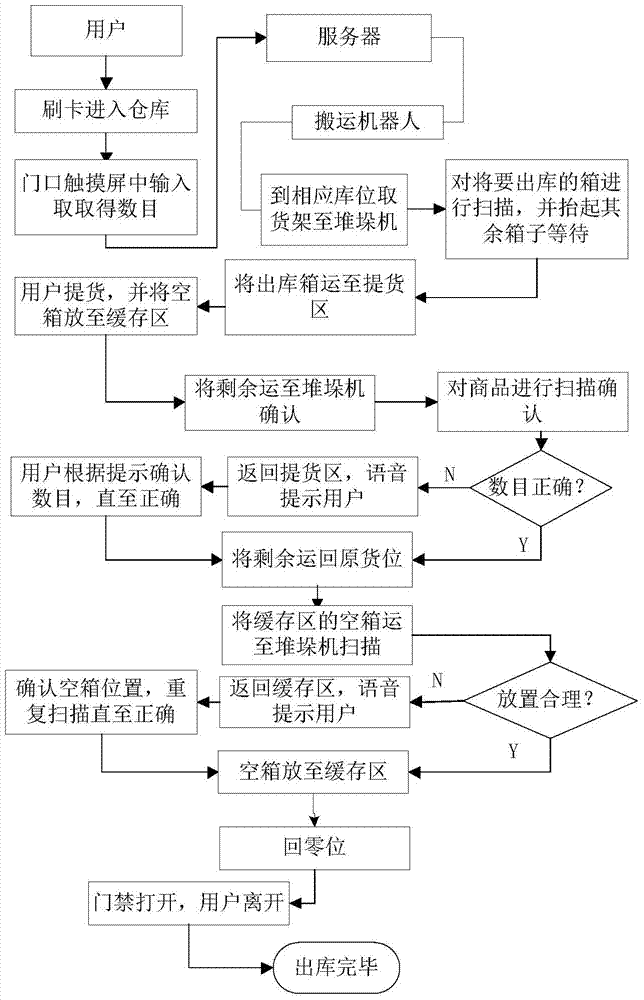

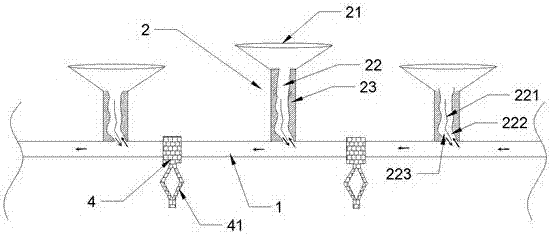

Intelligent flexible automation warehousing system and method

InactiveCN104460628AArbitrary arrangementWith flexible settingsTotal factory controlProgramme total factory controlControl systemTouchscreen

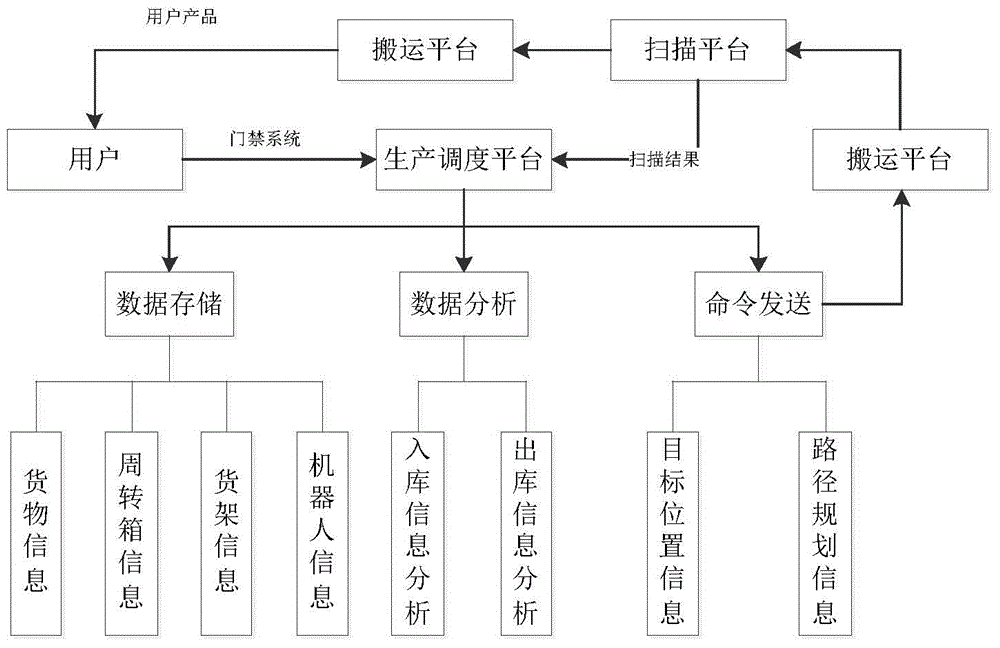

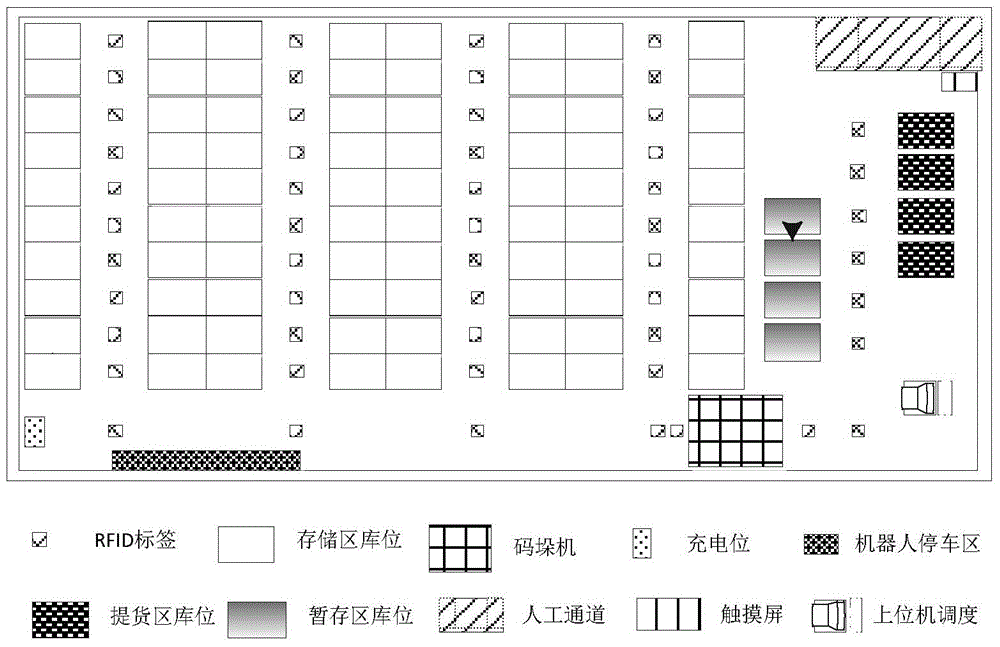

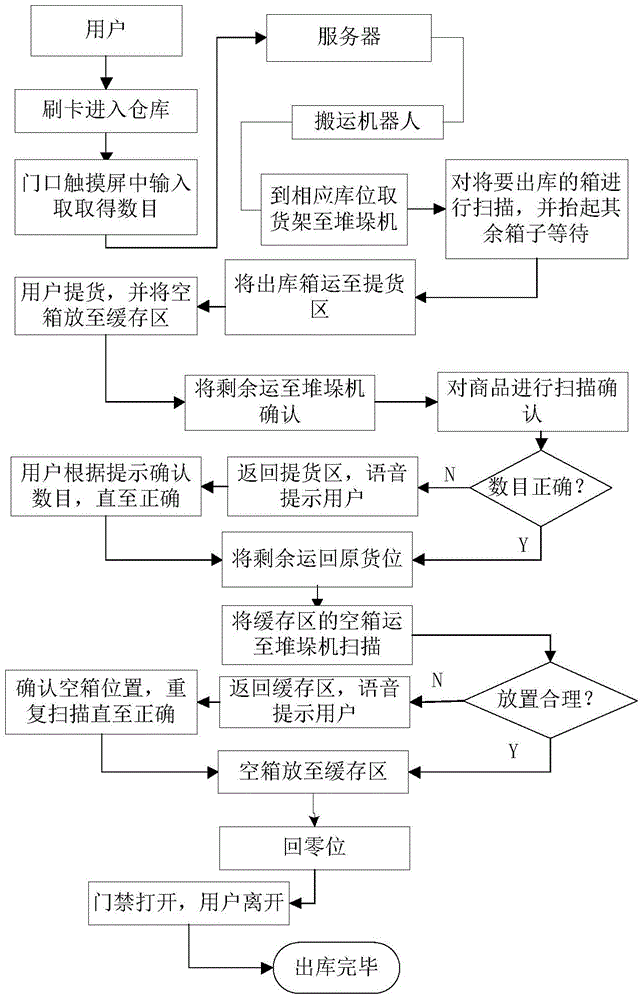

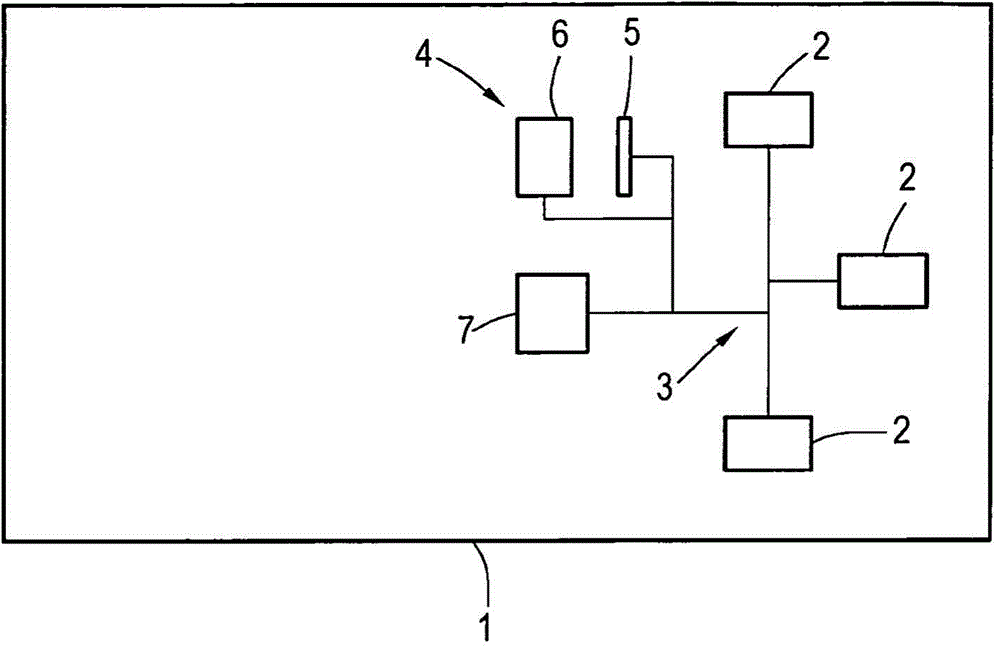

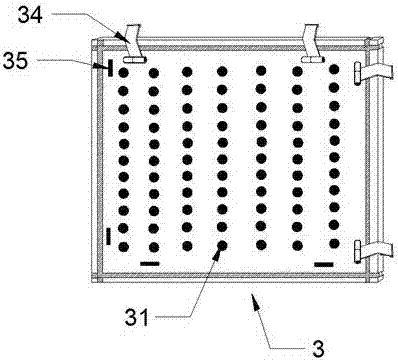

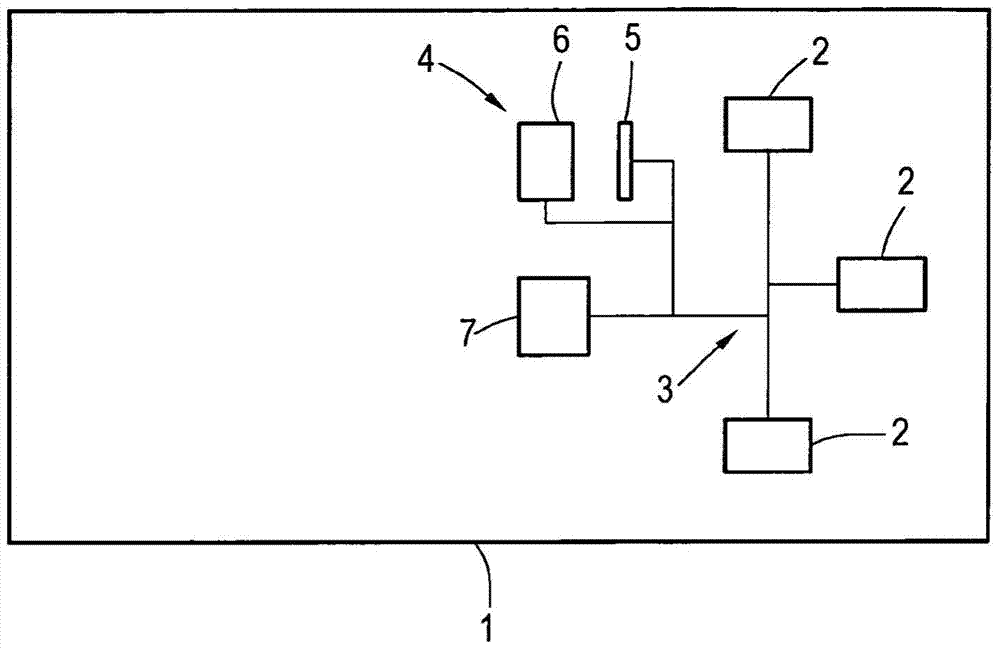

The invention discloses an intelligent flexible automation warehousing system and method. The intelligent flexible automation warehousing system comprises an automation door control system, an automatic carrying system, an automatic scanning system and a production scheduling system. The automation door control system is used for managing opening and closing of a warehouse door, is provided with a touch screen by which types and numbers of required commodities are input, and is connected with the production scheduling system; the production scheduling system receives commodity warehouse-in information and commodity warehouse-out information, stores warehouse information and sends positioning and navigation information to the automatic carrying system. The automatic carrying system comprises a plurality of carrying robots, and each carrying robot is provided with a positioning and navigation system. Data are read and uploaded through the scanning system in real time to a production scheduling platform system of a PC background server and guided into a system of a database through the production scheduling platform system, the database is updated in real time, warehouse management users can carry out real-time accessing and real-time management through remote client terminals, and running of the system is monitored.

Owner:HARBIN ZHONGDE HECHUANG INTELLIGENT EQUIP

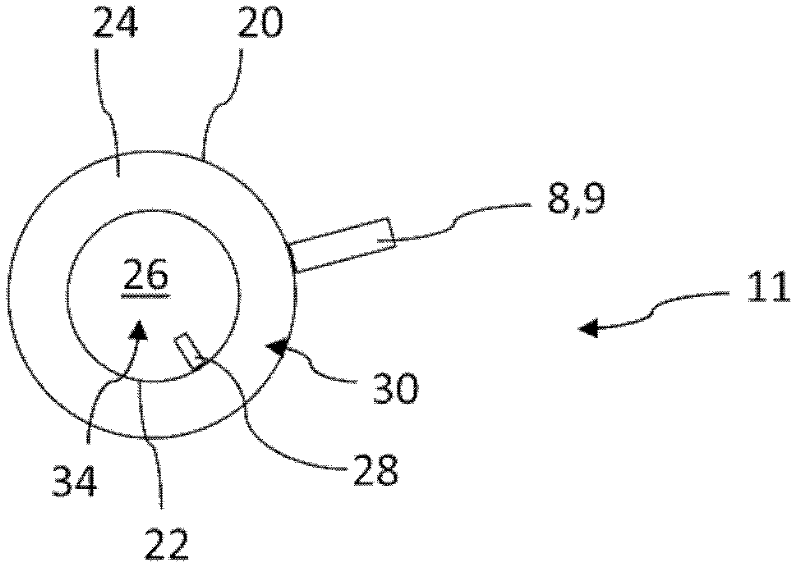

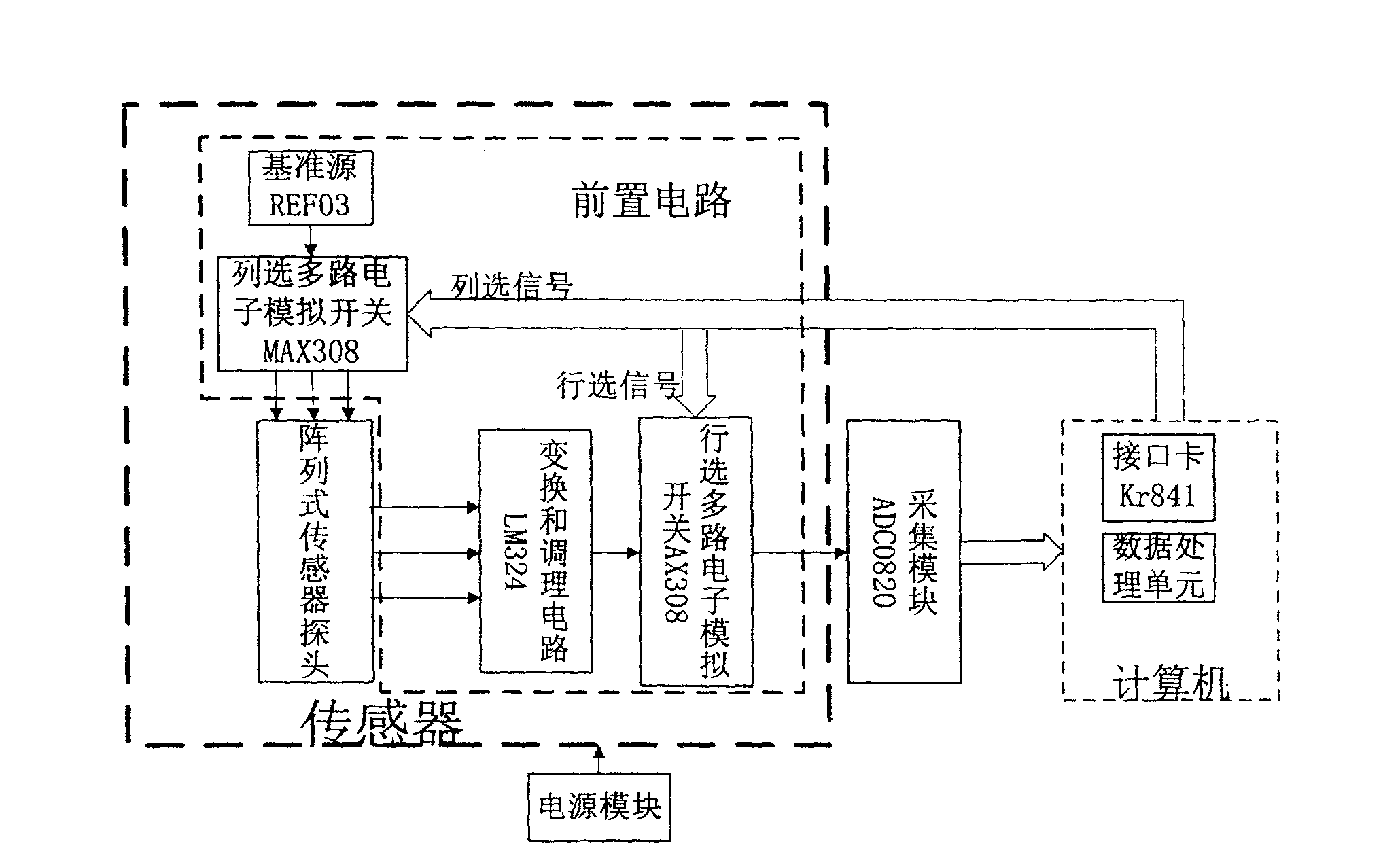

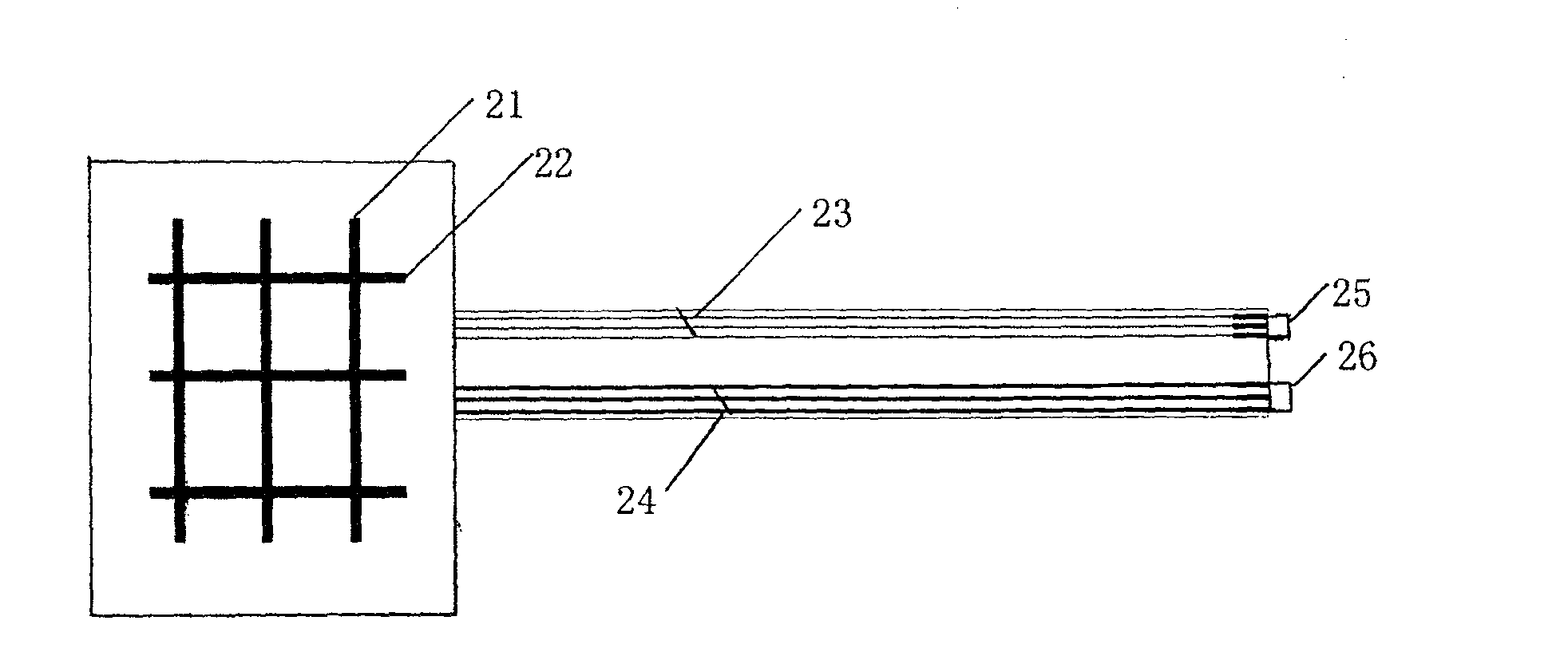

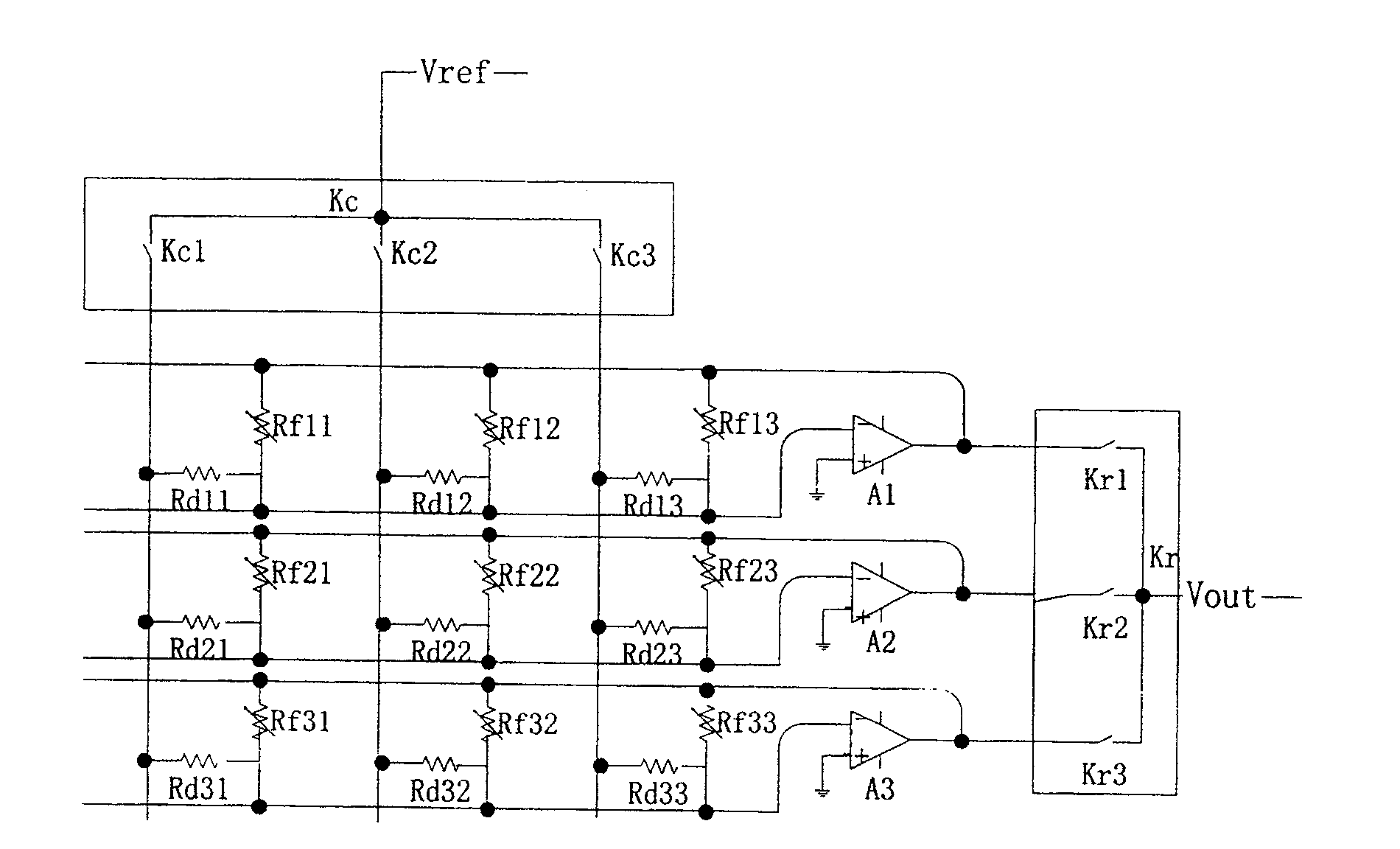

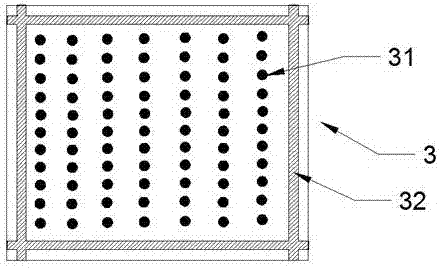

System for monitoring curved surface interlaminar extrusion pressure based on array type ultra-thin submissive force sensor

InactiveCN101201278AImprove flexibilityImprove temperature stabilityForce measurement using piezo-resistive materialsDiagnostic recording/measuringSurface layerComputer module

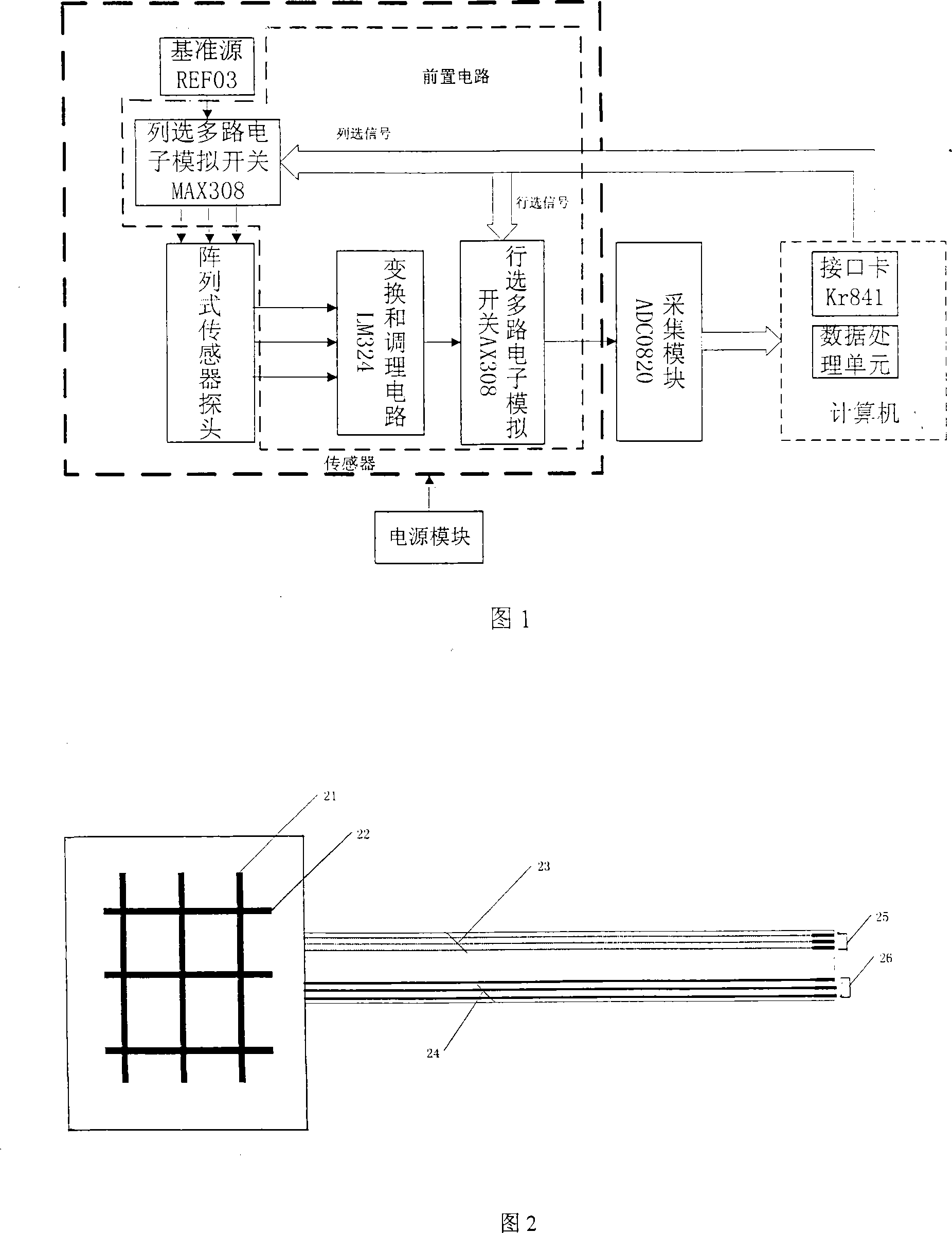

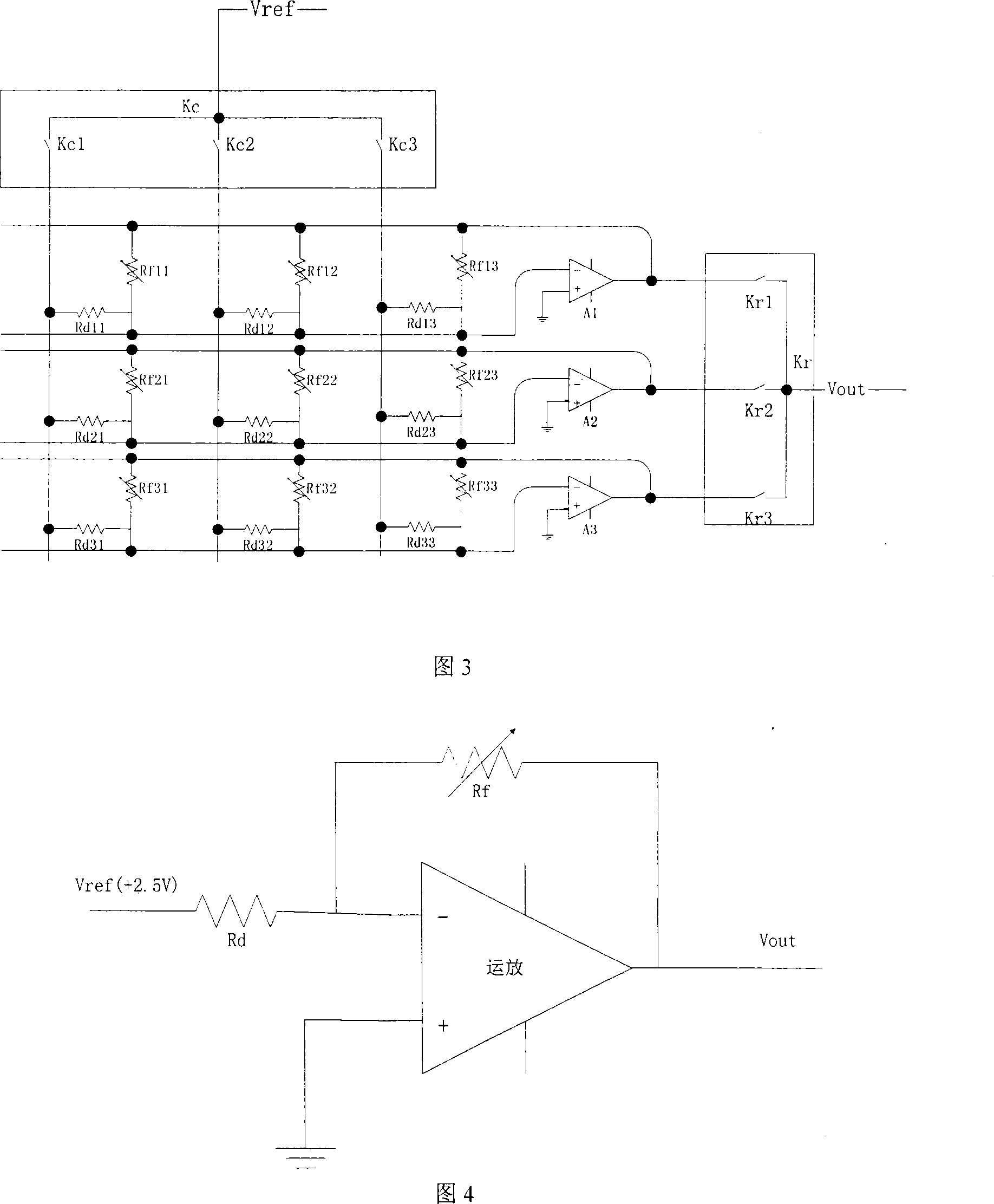

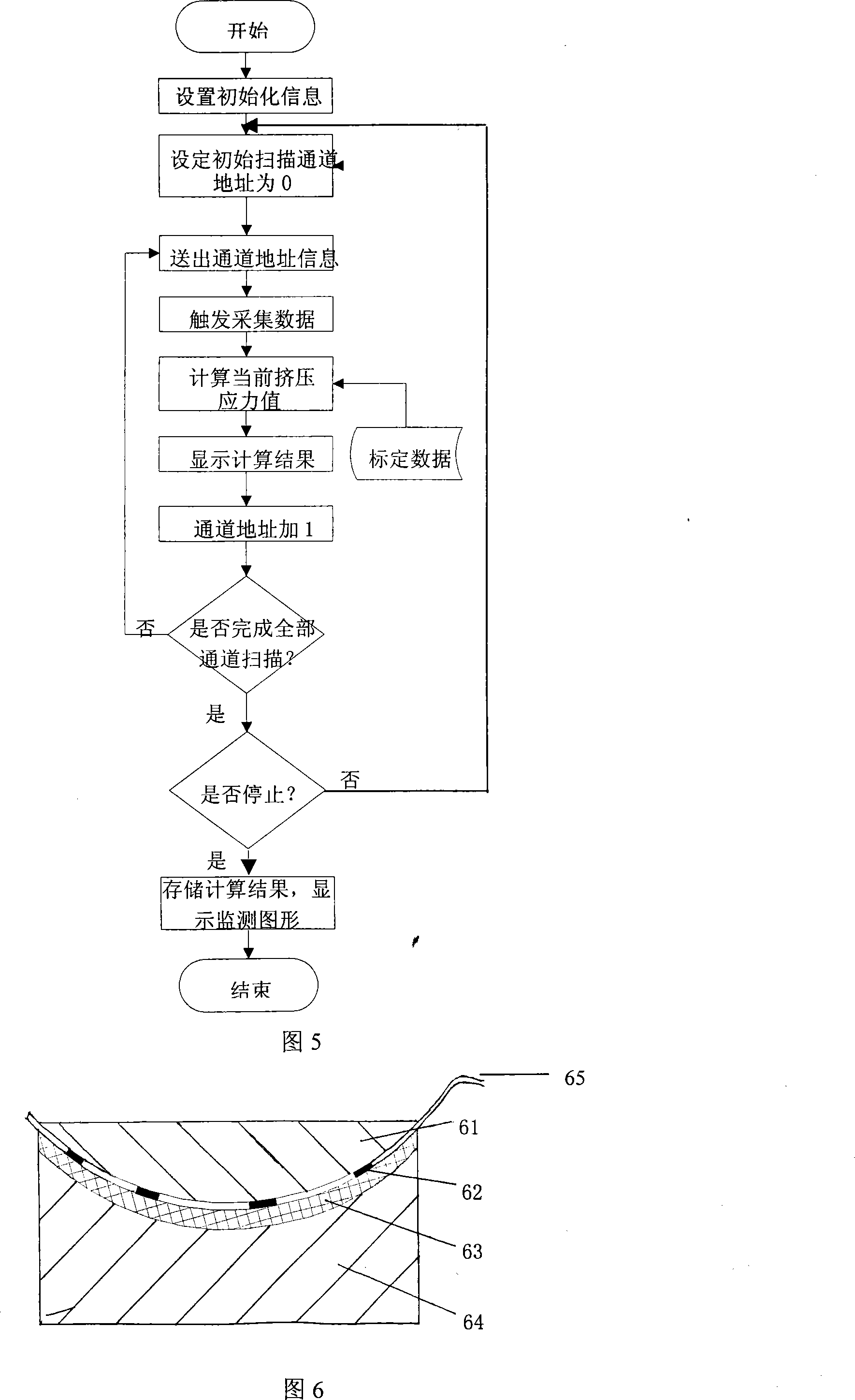

The invention relates to an inter-curved surface layer extrusion pressure monitoring system based on an array-type ultrathin compliant force sensor, and belongs to the technical field of precise measurement. The system comprises an array-type sensor consisting of an array-type ultrathin compliant force sensing probe and a front end circuit; a reference source; a collection module; a computer comprising an interface card and a data processing unit; and a power supply module. The power supply module is connected with the sensor and the collection module. The reference source is connected with the array-type sensing probe through line multi-route electronic simulation switches. The front end circuit is connected between the array-type sensing probe and the collection module. The interface card is connected with the row and line multi-route electronic simulation switches, respectively. The invention has the characteristics of simple structure, high antijamming capability, high accuracy of measurement, and capability of on-line monitoring of data processing in real time. The invention can monitor the extrusion pressure between face layers on line in real time.

Owner:TSINGHUA UNIV

Blade-free fan component

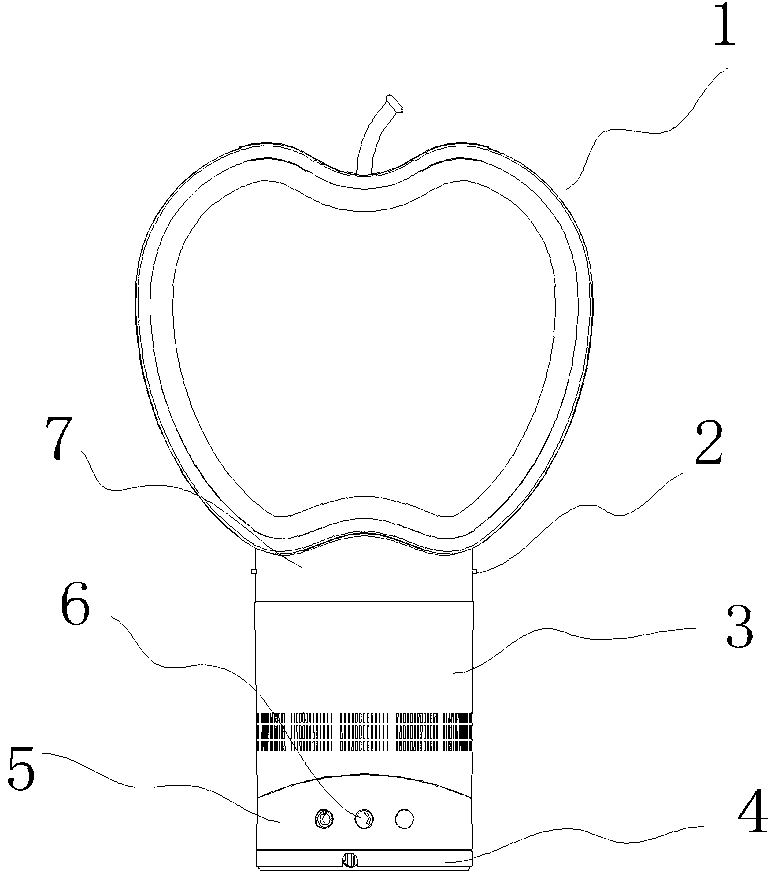

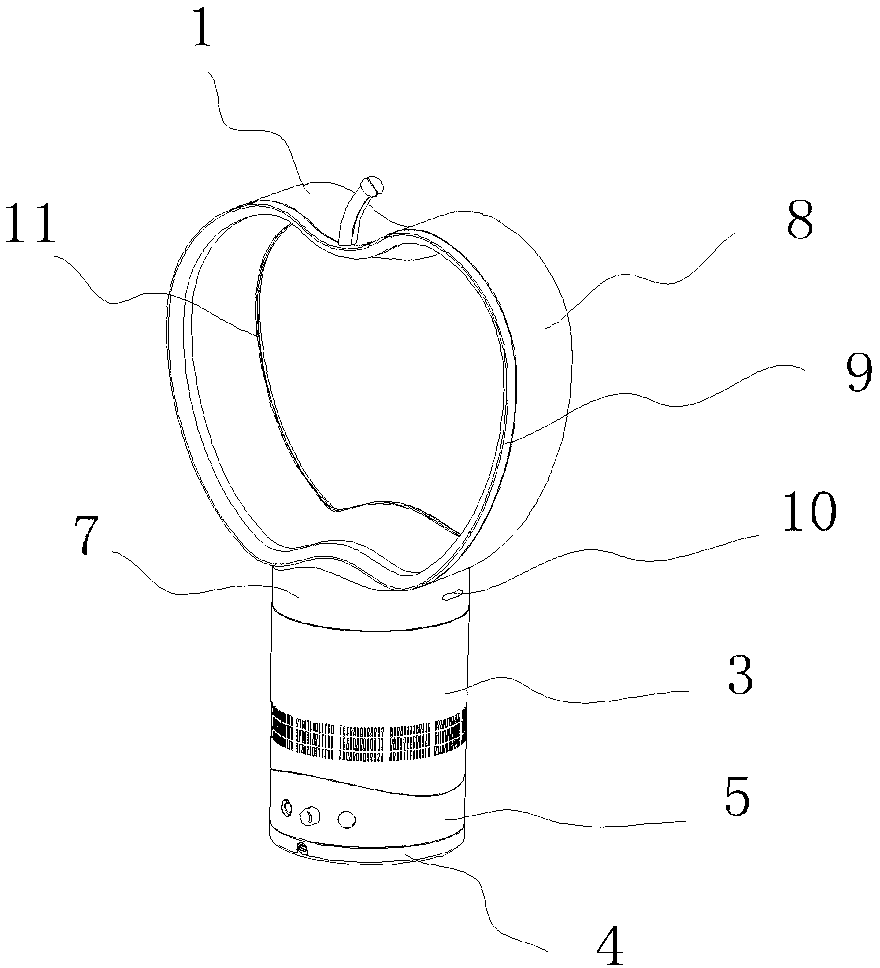

InactiveCN102840161AQuick assembly and disassemblyArbitrary arrangementPump componentsPumpsInternal pressureEngineering

The invention relates to a fan component, in particular to a wind ring of a blade-free fan and a connecting component connected to a mainframe at the lower part. A blade-free fan component comprises a mainframe and a wind ring arranged on the mainframe, wherein the mainframe comprises a machine shell, and a motor rotating component is arranged in the machine shell; the wind ring comprises a wind ring connecting part, and the wind ring connecting part is connected to a wind ring main body; an air outlet is arranged on the wind ring main body; a direct-insert clamping structure is arranged on an annular side face where the wind ring connecting part is connected with the upper opening of the machine shell; the buckling place of the clamping structure is provided with a sealing element. The invention provides a blade-free fan component; the blade-free fan component is simple in structure, convenient to dismount and transport and can effectively prevent the air flow from leaking and ensure that the pressure consumption figure of the air flow in the mainframe and the wind ring is as low as possible, thereby solving the technical problems existed in the prior art of inconvenient transport of the blade-free fan for the integrally shape basically, complex dismountable fan structure and poor sealing effect.

Owner:FOSHAN AARON APPLIANCE CO LTD

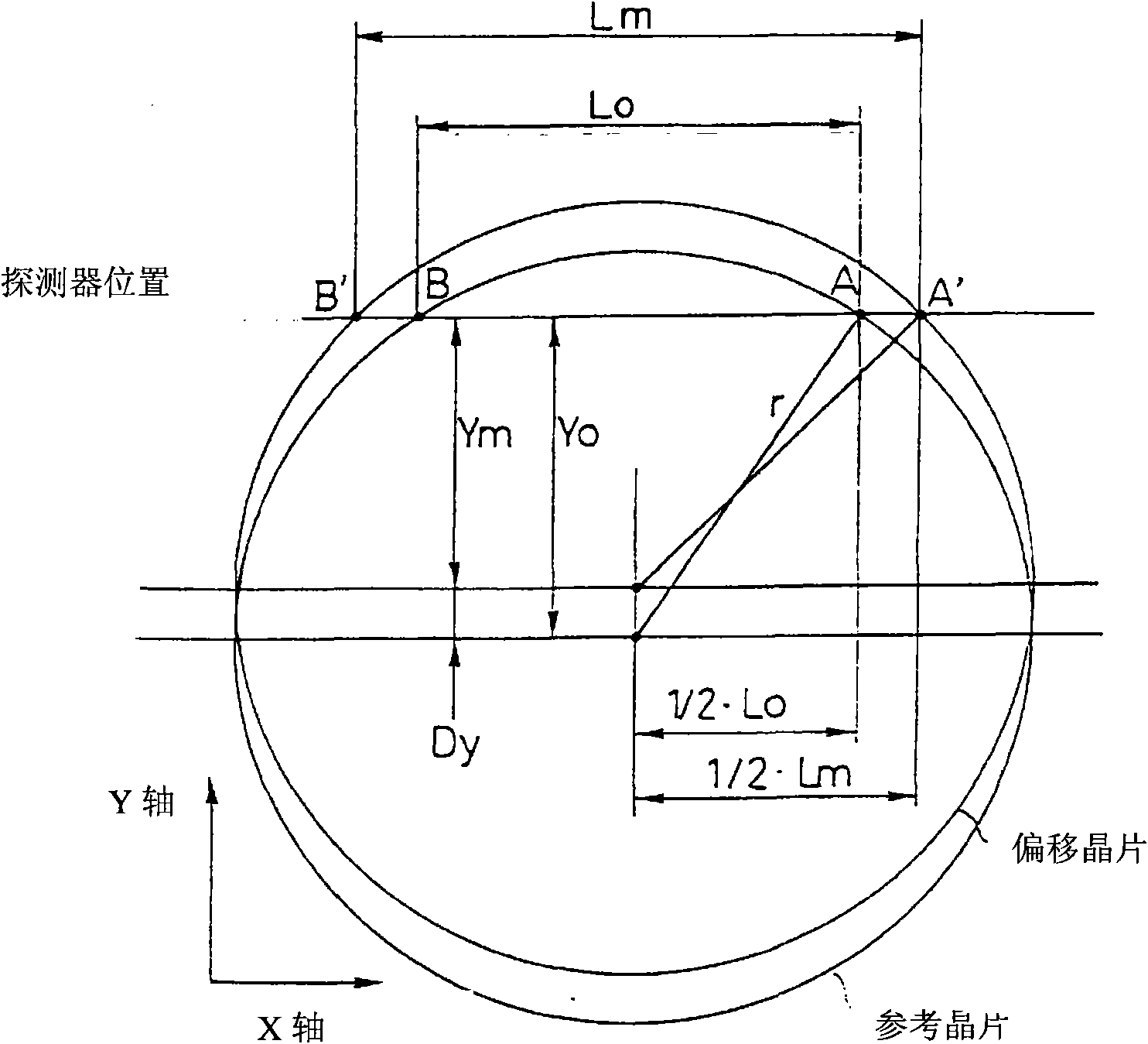

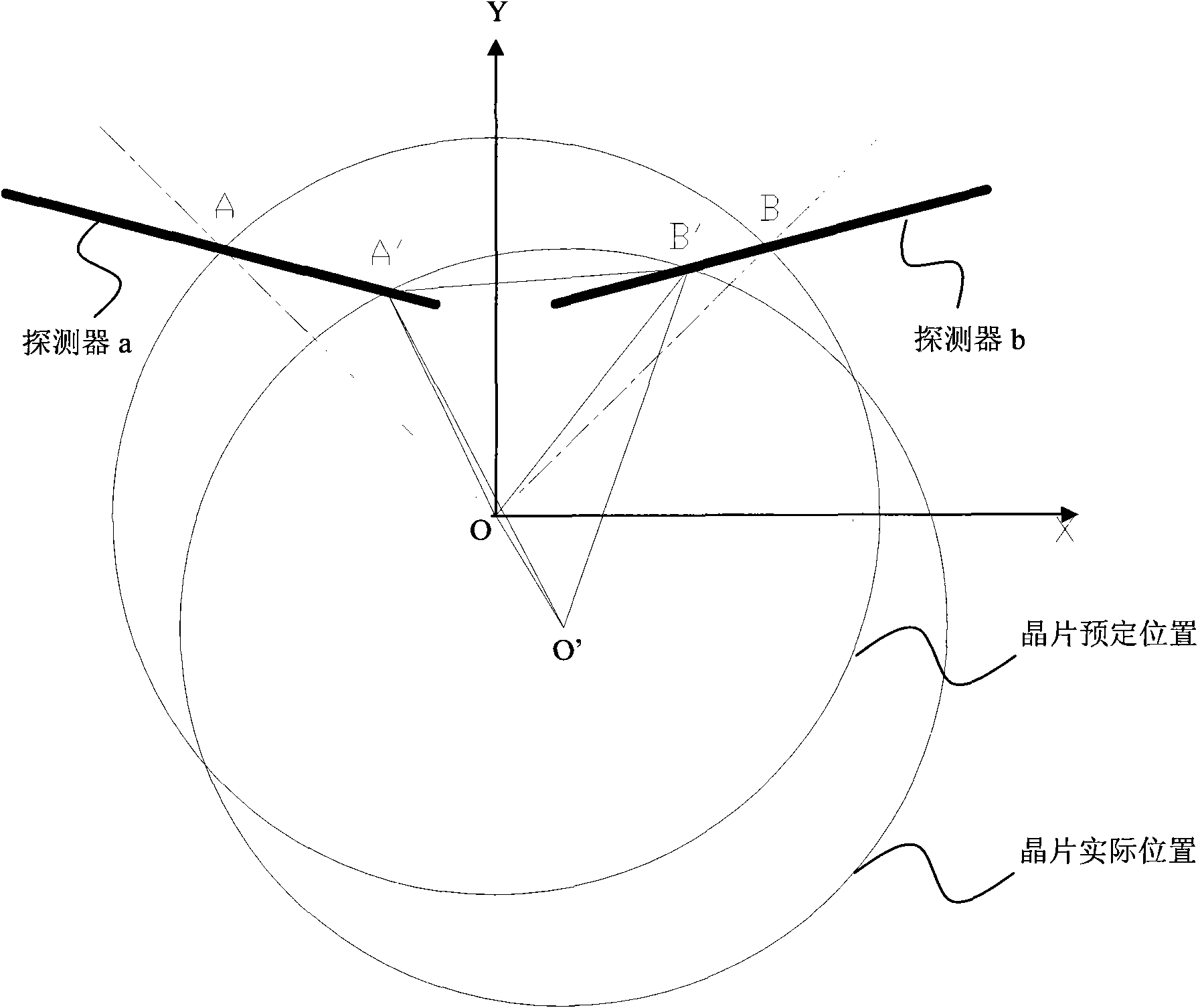

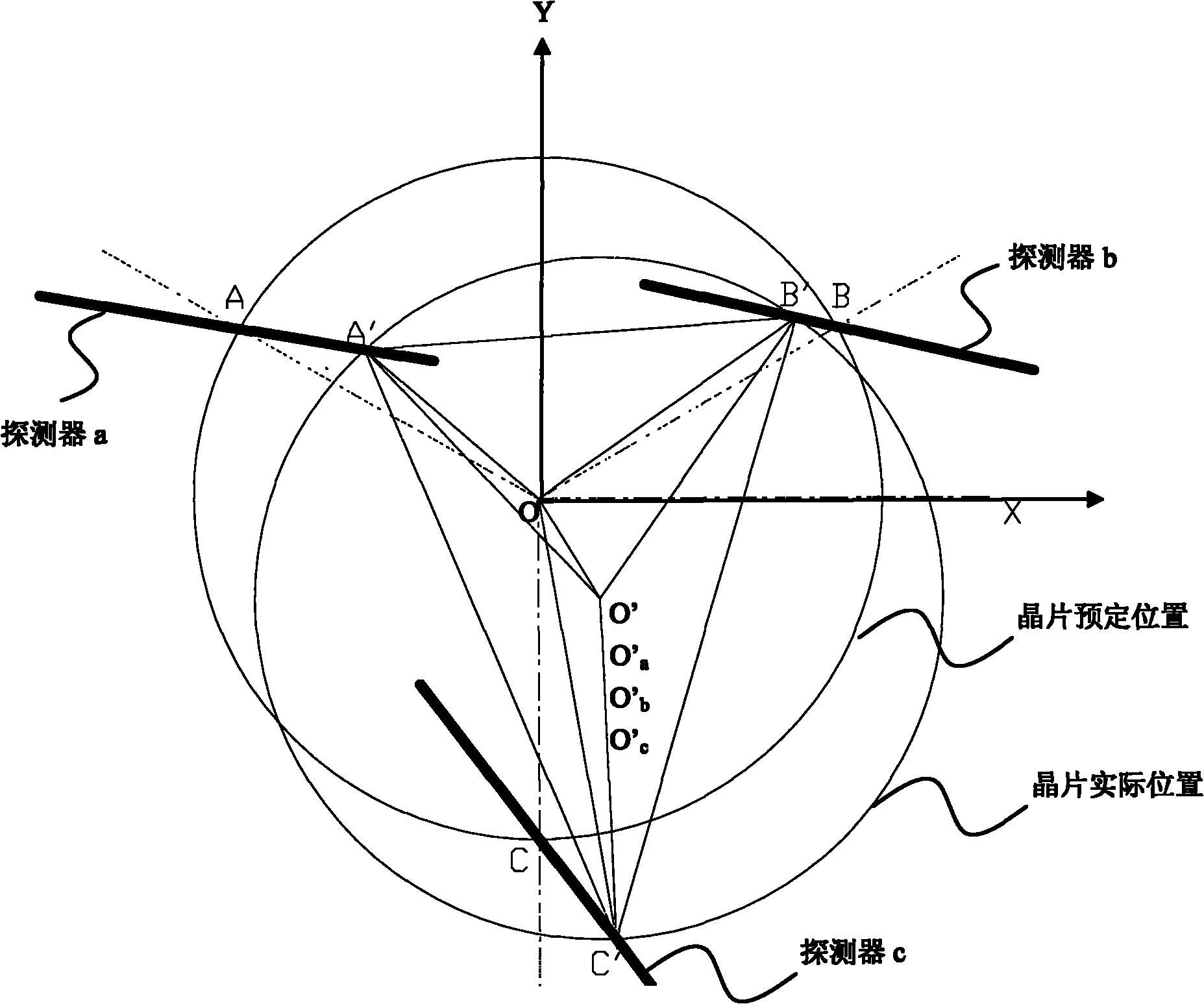

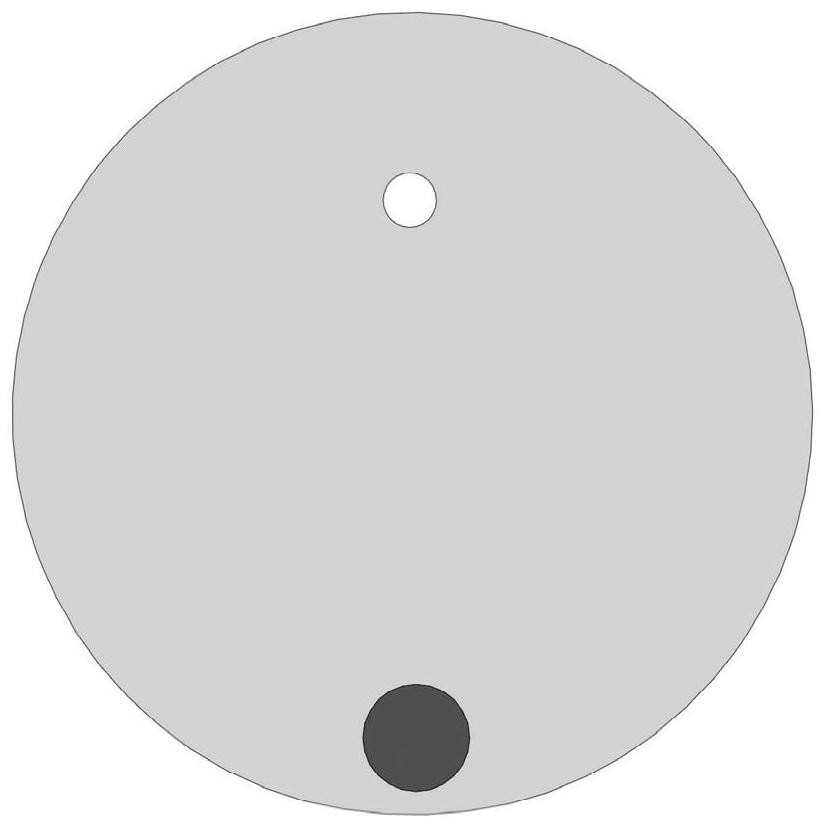

Method for detecting offset position of wafer

ActiveCN101832757AArbitrary arrangementIncrease flexibilityUsing optical meansComplex mathematical operationsPoint methodTwo point method

The invention discloses a method for detecting an offset position of a wafer by determining the offset of a central point of the wafer. The method comprises the following steps of: arranging a plurality of detectors around the wafer, arranging the detecting directions of the detectors along the radial direction of a predetermined position of the wafer, ensuring that any two detectors have no linear position relationship, and measuring and calculating the offset position of the wafer according to different numbers of the arranged detectors by selectively adopting a two-point method, a three-point method, a mean value two-point method or a mean value three-point method. The method improves the repeated precision of wafer transmission during manufacturing, and avoids wafer damage due to the offset of the wafer position.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

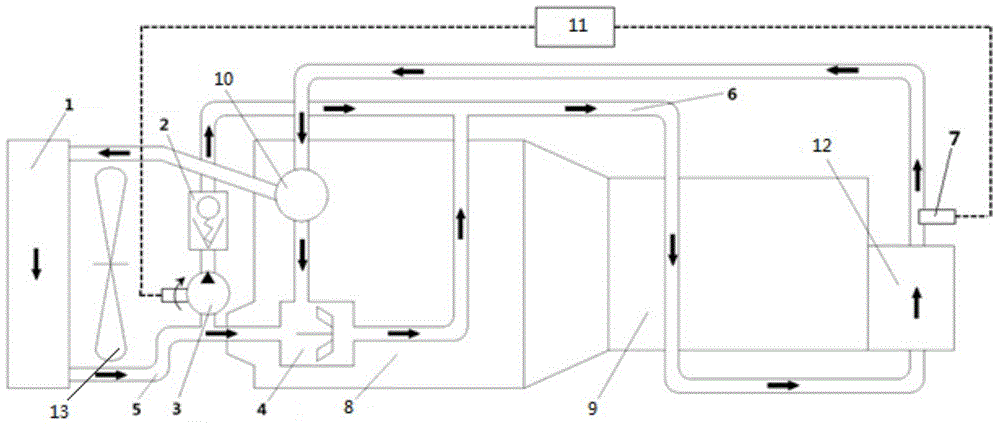

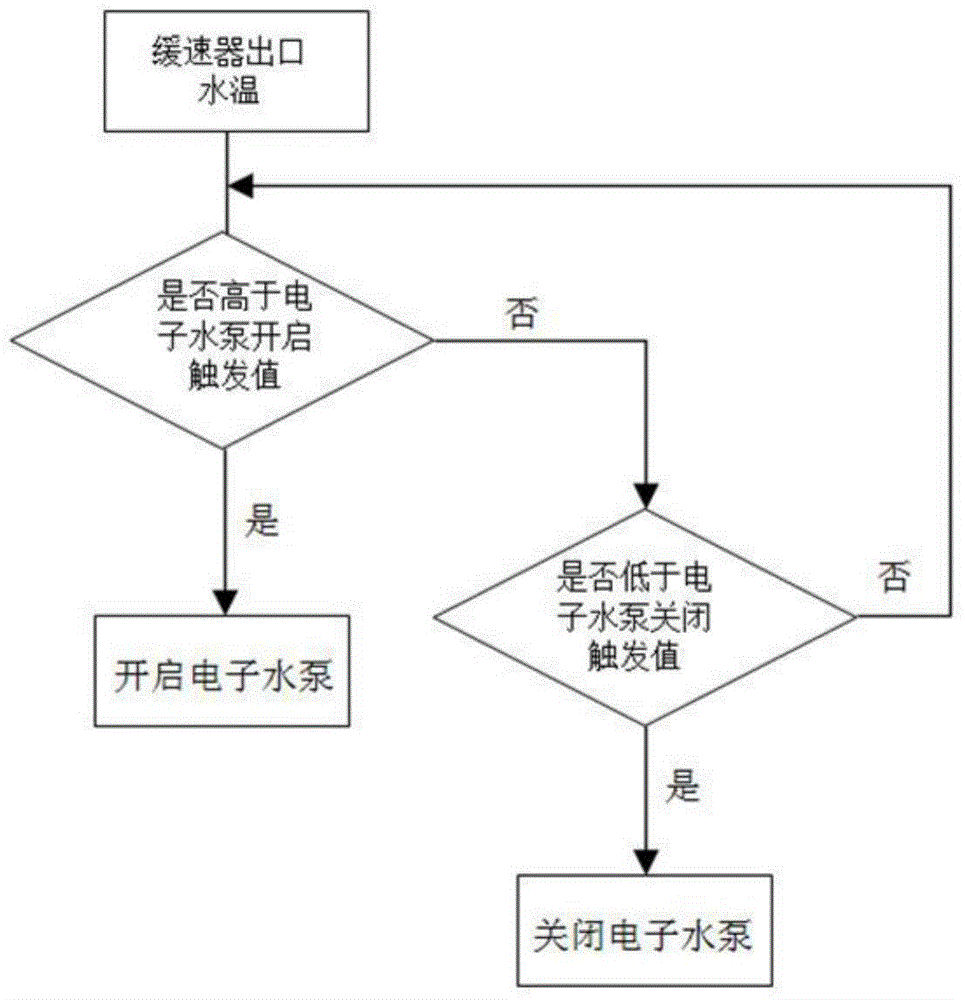

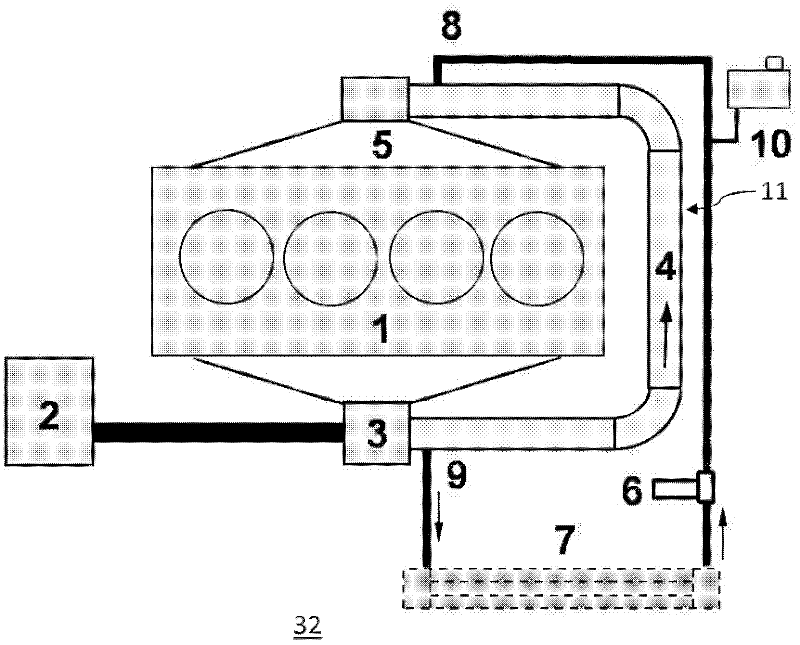

Automobile heat radiation system matched with hydraulic retarder and control method of automobile heat radiation system

ActiveCN104481662AEasy to implementSimple control methodLiquid coolingCoolant flow controlAutomotive engineeringSystem structure

The invention discloses an automobile heat radiation system matched with a hydraulic retarder and a control method of the automobile heat radiation system. The automobile heat radiation system comprises a cooling loop system, an electronic water pump, a water temperature sensor and a control module. The cooling loop system comprises a heat radiation water tank, an original automobile water pump, an engine water inlet pipe and an engine water outlet pipe. A water outlet of the original automobile water pump is communicated with the engine water outlet pipe, the engine water outlet pipe is communicated with a water inlet of a retarder, a water outlet of the retarder is communicated with a water inlet of a thermostat, a water outlet of the thermostat is divided into two communicated with a water inlet of the heat radiation tank and a water inlet of the original automobile water pump respectively, a water outlet of the heat radiation water tank is communicated with the engine water inlet pipe, and the engine water inlet pipe is communicated with the water inlet of the original automobile water pump; the electronic water pump is arranged in parallel to the original automobile water pump, and the control module controls opening and closing of the electronic water pump. The automobile heat radiation system is simple in structure and capable of meeting requirements of heat radiation of the automobile cooling system and is oil saving.

Owner:SHAANXI FAST GEAR CO

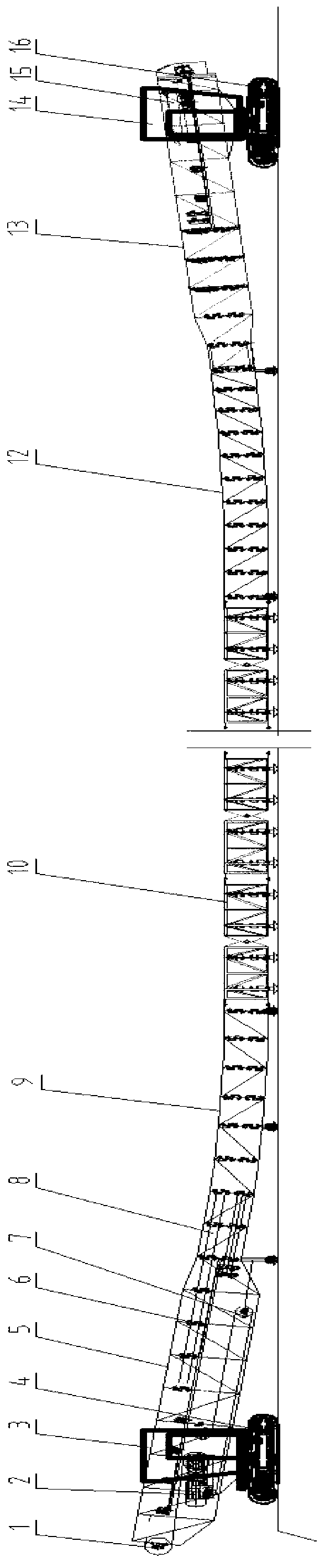

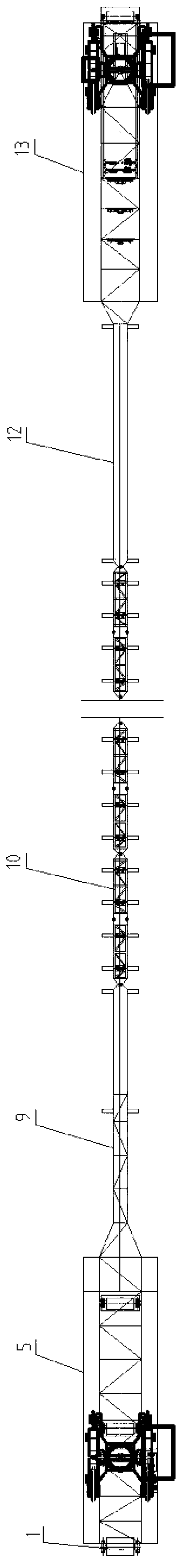

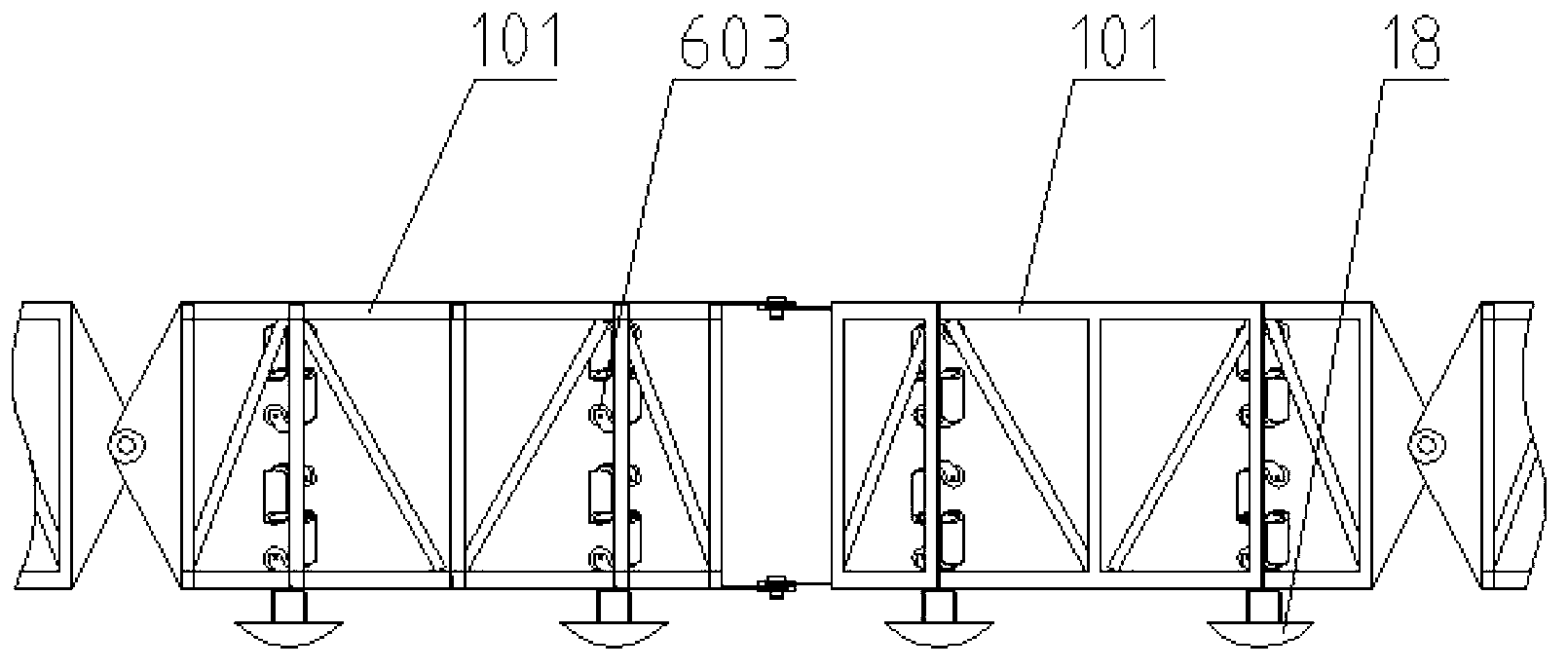

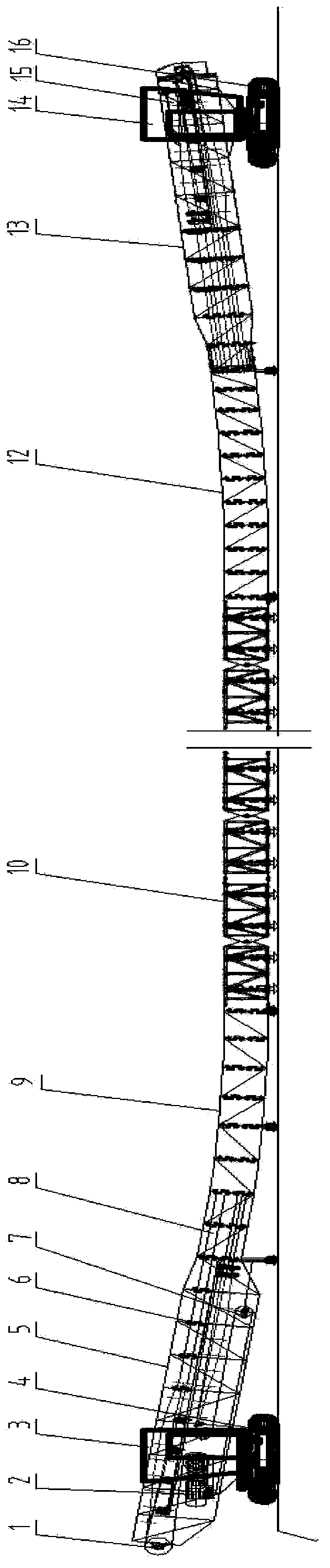

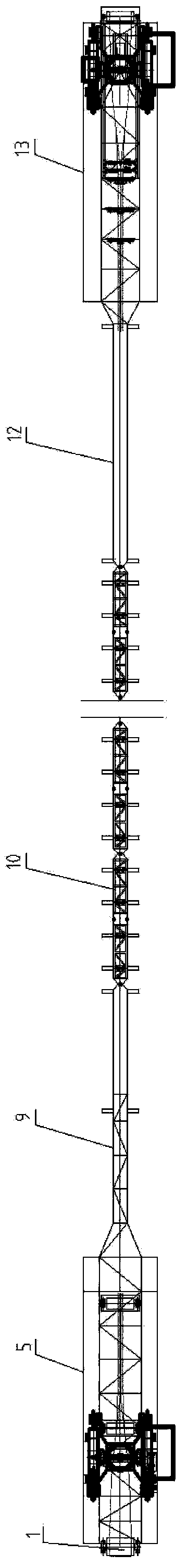

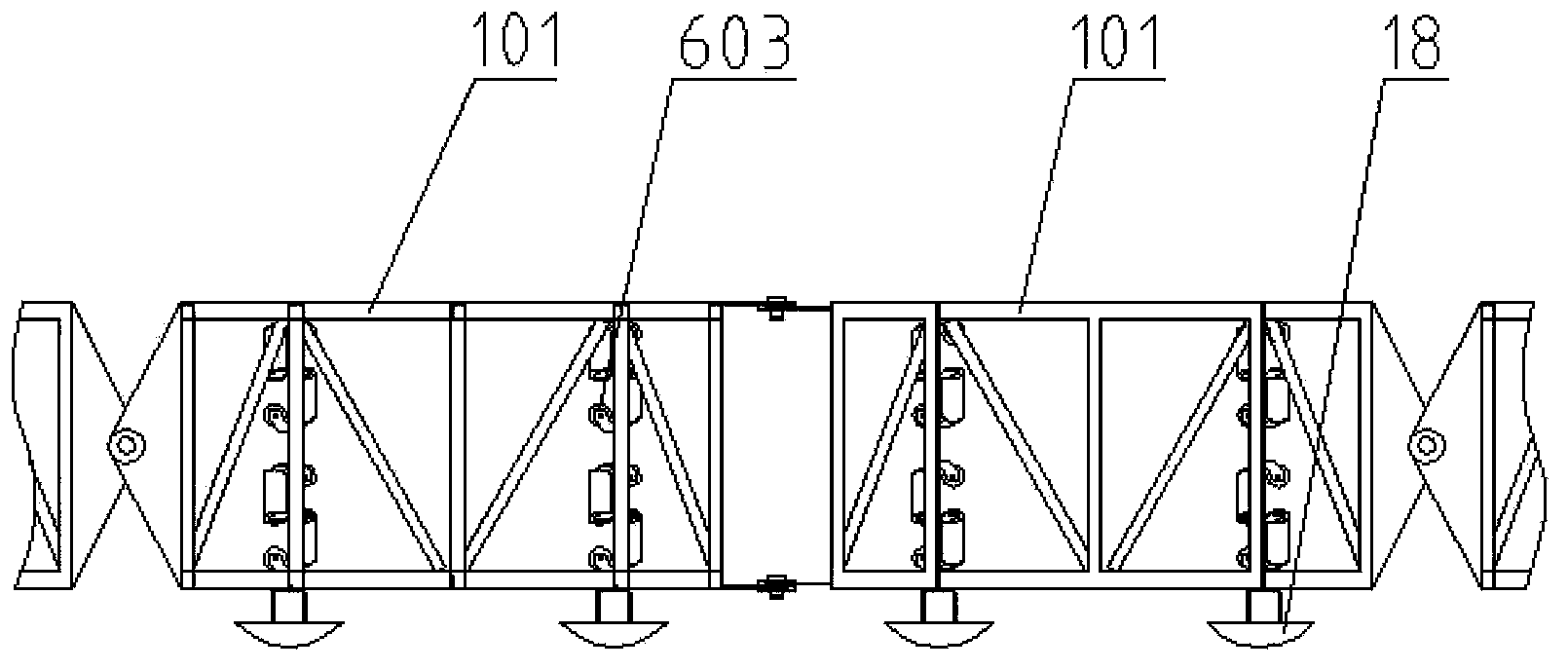

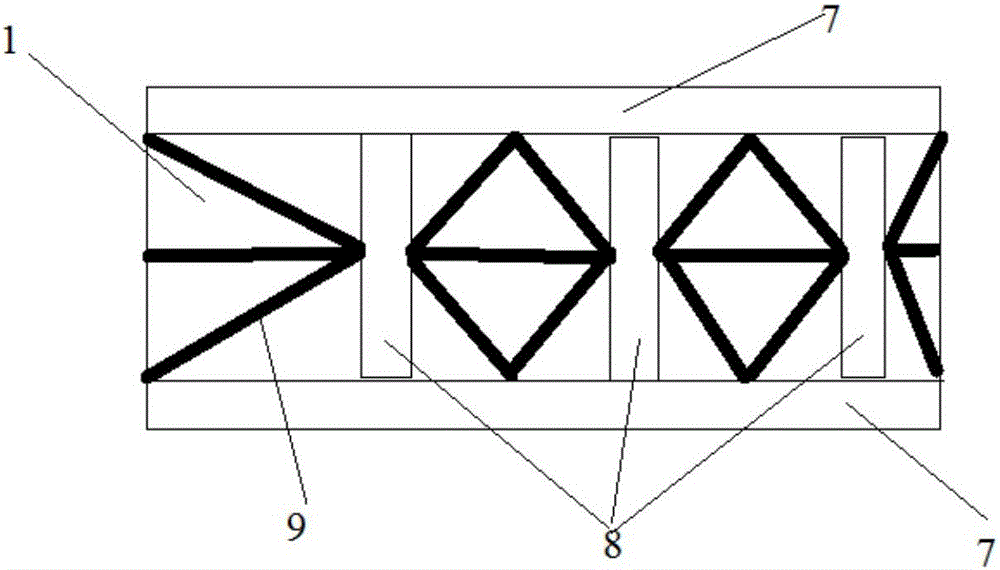

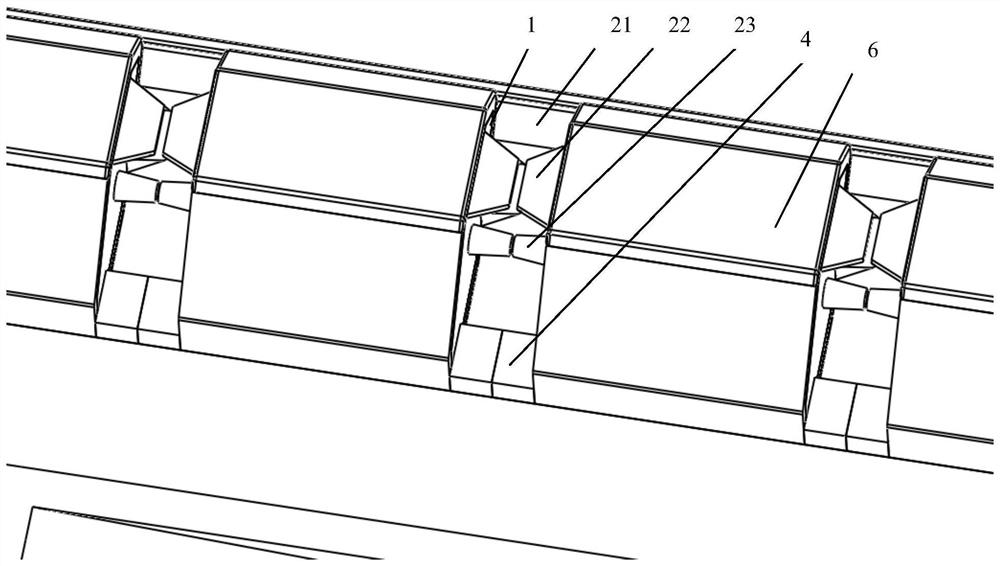

Movable type tubular belt conveyor

ActiveCN103241494ARealize continuous deliveryImprove efficiencyConveyorsSupporting framesTerrainVertical plane

The invention belongs to the field of continuous operating tubular belt conveyors, and particularly relates to a movable pipe belt conveyor. The movable pipe belt conveyor has the technical essentials that, running gears are arranged on the head and the tail of the pipe belt conveyor and enable both the head and the tail of the pipe belt conveyor to perform movements of loading points and emptying points according to practical situations on site, simultaneously middle adjustment machine frames are arranged between the head and the tail of the pipe belt conveyor, the middle adjustment machine frames are all composed of machine frame units and are respectively connected in mode of hinging horizontal planes and vertical planes, slide blocks or universal wheel devices are arranged on the lower portions of the machine frames, and therefore the machine frames can be bent in any horizontal plane, vertical plane and space in a certain bending radius range according to terrain, and materials can be conveyed in a plurality of ranges. The movable pipe belt conveyor can achieve continuous conveying, and thereby is high in efficiency; can effectively restrain dust rising for materials with high dust, and thereby is environment-friendly; and can adapt to topographic change to the upmost, and thereby is strong in adaptability.

Owner:TIDFORE HEAVY IND

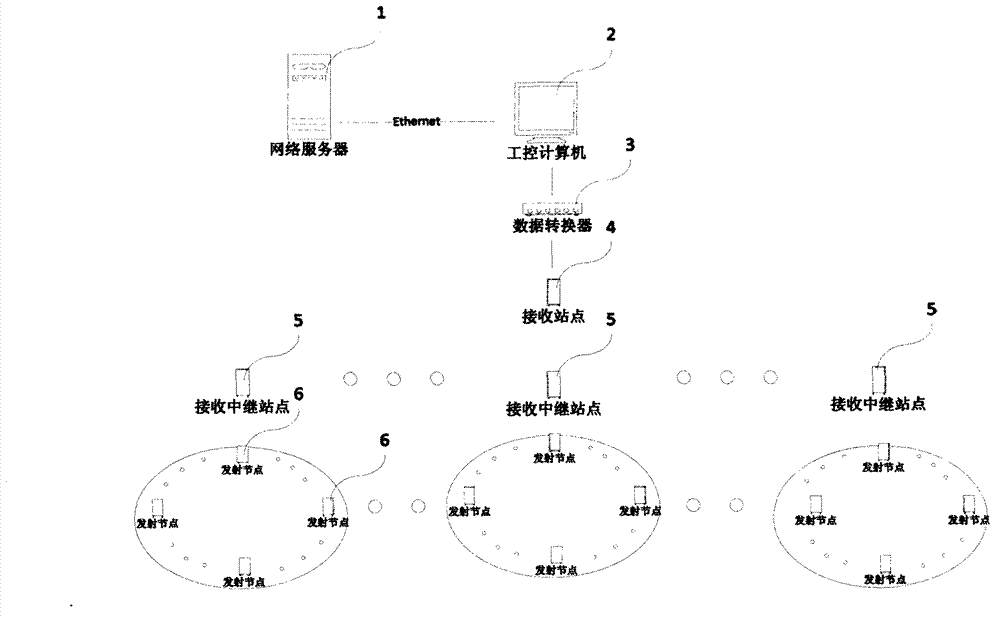

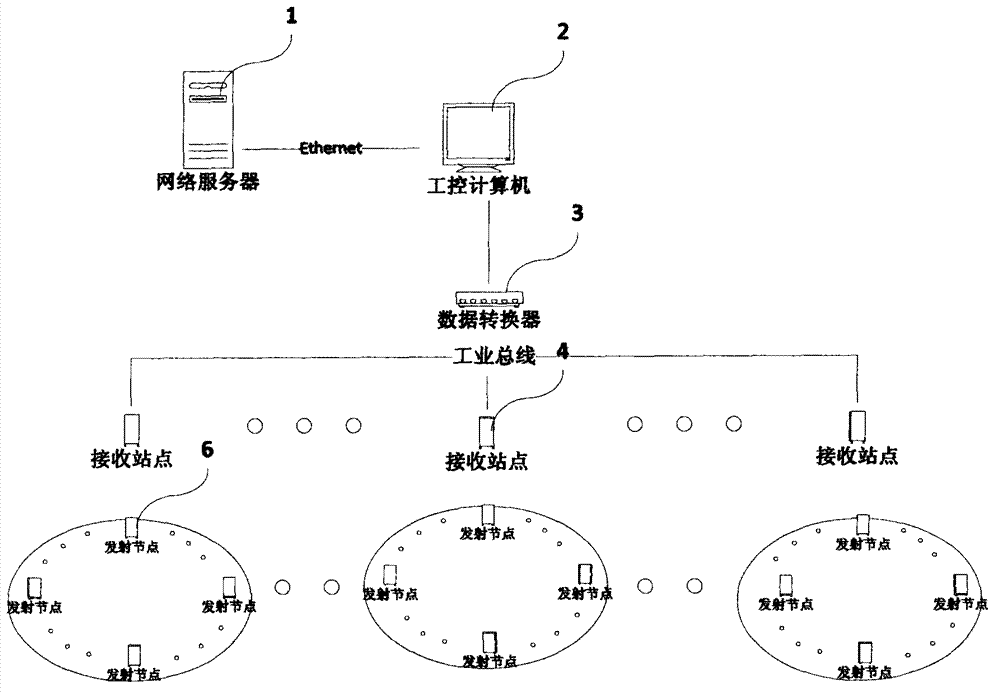

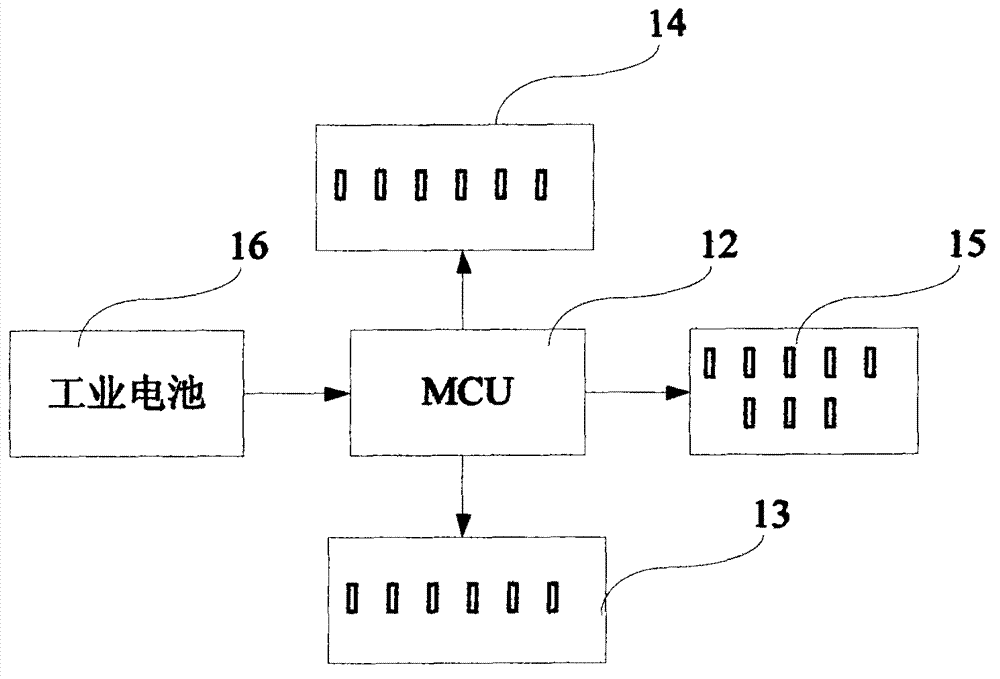

Online cooling water temperature difference measuring system for wireless blast furnace

InactiveCN102851424AImprove interchangeabilityImprove sealingCooling devicesChecking devicesHigh humidityWater temperature

The invention relates to an online cooling water temperature difference measuring system for a wireless blast furnace. The online cooling water temperature difference measuring system comprises a network server, an industrial control computer, a data converter, a receiving station and an emitting node, wherein the emitting node sends detected water temperature information to the receiving station; the receiving station sends the received temperature information to the industrial computer through the data converter; and the industrial control computer is used for sending the received temperature information to the network server. With the adoption of the online cooling water temperature difference measuring system for the wireless blast furnace, provided by the invention, compared with the wired water temperature measurement system, each temperature measuring point of the online cooling water temperature difference measuring system adopts a digital temperature measurement chip in a wireless digital transmission manner, so that the cable limitation is avoided; and the temperature measurement is accurate and is simple and convenient to transmit. Furthermore, no cable connected with the outside exists, so that the temperature measurement point is easy to seal, and has the relatively great advantages in high-temperature, high-dust-content and high-humidity environments.

Owner:BEIJING NORTH BILLION TECH CO LTD

Method and device for generating a 3d representation of a user interface in a vehicle

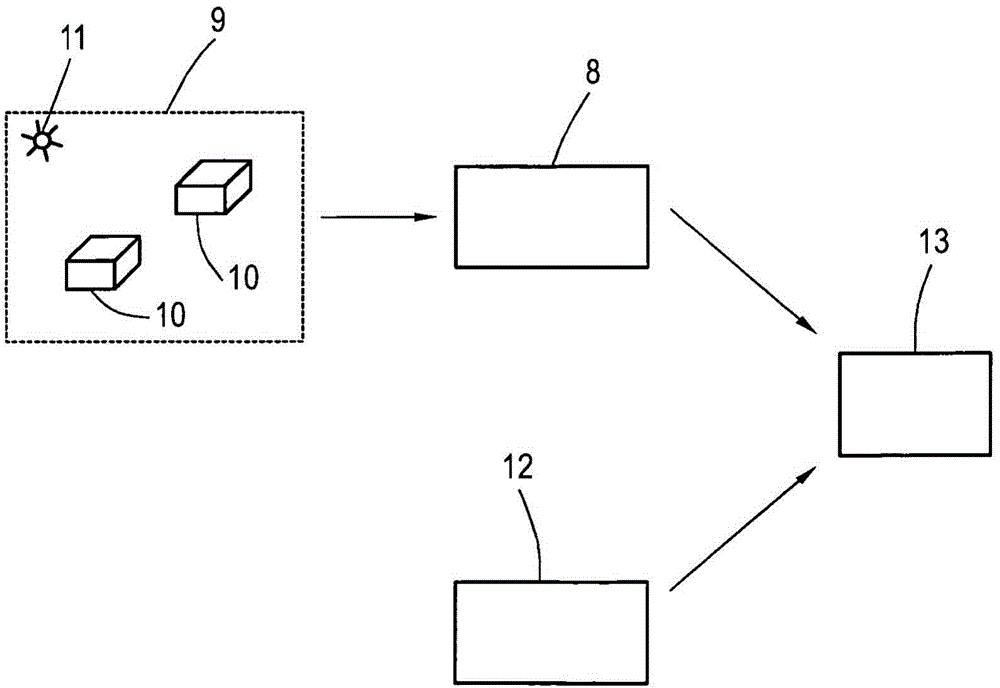

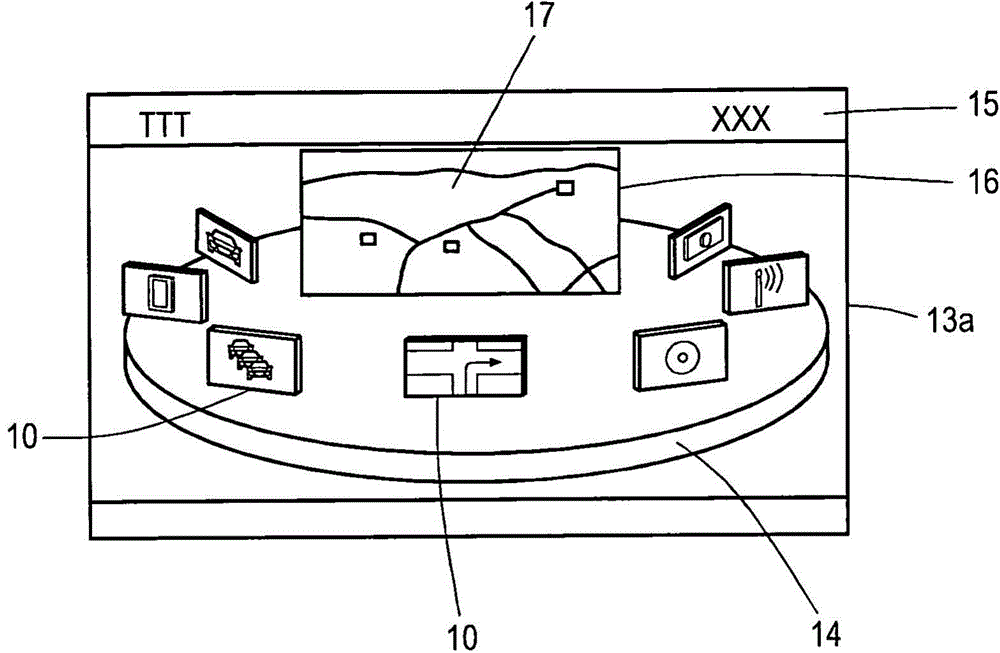

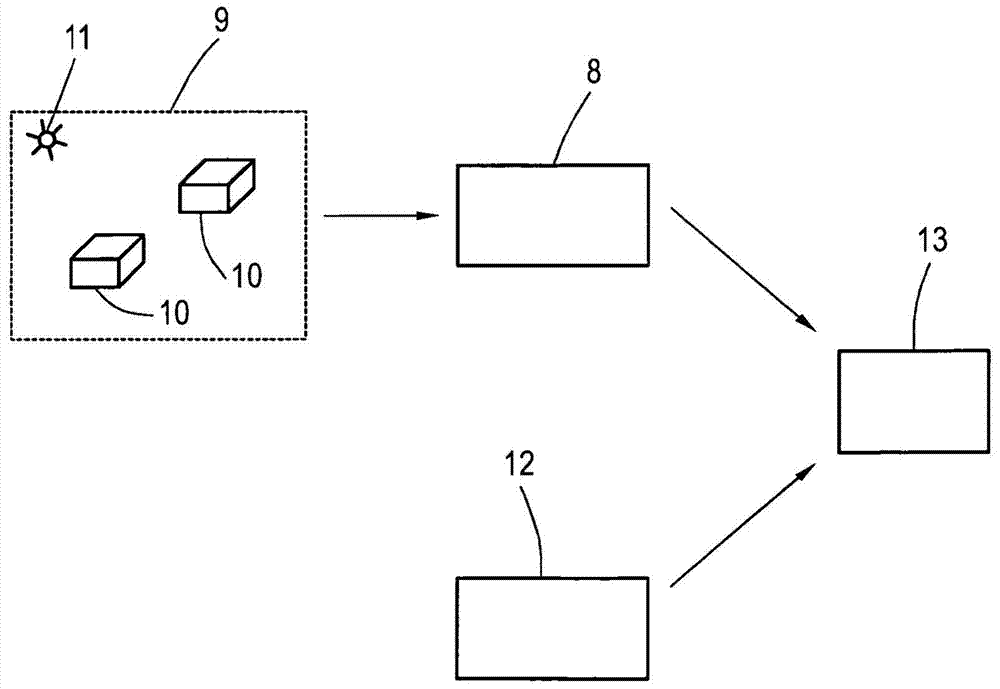

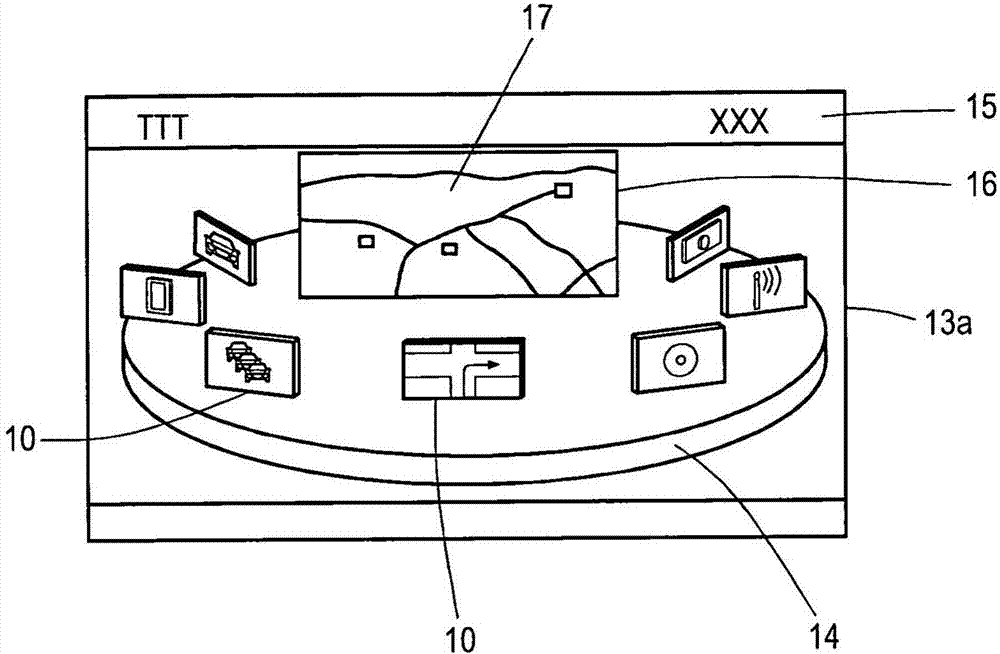

ActiveCN104039581AReduce the burden onIncrease flexibilityDashboard fitting arrangementsInstrument arrangements/adaptationsComputer graphics (images)3d user interface

Method for generating a 3D representation (8) of a user interface (13, 13a, 13b, 13c, 13d) in a vehicle (1), wherein a scene (9), particularly a moving scene, containing at least one 3D object (10), is rendered by an internal computing device (7) in the vehicle in order to determine the 3D representation (8).

Owner:AUDI AG

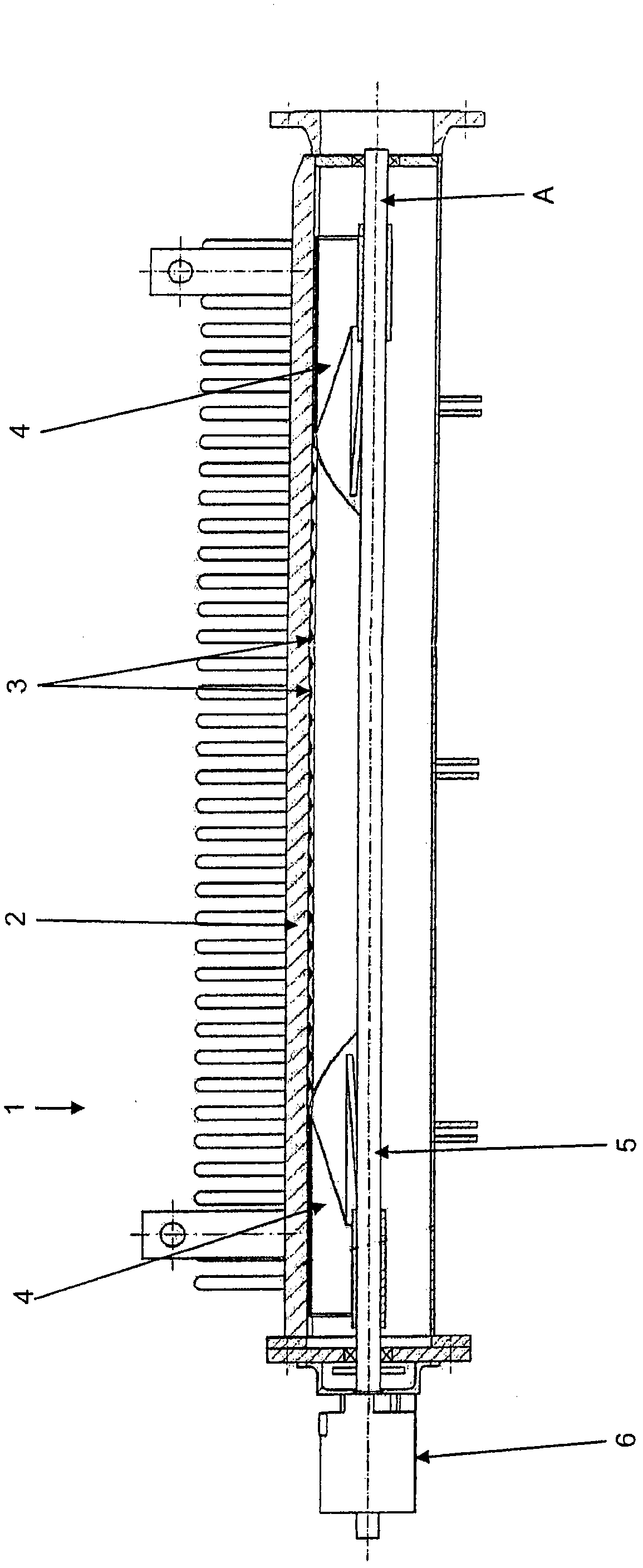

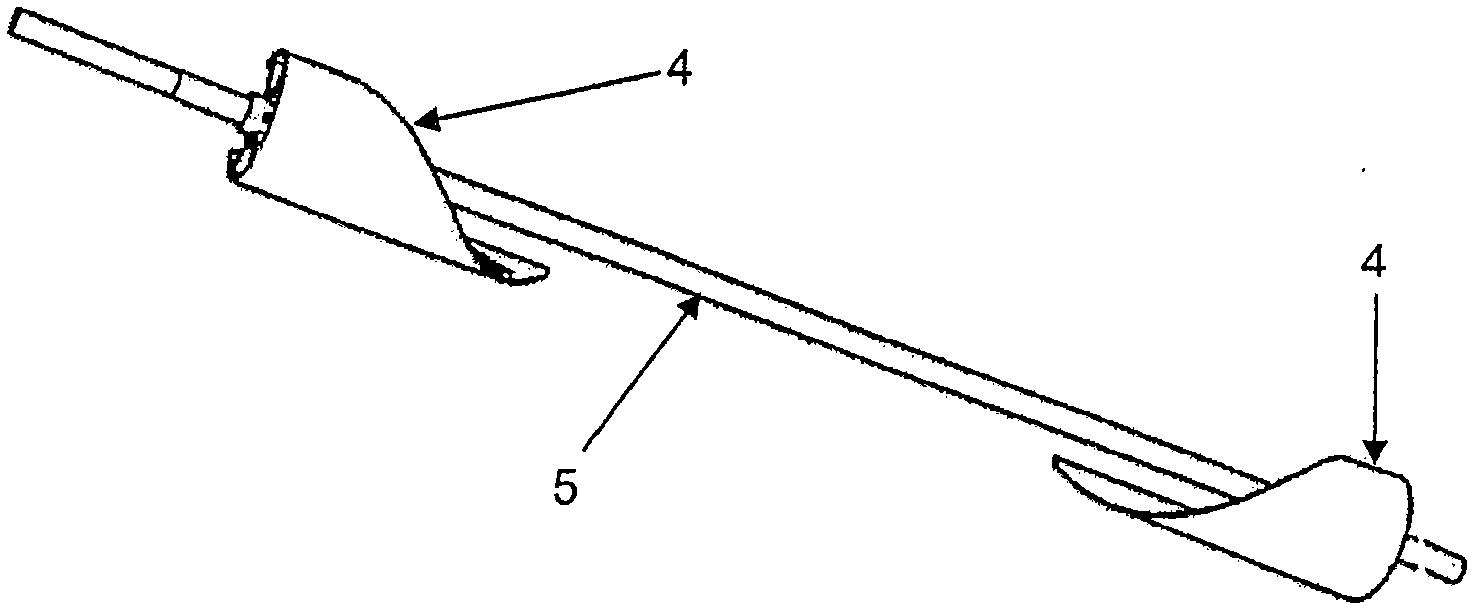

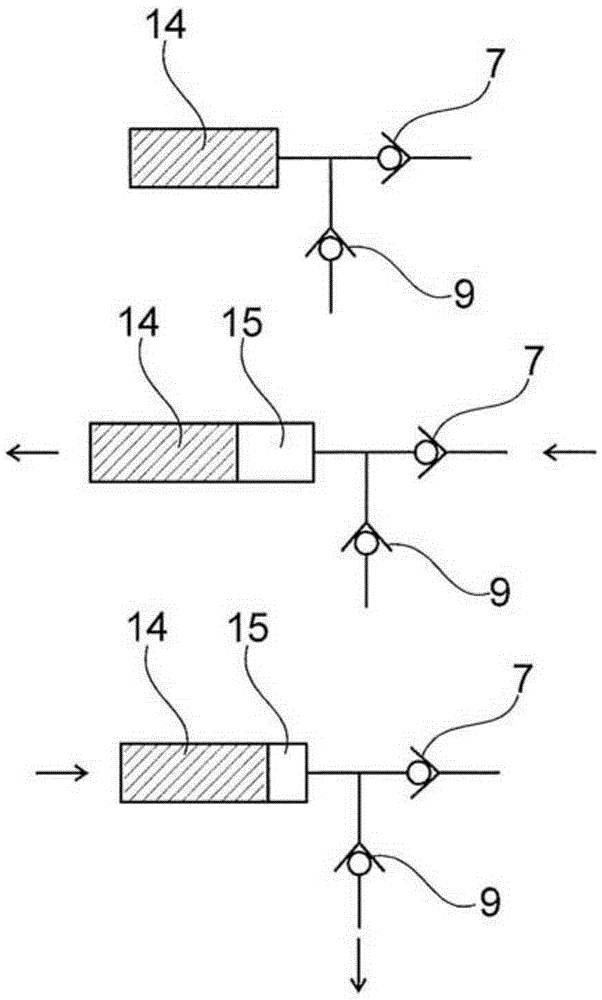

Spray bar, path and method for applying a medium onto a product

InactiveCN102421546AArbitrary arrangementIncrease flexibilityTemperature control deviceWork cooling devicesEngineeringMechanical engineering

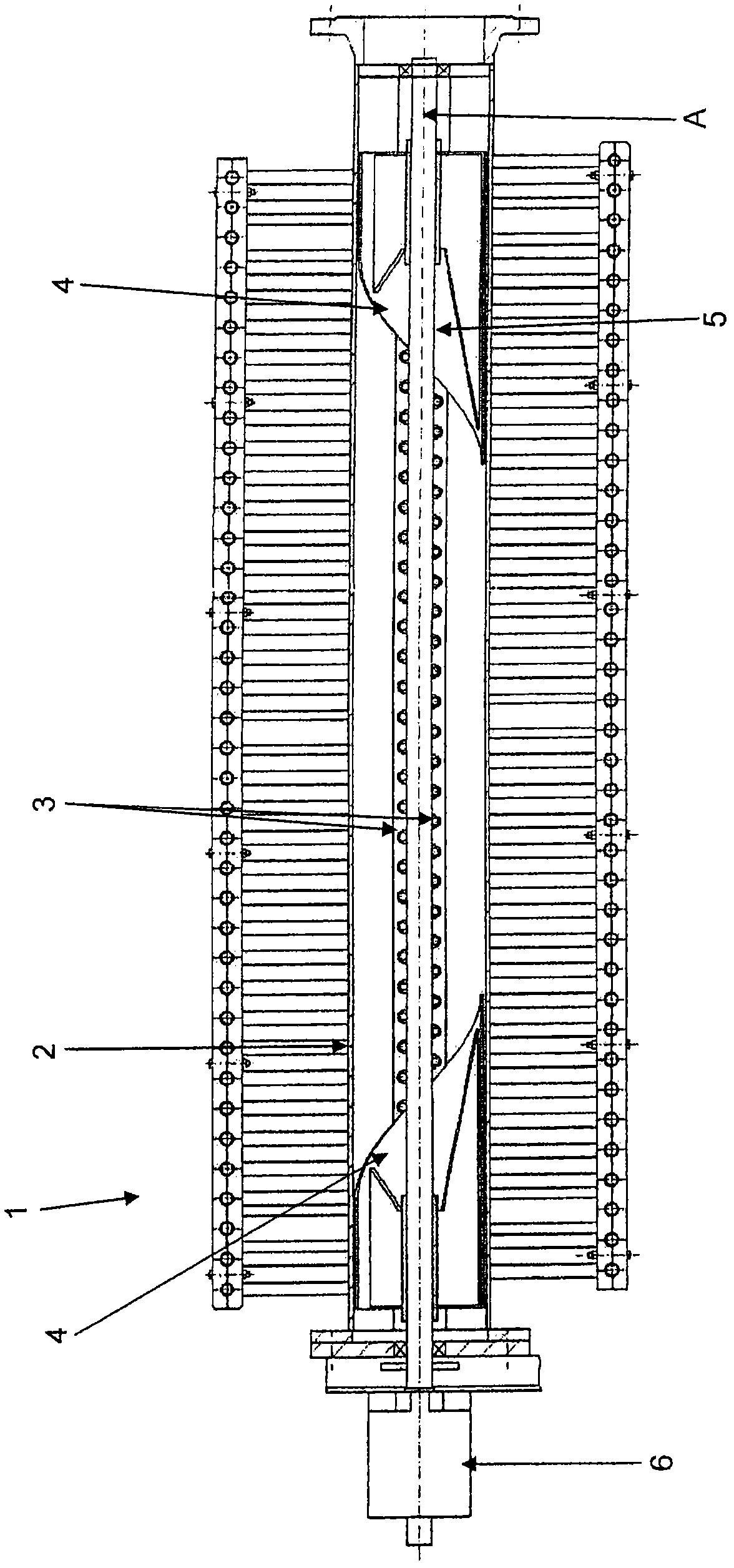

The invention relates to a spray bar, a path and a method for applying a medium onto a product, in particular in hot strip mills, CSP facilities or other strip processing lines. The spray bar (1) used therefor comprises a housing (2) with outlet openings (3) from which the medium can be applied onto the product. To this end, the outlet openings (3) can be covered in a sealing manner or can be released by a pivotable cover (4) which is formed by at least one segment of a hollow cylinder and which is arranged on at least one of the two ends of the housing. In this way, no medium is conducted onto edge regions which are not to be treated and, simultaneously, an accurate adjustability of the treatment is ensured.

Owner:SMS DEMAG AG

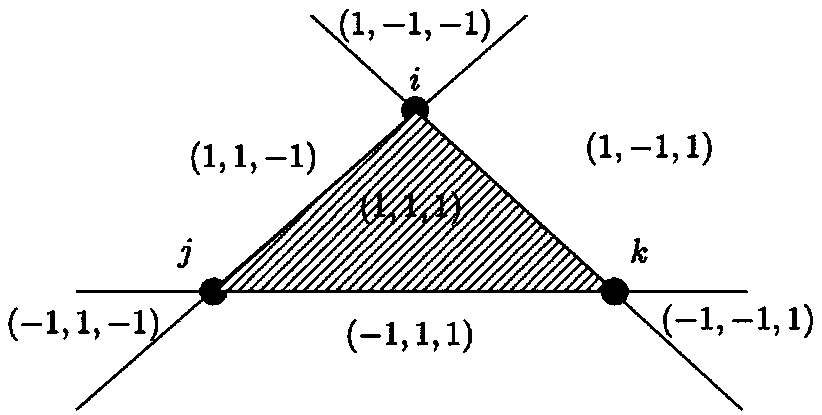

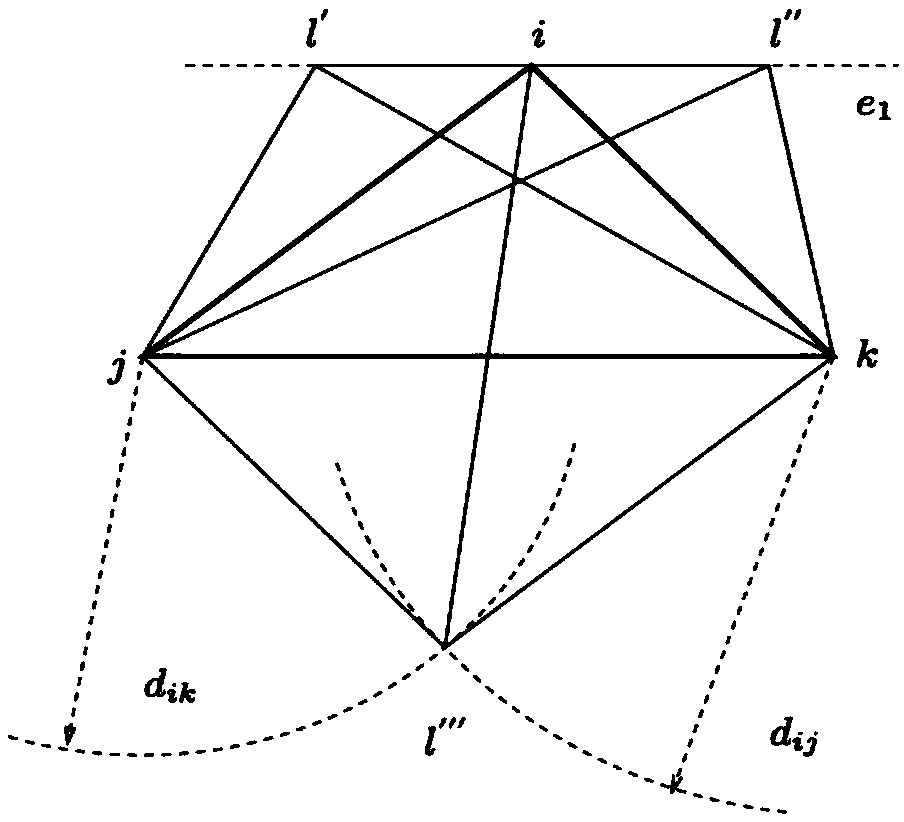

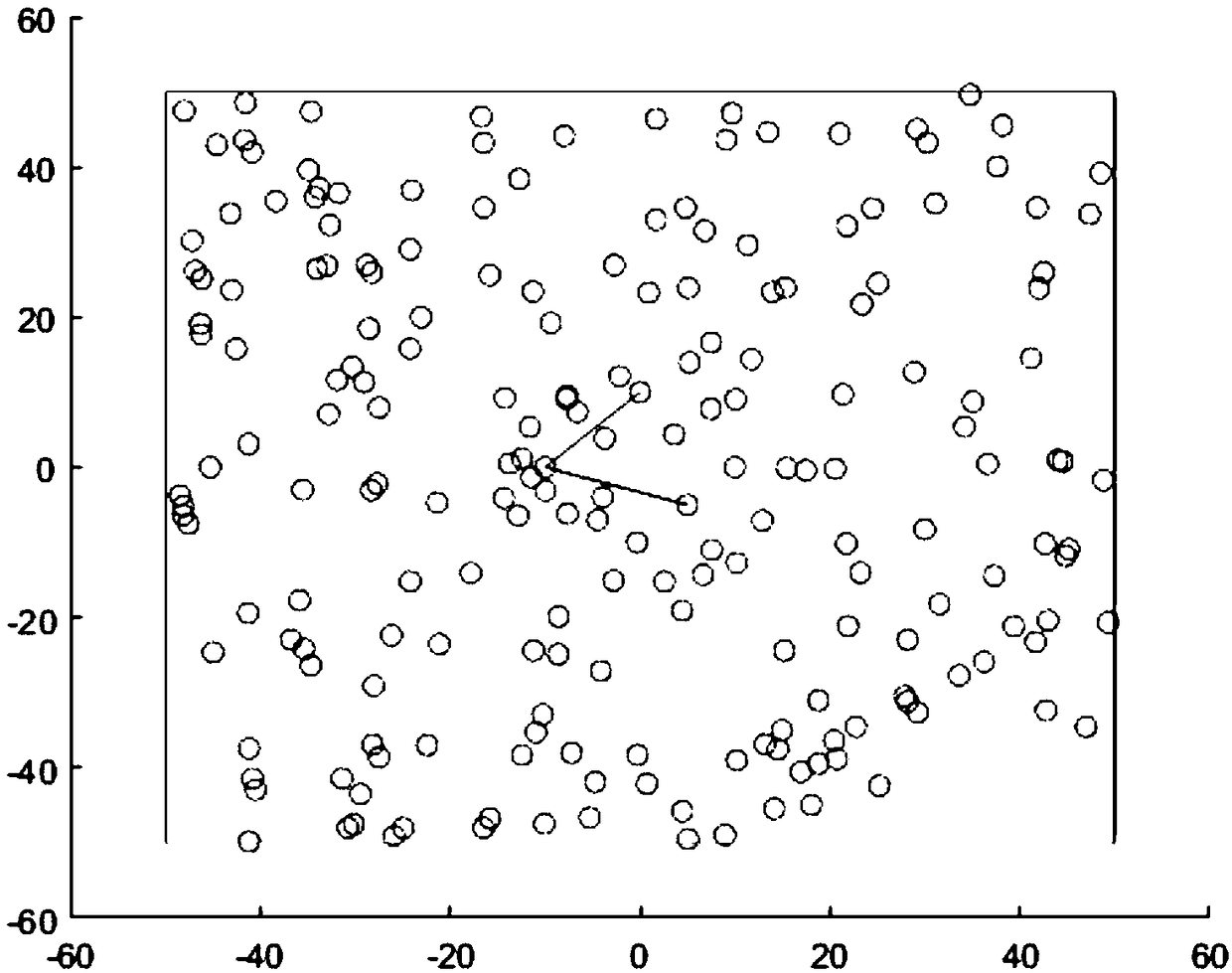

Three-anchor point and four-anchor point positioning method and device of sensor network considering error interference

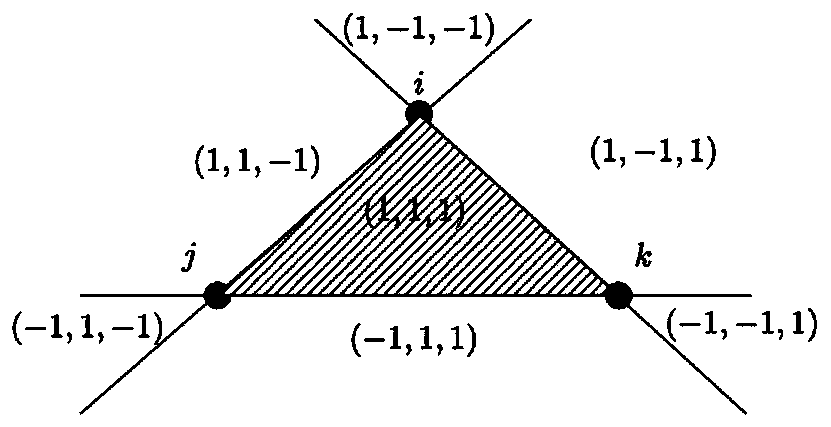

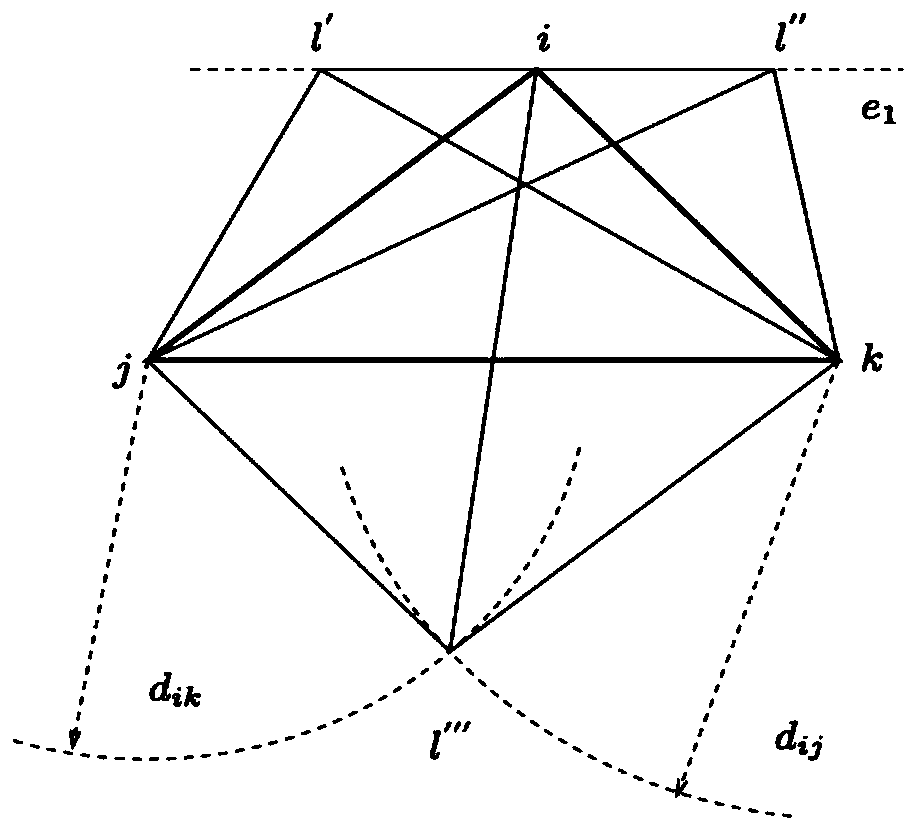

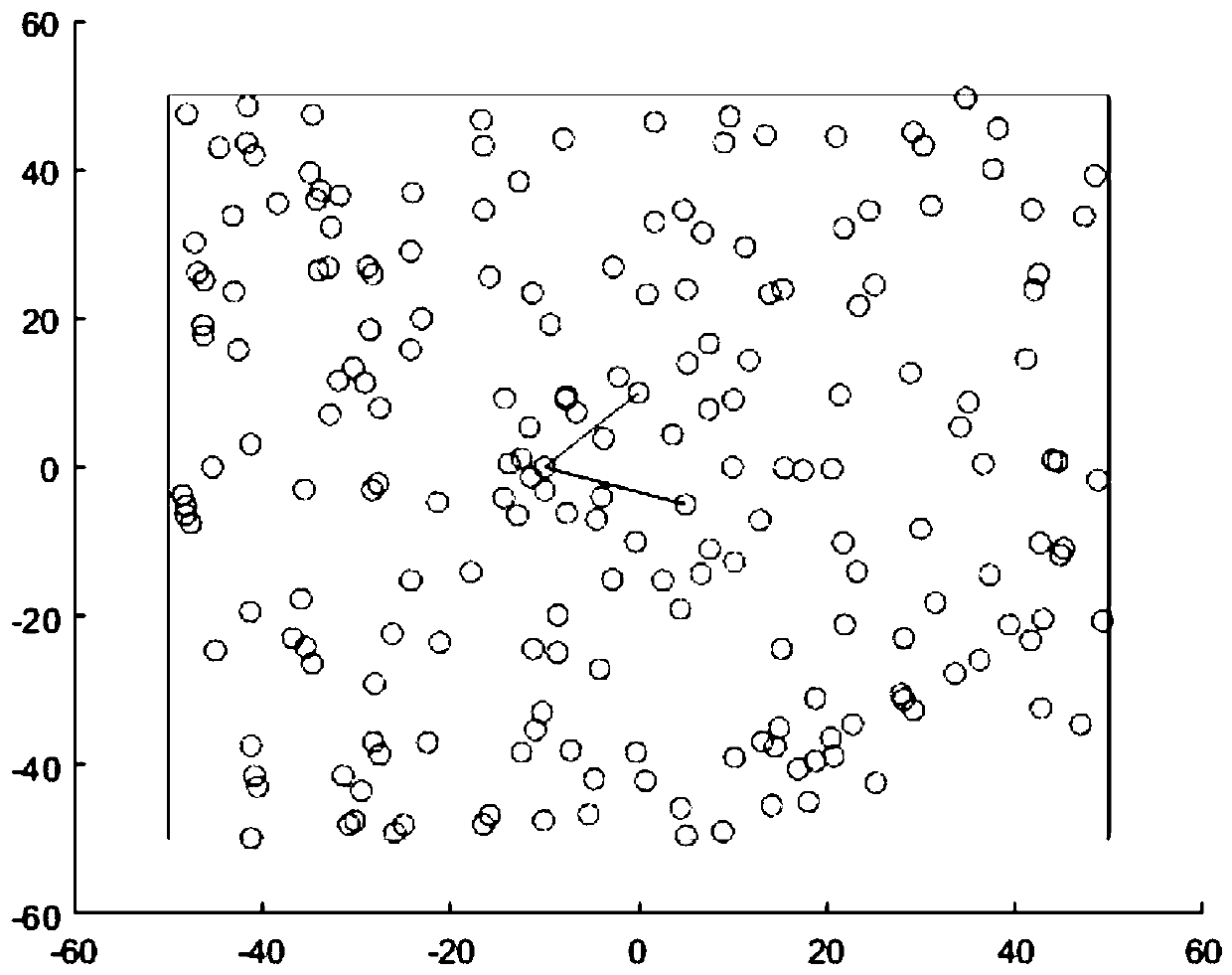

ActiveCN108989978AReduce the impact of accuracyImprove robustnessNetwork topologiesLocation information based serviceNODALGeometric relations

The invention discloses a method and a device for locating three anchor points and four anchor points of a sensor network considering error interference. Three anchor location methods include: selecting three sensor nodes as an anchor point to form a triangle; Node information is communicated between any two anchor points; The distance between the three anchor points and the target node to be located is measured respectively, and the absolute values of the barycentric coordinate coefficients of the three anchor points corresponding to the target node to be located are calculated according to the geometrical relationship between the three anchor points and the target node to be located; considering the measurement error, according to the sum of all barycentric coordinate coefficients beingbetween [1-Delta 1, 1 +Delta 1], the symbols of all barycentric coordinate coefficients are solved and determined, and the positioning of the target node to be positioned according to the barycentriccoordinate algorithm is completed,wherein Delta 1 is within the range of (0,1) . This method is not affected by the shape of the triangle formed by the anchor configuration, and is more robust to theerror.

Owner:SHANDONG UNIV

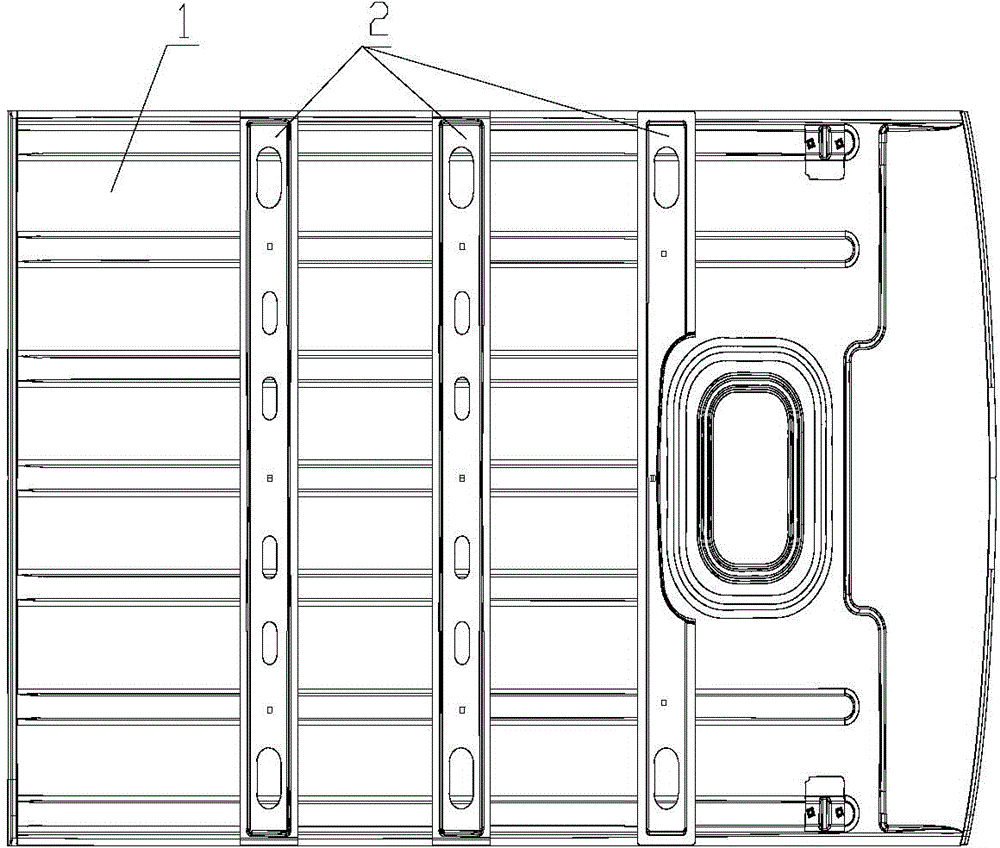

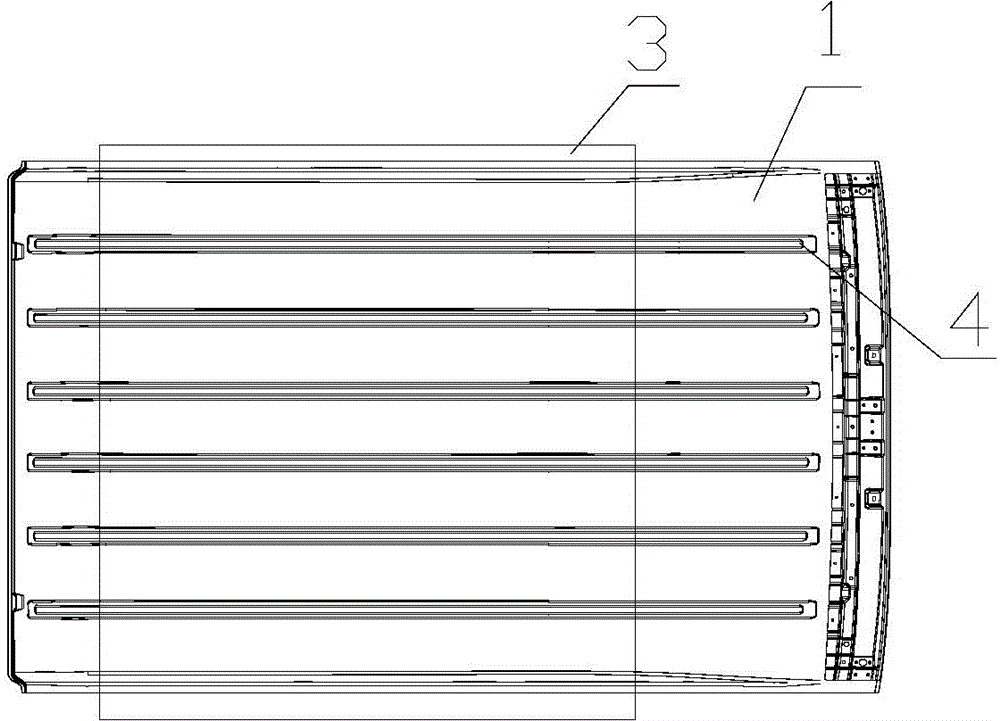

Roof cover and automobile

Owner:BEIQI FOTON MOTOR CO LTD

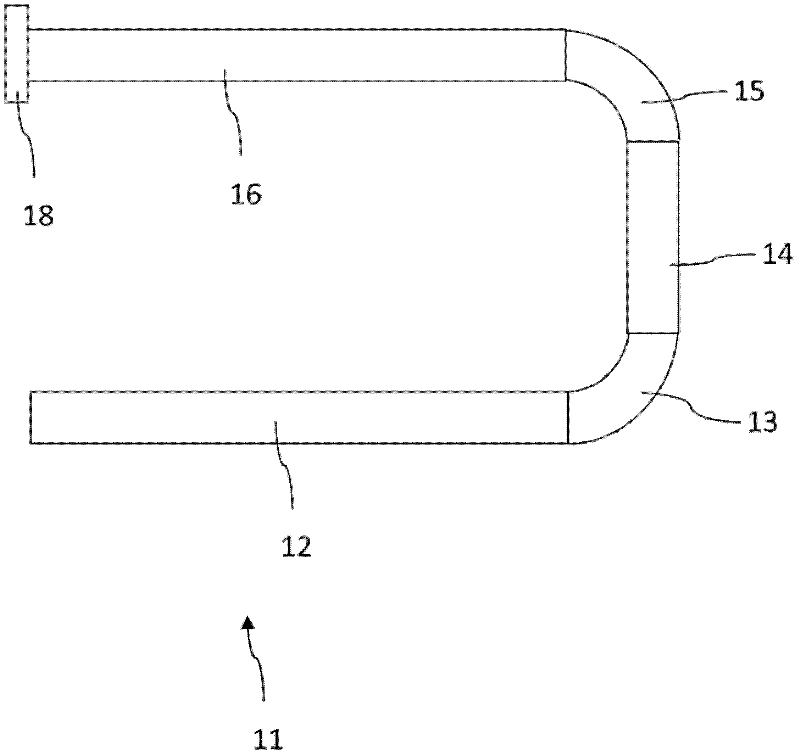

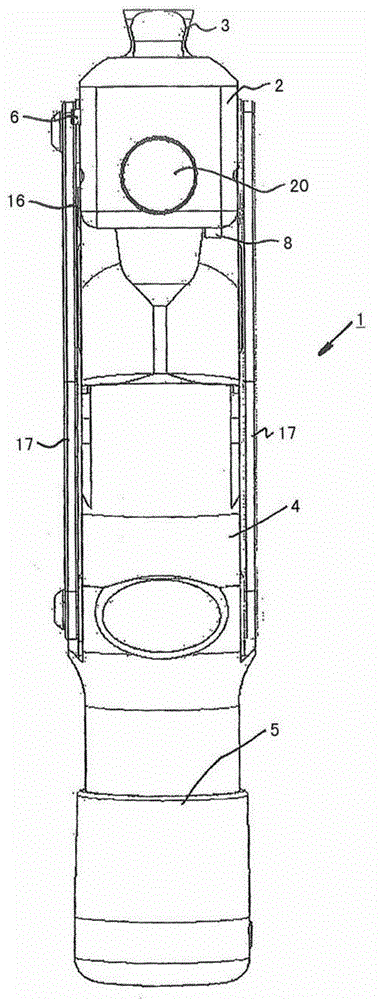

Charge air cooling device for a combustion engine

InactiveCN102444462AOptimize effective lengthImprove cooling efficiencyInternal combustion piston enginesStationary tubular conduit assembliesThermal energyCombustion

The present invention relates to a charge air cooling device for a combustion engine. The cooling device comprises a first heat exchanger 11 for transmitting thermal energy of a charge airflow to a coolant 30 and a second heat exchanger 7 for radiating thermal energy of the coolant 30 into the surrounding environment. The first heat exchanger 11 is designed as a coaxial tube heat exchanger 11 such that at least part of the first heat exchanger is coaxial with the charge air flow and is such that the coaxial tube heat exchanger directly connects a compressor 3 to the engine 1.

Owner:GM GLOBAL TECH OPERATIONS LLC

System for monitoring curved surface interlaminar extrusion pressure based on array type ultra-thin submissive force sensor

InactiveCN100585353CImprove flexibilityImprove temperature stabilityForce measurement using piezo-resistive materialsDiagnostic recording/measuringSurface layerComputer module

The invention relates to an inter-curved surface layer extrusion pressure monitoring system based on an array-type ultrathin compliant force sensor, and belongs to the technical field of precise measurement. The system comprises an array-type sensor consisting of an array-type ultrathin compliant force sensing probe and a front end circuit; a reference source; a collection module; a computer comprising an interface card and a data processing unit; and a power supply module. The power supply module is connected with the sensor and the collection module. The reference source is connected with the array-type sensing probe through line multi-route electronic simulation switches. The front end circuit is connected between the array-type sensing probe and the collection module. The interface card is connected with the row and line multi-route electronic simulation switches, respectively. The invention has the characteristics of simple structure, high antijamming capability, high accuracy of measurement, and capability of on-line monitoring of data processing in real time. The invention can monitor the extrusion pressure between face layers on line in real time.

Owner:TSINGHUA UNIV

Movable type tubular belt conveyor

ActiveCN103241494BRealize continuous deliveryImprove efficiencyConveyorsSupporting framesTerrainVertical plane

The invention belongs to the field of continuous operating tubular belt conveyors, and particularly relates to a movable pipe belt conveyor. The movable pipe belt conveyor has the technical essentials that, running gears are arranged on the head and the tail of the pipe belt conveyor and enable both the head and the tail of the pipe belt conveyor to perform movements of loading points and emptying points according to practical situations on site, simultaneously middle adjustment machine frames are arranged between the head and the tail of the pipe belt conveyor, the middle adjustment machine frames are all composed of machine frame units and are respectively connected in mode of hinging horizontal planes and vertical planes, slide blocks or universal wheel devices are arranged on the lower portions of the machine frames, and therefore the machine frames can be bent in any horizontal plane, vertical plane and space in a certain bending radius range according to terrain, and materials can be conveyed in a plurality of ranges. The movable pipe belt conveyor can achieve continuous conveying, and thereby is high in efficiency; can effectively restrain dust rising for materials with high dust, and thereby is environment-friendly; and can adapt to topographic change to the upmost, and thereby is strong in adaptability.

Owner:TIDFORE HEAVY IND

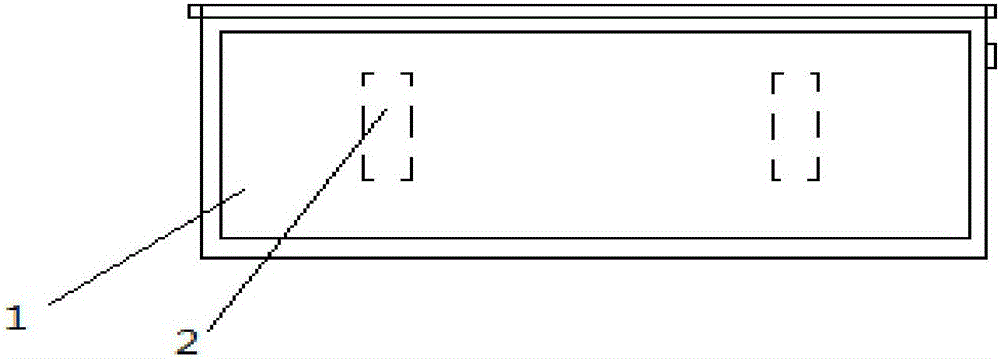

Shell of assembly body for assembling lithium battery and metal frame

InactiveCN105895842AReduce shockImprove vibration resistanceCell component detailsMechanical engineeringShock resistance

The invention discloses a shell of an assembly body for assembling a lithium battery and a metal frame. The metal frame comprises two metal plates and screw rods, wherein the two metal plates are used for clamping a battery pack between the metal plates, through holes in pair are respectively and symmetrically formed in a region above the battery pack on the metal plates and are used for allowing the screw rods to prop against the battery and pass through each pair of through holes, nuts are screwed into the two end parts of the screw rods to form the assembly body, the shell comprises an upper shell cover and a lower shell, guide ribs are arranged on an internal longitudinal surface of the lower shell and is used for guiding an external longitudinal surface of the assembly body, longitudinal grooves are formed in the bottoms of the inner sides of the internal longitudinal surface and the external longitudinal surface and are respectively used for receiving the upper parts and the lower parts of the metal plates, and transverse grooves are formed in the bottoms of the inner sides of the internal longitudinal surface and the external longitudinal surface, are crossed with the longitudinal surface and are respectively used for receiving the screw rods above and below the battery pack so that certain gaps are maintained between the screw rods and the bottom of the corresponding transverse grooves. The battery assembled by the shell bears force by the metal frame and the shell, the impact from each direction can be buffered, the shock resistance is improved, and an arbitrary face can face upwards.

Owner:北京恒绿源和科技有限公司 +1

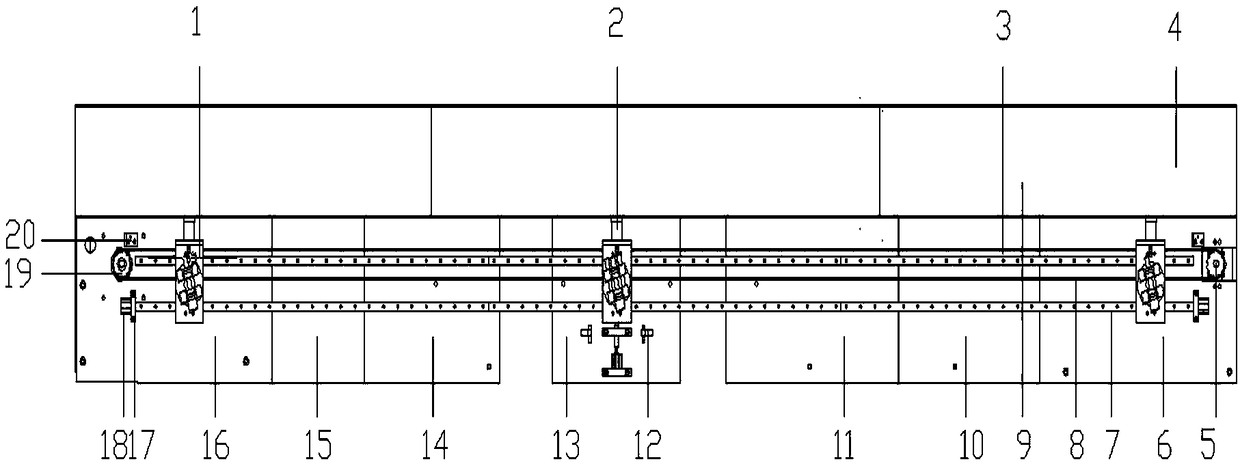

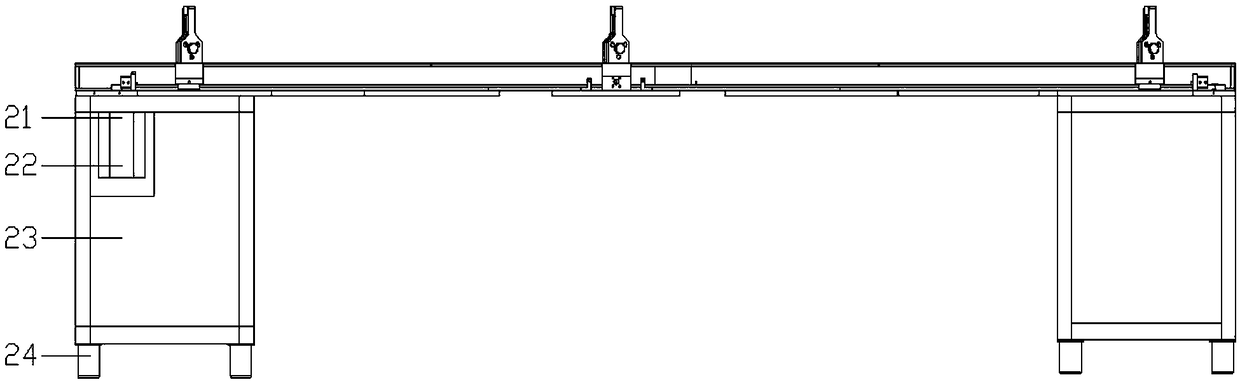

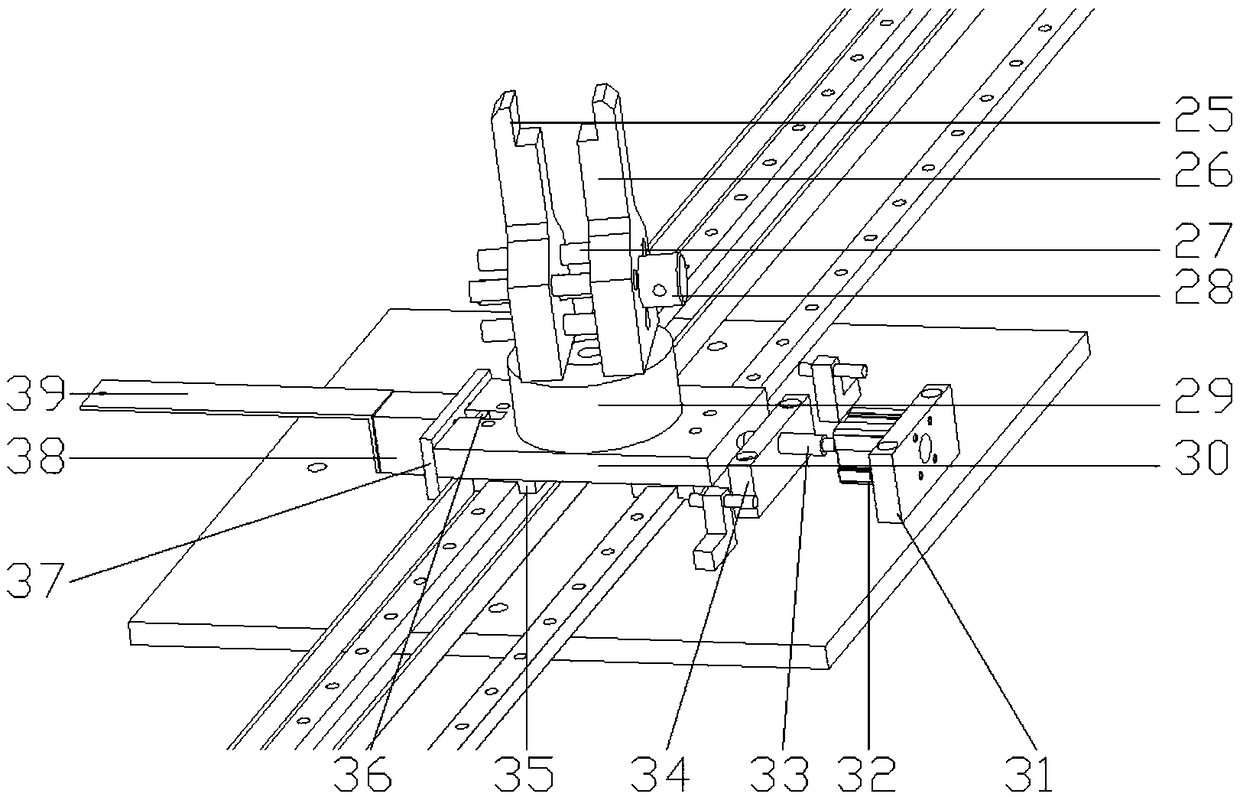

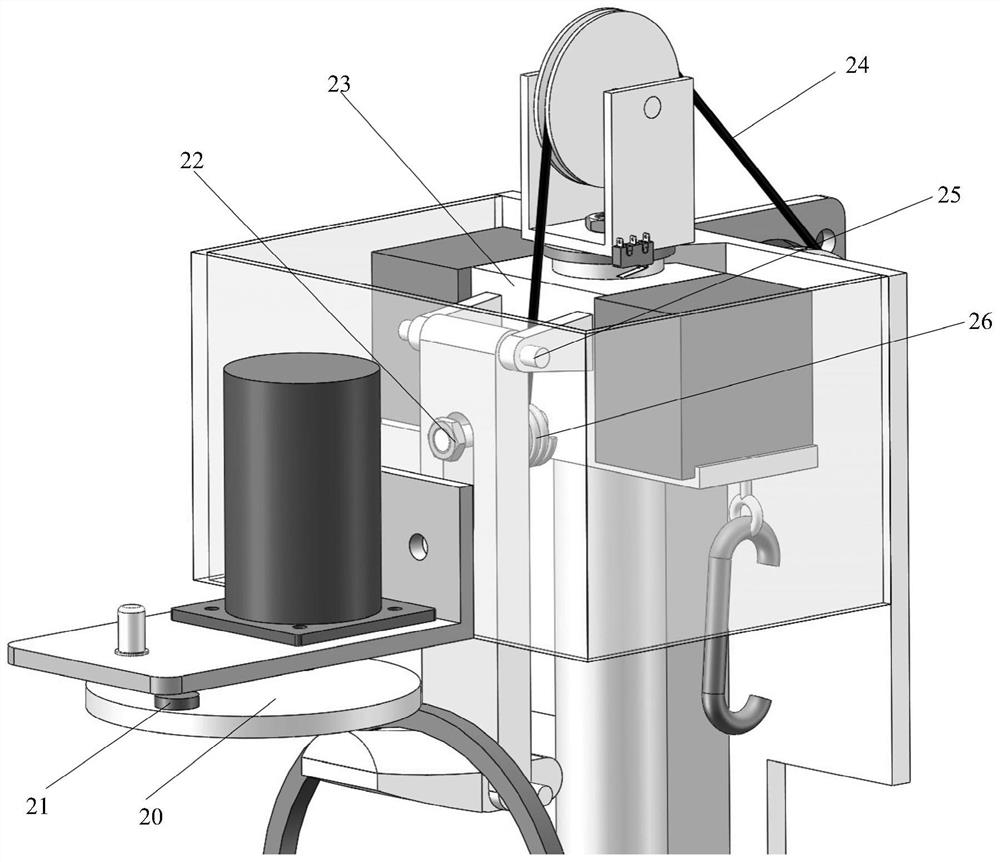

Three-coordinate multi-station automatic measuring device and method

ActiveCN109059820AContinuously adjustable widthArbitrary arrangementMeasurement devicesMeasurement deviceEngineering

The invention belongs to the field of mechanical automation measuring, and relates to a three-coordinate multi-station automatic measuring device and method. The three-coordinate multi-station automatic measuring device comprises an upper computer control device and an automatic feeding device. The upper computer control device is connected with the automatic feeding device to achieve control overthe automatic feeding device. The automatic feeding device comprises a fixture device, a transmission device, a positioning device and an auxiliary device. The positioning device is fixed on the fixture device; the positioning device can precisely position the fixture device; the fixture device is in sliding connection with the transmission device; and the transmission device is fixed to the auxiliary device. According to the three-coordinate multi-station automatic measuring device and method, the width of a clamping plate part of the fixture device is adjustable; the moving distance and theposition can be arranged randomly; the moving speed is continuously adjustable; by combining with a three-coordinate machine, the measuring angle is continuously adjustable, the measuring speed is continuously adjustable, the dimensions of parts are measured randomly; and therefore integrated automatic measuring to any pose positions and parts with any dimensions is achieved.

Owner:JIANGNAN UNIV

An intelligent and flexible automated storage system and method

InactiveCN104460628BArbitrary arrangementWith flexible settingsTotal factory controlProgramme total factory controlControl systemReal time management

The invention discloses an intelligent flexible automation warehousing system and method. The intelligent flexible automation warehousing system comprises an automation door control system, an automatic carrying system, an automatic scanning system and a production scheduling system. The automation door control system is used for managing opening and closing of a warehouse door, is provided with a touch screen by which types and numbers of required commodities are input, and is connected with the production scheduling system; the production scheduling system receives commodity warehouse-in information and commodity warehouse-out information, stores warehouse information and sends positioning and navigation information to the automatic carrying system. The automatic carrying system comprises a plurality of carrying robots, and each carrying robot is provided with a positioning and navigation system. Data are read and uploaded through the scanning system in real time to a production scheduling platform system of a PC background server and guided into a system of a database through the production scheduling platform system, the database is updated in real time, warehouse management users can carry out real-time accessing and real-time management through remote client terminals, and running of the system is monitored.

Owner:HARBIN ZHONGDE HECHUANG INTELLIGENT EQUIP

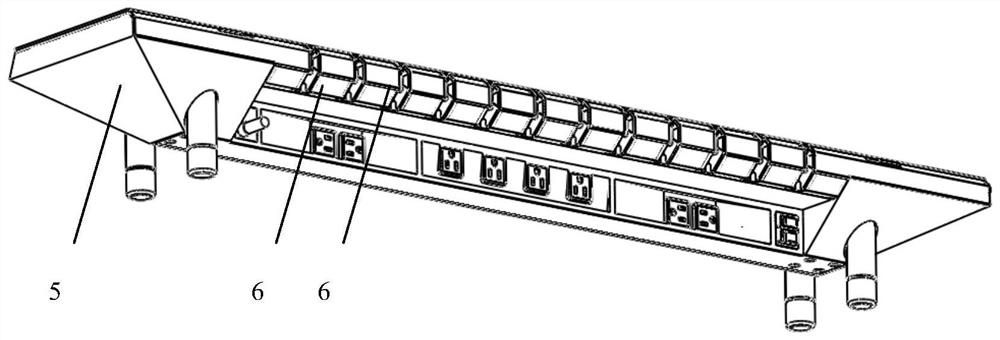

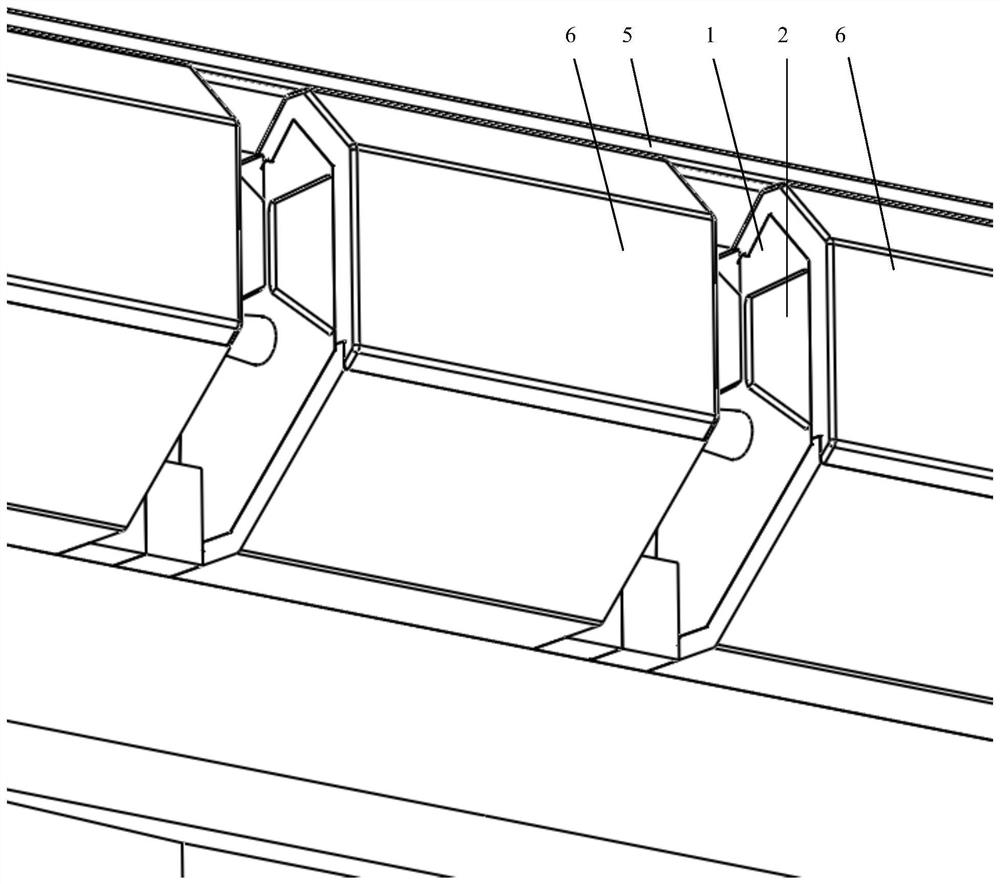

Wire harness collator and workbench

The invention discloses a wire harness collator and a workbench. The wire harness collator comprises two flexible plate-shaped structures which are oppositely arranged and at least one limiting structure, wherein one end of each plate-shaped structure is fixedly arranged; an accommodating space for accommodating a wire harness is defined between the two plate-shaped structures; the accommodating space forms a plurality of openings for allowing the wire harness to enter and exit at the edges of the plate-shaped structures; the openings are formed at intervals and communicate with the accommodating space; and the at least one limiting structure limits the minimum distance between the two plate-shaped structures and does not limit the maximum distance between the two plate-shaped structures. According to the wire harness collator and the workbench, the wire harness can enter or exit from multiple positions.

Owner:HEXCAL CO LTD

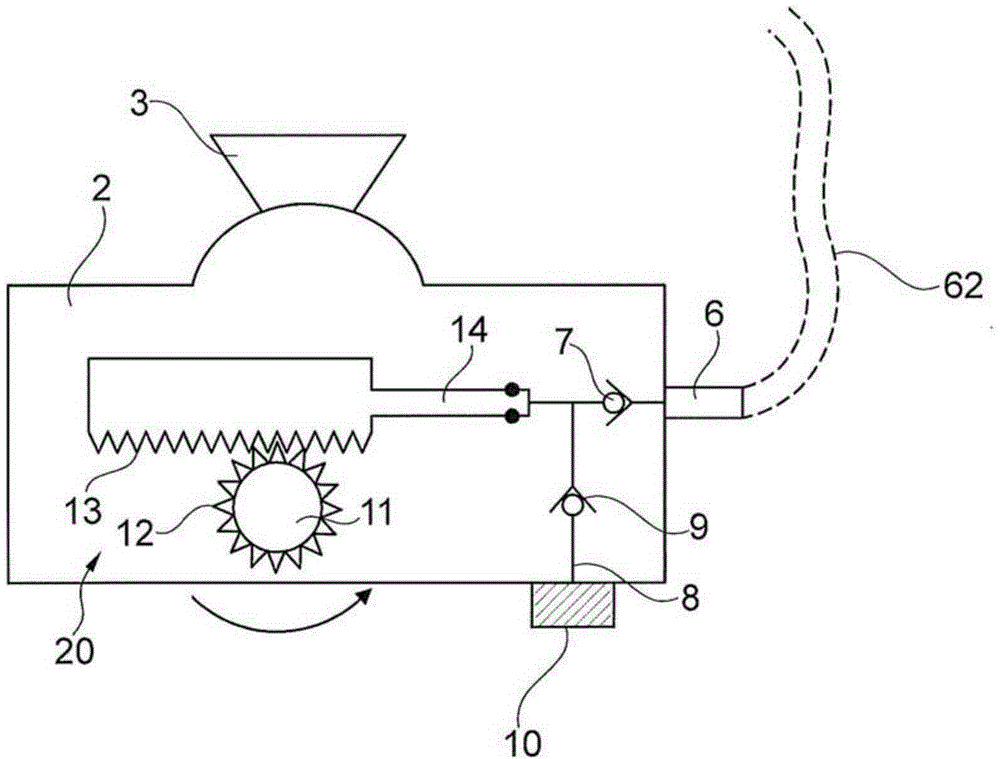

Prosthetic Knee

ActiveCN103384506BArbitrary arrangementJoint implantsPumpsPhysical medicine and rehabilitationKnee Joint

The invention relates to a prosthetic knee joint with an upper part (2) and a lower part (4) pivotably supported on said upper part (2), said upper part having an upper connection means (3), the The lower part has a lower connection means (5), wherein a vacuum pump (20) driven by the relative movement of the upper part (2) relative to the lower part (4) is assigned to the prosthetic knee joint, the The vacuum pump has an inlet (6) and an outlet (8).

Owner:OTTO BOCK HEALTHCARE IP GMBH & CO KG

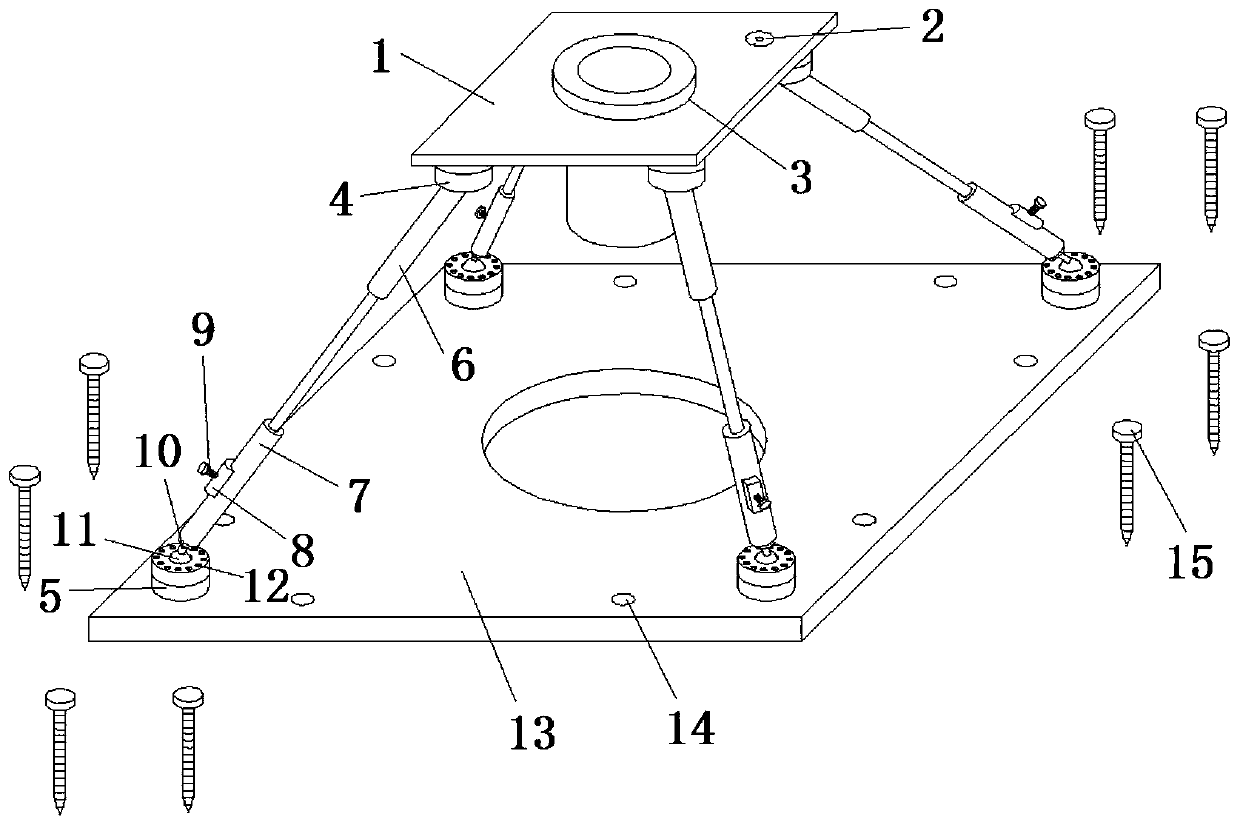

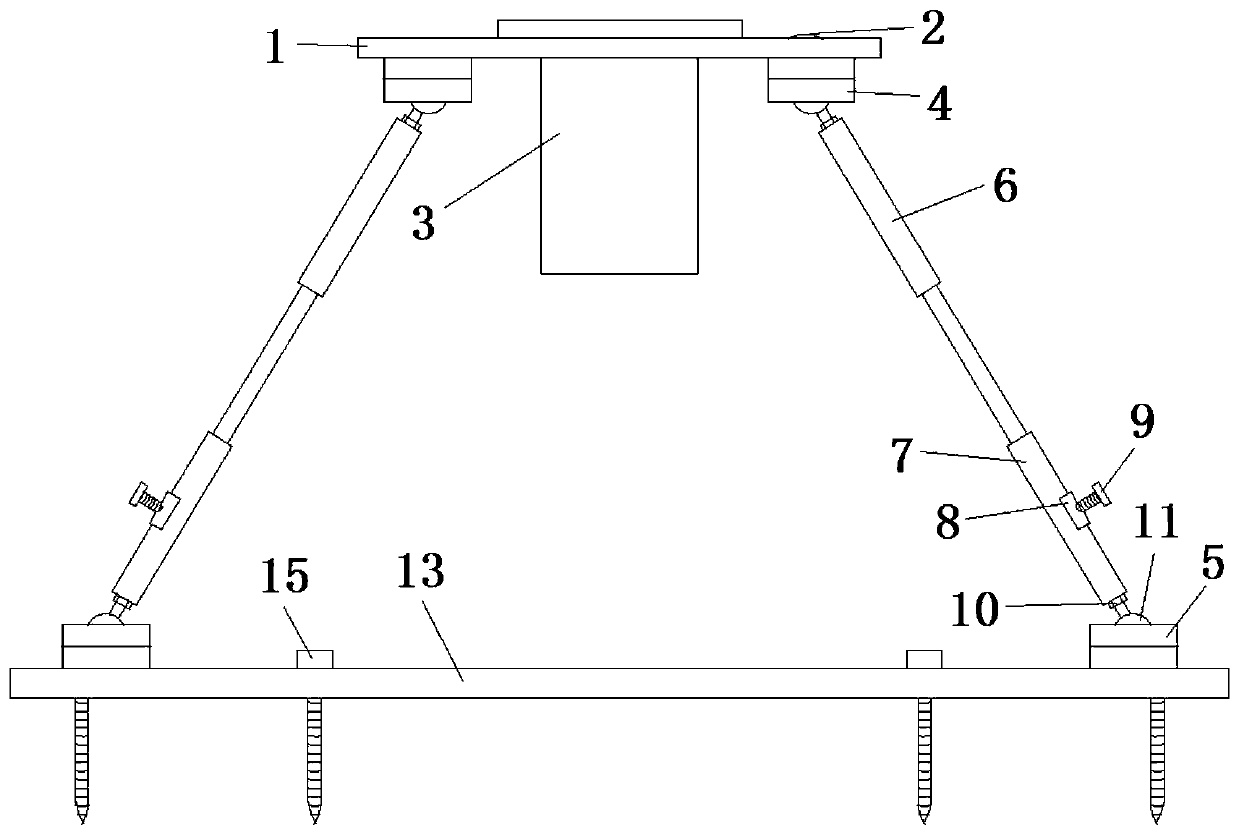

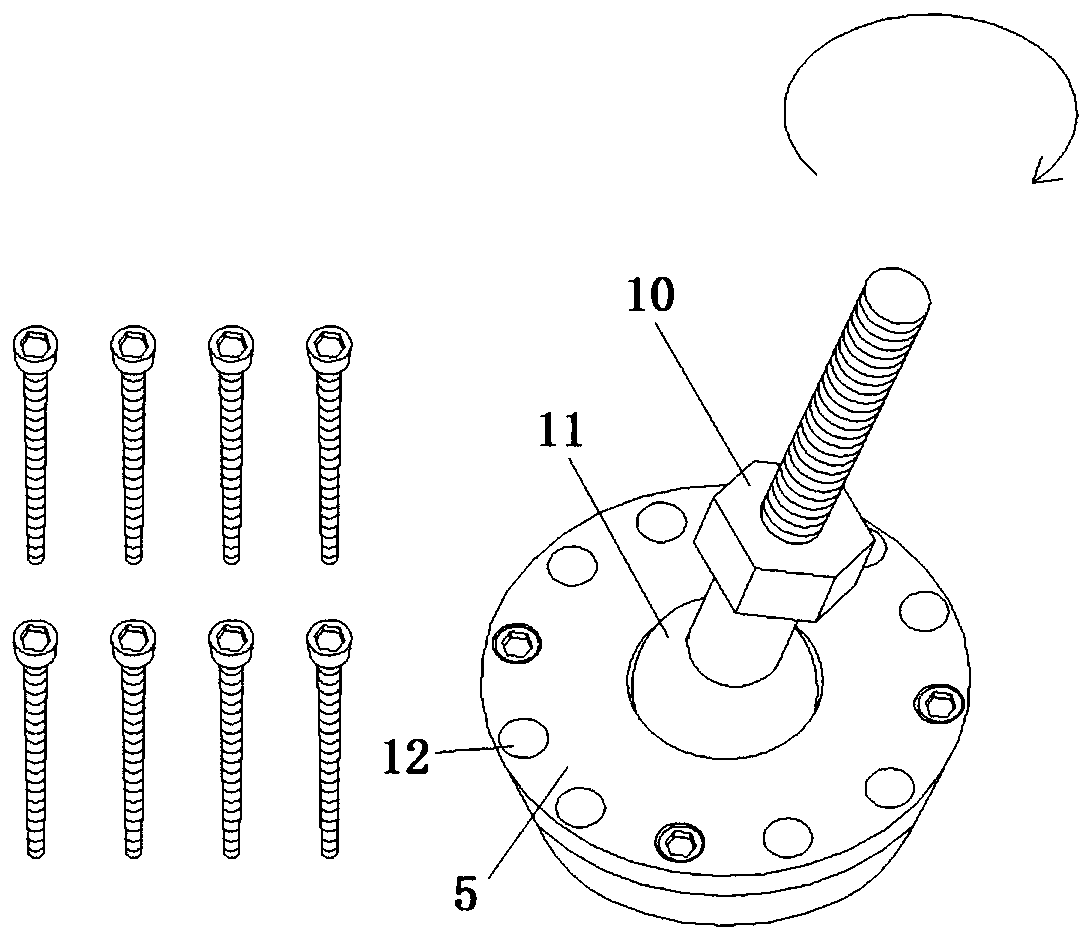

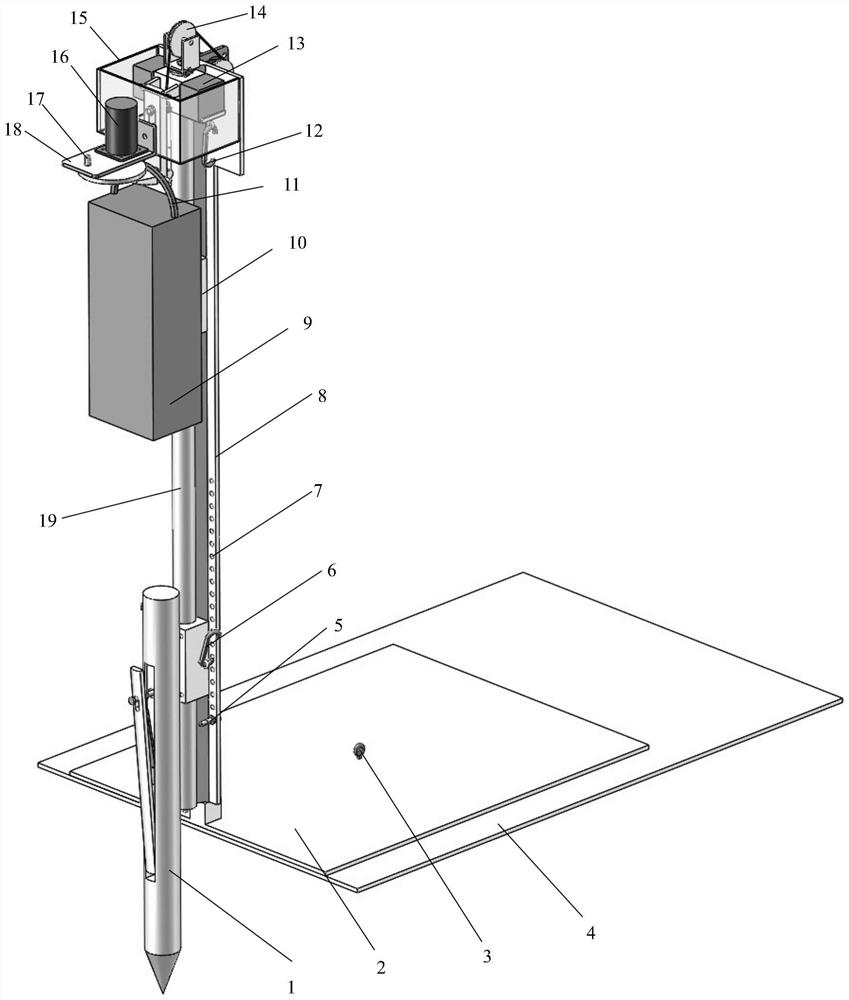

All-terrain static sounding counterforce bracket and mounting method

ActiveCN109695240AImprove applicabilityRealize detachable functionIn situ soil foundationTerrainLandform

The invention discloses an all-terrain static sounding counterforce bracket and a mounting method. The all-terrain static sounding counterforce bracket comprises an upper supporting plate, a lower supporting plate and four groups of height adjusting mechanisms, wherein the a round opening hole A for placing a guide pipe is formed in the center of the upper supporting plate; a metal bubble level gauge is inlaid in one corner of the upper surface of the upper supporting plate; a round opening hole B is formed in the center of the lower supporting plate; two rivet holes are formed in each side ofthe lower supporting plate; rivet bolts are fixed on the ground through the lower supporting plate; the upper ends and the lower ends of the four groups of height adjusting mechanisms are arranged onfour corners of the upper supporting plate and the lower supporting plate correspondingly; the four groups of height adjusting mechanisms are used for adjusting the distance from the upper supportingplate to the lower supporting plate and enabling the upper supporting plate to take on any angle change with the lower supporting plate. The all-terrain static sounding counterforce bracket providedby the invention can be in tight fit with the surface of the ground or other scenes, so that arrangement in different geotechnical engineering use scenes is effectively realized, the applicability ofstatic sounding is greatly enhanced, and various schemes are provided for geotechnical design construction.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

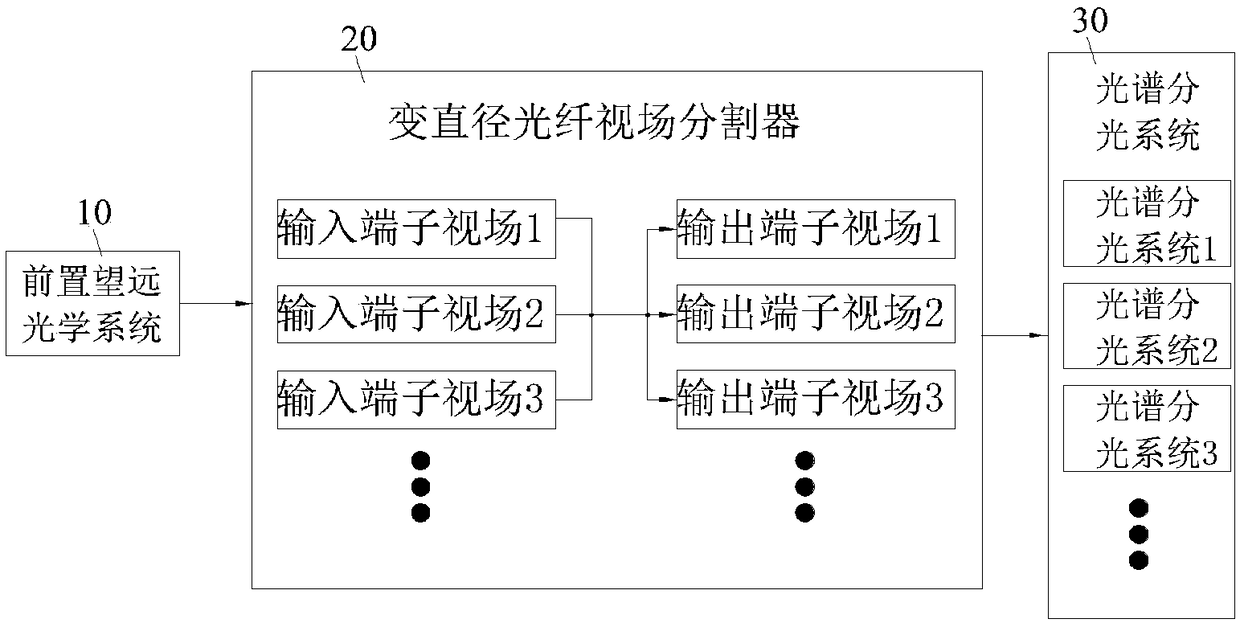

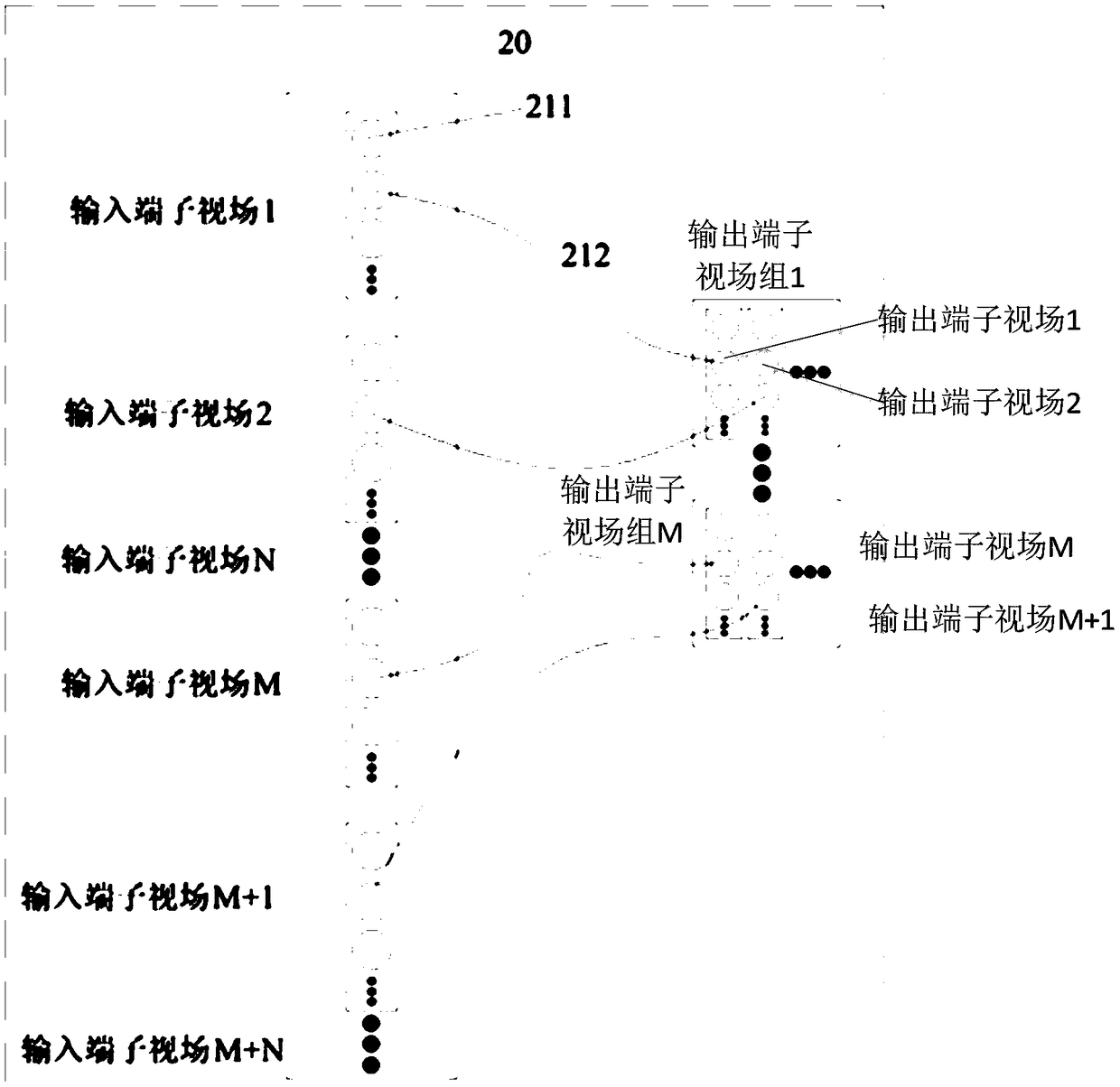

Spectral imaging system adopting variable-diameter fiber field-of-view divider to realize large field of view

ActiveCN108731807AImplement detectionArbitrary arrangementRadiation pyrometrySpectrum investigationFiber bundleMiniaturization

The invention discloses a spectral imaging system adopting a variable-diameter fiber field-of-view divider to realize a large field of view. The spectral imaging system comprises a front telescopic optical system, the variable-diameter fiber field-of-view divider and a spectral light splitting system, wherein the front telescopic optical system is used for completing collection of large field-of-view spectral information at a focal plane thereof; the variable-diameter fiber field-of-view divider comprises multiple sets of input terminal fields of view, multiple sets of output terminal fields of view and a variable-diameter fiber bundle; a large-size linear field of view of the front telescopic optical system is divided to multiple sets of the input terminal fields of view and regrouped inthe multiple sets of output terminal fields of view, and the multiple sets of output terminal fields of view are connected with the spectral light splitting system; and the spectral light splitting system is used for performing image field of view splicing on spectral imaging bands of the multiple sets of output terminal fields of view, so as to form the complete large field-of-view imaging spectral information. The spectral imaging system can perform optical division and regrouping on the large field of view to form small field of view groups, reduces the requirements of the large-size linearfield of view for the size of a spectral detecting system, and facilitates the miniaturization of the light splitting element and detector elements as well as the integration of the spectral imagingsystem.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

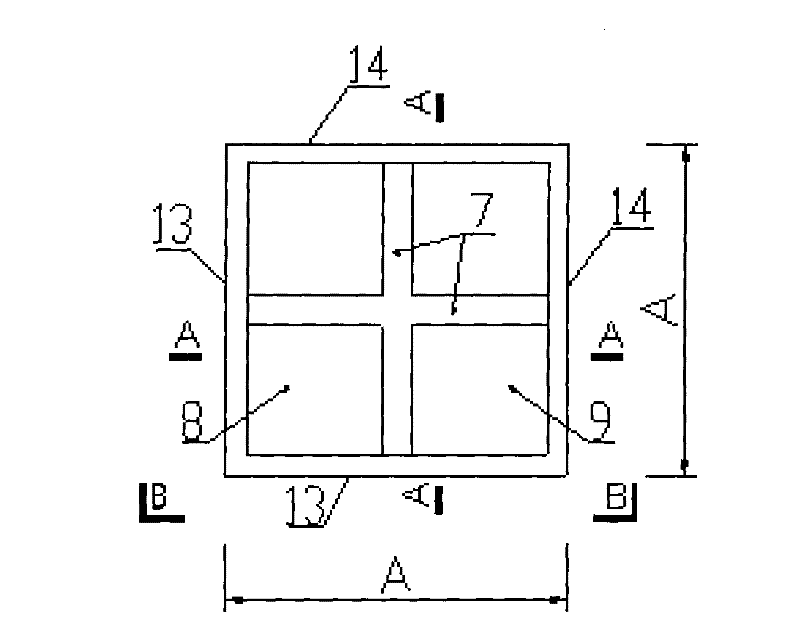

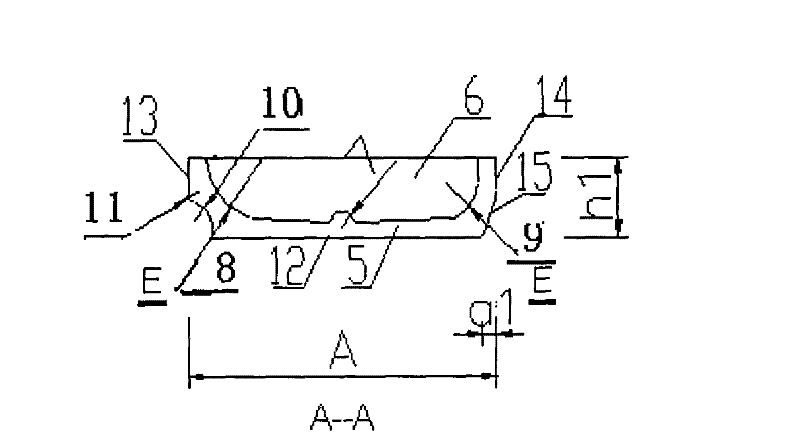

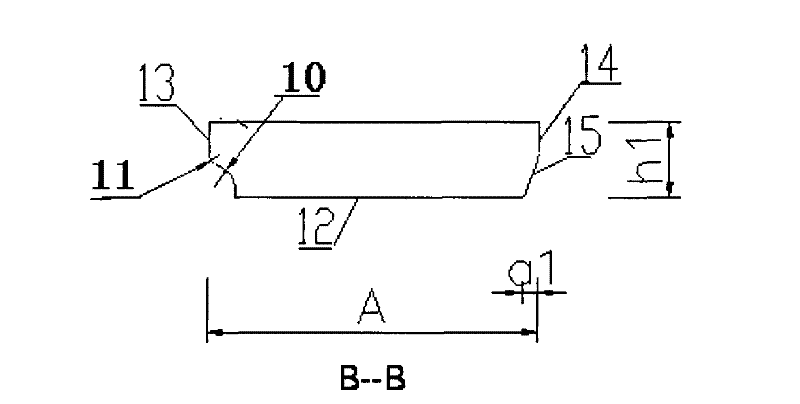

Assembling method of gypsum evacuated mould

InactiveCN101644082BImprove fire performanceLight weightFloorsForms/shuttering/falseworksRebarHollow core

The invention discloses an assembling method of gypsum evacuated mould, including paving a horizontal template at the bottom, determining positions of concrete beam and secondary girtstrip for assembling and fixing mould box, binding concrete beam and secondary girtstrip beam steel and embedding line pipes such as power and telecommunication and the like at the bottom of the secondary girtstrip. Floor plate beam steel is bound at the top of the gypsum evacuated mould box, concrete beam, secondary girtstrip and floor plate concrete are cast and vibrated, when concrete reaches designed age, thehorizontal template paved at the bottom is removed. Although connecting and assembling of mould box can be in multiple ways, the scheme shows that the assembling way of the invention is unique, the assembling method is combined with civil engineering construction, the mould box is embedded and fixed in steel concrete, no residual civil engineering construction procedure is produced, and the method is simple and feasible and is economic and practical. Contradiction of mould box production processing and architectural construction dimension requirement is solved, and the invention lays the foundation for the technology of making hollow floor system by promotion and application of concrete gypsum evacuated mould box in large scale.

Owner:贵州金三利科技建材有限公司

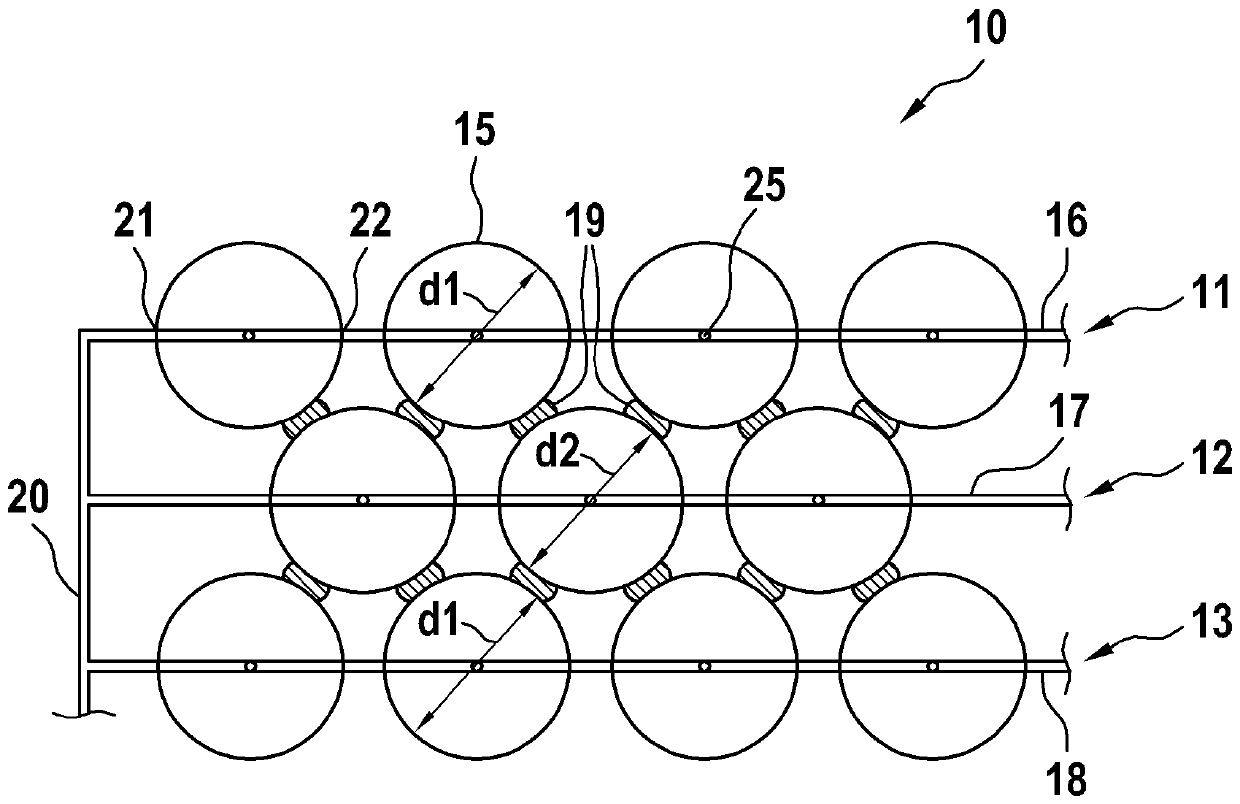

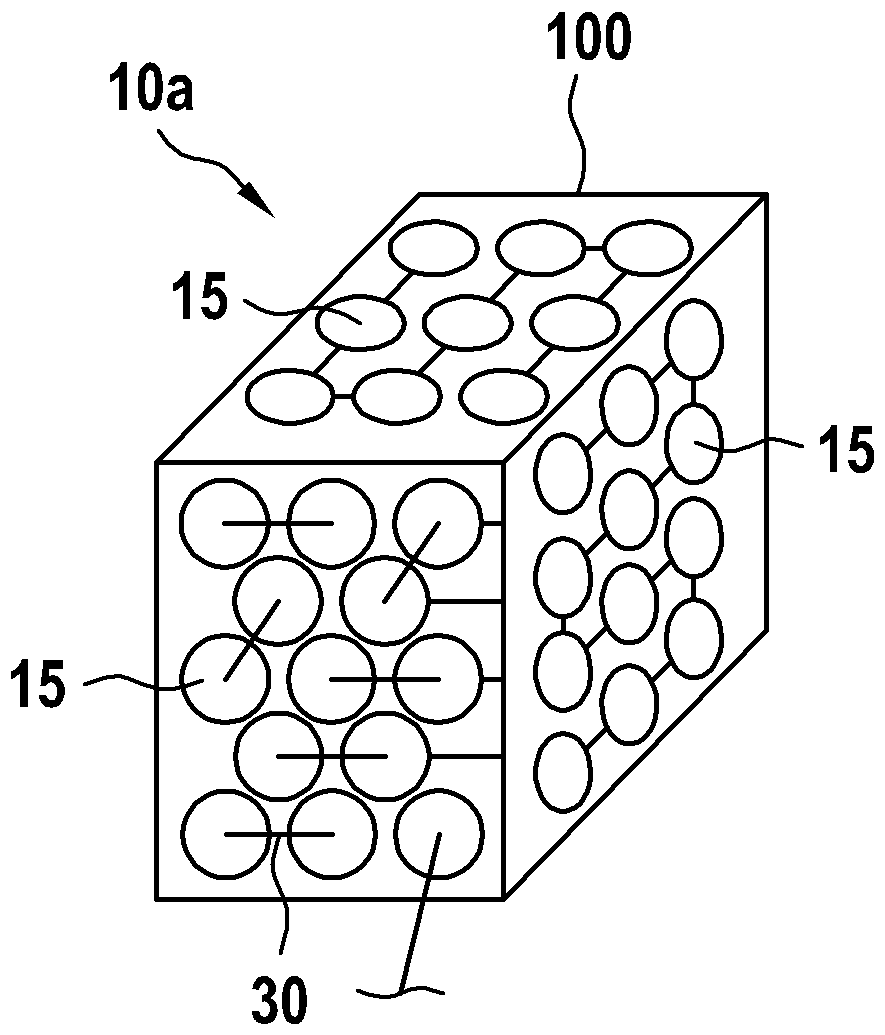

Fuel storage device

ActiveCN107685627AReduce weightArbitrary arrangementVessel mounting detailsVessel manufacturingEngineeringSingle chamber

The invention relates to a fuel storage device (10;10a) which is particularly used for a gasous fuel under pressure in a motor vehicle. The fuel storage device is provided with a plurality of spherical single chambers (15) which are interconnected with connecting lines (16,17,18,20,30).

Owner:ROBERT BOSCH GMBH

Electronic equipment modular water cooling heat dissipation device

ActiveCN107094364AHigh environmental valueImprove cycle efficiencyModifications by conduction heat transferEngineeringWater cooling

The invention belongs to the technical field of heat dissipation equipment and particularly relates to an electronic equipment modular water cooling heat dissipation device. The device comprises a water tank, a water inflow water pump, a water outflow water pump, circulating liquid, a circulating guide pipe, heat exchangers, a heat dissipation plate and other functional parts. The heat dissipation plate is modularly assembled, a component for assembly is arranged on the plate, the circulating guide pipe can be freely arranged on the heat dissipation plate, the heat exchangers are communicated with the interior of the circulating guide pipe, the heat exchangers are connected with the exterior of the circulating guide pipe through elastic parts, the heat exchangers can be tightly connected with different kinds of electronic equipment, and the heat dissipation efficiency is improved. The device has the advantages of being wide in application range, excellent in heat dissipation effect and capable of being freely disassembled and reused.

Owner:凤阳凤辰电子科技有限公司

Three-anchor and four-anchor positioning method and device for sensor network considering error interference

ActiveCN108989978BReduce the impact of accuracyImprove robustnessNetwork topologiesLocation information based serviceAlgorithmEngineering

The invention discloses a method and a device for locating three anchor points and four anchor points of a sensor network considering error interference. Three anchor location methods include: selecting three sensor nodes as an anchor point to form a triangle; Node information is communicated between any two anchor points; The distance between the three anchor points and the target node to be located is measured respectively, and the absolute values of the barycentric coordinate coefficients of the three anchor points corresponding to the target node to be located are calculated according to the geometrical relationship between the three anchor points and the target node to be located; considering the measurement error, according to the sum of all barycentric coordinate coefficients beingbetween [1-Delta 1, 1 +Delta 1], the symbols of all barycentric coordinate coefficients are solved and determined, and the positioning of the target node to be positioned according to the barycentriccoordinate algorithm is completed,wherein Delta 1 is within the range of (0,1) . This method is not affected by the shape of the triangle formed by the anchor configuration, and is more robust to theerror.

Owner:SHANDONG UNIV

Method and device for generating 3d-graphics of a user interface in a vehicle

ActiveCN104039581BReduce the burden onIncrease flexibilityDashboard fitting arrangementsInput/output processes for data processingGraphicsComputer graphics (images)

The invention relates to a method for generating a 3D-representation (8) of a user interface (13, 13a, 13b, 13c, 13d) in a vehicle (1), wherein a computing device (7) inside the vehicle controls the A particularly moving scene (9) containing at least one 3D object (10) is rendered in order to determine a 3D-representation (8).

Owner:AUDI AG

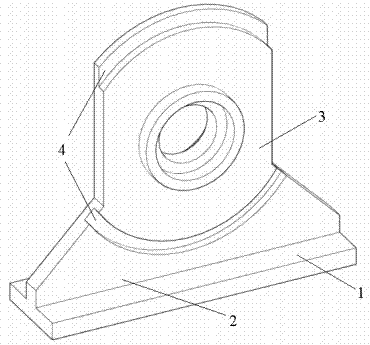

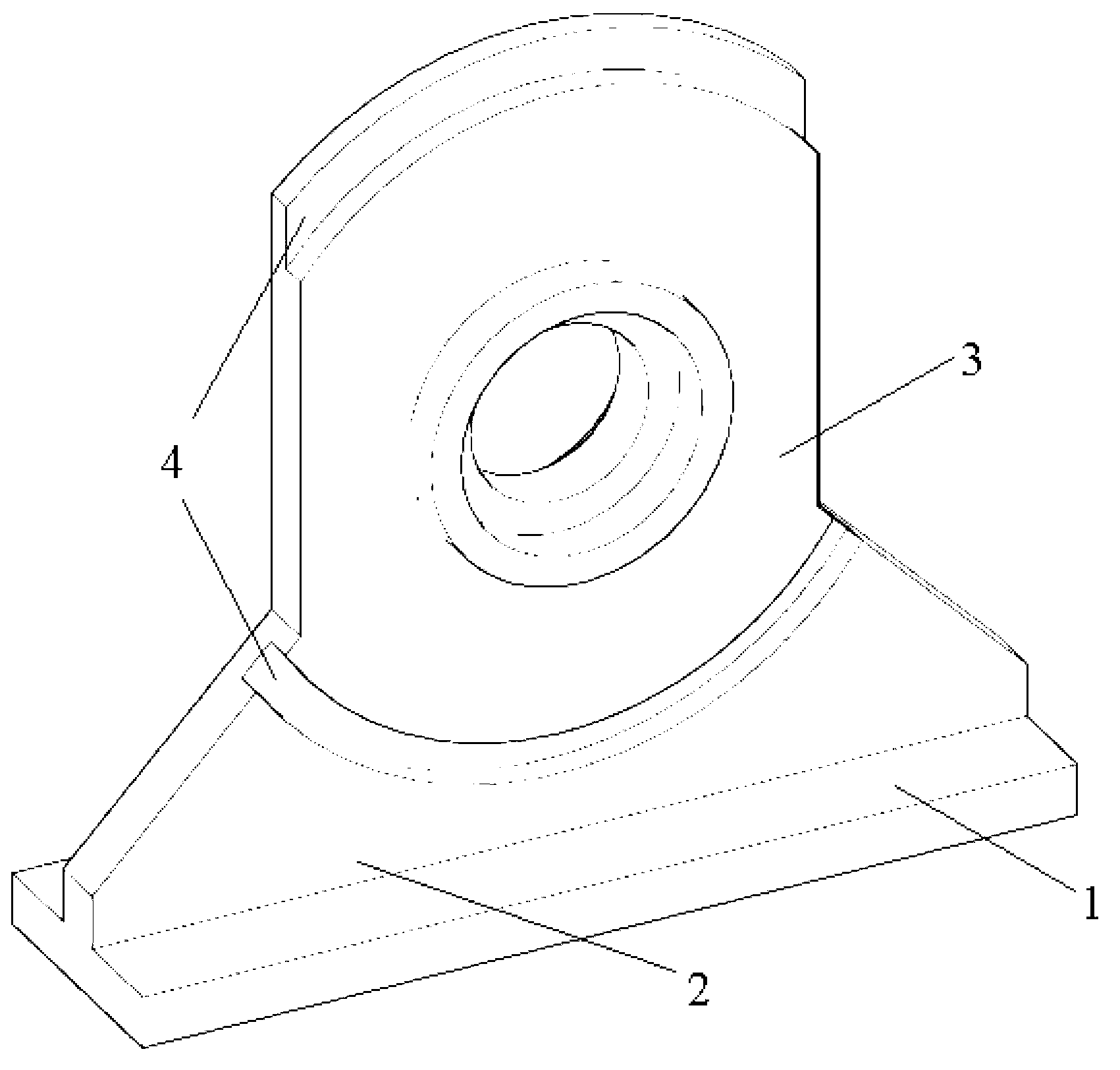

Bearing holder

InactiveCN104847798AArbitrary arrangementBearing unit rigid supportAgricultural engineeringWhole body

The invention relates to a bearing holder, which is characterized in that a substrate is rectangular, wherein a connecting plate is arranged on the substrate, the connecting plate is approximately trapezoid; a mounting plate is arranged on the connecting plate; the lower end of the mounting plate is connected with the connecting plate; the left and right sides of the mounting plate are perpendicular to the substrate; the upper end of the mounting plate is convex upwards to form an arc; a bearing mounting hole is formed in the central position of the mounting plate; the mounting plate and the connecting plate are connected to form a plate-shaped whole body; an arc-shaped groove is formed below the bearing mounting hole in the plate-shaped whole body and is concentric with the bearing mounting hole; the cross section of the arc-shaped groove is rectangular. The bearing holder has the advantage that by virtue of the independent substrate, the bearing holder can be arranged at a desired place at random and used at any time.

Owner:XINCHANG HUAXIONG MACHINERY

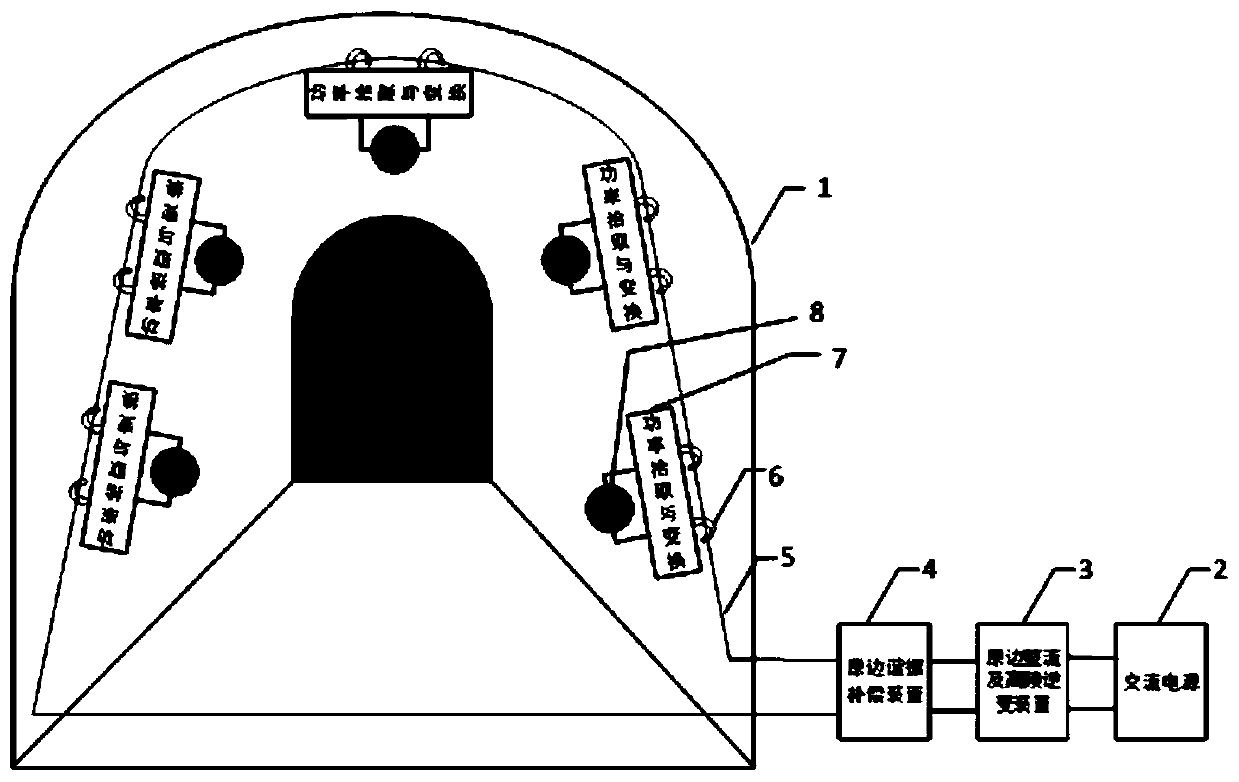

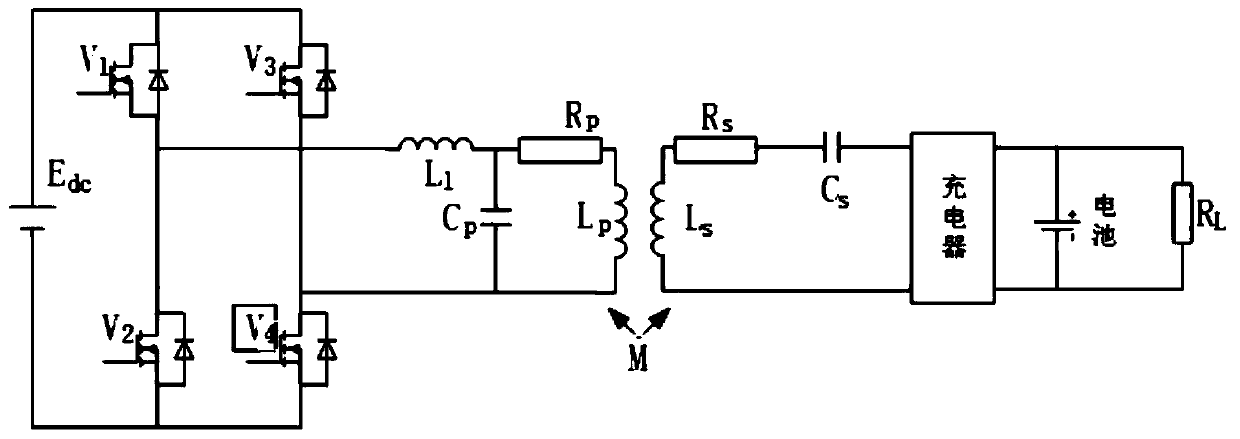

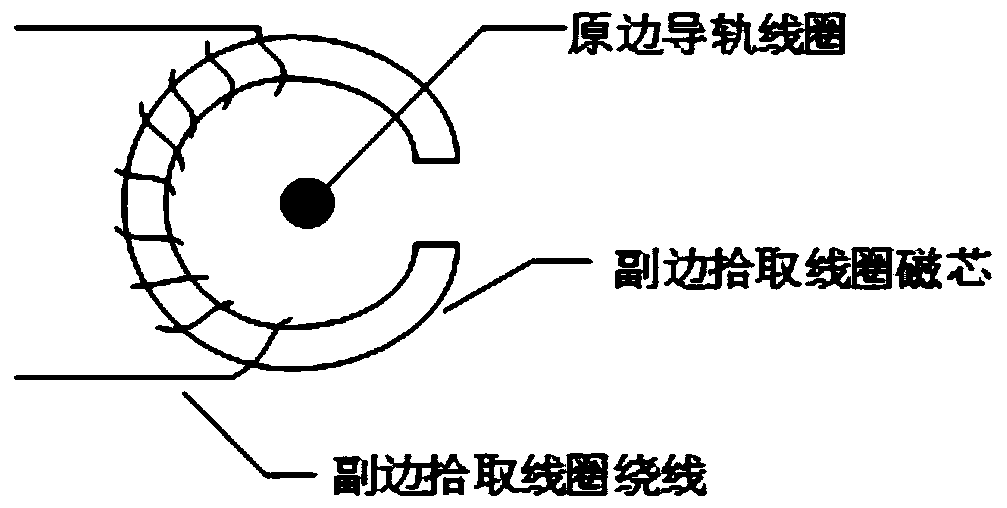

Underground long-distance intelligent wireless lighting system for coal mine

PendingCN110049607AReasonable designRealize wireless power supplyElectrical apparatusElectric light circuit arrangementLight equipmentResonance

The invention discloses an underground long-distance intelligent wireless lighting system for a coal mine. The underground long-distance intelligent wireless lighting system comprises a main roadway wall, an alternating-current power supply, a primary side rectifying and high-frequency converting device, a primary side resonance compensating device, an energy transmitting guide rail coil, a hook,a power pick-up and conversion device and lighting equipment. The lighting system has the beneficial effects that the energy transmitting guide rail coil can be arranged at will according to the actual illumination area requirement; the power pick-up and conversion device and the lighting equipment can be placed at any position of the energy transmitting guide rail coil according to lighting requirements; the power pickup and conversion device and the lighting equipment can be moved, overhauled and replaced at will, the whole circuit does not need to be powered off, the power supply reliability is higher, risks are reduced, and meanwhile due to the fact that the energy transmitting guide rail coil is electrically isolated from the power pickup and conversion device, the lighting system hasthe advantages of being flexible in power supply, easy to control, high in safety and convenient to maintain.

Owner:徐州凯思特机电科技有限公司

A reconfigurable intelligent ice cutting device

ActiveCN111809583BIngenious designEasy to useLighting and heating apparatusIce storing/distributionChiselStructural engineering

The invention discloses a reconfigurable intelligent ice digging device, which belongs to the field of ice mining on natural ice. A reconfigurable intelligent ice-cutting device of the present invention is ingeniously designed, adopts a mechanical method to realize the process of artificial ice mining, and can be arranged arbitrarily according to the shape and size of the ice to be mined. It is easy to use, has a high degree of automation, and greatly The efficiency of ice cutting is greatly improved and the labor intensity of workers is reduced.

Owner:BEIJING FORESTRY UNIVERSITY

Bearing seat

InactiveCN103075428AArbitrary arrangementBearing unit rigid supportAgricultural engineeringEngineering

Owner:SUZHOU BOOMINGWELL MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com