Method for detecting offset position of wafer

A technology of offset position and wafer, which is applied to measurement devices, optical devices, complex mathematical operations, etc., can solve problems such as inability to proceed, wafer damage process, errors, etc., and achieve the effect of improving repeatability and avoiding wafer damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

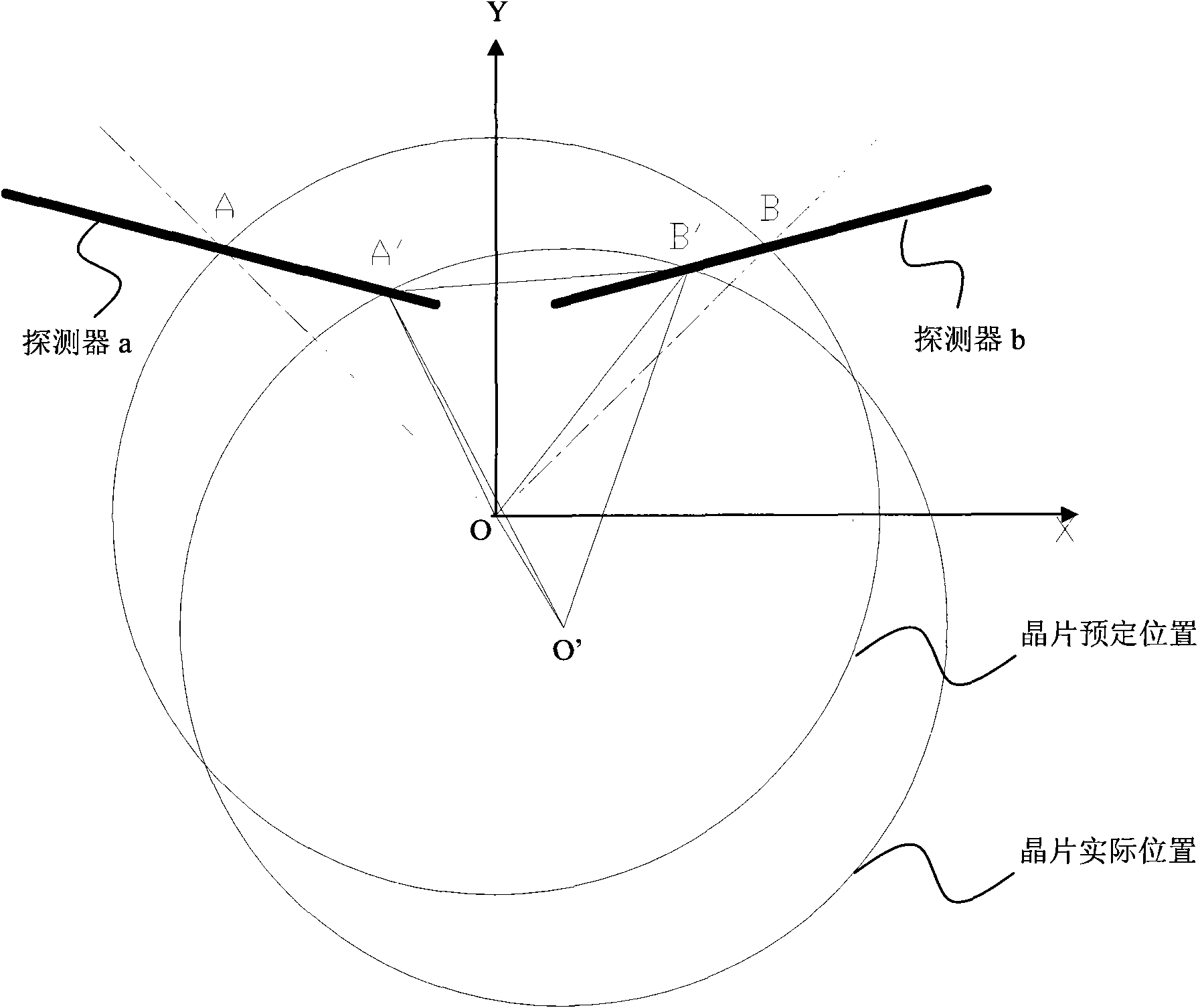

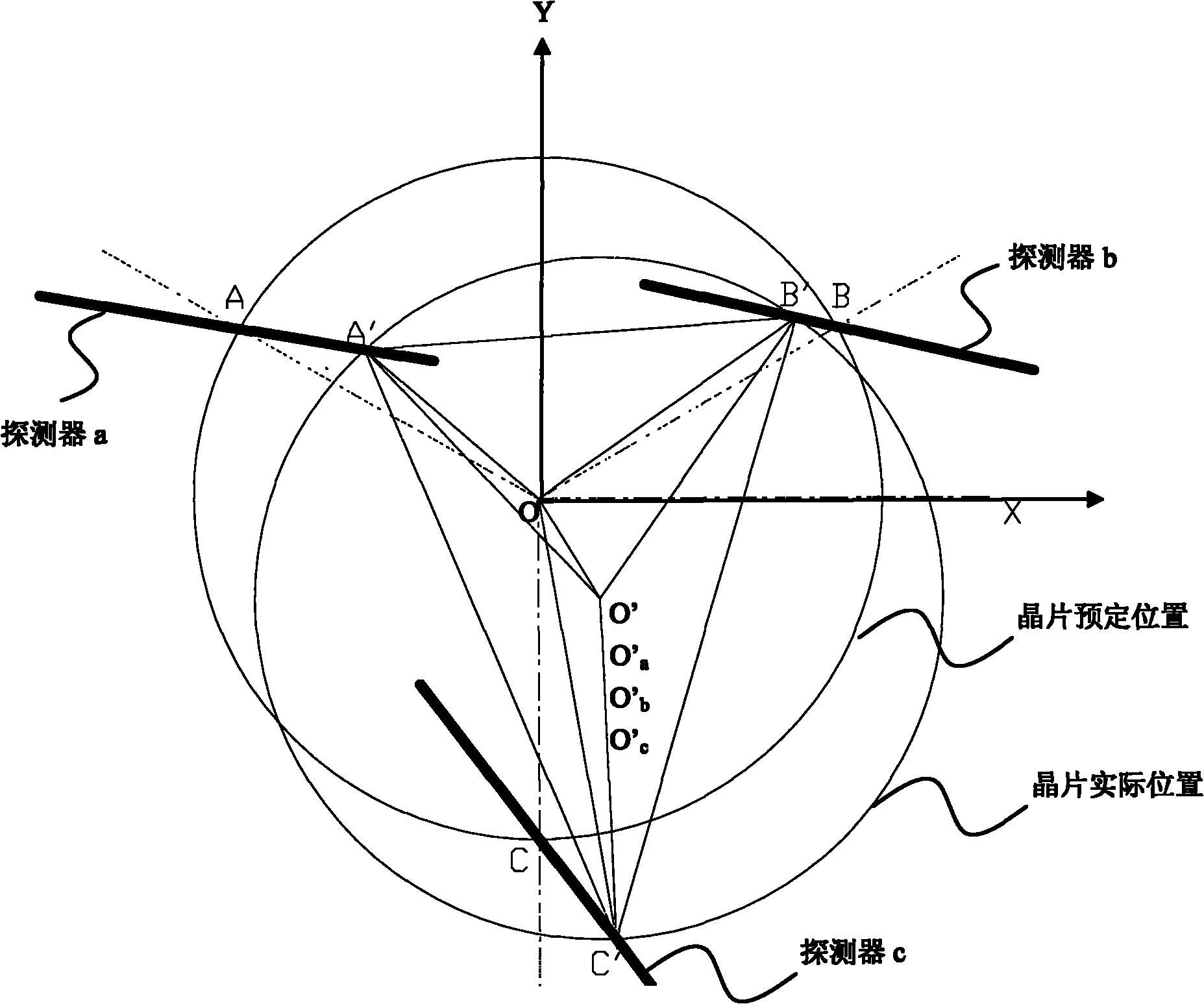

[0100] The following evidence Figure 2-Figure 4 , specify the preferred embodiment of the present invention:

[0101] Such as figure 2 As shown, the center of the wafer at the predetermined position is O, and the center of the wafer after the offset is O'. Two detectors a and b are arranged around the wafer, and the detection direction of the detector is along the radial direction of the predetermined position of the wafer. Arrangement, there is no linear positional relationship between the two detectors, the two detection points on the edge of the wafer at the predetermined position detected by the detector are respectively A and B, and the two detection points on the edge of the wafer after the offset detected by the detector The detection points are A' and B' respectively;

[0102] For the setting of two detectors, the two-point method can be used for detection, and the detection method includes the following steps:

[0103] Step 2.1, the detector detects and obtains t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com