Fuel storage device

A fuel storage and fuel technology, applied in the direction of the arrangement combined with the fuel supply of internal combustion engines, electrochemical generators, container filling methods, etc., can solve the problems of high weight, expensive fuel storage, and unoptimized storage volume, etc., to achieve small effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In the figures, the same elements or elements with the same function are provided with the same reference numerals.

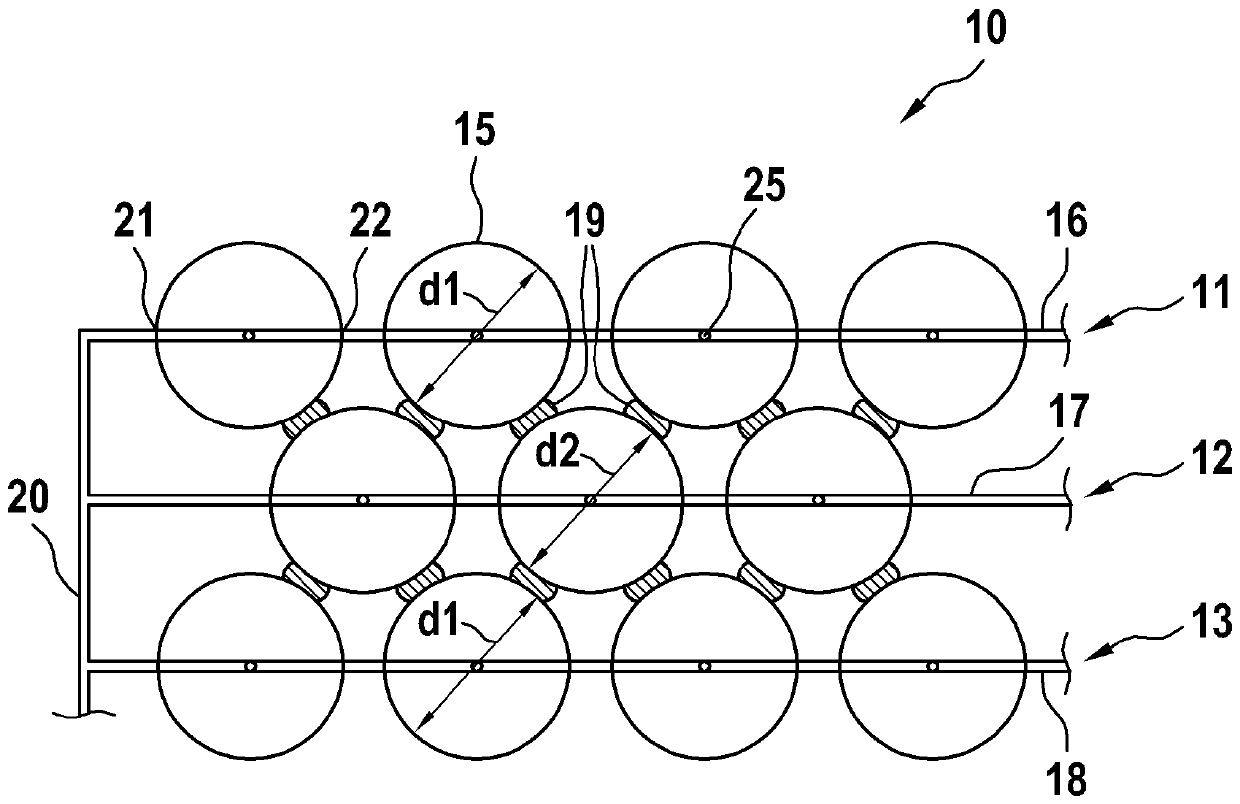

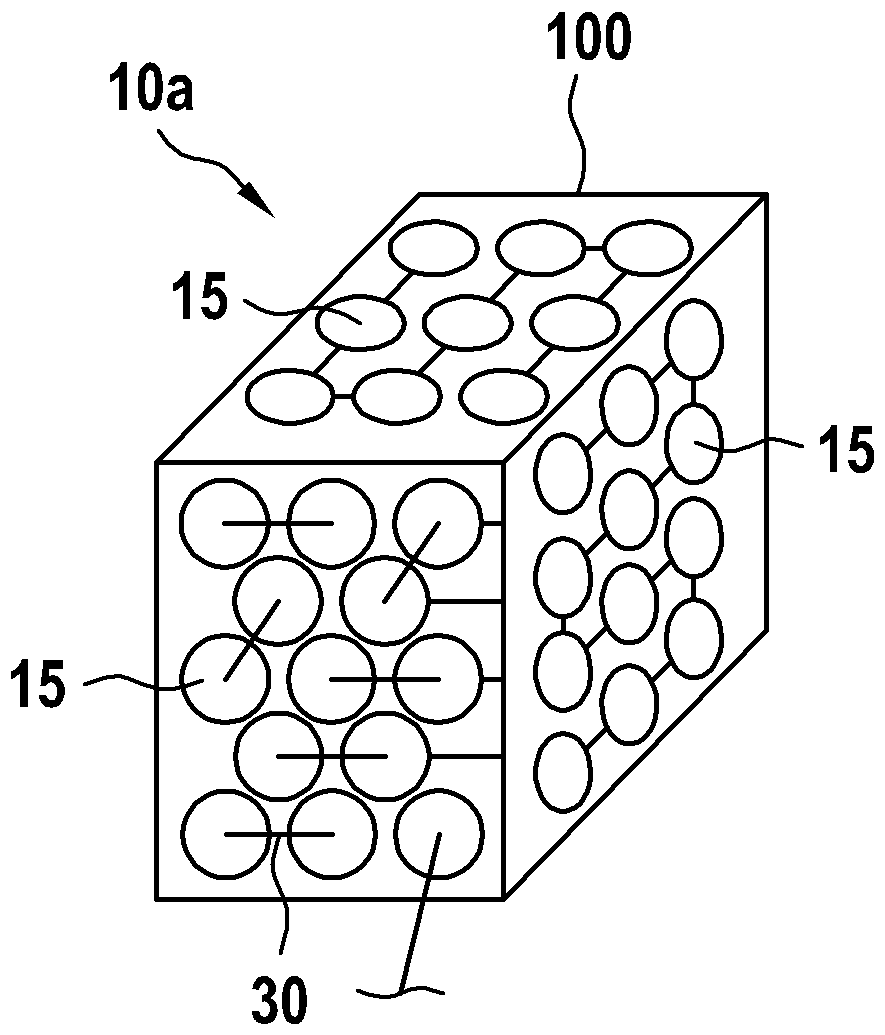

[0019] exist figure 1 The fuel accumulator 10 shown in is used as a storage tank for storing gaseous fuel, for example hydrogen, in a motor vehicle. However, the invention is not restricted to the use of hydrogen as a gaseous fuel and to the use in motor vehicles.

[0020] The fuel storage tank 10 is designed in particular to store gaseous fuel at a pressure between 200 bar and 700 bar. The fuel storage tank 10 has, for example, three layers 11 , 12 and 13 arranged parallel to one another, wherein the layers 11 to 13 each have a plurality of individual volumes 15 designed as hollow spheres for storing gaseous fuel. The single volume 15 of the two outer layers 11 and 13 has, for example, a diameter d 1 , which is slightly larger than the diameter d of the single volume 15 of the intermediate layer 12 2 , wherein the individual volumes 15 of the two ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com